Ionic vs. Metal Bonds: Understanding the Key Differences

By:Admin

With a focus on innovative materials science, {}, a leading chemical company, has recently announced the development of a groundbreaking new product line that combines the unique properties of ionic and metal bonds. This new line of products has the potential to revolutionize various industries, from electronics to pharmaceuticals, with its innovative approach to material design and engineering.

Ionic bonds are formed between two atoms when one atom gives up an electron to another. This results in the formation of positively and negatively charged ions which then attract each other, creating a strong bond. On the other hand, metal bonds are formed when metal atoms share their electrons with each other, creating a "sea" of electrons that hold the metal atoms together. By combining these two types of bonds, {} has created a range of materials with unique properties and applications.

The new product line, developed by a team of experienced chemists and material scientists at {}, has been designed to offer enhanced conductivity, high tensile strength, and improved corrosion resistance. These properties make the materials ideal for use in electronic components, structural applications, and even medical devices.

In the electronics industry, the application of these new materials could lead to the development of faster and more efficient electronic devices. With their enhanced conductivity and durability, the materials could be used to create smaller, more powerful components for smartphones, computers, and other high-tech devices. This could potentially revolutionize the way we use and interact with technology on a daily basis.

Furthermore, the high tensile strength and corrosion resistance of these materials make them suitable for a wide range of structural applications. From building materials to aerospace components, these advanced materials have the potential to improve the safety and performance of a variety of products and structures.

In the medical industry, the unique properties of the new materials could lead to the development of advanced medical devices with improved biocompatibility and durability. This could have a significant impact on the treatment and management of various medical conditions, leading to better patient outcomes and improved quality of life.

The development of this innovative new product line is a testament to {}'s commitment to pushing the boundaries of materials science and engineering. With a focus on research and development, {} has established itself as a leader in the chemical industry, consistently delivering cutting-edge solutions to a diverse range of global challenges.

As a company, {} has a long history of innovation and a strong track record of delivering high-quality products to its customers. With a global presence and a commitment to sustainability, {} is well-positioned to drive the adoption of these new materials across various industries, providing sustainable solutions to complex challenges.

With the development of this groundbreaking new product line, {} has once again demonstrated its ability to innovate and lead the way in the chemical industry. The potential applications of these new materials are vast, and they have the potential to disrupt and transform a wide range of industries. As the world's demand for advanced materials continues to grow, {}'s new product line could play a significant role in shaping the future of materials science and engineering.

Company News & Blog

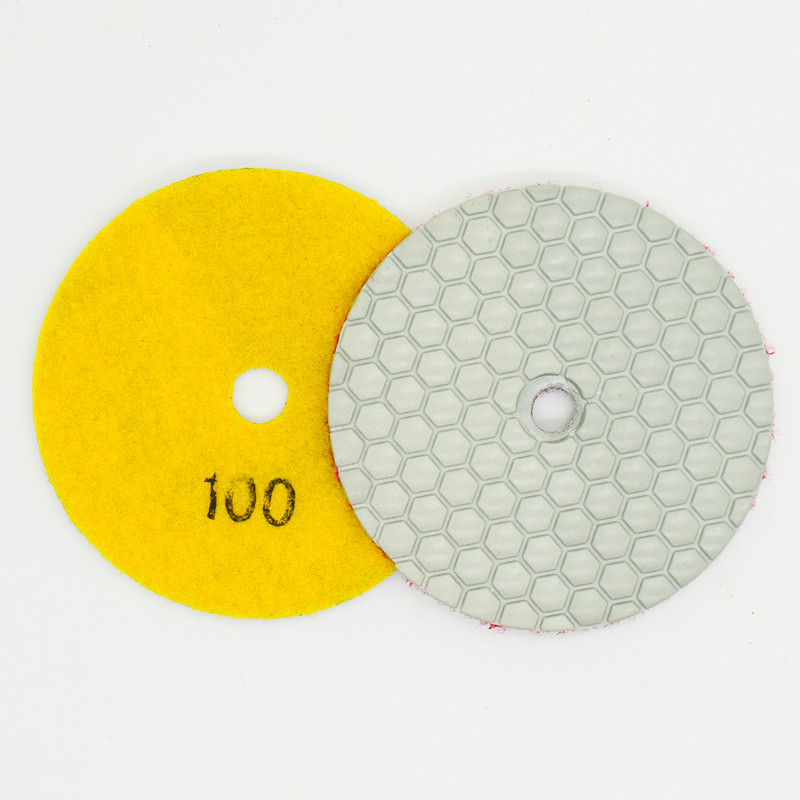

High-Quality 100mm Polishing Pads for Professional Detailing

The company, a leading provider of industrial tools, has recently introduced a new line of 100mm Polishing Pads to its wide range of products. These high-quality polishing pads are designed to meet the growing demand for precision and efficiency in the industrial sector.The 100mm Polishing Pads are made with top-grade materials and advanced technology to ensure superior performance and durability. These pads are suitable for use on a variety of surfaces, including metal, concrete, granite, and marble. The company's commitment to quality and innovation is reflected in the design and manufacturing process of these polishing pads, making them an ideal choice for professionals and DIY enthusiasts alike.The company has a long-standing reputation for delivering reliable and efficient industrial tools, and the addition of the 100mm Polishing Pads further solidifies its position as a trusted provider in the industry. With a focus on continuous improvement and customer satisfaction, the company has invested significant resources in research and development to bring cutting-edge products to the market.In addition to their exceptional performance, the 100mm Polishing Pads are also designed for ease of use. The company understands the importance of user-friendly tools in enhancing productivity, and these pads are engineered to provide a smooth and hassle-free polishing experience. Whether for heavy-duty industrial applications or intricate detailing work, these pads deliver consistent results with minimal effort.Furthermore, the 100mm Polishing Pads are part of the company's broader commitment to sustainability. By utilizing eco-friendly materials and energy-efficient manufacturing processes, the company strives to minimize its environmental footprint while delivering products that meet the highest standards of quality and safety.To support the launch of the 100mm Polishing Pads, the company is offering comprehensive customer support and technical assistance. With a team of experienced professionals, customers can rely on the company for expert guidance and assistance in choosing the right polishing pads for their specific requirements. This dedication to customer care is an integral part of the company's philosophy, ensuring that every customer receives the support they need to achieve optimal results.The introduction of the 100mm Polishing Pads is a testament to the company's ongoing commitment to innovation and excellence. By leveraging its expertise and resources, the company continues to expand its product offerings and provide solutions that meet the evolving needs of the industrial sector. With a strong emphasis on quality, performance, and sustainability, these polishing pads are poised to make a significant impact in the market.As the industrial sector continues to evolve, the demand for high-quality tools and equipment remains constant. The release of the 100mm Polishing Pads represents a major milestone for the company and reinforces its position as a leader in the industry. With a focus on innovation and customer satisfaction, the company is well-positioned to meet the diverse needs of its clientele and maintain its reputation as a trusted provider of industrial tools.

Supplier of Wet Polishing Pad - Weihai Chengxun Import & Export Co., Ltd. offers a wide range of stone products

Weihai Chengxun Import & Export Co., Ltd. – Your Top Partner for Premium Quality Polishing PadsIf you are in the market for the highest quality polishing pads, then look no further than Weihai Chengxun Import & Export Co., Ltd. For years now, we have been providing customers from all over the world with exceptional polishing pads that deliver superior results. Our products have become recognized globally as the best in class, as we utilize only the finest materials to manufacture them.At Weihai Chengxun Import & Export Co., Ltd., we understand the importance of high-quality pads that are able to withstand and adapt to any surface, while delivering an unmatched performance. It is for this reason that we have placed customer satisfaction at the core of our operations, and this has made us a leading supplier of wet polishing pads in the market.Our premium quality polishing pads are manufactured with leading-edge production technology. This ensures that our products remain innovative, durable, and able to provide superior polishing results. We are committed to quality, and this shows in the way our products have been able to withstand the test of time.Our wet polishing pads are a favorite among many customers around the world. They are engineered for use with a wet polishing machine and are ideal for granite or marble, as they yield a glossy finish. Additionally, our wet polishing pads are available in different configurations and sizes, so you can choose the one that best suits your needs.At Weihai Chengxun Import & Export Co., Ltd., we believe that our customers deserve the best quality products, and we are dedicated to providing that to them. Our products are designed to deliver unmatched performance and quality, making them a valuable investment for your business. Our wet polishing pads have been tested and proven to withstand the toughest polishing jobs and conditions.Moreover, Weihai Chengxun Import & Export Co., Ltd. is home to some of the most experienced and skilled professionals in the field of polishing pads. Our team is knowledgeable, dedicated, and committed to customer satisfaction. They are always on standby to answer any questions or concerns that our customers may have regarding our products. We also provide regular training to our team to ensure that they stay current with industry trends and standards.In addition to wet polishing pads, our product line also includes dry polishing pads, diamond saw blades, grinding wheels, concrete cutting tools, and much more. We also offer customization services, tailoring our products to the unique needs of our esteemed customers.At Weihai Chengxun Import & Export Co., Ltd., we understand that the success of our clients' businesses is vital to our own success. Therefore, we have made it our mission to provide our customers with value-added services that set us apart from other polishing pad suppliers.In conclusion, if you are in the market for top-quality polishing pads that offer superior performance, then look no further than Weihai Chengxun Import & Export Co., Ltd. Our products have become renowned globally for their quality and consistent delivery of superior results. Call us today and take your polishing experience to the next level!

Dry Polishing Pads: Achieve Diamond-like Results with this Revolutionary Technique

Title: Revolutionizing Stone Polishing: Diamond Dry Polishing Pads Deliver Superior ResultsIntroduction:In the competitive field of stone polishing, a breakthrough has been achieved with the development of the innovative Diamond Dry Polishing Pads. These pads, specifically designed for stone polishing tasks, have quickly gained recognition for their exceptional performance and ability to deliver superior results. Pioneered by a leading industry player specializing in diamond tool manufacturing, this revolutionary product has the potential to transform the stone polishing industry for professionals and enthusiasts alike.Company Introduction: [Company Name]With over two decades of industry experience, [Company Name] has emerged as a leading entity in the field of diamond tool manufacturing. The company prides itself on its extensive research and development to create cutting-edge products that cater to the requirements of various industries. Utilizing state-of-the-art technology and a highly skilled team, [Company Name] consistently delivers innovative solutions that are at the forefront of the industry.Article Body:The quest for a precise and effective stone polishing method has led [Company Name] to develop Diamond Dry Polishing Pads, a game-changer in the field. By honing the perfect combination of advanced materials and groundbreaking manufacturing techniques, these pads have managed to set a new benchmark for stone polishing.The unique composition of Diamond Dry Polishing Pads ensures exceptional durability and longevity. The pads are crafted using high-quality diamond particles that are meticulously embedded into a resin matrix, enabling them to withstand the most demanding polishing applications. This design promotes consistent performance throughout the polishing process, resulting in a flawlessly polished stone surface every time.One of the standout features of the Diamond Dry Polishing Pads is their ability to function without the need for water or any other lubricating agent. This characteristic significantly expedites the polishing process, eliminates the mess associated with traditional methods, and reduces water consumption. The eco-friendly nature of these pads aligns perfectly with the growing demand for sustainable practices within various industries.Compatibility across an extensive range of stone types is another noteworthy advantage of Diamond Dry Polishing Pads. Whether it's marble, granite, quartz, or even engineered stone, these pads deliver exceptional results on any surface. This versatility has made them a favorite among professionals in the stonework industry, ensuring that each project is executed with precision and efficiency.Furthermore, Diamond Dry Polishing Pads are designed to operate at optimal speeds, reducing the overall polishing time without compromising on the quality of the finish. The superior heat dissipation of these pads not only enhances efficiency but also extends their lifespan, ultimately providing cost-effective solutions for businesses in the stone polishing sector.In addition to their remarkable polishing capabilities, Diamond Dry Polishing Pads also boast an innovative design that guarantees ease of use. The flexible and lightweight construction ensures comfortable handling, thereby reducing operator fatigue and enhancing overall productivity. The gripping technology incorporated within the pads minimizes slippage and ensures stable control, allowing for smooth and consistent polishing motions.Recognizing the industry's changing dynamics and the need for continuous improvement, [Company Name] remains committed to further enhancing the performance of their Diamond Dry Polishing Pads. The team is constantly investing in research and development, exploring new advancements in materials and manufacturing techniques to stay at the forefront of an ever-evolving industry.Conclusion:In conclusion, the introduction of Diamond Dry Polishing Pads by [Company Name] has marked a significant milestone in the stone polishing industry. Achieving unparalleled results, these innovative pads have revolutionized stone polishing techniques with their durability, compatibility, eco-friendliness, and exceptional performance. With the constant pursuit of perfection, [Company Name] continues to redefine industry standards, cementing its position as a leading player in the diamond tool manufacturing sector.

Durable and Efficient Cutting Tools for Diamond Processing

Diamond cutting tools are an essential component in a wide range of industries, including construction, automotive, aerospace, and mining. These tools are renowned for their strength, durability, and precision, making them an indispensable asset for companies in need of high-quality cutting solutions. One company that has been at the forefront of producing top-notch diamond cutting tools is (remove brand name). With a rich history dating back over 50 years, (remove brand name) has established itself as a leader in the manufacturing and distribution of diamond cutting tools. The company's commitment to innovation, quality, and customer satisfaction has earned them a strong reputation in the industry.One of the key factors that sets (remove brand name) apart from its competitors is its use of advanced technology and state-of-the-art machinery in the production process. The company's manufacturing facilities are equipped with the latest machinery and equipment, allowing for the precise and efficient production of diamond cutting tools. This commitment to technological advancement ensures that (remove brand name) remains at the forefront of the industry, constantly delivering cutting-edge solutions to its customers.In addition to its technological prowess, (remove brand name) is also known for its emphasis on research and development. The company boasts a team of highly skilled engineers and designers who are dedicated to creating innovative and efficient cutting tool solutions. Through extensive research and testing, (remove brand name) is able to develop cutting tools that are not only durable and reliable but also tailored to meet the specific needs of its customers.Furthermore, (remove brand name) takes great pride in its commitment to quality control and assurance. The company's rigorous quality control measures ensure that every single cutting tool produced meets the highest standards of performance and reliability. This dedication to quality has earned (remove brand name) the trust and loyalty of countless customers around the world.Another distinguishing factor of (remove brand name) is its dedication to customer service. The company's team of professionals is committed to providing unparalleled customer support, offering technical expertise, personalized solutions, and prompt assistance to ensure that every customer's needs are met. This customer-centric approach has been a driving force behind (remove brand name)'s success and has solidified its position as a trusted partner in the industry.Looking ahead, (remove brand name) is poised to continue its legacy of excellence in the production of diamond cutting tools. With a relentless focus on innovation, quality, and customer satisfaction, the company is well-equipped to meet the evolving needs of industries that rely on cutting-edge cutting solutions. (remove brand name) remains steadfast in its commitment to delivering top-quality products and services, ensuring that it will remain a leader in the diamond cutting tool industry for years to come.In conclusion, (remove brand name) is a company that exemplifies excellence in the production of diamond cutting tools. With its cutting-edge technology, commitment to research and development, emphasis on quality control, and dedication to customer service, (remove brand name) has earned a stellar reputation as a leader in the industry. As the company continues to innovate and expand its offerings, it is poised to remain a top choice for businesses in need of high-quality diamond cutting tools.

Top 5 Dry Polishing Pads for Granite to Achieve a High-Quality Finish

The use of dry polishing pads for granite has gained traction in recent years, as more and more professionals and DIY enthusiasts seek effective and convenient solutions for polishing granite surfaces. A leading player in this field is [brand name], a company that has firmly established itself as a go-to source for high-quality dry polishing pads for granite.Headquartered in [location], [brand name] has been a key player in the construction and renovation industry for over a decade. The company has built a solid reputation for providing innovative and reliable products to meet the needs of its customers. With a focus on quality and customer satisfaction, [brand name] has become a trusted name in the industry.[Brand name] offers a range of dry polishing pads specifically designed for granite surfaces. These pads are engineered to deliver exceptional results while ensuring ease of use. Whether it's for a professional job or a DIY project, [brand name] understands the importance of having the right tools for the task at hand. As such, their dry polishing pads are crafted with precision and attention to detail, with a focus on achieving the best possible finish on granite surfaces.One of the key reasons for the increasing popularity of dry polishing pads for granite is their convenience and efficiency. Unlike traditional wet polishing methods, dry polishing pads eliminate the need for water or any other liquid, making the process less messy and more manageable. This not only saves time and effort but also reduces the overall cost of the polishing process.In addition to their convenience, dry polishing pads for granite offered by [brand name] are known for their exceptional performance. The pads are designed to provide a consistent and uniform finish, enhancing the natural beauty of the granite surface. The superior quality of the pads ensures that they are durable and long-lasting, making them a cost-effective choice for professionals and DIYers alike.Furthermore, [brand name] takes pride in its commitment to environmental sustainability. The company recognizes the importance of minimizing its impact on the environment and strives to offer products that are eco-friendly. As such, their dry polishing pads are designed to be used without the need for water, reducing the consumption of this precious resource and minimizing waste.As the demand for high-quality dry polishing pads for granite continues to rise, [brand name] remains dedicated to meeting the needs of its customers. The company's focus on innovation and continual improvement ensures that their products are always at the forefront of the industry. [Brand name] also places a strong emphasis on customer support, providing expert guidance and assistance to help customers achieve the best results with their products.In conclusion, dry polishing pads for granite offered by [brand name] combine convenience, efficiency, and exceptional performance. As the industry continues to evolve, [brand name] remains at the forefront, providing top-notch products for professionals and DIY enthusiasts alike. With a strong commitment to quality and customer satisfaction, [brand name] is poised to continue leading the way in the market for dry polishing pads for granite.

Understanding Nonmetal Bonds in the Market: Everything You Need to Know

Nonmetal Bonds Celebrates Innovation in Chemical IndustryNonmetal Bonds, a leading supplier of innovative chemical solutions, is proud to celebrate their latest breakthrough in the field of nonmetal bonding technology. With a rich history of providing high-quality products and exceptional customer service, Nonmetal Bonds continues to lead the way in the chemical industry.The company is known for its commitment to research and development, and their latest innovation in nonmetal bonding technology is a testament to their dedication to excellence. By combining their expertise in chemistry with cutting-edge technologies, Nonmetal Bonds has created a revolutionary new product that has the potential to transform the industry.Nonmetal bonding is a process that involves the formation of chemical bonds between nonmetal elements. This technology has a wide range of applications, including in the production of advanced materials, electronics, and pharmaceuticals. The development of new nonmetal bonding solutions has the potential to drive innovation and create new opportunities for a wide range of industries.The team at Nonmetal Bonds is thrilled to introduce their latest nonmetal bonding technology to the market. This breakthrough has been the result of years of intensive research and development, and the company is proud to see their hard work come to fruition. With this new product, Nonmetal Bonds aims to provide their customers with a competitive edge in their respective industries.Nonmetal Bonds has a long history of providing high-quality chemical solutions to their customers. The company was founded on the principles of innovation, quality, and service, and these values continue to guide their operations today. With a team of highly skilled and experienced chemists, engineers, and technical experts, Nonmetal Bonds is committed to pushing the boundaries of what is possible in the world of chemical technology.In addition to their expertise in nonmetal bonding, Nonmetal Bonds also offers a wide range of other chemical products and solutions. Their portfolio includes adhesives, coatings, and specialty chemicals, all of which are designed to meet the needs of their diverse customer base. Nonmetal Bonds prides itself on providing personalized service and tailor-made solutions for their clients, ensuring that they are able to achieve their specific goals and objectives.Nonmetal Bonds is dedicated to sustainability and environmental responsibility, and they are constantly seeking ways to minimize their environmental impact. The company is committed to complying with all relevant regulations and standards, and they prioritize the safe and responsible use of chemicals in all of their operations. Nonmetal Bonds takes their role as a responsible corporate citizen seriously and is always looking for ways to improve their sustainability practices.As Nonmetal Bonds celebrates their latest innovation in nonmetal bonding technology, they are excited about the potential impact it could have on the industry. With this new product, the company hopes to open up new possibilities for their customers and drive further innovation in the field of nonmetal bonding. Nonmetal Bonds looks forward to continuing to serve as a trusted partner to their customers and to deliver exceptional chemical solutions that meet their evolving needs.In conclusion, Nonmetal Bonds' latest breakthrough in nonmetal bonding technology is a testament to their commitment to excellence and innovation. By combining their expertise in chemistry with cutting-edge technologies, the company has developed a revolutionary new product that has the potential to transform the industry. Nonmetal Bonds looks forward to bringing this new technology to the market and to seeing the positive impact it will have on their customers and the wider chemical industry.

Unveiling the Ultimate Collection of 8 Polishing Pads: A Must-Have for Precision Car Detailing

Title: Industry Leader Launches Innovative Polishing Pads for a Superior ShineIntroduction:In a bid to revolutionize the automotive detailing industry, one of the leading manufacturers of car care products has unveiled a cutting-edge line of Polishing Pads. These innovative pads promise to provide a superior shine while streamlining the polishing process. With a commitment to excellence and a focus on customer satisfaction, the company aims to set a new benchmark in automotive detailing.Brand's Pioneering Legacy:With a rich history spanning over two decades, this prominent manufacturer has earned a reputation for producing top-quality car care products. The brand's commitment to innovation and quality has consistently placed it at the forefront of the industry. Through extensive research and development, the company has continuously pushed boundaries to provide car enthusiasts and professionals with the most effective solutions.Unveiling the Revolutionary Polishing Pads:Committed to delivering exceptional results, the brand brings forth its groundbreaking line of Polishing Pads. Developed after years of research, these pads are engineered to address the most common challenges faced by automotive detailers. They guarantee a professional-grade finish and an unmatched shine, bringing out the true beauty of any vehicle.1. Advanced Material Technology:The introduction of these Polishing Pads showcases the brand's dedication to technological advancement. Featuring an innovative blend of abrasives and foams, these pads offer enhanced cutting power and improved performance. The unique composite material allows for efficient removal of imperfections, fine scratches, and swirl marks.2. Customized Solutions:Recognizing that no two polishing jobs are the same, the brand has introduced a range of eight specialized Polishing Pads to cater to various needs. Offering different levels of aggressiveness, these pads are designed to accommodate varying paint types, hardness, and surface conditions. This ensures that professionals and enthusiasts can achieve optimal results for any vehicle type.3. Ergonomic Design:The brand's commitment to user-friendly products is evident in the design of its Polishing Pads. The pads are crafted with precision and attention to detail, featuring a comfortable grip and strategic contours. This ergonomic design ensures ease of use and prevents hand fatigue during long polishing sessions, enabling detailers to work efficiently without compromising on quality.4. Longevity and Durability:The durability of these Polishing Pads is another area where the brand truly excels. Built to withstand the rigors of professional use, these pads are engineered to deliver consistent performance even under demanding conditions. Their long lifespan ensures that users can rely on them for multiple projects, making them a cost-effective choice for both professionals and hobbyists.5. Environmentally Conscious Approach:Amid growing concerns about environmental sustainability, the brand has demonstrated responsible manufacturing practices with these Polishing Pads. By adhering to stringent eco-friendly standards, the company minimizes its carbon footprint while delivering industry-leading products. This commitment to the environment showcases the brand's dedication to overall well-being and responsible business practices.Conclusion:With the launch of its state-of-the-art Polishing Pads, this industry-leading manufacturer continues to push boundaries and redefine automotive detailing standards. Combining cutting-edge technology, customizability, and ergonomic design, these pads are poised to become an essential tool for both professionals and enthusiasts. As the brand's commitment to excellence remains unwavering, automotive enthusiasts can now look forward to achieving a superior shine with ease and precision.

12PCS Car Foam Drill Polishing Pad Kit for Easy Car Polishing and Waxing

The HMPLL 12PCS Car Foam Drill Polishing Pad Kit is a must-have for car enthusiasts looking to achieve a showroom-quality finish. This kit includes 12 different polishing pads, each designed to tackle specific aspects of the polishing process.Firstly, you will receive four waffle buffer polishing pads, perfect for removing swirls, scratches, and water spots from your car's paintwork. These pads are made from high-quality foam that is firm yet gentle on the surface. The waffle design allows for better absorption of polishing compounds, resulting in a smoother and more even finish.Additionally, you will also get four flat buffer polishing pads, ideal for applying wax or sealant to protect your car's paint from harmful UV rays and contaminants. These pads are designed to evenly distribute the product, ensuring maximum coverage and longevity of the protective layer.To further enhance the polishing process, the HMPLL kit includes one woolen buffer pad. This pad is perfect for removing stubborn oxidation or deep scratches. The thick and plush wool fibers effectively remove imperfections while also leaving a glossy finish.For the final touch, the kit includes one microfiber buffing pad. Microfiber is renowned for its superior polishing and buffing capabilities. This pad is great for removing any remaining residue and bringing out the ultimate shine on your car's surface.In terms of convenience, the HMPLL kit is equipped with a Velcro sucker. This attachment allows the pads to be easily secured onto a drill or polisher for efficient and effortless use. The Velcro design also ensures a tight and secure fit, preventing the pads from slipping or detaching during use.Furthermore, the branding on the kit is removable, allowing you to customize the appearance of your tools. Whether you prefer a clean and minimalistic look or want to add your own personal touch, the choice is yours.With the HMPLL 12PCS Car Foam Drill Polishing Pad Kit, you can say goodbye to tedious and time-consuming polishing processes. This comprehensive kit provides you with everything you need to achieve a professional-grade finish in the comfort of your own garage.Not only will your car's paintwork look visually stunning, but it will also be better protected against the elements. The waxing and buffing process creates a shield that repels water, dirt, and other contaminants, ensuring that your car stays cleaner for longer.In summary, the HMPLL 12PCS Car Foam Drill Polishing Pad Kit is a fantastic investment for anyone looking to elevate their car care routine. With a variety of pads and attachments included, you will have all the tools needed to achieve a flawless and long-lasting finish. Don't settle for anything less than perfection - choose the HMPLL Car Polishing and Buffing Kit today and enjoy the benefits of a showroom-quality shine.

Metallic Diamond Abrasive Pads for Coarse Marble Grinding in UK Market

, Marble Polishing, Diamond Polishing Pads, Marble Abrasives, Diamond Metallic Frankfurt Abrasive PadWhen it comes to marble polishing, there is no denying that you need the right tools to accomplish the job. This is where Frankfurt Diamond Abrasives come in - they are one of the most effective and efficient tools for polishing marble.Frankfurt Diamond Abrasives are specially designed to polish marble, offering a unique abrasive surface that works to remove scuffs, scratches, and other imperfections on the stone's surface. This abrasive tool is manufactured with diamond crystals, which is why it has become such a popular option for those looking to polish marble.Marble Abrasives are specifically designed to work on marble surfaces, providing the perfect texture needed for a clean and polished finish. The use of abrasives in marble polishing is a must-have, as they help to remove any imperfections on the surface of the stone.Diamond Polishing Pads are also crucial for marble polishing, and they come in different grades of coarseness. The lower the grit number, the coarser the pad is, and the higher the grit number, the smoother the pad is. Using the correct grade of polishing pad is important, as it will determine the final look of the marble.One of the newest options for marble polishing comes in the form of Diamond Metallic Frankfurt Abrasive Pads. These pads use a combination of diamond crystal and metallic materials, which helps to achieve a polished and glossy finish easily. This new option has become increasingly popular in the UK market due to its effectiveness and efficiency.In conclusion, the use of Frankfurt Diamond Abrasives, Marble Polishing, Diamond Polishing Pads, Marble Abrasives, and Diamond Metallic Frankfurt Abrasive Pads have become necessary for a great marble polishing job. Using the right tools and techniques helps to achieve a polished and glossy finish on your marble surface, making it look brand new and elegant. When looking for the right tools to use in marble polishing, consider the products mentioned above, as they have proved to be the most effective and popular in the market.

High-Quality 150mm Diamond Grinding Wheel for Precise Grinding Applications

Diamond Grinding Wheel: The Ultimate Companion for Precision GrindingGrinding is an essential process across various manufacturing industries to shape and finish workpieces to precision. It’s a process of material removal from a workpiece using grinding wheels to create a desired finish and tolerance. However, this process requires the right equipment, and one of the most popular ones is the diamond grinding wheel.Diamond grinding wheels are specialized tools employed for grinding hard materials, including carbides and ceramics. The wheel consists of industrial-grade diamonds that are bonded together in the shape of a grinding wheel. These grinding wheels are much more durable than other grinding wheels and are ideal for precision grinding. With its versatility and efficiency, diamond grinding wheels have become the go-to choice for many modern manufacturing industries.One such company known for producing high-quality diamond grinding wheels is located in China. Bearing the hallmark of providing high-quality tools and unmatched customer service, the company has become a leading name in manufacturing diamond grinding wheels.Their diamond grinding wheels are made from high-quality industrial grade diamonds that ensure durability and backed with a comprehensive guarantee. These tools are available in various shapes and sizes to cater to a wide range of grinding applications. The company believes that their diamond grinding wheels are the best in terms of performance and durability.The importance of choosing the right diamond grinding wheel cannot be understated. An ideal diamond grinding wheel should be able to remove material efficiently, provide an excellent finish and should be long-lasting. The company has several diamond grinding wheels, including 150mm diamond grinding wheels that cater to high-performance grinding tasks. The 150mm diamond grinding wheel is made with high-quality materials, where these wheels feature exceptional precision and accuracy, making it ideal for various industrial applications.The 150mm diamond grinding wheel has fantastic grinding capabilities boasting a big segment that facilitates fast material removal while also providing excellent wear resistance, making it a perfect choice for grinding hard materials. Furthermore, the diamond grinding wheel is designed to produce a smoother finish than other grinding wheels, making it a more versatile tool. The 150mm diamond grinding wheel can be used on a wide variety of materials that include ceramics, stone, glass, quartz, and carbide, among others.The company has invested time and resources to ensure their diamond grinding wheel is compatible with various grinding machine models, making it easy for their customers to use the wheels on machines they already own.The diamond grinding wheel technology has come a long way since it was first introduced. From a wider range of grits to longer-lasting wheels, diamond grinding wheels have undoubtedly revolutionized the manufacturing process. The 150mm diamond grinding wheel is no different.Notably, the company provides exceptional customer care, ensuring that their clients have access to accurate information, including technical support, ordering information, and shipping details. Their diamond grinding wheels are available at competitive prices without compromising on quality. The company remains committed to providing quality tools and equipment to meet its clients' various industrial needs. They appreciate the critical role a diamond grinding wheel plays in achieving excellent manufacturing results, and they aim to make their clients’ jobs easier by providing products that surpass expectations.In conclusion, diamond grinding wheels are essential tools in many industries, and the 150mm diamond grinding wheel is the perfect solution for precision grinding tasks. The company has produced excellent quality diamond grinding wheels that cater to a broad range of industrial applications. They have a competent team that provides exceptional customer service, ensuring that clients get access to accurate information about the products they offer. Their diamond grinding wheels are affordably priced, making them accessible to many manufacturers who are looking for high-quality tools to achieve excellent manufacturing results. Contact them today and experience the best in diamond grinding technology.