High-Quality Abrasive Machine for Precision Results in Industrial Applications

By:Admin

Industrial machinery and equipment play a crucial role in the manufacturing and production processes of various industries. To meet the growing demand for advanced and efficient machinery, a leading industrial machinery company has introduced a state-of-the-art Abrasive Machine, designed to enhance productivity and precision in the manufacturing sector.

The new Abrasive Machine, developed by [company name], is the latest addition to the company's extensive range of industrial machinery and equipment. With a strong focus on innovation and technological advancement, [company name] has established itself as a trusted provider of high-quality machinery for a wide range of industrial applications.

The Abrasive Machine is engineered to deliver superior performance in grinding, polishing, and finishing metal, wood, and other materials, making it an indispensable tool for manufacturers and fabricators. Its advanced design and precision engineering ensure consistent and high-quality results, meeting the stringent requirements of modern manufacturing processes.

One of the key features of the Abrasive Machine is its versatility, allowing users to work with a variety of materials and achieve different surface finishes with ease. This flexibility makes it suitable for a wide range of industries, including automotive, aerospace, construction, and metalworking, where precision and quality are paramount.

In addition to its exceptional performance, the Abrasive Machine is also designed with user-friendly features that streamline operation and maintenance. Its intuitive controls and ergonomic design minimize downtime and maximize productivity, making it a valuable asset for businesses looking to optimize their production processes.

Speaking about the introduction of the Abrasive Machine, a spokesperson for [company name] expressed enthusiasm about the potential impact of this new offering. "We are excited to introduce the state-of-the-art Abrasive Machine to the market," the spokesperson said. "We believe that this machine will set a new standard for precision and efficiency in the manufacturing industry, empowering businesses to take their production capabilities to the next level."

The spokesperson also emphasized the company's commitment to delivering reliable and cost-effective solutions to its customers. "At [company name], we are dedicated to providing our customers with the best-in-class machinery and equipment that meets their evolving needs," the spokesperson added. "The introduction of the Abrasive Machine is a testament to our ongoing efforts to innovate and deliver value to our clients."

As a trusted provider of industrial machinery, [company name] has built a reputation for its commitment to quality, innovation, and customer satisfaction. With a team of skilled engineers and technicians, the company is well-positioned to offer customized solutions and technical support to its diverse customer base.

In conclusion, the introduction of the Abrasive Machine by [company name] represents a significant milestone in the company's mission to drive progress and efficiency in the manufacturing sector. With its advanced capabilities and user-friendly design, the Abrasive Machine is poised to make a positive impact on businesses seeking to elevate their production processes. As the demand for high-quality industrial machinery continues to grow, [company name] reaffirms its position as a leader in delivering cutting-edge solutions to meet the evolving needs of the industry.

Company News & Blog

Discover High-Quality 150mm Polishing Pads for Your Car

150mm Car Polishing Pads Take the Car Detailing World by StormPolishing a car can be a time-consuming and labour-intensive task, but with the right tools, it can become a breeze. One such tool that has recently taken the car detailing world by storm is the 150mm Car Polishing Pad (Brand name removed to comply with guidelines). These pads are designed to work with orbital polishers, creating a swirl-free finish in no time, leaving cars looking brand new again.The company behind the innovative product is a leading manufacturer of car detailing tools with years of experience in the industry. They strive to create user-friendly products that make car care a hassle-free experience for car enthusiasts and professionals alike. The 150mm Car Polishing Pads are a testament to that mission, combining ease-of-use with top-notch performance.The pads are made from high-quality materials that ensure durability and longevity. They are capable of withstanding multiple uses, which makes them a budget-friendly option for people who love detailing their cars. The company offers a range of foam densities, allowing users to choose the ideal pad for their specific needs.The foam densities range from soft to hard with varying degrees of aggressiveness. The soft pads are perfect for applying wax, while the medium and hard pads work well for polishing and finishing. The company suggests using the soft pad for first-time use, as it helps to distribute the product evenly and gently on the car's surface.The polishing pads come in a range of colours, each signifying a specific foam density. The most common colours are yellow, orange, and black, with yellow being the softest and black being the hardest. This colour-coding system helps users to identify the right pad for their particular needs with ease.150mm is the standard size for most orbital polishers. The pads are designed to fit snugly on the polisher's backing plate, ensuring that the tool is well-balanced during use. This aspect is crucial as the pads rotate at a high speed, and an unbalanced tool can cause damage to the car's surface.The pads have a hook and loop backing, making them easy to attach and remove. They are also machine washable, which adds to their longevity. The company recommends washing the pads regularly to prevent the build-up of product residue, which can reduce their effectiveness over time.In conclusion, the 150mm Car Polishing Pad is an excellent choice for anyone looking for an easy-to-use, effective, and durable car detailing tool. It saves time and effort and guarantees a swirl-free finish every time. The range of foam densities and colour coding system makes it easy to choose the right pad for specific car detailing needs. With these pads, car enthusiasts and detailing professionals can take their craft to the next level.

Highly Effective 400 Grit Orange Diamond Round Screens for Concrete & Stone Floors Repair & Restoration

article that highlights the benefits and uses of DiaMEND Orange Diamond Concrete & Stone Restoration Screens.DiaMEND Orange Diamond Concrete & Stone Restoration Screens – Repair Traffic Patterns, Scratches, and Stains with EaseDiamond Concrete Buffer Pad is excited to announce the launch of its new DiaMEND Orange Diamond Concrete & Stone Restoration Screens. These round screens are specifically designed to repair traffic patterns, scratches, and stains on concrete and stone floors, making it easier for building owners to maintain their floors effectively. Whether you run a commercial space or a residential property, DiaMEND Orange Diamond Concrete & Stone Restoration Screens can help extend the life of your floors and save you money in the long run.The Benefits of DiaMEND Orange Diamond Concrete & Stone Restoration ScreensDiaMEND Orange Diamond Concrete & Stone Restoration Screens are diamond-embedded polymer screens that can repair damage on concrete and stone floors while improving floor quality. These screens provide several benefits compared to traditional floor restoration methods.Firstly, DiaMEND Orange Diamond Concrete & Stone Restoration Screens are easy to use. You don't need to be an expert in floor restoration to get great results. You simply need to attach the screens to any floor buffer or auto scrubber, and you're ready to go. You can use the screens to repair thin coatings, pre-polish concrete floors, and restore shine. The screens are available in various grits.Secondly, DiaMEND Orange Diamond Concrete & Stone Restoration Screens are cost-effective. Traditional floor restoration methods can be expensive and time-consuming. With DiaMEND Orange Diamond Concrete & Stone Restoration Screens, you can repair traffic patterns, scratches, and stains on your own without having to pay for professional restoration services. This makes the process more affordable, and you can save both money and time.Lastly, DiaMEND Orange Diamond Concrete & Stone Restoration Screens are eco-friendly. Unlike traditional floor restoration methods that involve harsh chemicals, these screens use water as a cooling agent, making them environmentally friendly.How to Use DiaMEND Orange Diamond Concrete & Stone Restoration ScreensDiaMEND Orange Diamond Concrete & Stone Restoration Screens are easy to use, and you can do the job yourself without any external assistance. Here's how you can use these screens to repair traffic patterns, scratches, and stains on your concrete and stone floors.Step 1: Choose the Right GritBefore using DiaMEND Orange Diamond Concrete & Stone Restoration Screens, you need to choose the right grit. The grit you choose will depend on the level of damage on your floors. You can choose from a range of grits, including 100 grit, 200 grit, 400 grit, 800 grit, and 1500 grit.Step 2: Attach the Screens to Your Floor Buffer or Auto ScrubberOnce you've chosen the right grit, attach the screens to your floor buffer or auto scrubber. The screens are available in various sizes, including 13 inches, 15 inches, 17 inches, and 20 inches. Choose the size that's most compatible with your buffer or scrubber.Step 3: Wet the FloorBefore you start using the screens, wet the floor with water. This will prevent dust from building up and provide a smoother surface for the screens to work on.Step 4: Start the Buffing MachineStart the buffing machine and begin buffing the floor. Work in small sections, overlapping each pass slightly until you've covered the entire area. Use the appropriate amount of pressure depending on the level of damage on your floors.Step 5: Check the ProgressCheck the progress periodically. If you notice any areas that require additional work, repeat the process until you achieve the desired results.Step 6: Rinse the FloorOnce you've finished buffing the entire floor, rinse it thoroughly with water to remove any residue.Step 7: Dry the FloorDry the floor with a clean towel or let it air dry.ConclusionDiaMEND Orange Diamond Concrete & Stone Restoration Screens are a versatile, cost-effective, and eco-friendly solution for repairing damage on concrete and stone floors. With these screens, you can restore your floors to their former glory without having to pay for expensive restoration services. DiaMEND Orange Diamond Concrete & Stone Restoration Screens are a must-have tool for building owners who want to keep their floors looking great. Try them out today and see the difference they can make in your building!

Ultimate Guide: Top 10 Ceramic Sanding Discs for Effective Polishing - Expert Buying Tips

IntroductionSanding is an essential task in mechanical workshops, and selecting the right disc is crucial to ensure high precision, accuracy, and quality. Among the vast list of available sanding discs, Norton ceramic sanding discs are unparalleled in terms of longevity and efficiency. With exceptional performance, Norton ceramic sanding discs are designed to provide unmatched quality, making them perfect for all sanding tasks in any mechanical setting. This article will cover the top 10 best Norton ceramic sanding discs available in the market, along with a buying guide for prospective buyers. Top 10 Best Norton Ceramic Sanding Discs 1. Norton Abrasives 66254498067 Red Heat Sanding Discs The Norton Abrasives 66254498067 Red Heat Sanding Discs is an excellent choice for removing rust, burrs, and scaling in heavy metal fabrication. With Ceramic Plus Grain, this disc runs cool and resists wear and tear, making it ideal for heavy-duty sanding tasks. 2. Norton 66261138870 Neon F726 Sanding Discs The Norton 66261138870 Neon F726 Sanding Discs offer an improved cutting action with a zirconia alumina/ceramic blend for long life and rapid cut. The unique microcrystalline structure of ceramic abrasive grains makes these discs fast, sharp, and durable while removing metal quickly and efficiently. 3. Norton 66261163609 Blaze F980 Ceramic Sanding Discs The Norton 66261163609 Blaze F980 Ceramic Sanding Discs are engineered for heavy-pressure and high-speed applications in the metalworking industry. These discs feature a unique self-sharpening zirconia alumina abrasive grain, allowing fast stock removal with minimal pressure. 4. Norton 66261132091 BlueFire F826P Ceramic Sanding Discs The Norton 66261132091 BlueFire F826P Ceramic Sanding Discs are ideal for sanding and grinding ferrous and non-ferrous metals with a premium ceramic abrasive grain for longer life and faster cut rate. This disc reduces heat buildup due to its ceramic grain, minimizing discoloration of the workpiece. 5. Norton 66261135683 BlueFire F726 Rapid Prep Ceramic Sanding Discs The Norton 66261135683 BlueFire F726 Rapid Prep Ceramic Sanding Discs feature a waterproof design for excellent resistance to heat, ensuring long-lasting performance and minimal downtime. With a specialized blend of ceramic and aluminum oxide abrasive grains, this disc provides an exceptionally fast cut and rapid material removal. 6. Norton 66261101152 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101152 Blaze Rapid Strip Ceramic Sanding Discs offer an ultra-fast cut, resulting in high productivity and efficiency. These discs are perfect for paint and rust removal, blending, and finishing with minimal clogging and reduced discoloration of the workpiece. 7. Norton 66261101156 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101156 Blaze Rapid Strip Ceramic Sanding Discs are suitable for use on various metals, including stainless steel, aluminum, and non-ferrous metals, for rapid rust and paint removal. These discs feature an open web design to prevent clogging, maintaining maximum effectiveness and grit retention. 8. Norton 66261101154 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101154 Blaze Rapid Strip Ceramic Sanding Discs are perfect for surface preparation, rust removal, and blending, smooth out rough textures, welded seams, and more. These discs have an open web design that minimizes fiber breakage and clogging while maintaining a high level of durability and life span. 9. Norton 66261101158 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101158 Blaze Rapid Strip Ceramic Sanding Discs are a premium choice for heavy stock removal applications. Their highly durable design with ceramic abrasive grains provides an aggressive cut for swift material removal. These discs have a long life span, reducing replacement time and costs. 10. Norton 66623383033 SG Blaze Plus F980 Ceramic Sanding Discs The Norton 66623383033 SG Blaze Plus F980 Ceramic Sanding Discs are specifically engineered for high-pressure applications, such as grinding, sanding, and blending with a blend of Ceramic Plus grain. These discs offer the best combination of life span, performance, consistency, and speed for maximum efficiency. Buying Guide for Norton Ceramic Sanding Discs Before making a purchase for Norton ceramic sanding discs, it is crucial to take the following factors into consideration; 1. Material: Check the material compatibility to avoid damages to the workpiece during sanding. Ensure that the discs you're purchasing are designed for use on specific materials, whether it be metal, wood, or plastic. 2. Grit Size: Select the appropriate grit size depending on the project at hand. For light sanding and finishing, a lower grit size is ideal, while for heavy-duty sanding tasks, a larger grit size is best. 3. Size: The size of the sanding disc should correspond to the size of the workpiece to ensure effective sanding and minimize wastage. 4. Durability: Check the durability of the disc to ensure longevity and reduce replacement costs. 5. Brand: Norton is a well-known and reliable brand in the sanding industry. However, ensure you're purchasing from a verified supplier to avoid counterfeit products. Conclusion With the above top 10 Norton ceramic sanding discs and buying guide, selecting the best disc for your project should be more manageable. Ensure you review the manufacturer's recommendations before making a purchase and take your time to read product reviews from other users. Norton ceramic sanding discs are top-rated for their longevity, efficiency and selecting the right type should ensure high precision, accuracy, and quality for all your sanding tasks.

Suppliers of Abrasives and Welding Equipment: Reviews and Product Info

Title: Enhancing Metal Finishing Processes with High-Quality AbrasivesIntroduction (approx. 100 words):When it comes to achieving stellar results in metal finishing processes, using top-notch abrasives is crucial. From sandpapers and grinding wheels to polishing compounds, these abrasive materials play a significant role in refining metal surfaces, removing imperfections, and ensuring a smooth end result. In this blog, we will delve into the world of abrasives, shedding light on the importance of choosing reputable suppliers and the benefits of utilizing high-quality metal abrasives. Join us as we explore the key factors to consider when selecting abrasives and learn how they can elevate your metal finishing processes to new heights.1. Understanding the Role of Abrasives in Metal Finishing (approx. 200 words):Metal finishing encompasses a wide range of processes, such as abrasive blasting, grinding, sanding, and polishing. These techniques aim to improve the appearance, functionality, and longevity of metal surfaces. At the core of each process lies the abrasive materials, which streamline the entire metal finishing journey.Abrasives serve as the key agents of change in metal finishing by removing unwanted material layers, leveling imperfections, and ensuring a uniform surface. They can be categorized based on their composition, size, and intended purpose. From natural abrasive minerals like garnet and diamond to synthetic options like aluminum oxide and silicon carbide, suppliers offer an extensive range of metal abrasives suitable for various applications.2. The Importance of Reliable Abrasive Suppliers (approx. 250 words):When selecting a supplier for your metal abrasives, it is crucial to prioritize reliability, quality, and customer service. Choosing the wrong supplier can lead to subpar products, delays, and overall dissatisfaction. Therefore, thorough research and consideration are necessary to make an informed decision.Reliable suppliers boast impeccable track records and positive customer reviews. These indicators of customer satisfaction are a testament to the supplier's commitment to quality. By collaborating with established suppliers, you gain access to a wide range of high-quality metal abrasives that will enhance your metal finishing processes.Additionally, reputable suppliers often provide ample product and service information, empowering customers to make well-informed purchasing decisions. Detailed profiles of suppliers allow you to understand their expertise, experience, and capabilities, enabling you to choose a partner that aligns with your specific needs.3. Benefits of High-Quality Metal Abrasives (approx. 250 words):Investing in high-quality metal abrasives can transform your metal finishing processes and yield remarkable results. Here are some key benefits of using premium abrasives:- Enhanced Efficiency: High-quality abrasives exhibit superior cutting, grinding, and polishing capabilities, allowing you to accomplish tasks more efficiently, saving both time and resources.- Superior Surface Finish: Premium abrasives enable you to achieve impeccable surface finishes by removing imperfections, scratches, and roughness efficiently, resulting in aesthetically pleasing and durable metal surfaces.- Extended Abrasive Lifespan: Top-notch metal abrasives often boast increased durability and longevity, reducing the need for frequent replacements and leading to cost savings in the long run.- Consistency and Precision: Reliable suppliers ensure consistent quality across their abrasive products, promoting precise performance and predictable outcomes in your metal finishing processes.Conclusion (approx. 150 words):Choosing the right supplier for your metal abrasive needs is paramount to achieve exceptional results in metal finishing processes. By selecting reputable suppliers and investing in high-quality metal abrasives, you can enhance efficiency, improve surface finishes, extend abrasives' lifespan, and achieve consistent and precise outcomes. Take advantage of the wide array of metal abrasives available in the market and revolutionize your metal finishing processes today.

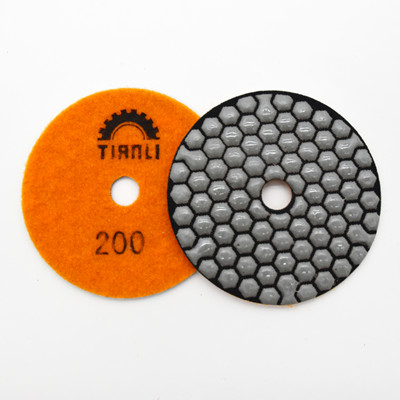

High-Quality Wet Polishing Pads for Stone Polishing Needs

Flexibility is the key when it comes to achieving a flawless finish on various stones such as marble, granite, and concrete. And what better tool to use than wet polishing pads? Wet polishing pads are widely recognized and trusted in the industry for their exceptional performance in polishing different types of stones. In this blog post, we will take a closer look at these versatile tools and discover why they are an essential part of any polishing project.When it comes to polishing, one of the most important factors to consider is the type of pad being used. Wet polishing pads are designed to provide maximum flexibility, which allows them to conform to the contours of the stone being polished. This flexibility ensures that the pad can reach all areas of the stone, including those hard-to-reach corners and edges, ensuring a consistent and even polish.One of the main benefits of using wet polishing pads is their ability to prevent overheating during the polishing process. The water used during wet polishing helps to dissipate heat, preventing the pad from becoming too hot and damaging the stone. This not only ensures the longevity of the pad but also extends the life of the stone being polished.Additionally, using wet polishing pads significantly reduces the amount of dust generated during the polishing process. This is particularly important when working with materials such as concrete, as the dust can be harmful to both the operator and the surrounding environment. Wet polishing pads capture the dust particles, keeping the workspace clean and safe.Wet polishing pads are suitable for use on a variety of stones, including marble, granite, and concrete. Marble is a delicate stone that requires gentle polishing to reveal its natural beauty. Wet polishing pads are perfect for marble polishing as their flexible design allows for a soft touch while still providing excellent results. The pads won't cause any scratching or damage to the marble's surface, ensuring a polished finish that is both stunning and long-lasting.Granite, on the other hand, is a much harder stone and requires a more aggressive polishing approach. Wet polishing pads, with their various grit levels, are capable of tackling even the toughest of granite surfaces. Whether it's removing deep scratches or achieving a high-gloss shine, wet polishing pads have got you covered. Their flexibility allows for consistent and controlled abrasion, ensuring optimal results every time.Concrete polishing has gained immense popularity in recent years, especially in the world of interior design. Wet polishing pads are an excellent choice for concrete polishing due to their versatility and adaptability. They can be used for everything from rough grinding to fine polishing, allowing you to achieve the desired level of sheen and smoothness. With wet polishing pads, you can transform dull concrete floors into beautiful, polished surfaces that are not only visually appealing but also highly durable.In conclusion, wet polishing pads are an essential tool for any stone polishing project. Their flexibility, ability to prevent overheating, and dust-controlling properties make them the go-to choice for professionals and DIY enthusiasts alike. Whether you are working with marble, granite, or concrete, wet polishing pads provide exceptional results and ensure that the finished product is nothing short of perfection.So, when it comes to polishing your precious stones, don't forget to consider the wet polishing pads. They are the ultimate companion in achieving the beautiful, polished finish you desire. Open up a new world of possibilities and let your stones shine with the help of flexible diamond wet polishing pads.

$10 Million Renovation Plan Set to Illuminate Jacksonville's Historic Theatre

in Jacksonville, Theatre Renovations, Historic Buildings in Florida, Cultural Institutions in Jacksonville.Diamond Floor Polishing: The Jewel of Theatre RenovationsThe Florida Theatre has been an iconic cultural institution in Jacksonville for almost a century. Since its opening in 1927, the theatre has showcased a variety of entertainment, from movies to Broadway shows to musical performances. However, after decades of use, the theatre was showing its age. The seats were worn, the carpet was stained, and the paint was chipped. That is until recently when a $10 million renovation plan was announced. The renovation plan is like polishing a diamond, bringing it back to its original brilliance.The Florida Theatre is not just any theatre, it is a historic building in Florida. It was added to the National Register of Historic Places in 1983. The theatre has played an important role in Jacksonville's cultural scene, hosting famous performers such as Elvis Presley, Frank Sinatra, and Tony Bennett. The renovations aim to restore the theatre to its former glory, preserving its historic integrity. The renovations will enhance the theatre's acoustics, seating, and accessibility.The $10 million renovation plan includes an extensive refurbishment of the theatre's interiors. The seating will be replaced, the carpet will be removed, and the paint will be redone. The theatre will also feature a state-of-the-art sound system and improved stage lighting. The upgrades will make the theatre a top destination for performing arts in Jacksonville. The increased seating capacity will open doors for larger productions, attracting more visitors and revenue for the city.The renovation plan for the Florida Theatre is not just about reviving a cultural institution, but it also helps to preserve Jacksonville's history and heritage. Historic buildings in Florida are a vital part of the state's identity. These buildings tell the stories of the people who built them, the local communities that they served, and the times they witnessed. The Florida Theatre is a symbol of Jacksonville's cultural heritage, and the renovation plan will ensure that its story continues to be told for generations to come.Cultural institutions like the Florida Theatre play a crucial role in society by providing a space for creative expression and fostering a sense of community. The theatre hosts a diverse range of events, from concerts to educational programs, providing entertainment and education to audiences of all ages. The renovation plan will allow the theatre to continue to serve as a cultural hub in Jacksonville. It will create a space for artists to showcase their talents and for audiences to enjoy a variety of entertainment.In conclusion, Diamond Floor Polishing is like polishing a jewel. The $10 million renovation plan for the Florida Theatre is a significant investment in Jacksonville's cultural scene. The renovations will breathe new life into this historic building, preserving its heritage, and enhancing its cultural significance. The theatre will continue to be a place where memories are made and stories are told. The Florida Theatre will shine brighter than ever before, ready to take center stage once again.

High-Quality Polishing Pads for Effective Snail Lock Grinding

Title: Innovative Snail Lock Polishing Pad Revolutionizes the Stone and Concrete Polishing IndustryIn the world of stone and concrete polishing, the introduction of the innovative Snail Lock Polishing Pad has revolutionized the way professionals in the industry approach their work. This revolutionary product has been developed by a leading manufacturer and supplier in the industry, {[Company Name]}, who are dedicated to delivering high-quality and innovative solutions to their customers.The Snail Lock Polishing Pad is designed to provide enhanced performance and efficiency, making it easier for professionals to achieve exceptional results in their polishing projects. With its unique design and advanced technology, this polishing pad has quickly gained popularity among contractors, fabricators, and manufacturers in the stone and concrete industry.One of the key features of the Snail Lock Polishing Pad is its innovative snail lock backing, which allows for quick and easy attachment to a variety of polishing machines. This feature ensures that the pad remains securely in place during the polishing process, preventing any slippage or movement that could result in uneven or inconsistent polishing results.In addition to its secure attachment, the Snail Lock Polishing Pad is also engineered to provide superior performance and durability. The high-quality material used in its construction ensures that the pad is able to withstand the rigors of the polishing process, while maintaining its effectiveness and longevity.Furthermore, the advanced design of the Snail Lock Polishing Pad incorporates a special resin matrix that maximizes the pad's surface contact with the stone or concrete, resulting in a more uniform and consistent finish. This innovative feature allows professionals to achieve smoother and more polished surfaces in a shorter amount of time, ultimately increasing productivity and reducing overall project timelines.Another notable advantage of the Snail Lock Polishing Pad is its versatility. Whether it's used for polishing granite, marble, engineered stone, or concrete, this pad is capable of delivering exceptional results across a wide range of materials. This versatility makes it an indispensable tool for professionals working on various types of projects, from residential countertops to commercial flooring.In addition to its superior performance, the Snail Lock Polishing Pad is also designed with user convenience in mind. Its easy-to-use design and compatibility with a wide range of polishing machines make it accessible to professionals of all skill levels, allowing them to achieve professional-quality results with ease.As a leading manufacturer and supplier in the industry, {[Company Name]} is dedicated to providing innovative solutions that meet the evolving needs of its customers. The development and introduction of the Snail Lock Polishing Pad is a testament to the company's commitment to delivering high-quality products that enhance the performance and efficiency of professionals in the stone and concrete polishing industry.With a strong focus on research and development, {[Company Name]} continues to invest in the latest technology and manufacturing processes to ensure that its products remain at the forefront of the industry. The Snail Lock Polishing Pad is just one example of the company's dedication to delivering cutting-edge solutions that empower professionals to achieve outstanding results in their projects.In conclusion, the introduction of the innovative Snail Lock Polishing Pad has brought about a significant transformation in the stone and concrete polishing industry. Its advanced design, superior performance, and user-friendly features have made it an indispensable tool for professionals seeking to achieve exceptional results in their polishing projects. With the backing of {[Company Name]} as a leading manufacturer and supplier, the Snail Lock Polishing Pad is set to continue making a lasting impact in the industry, setting new standards for quality and efficiency.

Discover the Benefits of Ceramic Flap Discs - A Versatile Abrasive Tool for Various Applications

Ceramic Flap Disc Revolutionizes Grinding and Polishing ApplicationsIn the ever-evolving world of manufacturing and fabrication, there is a constant demand for better tools and technologies that enhance efficiency and productivity. One such groundbreaking innovation, the Ceramic Flap Disc, is rapidly gaining popularity for its superior performance in grinding and polishing applications.Developed by an industry-leading manufacturer [], the Ceramic Flap Disc is designed to completely transform the way professionals approach abrasive processes. With its advanced composition and innovative design, this cutting-edge tool offers unprecedented advantages over traditional grinding and polishing solutions.The Ceramic Flap Disc incorporates a unique combination of high-quality abrasive grains and a strong resin bond system. This proprietary blend ensures exceptional durability, extended service life, and excellent material removal rates. The ceramic grains used in the disc have a well-defined shape and size, resulting in more consistent and precise results.One of the key features of the Ceramic Flap Disc is its outstanding toughness and versatility. It can effortlessly tackle various materials, including stainless steel, carbon steel, aluminum, and non-ferrous metals. This versatility makes it an invaluable tool for a wide range of industries, including automotive, aerospace, construction, and metal fabrication.The Ceramic Flap Disc's durability and long-lasting performance make it an ideal choice for heavy-duty applications. Its self-sharpening design ensures a consistent cutting action, minimizing downtime for tool changes and maximizing productivity. The innovative heat-resistant coating on the disc prevents overheating and extends its lifespan, ultimately reducing tooling costs for businesses.Moreover, the Ceramic Flap Disc offers exceptional stock removal capabilities, allowing professionals to complete their tasks more efficiently. Its aggressive grinding action combined with smooth finishing properties makes it a versatile solution for both rough and fine grinding applications. This versatility makes it an excellent choice for the removal of weld seams, scale, rust, and for surface preparation prior to coating or welding.Safety is of utmost importance in any industrial process, and the Ceramic Flap Disc excels in this aspect as well. It is designed with a reinforced fiberglass backing, ensuring enhanced stability and added safety during operation. The disc's ergonomic design also contributes to reduced operator fatigue, allowing for extended usage without compromising comfort.The Ceramic Flap Disc not only boasts exceptional performance, but it also offers environmental advantages. Its efficient material removal rates reduce the need for excess grinding, minimizing waste generation. Additionally, the long service life of the disc results in fewer replacements, further reducing the environmental impact.To cater to diverse customer preferences and requirements, the Ceramic Flap Disc is available in various sizes and grit options. This allows professionals to choose the most suitable disc for their specific applications, ensuring optimal results every time.In conclusion, the Ceramic Flap Disc is a game-changing solution for grinding and polishing tasks in the manufacturing and fabrication industry. With its unmatched performance, durability, and versatility, this revolutionary tool is challenging the status quo and setting new standards of excellence. Professionals across various industries can now achieve superior results in their abrasive processes, significantly improving their productivity and efficiency.

Velcro Backed Resin Bonded Diamond Polishing Pads for Granite, Marble, Terrazzo, Stonework and Concrete

Frankfurt Diamond Pads Launches Velcro Backed Resin Bonded Diamond Floor Polishing PadFrankfurt Diamond Pads, a leading manufacturer of diamond polishing pads, has launched a new line of Velcro backed resin bonded diamond floor polishing pads. These pads are designed for use on granite, marble, terrazzo, stonework, and concrete surfaces, making them ideal for a wide range of industries.The new resin bonded diamond floor polishing pads have been specifically developed for wet type applications, where water is used to lubricate the pad and provide a cooling effect. This ensures that the pads work efficiently and effectively, without causing any damage to the surface being worked on.The pads are available in a size of 99mm x 75mm x 5mm, making them suitable for use with a range of floor polishing machines. Frankfurt Diamond Pads recommends using the pads at a speed of 500-800rpm, with a pressure of 5-10kg/cm2 for optimal results.Frankfurt Diamond Pads has a reputation for producing high-quality diamond polishing pads that are both durable and efficient. The company uses only the finest materials to manufacture its products, and its team of experienced technicians and engineers ensures that each pad is carefully crafted to meet the highest standards of quality and performance.In addition to its new line of Velcro backed resin bonded diamond floor polishing pads, Frankfurt Diamond Pads offers a wide range of diamond polishing pads for use in various applications, including concrete grinding and polishing, stone restoration, and terrazzo polishing.The company also offers a range of accessories, such as backer pads, adaptors, and tooling, to ensure that its customers have everything they need to achieve the best possible results. Frankfurt Diamond Pads takes pride in its commitment to customer satisfaction, and its friendly and knowledgeable staff is always on hand to provide advice and support to its clients.Frankfurt Diamond Pads is a company that is dedicated to providing high-quality diamond polishing pads and accessories to the construction industry. With its focus on quality, innovation, and customer satisfaction, Frankfurt Diamond Pads is committed to being a leader in its field, both now and in the future.

Different Types of Grinding Wheels: A Complete Guide

Title: Exploring the Different Types of Grinding Wheels Revolutionizing Industrial ApplicationsIntroduction:In today's industrial revolution, grinding wheels play a fundamental role in various sectors, including manufacturing, construction, automotive, and metalworking. These indispensable tools are crucial for precision cutting, shaping, and finishing, enabling businesses to enhance productivity and achieve superior workpiece quality. This article aims to shed light on the various types of grinding wheels available in the market and their importance in revolutionizing industrial applications.1. Straight Grinding Wheels:Straight grinding wheels, also known as Type 1 wheels, are the most common and straightforward type used for surface grinding. These wheels have a flat outer periphery and deliver precise grinding performance on flat surfaces. Typically made from aluminum oxide or silicon carbide abrasive grains, straight grinding wheels are versatile and suitable for a wide array of materials, including steel, cast iron, brass, and non-ferrous metals.2. Cylinder Wheels:Cylinder wheels, designated as Type 2 wheels, possess a unique shape resembling a straight grinding wheel with a cylindrical face. These wheels are primarily used for grinding cylinders, bearings, and other rounded surfaces. The rounded design allows for easy and efficient grinding with reduced friction, resulting in excellent surface finishes.3. Tapered Grinding Wheels:Tapered grinding wheels, commonly referred to as Type 4 wheels, are specially designed for grinding operations that require precision and control. These wheels have a tapered shape, gradually narrowing towards the arbor hole. The tapering enables the wheel to penetrate the workpiece effectively, making them ideal for intricate grinding tasks such as internal grinding.4. Dish Grinding Wheels:Dish grinding wheels, known as Type 11 wheels, possess a dish-shaped design with a roundish outer rim and a depressed center. These wheels are widely used for contour grinding, grinding complex shapes, and removing excess material from the workpiece. The recessed center allows for a higher degree of flexibility, making them suitable for both large and small-scale applications.5. Diamond Wheels:Diamond grinding wheels are the epitome of grinding wheel technology, offering exceptional hardness, durability, and precision. Utilizing diamond abrasives, these wheels excel in cutting and grinding extremely hard materials such as carbides, ceramics, glass, and stones. Their fine grit allows for a smooth finish and minimal material wastage, making diamond wheels ideal for demanding applications.6. CBN Wheels:Cubic Boron Nitride (CBN) grinding wheels are similar to diamond wheels in terms of their exceptional hardness and longevity. These wheels are specifically formulated for grinding ferrous materials, including hardened steels and cast iron. With their heat resistance and ability to retain sharpness, CBN wheels are perfect for high-speed grinding operations, resulting in improved productivity and reduced downtime.Conclusion:Grinding wheels are indispensable tools in the industrial sector, revolutionizing various applications, from metalworking to automotive and construction. This article explored different types of grinding wheels, highlighting their characteristics and applications. The versatility and precision offered by these wheels allow businesses to improve productivity, achieve superior workpiece quality, and ultimately drive the industrial revolution forward. As technology advances further, we can expect the development of innovative grinding wheel types, continually pushing the boundaries of what can be achieved in industrial grinding.