Durable Dry Grinding Disc for Granite: 0 to 6 Grit Options Available

By:Admin

{Company Name}, a leading manufacturer of high-quality construction and industrial tools, has recently launched a new product that is set to revolutionize the dry grinding industry. The new Granite Dry Grinding Disc 0 to 6 is a game-changer in the field of grinding, offering unparalleled performance and durability.

The innovative dry grinding disc is designed to meet the growing demands of the construction and industrial sectors, offering a solution for professionals seeking a reliable and efficient tool for their grinding needs. The disc is specially engineered to provide a smooth and consistent grinding experience, allowing for faster and more precise results.

One of the key features of the Granite Dry Grinding Disc is its versatility. It is suitable for a wide range of materials, including granite, marble, and concrete, making it an essential tool for professionals working in various industries. The disc is also compatible with most standard grinding machines, making it easy to integrate into existing workflows.

In addition to its versatility, the Granite Dry Grinding Disc is known for its exceptional durability. Constructed from high-quality materials, the disc is designed to withstand the rigors of heavy-duty use, ensuring that it can keep up with the demands of even the most challenging grinding tasks.

The design of the disc also minimizes dust and debris, providing a cleaner and healthier work environment for professionals. This not only improves the working conditions but also contributes to a more efficient and productive grinding process.

Furthermore, the innovative design of the Granite Dry Grinding Disc reduces heat generation during the grinding process, minimizing the risk of overheating and ensuring a longer lifespan for the disc. This ultimately translates to cost savings for professionals, as they can rely on the disc for extended periods without the need for frequent replacements.

{Company Name} has a strong reputation for delivering high-quality products that meet the needs of professionals across the construction and industrial sectors. With a history of innovation and dedication to excellence, the company is committed to developing tools that improve the efficiency and effectiveness of their customers' work.

The launch of the Granite Dry Grinding Disc is a testament to {Company Name}'s ongoing commitment to innovation and quality. By combining cutting-edge technology with the latest materials and manufacturing techniques, the company has once again raised the bar for the industry, providing professionals with a reliable and high-performance tool that meets their evolving needs.

The introduction of the Granite Dry Grinding Disc has already garnered significant attention from professionals in the construction and industrial sectors. With its unmatched performance, durability, and versatility, the disc is poised to become an essential tool for professionals seeking a reliable and efficient solution for their grinding needs.

As {Company Name} continues to expand its product range and push the boundaries of innovation, the launch of the Granite Dry Grinding Disc is yet another milestone in the company's journey towards excellence. With a focus on delivering the highest quality products and meeting the evolving needs of professionals, {Company Name} is set to remain a leading force in the construction and industrial tool industry for years to come.

In conclusion, the Granite Dry Grinding Disc 0 to 6 represents a significant advancement in the field of dry grinding, offering professionals a reliable, efficient, and versatile tool for their grinding needs. With its exceptional performance, durability, and innovative design, the disc is set to become an essential addition to the toolkit of professionals across the construction and industrial sectors. As {Company Name} continues to lead the way in innovation and quality, the launch of the Granite Dry Grinding Disc further solidifies its position as a trusted provider of high-quality tools for professionals around the world.

Company News & Blog

Versatile Grinding Wheels for Industrial Metal Work and Deburring Applications

s, Bonded Grinding Wheels, Industrial Applications, Metal Work, Deburring, Bench Mounted Applications, Surface Grinding Wheels, Carbide BurrsGrinding Wheels and Tooling for Industrial ApplicationsGrinding wheels are essential tools for metalworking, deburring, and machine-mounted works. They come in various shapes and sizes and are known to be one of the most versatile abrasive tools available in the market. They are made of abrasive grains, bonding materials, and fillers, and can be used for a wide range of tasks. In this article, we will discuss the different types of grinding wheels and tooling for industrial applications.Bonded Grinding WheelsBonded grinding wheels are the most commonly used type of grinding wheel. They are made of a composite material that consists of abrasive grains held together by a bonding material. The abrasive grains are usually made of aluminum oxide, silicon carbide, or diamond, depending on the type of material being ground and the desired finish. The bonding material can be resin, metal, or vitrified.Resin-bonded wheels are commonly used for precision grinding, surface grinding, and tool and cutter grinding. They are versatile and affordable, making them suitable for most applications. Metal-bonded wheels are used for grinding harder materials, such as high-speed steel and carbide. They are also used for rough grinding and form grinding. Vitrified-bonded wheels are used for precision grinding and sharpening of carbide tools.Wire BrushesWire brushes are another type of abrasive tool that is used for cleaning, deburring, and finishing metal surfaces. They are made of metal wire bristles that are mounted on a rotating shaft. The wire bristles can be made of different materials, including steel, brass, and stainless steel. Wire brushes are used for removing rust, paint, and other surface contaminants from metal surfaces. They are also used for cleaning welds and deburring edges.Bench Mounted ApplicationsBench-mounted grinding wheels are used for precision grinding, sharpening, and polishing of metal parts. They are mounted on a bench or pedestal and can be used for a wide range of tasks, such as grinding, deburring, and sanding. Bench-mounted wheels are available in various sizes and materials, depending on the application.Surface Grinding WheelsSurface grinding wheels are used for precision grinding of flat surfaces. They are typically used on a reciprocating table, where the workpiece is moved back and forth against the grinding wheel. Surface grinding wheels are available in different sizes and materials, depending on the type of material being ground and the desired finish.Carbide BurrsCarbide burrs are used for shaping, deburring, and finishing metal surfaces. They are made of carbide, a hard and brittle material that is ideal for grinding and cutting. Carbide burrs are available in various shapes and sizes, depending on the application. They can be used on a variety of materials, including steel, aluminum, and cast iron.In conclusion, grinding wheels and tooling for industrial applications are essential tools for metalworking, deburring, and machine-mounted works. Bonded grinding wheels, wire brushes, bench-mounted applications, surface grinding wheels, and carbide burrs are just some of the available options. When choosing a grinding wheel or tool, it is important to consider the type of material being ground, the desired finish, and the application.

Durable Nylon Wheel Brush for Effective Cleaning and Maintenance

Nylon Wheel Brush – The Ultimate Solution for Cleaning and MaintenanceWhen it comes to maintaining the cleanliness and appearance of industrial equipment and machinery, having the right tools and accessories is crucial. One such essential tool is the Nylon Wheel Brush, a versatile and effective cleaning solution that is specially designed to meet the needs of various industries. Whether it's for removing debris and dirt from conveyor belts, cleaning machinery, or any other industrial equipment, the Nylon Wheel Brush is a game-changer when it comes to keeping your workspace clean and well-maintained.With its durable nylon bristles, the Nylon Wheel Brush is designed to effectively remove tough build-up, grime, and debris from a wide range of surfaces. Its high-quality construction makes it suitable for use in demanding industrial environments, where it can withstand heavy-duty usage and deliver consistent results. From metal surfaces to rubber, plastic, and other materials, the Nylon Wheel Brush is capable of tackling various cleaning challenges with ease.In addition to its cleaning capabilities, the Nylon Wheel Brush is also designed with the user's comfort and safety in mind. Its ergonomic handle ensures a comfortable and secure grip, allowing users to maintain control and stability while using the brush for extended periods. Furthermore, its design minimizes the risk of accidental injury or damage to the surfaces being cleaned, making it a reliable and safe tool for industrial cleaning tasks.The Nylon Wheel Brush is also compatible with a range of power tools and machines, allowing for an efficient and time-saving cleaning process. Whether used with a handheld power tool or a stationary cleaning machine, the Nylon Wheel Brush is versatile enough to adapt to different cleaning requirements and applications. This flexibility and compatibility make it a valuable asset for companies looking to streamline their cleaning and maintenance processes.Company Introduction: The manufacturer behind the Nylon Wheel Brush is a leading provider of industrial cleaning solutions, with a strong reputation for innovation, quality, and reliability. With years of experience in the industry, they have continually focused on developing and improving their product range to meet the evolving needs of their customers.The company's commitment to quality and performance is evident in the design and construction of the Nylon Wheel Brush. By using high-grade nylon bristles, durable materials, and rigorous manufacturing standards, they have created a product that delivers outstanding results and durability, even in the harshest industrial environments. Furthermore, their dedication to user safety and ergonomics ensures that the Nylon Wheel Brush is not only effective but also comfortable and easy to use.Aside from the Nylon Wheel Brush, the company offers a comprehensive range of cleaning and maintenance solutions, including brushes, squeegees, mop systems, and more. Their extensive product line caters to a wide range of industries, including manufacturing, food processing, pharmaceuticals, automotive, and more. By understanding the unique challenges faced by each industry, they have developed specialized solutions that address specific cleaning and maintenance needs, helping companies to achieve higher standards of cleanliness and hygiene.In conclusion, the Nylon Wheel Brush is a versatile and reliable tool that offers an effective solution for industrial cleaning and maintenance. With its durable construction, ergonomic design, and compatibility with power tools, it is a valuable asset for companies looking to improve their cleaning processes. Backed by a reputable manufacturer known for its commitment to quality and innovation, the Nylon Wheel Brush is a must-have tool for any industrial environment.

Ceramic Tile Flooring in Mooresville, NC: Easy Selection & Free Consultation Services | Floor Coverings International

Ceramic Floor Tiles, a leading provider of ceramic tile flooring solutions, is proud to offer its extensive range of products and services to homeowners in Mooresville, NC. With a commitment to quality and customer satisfaction, the company has built a reputation as a trusted provider of beautiful and durable flooring options.Ceramic tile flooring has been a popular choice for homeowners for centuries, thanks to its timeless beauty and durability. These types of tiles are made from natural clay that is fired at high temperatures, creating a durable and versatile material that can be used in a variety of settings. Ceramic tiles are available in a wide range of colors, shapes, sizes, and patterns, making them perfect for any living space.At Ceramic Floor Tiles, we understand that choosing the right flooring for your home can be a daunting task. That's why we offer free in-home consultation services to help you navigate your options and select the perfect ceramic tile flooring solution for your Mooresville home. Our team of flooring experts will work with you to understand your design preferences, budget, and lifestyle needs, so we can recommend the best options for your unique situation.We offer a wide range of ceramic tile flooring options for our Mooresville clients. Our selection includes traditional ceramic tiles, which are made from natural clay and come in a variety of colors and patterns. These tiles are perfect for homeowners who want a classic and timeless look. We also offer porcelain tiles, which are made from a denser type of clay and are more resistant to chips, scratches, and stains. Porcelain tiles are a popular choice for high-traffic areas, such as kitchens and bathrooms.In addition to our extensive variety of ceramic tile options, Ceramic Floor Tiles also offers expert installation services. Our team of skilled technicians will ensure that your new flooring is installed correctly, so it looks beautiful and performs well for years to come. We use high-quality materials and follow industry best practices to ensure a flawless finish every time.At Ceramic Floor Tiles, we're committed to providing our Mooresville clients with exceptional customer service. We understand that selecting new flooring is a significant investment for your home, and we're dedicated to helping you make a decision that you'll be happy with for years to come. Our team is available to answer any questions you may have throughout the flooring selection and installation process.In conclusion, if you're looking for a beautiful and durable flooring solution for your Mooresville home, look no further than Ceramic Floor Tiles. With our extensive variety of ceramic tile options, free in-home consultation services, and expert installation, we're the perfect partner for your flooring needs. Contact us today to schedule your consultation and get started on your flooring project.

High-Quality Diamond Polishing Pads for Dry Polishing - The Latest in Polishing Technology

Introducing the Next Generation of Dry Diamond Polishing PadsIn the world of stone and concrete polishing, one company is making waves with their innovative new product: the Dry Diamond Polishing Pads. This revolutionary new system is changing the game for contractors and DIY enthusiasts alike, providing a faster, more efficient, and environmentally friendly way to achieve the perfect polished finish. With its unique design and superior performance, these pads are quickly becoming a favorite among industry professionals.The Dry Diamond Polishing Pads are the brainchild of {}. As a leading manufacturer of diamond tools and abrasives, they have built a reputation for providing high-quality products that deliver exceptional results. With over 20 years of experience in the industry, they have consistently pushed the boundaries of innovation, and their latest offering is no exception.The Dry Diamond Polishing Pads are specifically designed for dry polishing applications, making them a versatile and convenient choice for a wide range of projects. Whether working with natural stone, concrete, granite, or marble, these pads provide a high level of performance and durability, ensuring a smooth and consistent finish every time.One of the key features that sets these pads apart is their diamond matrix technology, which allows for superior cutting and polishing efficiency. This means that users can achieve excellent results in less time, without compromising on the quality of the finish. Additionally, these pads are designed to produce less dust and debris, creating a safer and cleaner working environment for the user.In addition to their impressive performance, the Dry Diamond Polishing Pads are also environmentally friendly. By eliminating the need for water during the polishing process, they help to reduce water consumption and waste, making them a sustainable choice for environmentally conscious users.To further enhance their versatility, these pads are available in a wide range of grit sizes, allowing users to achieve their desired level of polish with ease. This makes them suitable for both coarse and fine polishing applications, giving users the flexibility to tackle a variety of projects with just one set of pads.Committed to delivering the highest level of quality, {} has rigorously tested and refined the Dry Diamond Polishing Pads to ensure that they meet the demands of professional contractors and DIY enthusiasts alike. Their dedication to innovation and excellence shines through in every aspect of the design and performance of these pads, making them a must-have tool for anyone in the stone and concrete polishing industry.Upon its release, the Dry Diamond Polishing Pads have received an overwhelmingly positive response from industry professionals. Contractors and skilled tradespeople have praised the pads for their exceptional performance and ease of use, noting that they have significantly improved their efficiency and productivity on job sites. DIY enthusiasts have also embraced the pads for their user-friendly design and outstanding results, giving them the confidence to tackle their own projects with professional-level precision.As the demand for high-quality, efficient, and sustainable polishing solutions continues to grow, the Dry Diamond Polishing Pads from {} are poised to become an industry standard. With their cutting-edge technology, superior performance, and commitment to environmental responsibility, these pads are redefining the way that stone and concrete are polished, setting a new benchmark for excellence in the industry. For anyone seeking a reliable, versatile, and environmentally conscious polishing solution, the Dry Diamond Polishing Pads are the clear choice.

How to Choose the Best Polishing Pads for Your Granite Surfaces

(title): Revolutionary Granite Polishing Technology Set to Redefine Stone Restoration(subtitle): [Company Name] Launches Groundbreaking Granite Polishing Pads for Unmatched Performance and Shine[date][Location]In a game-changing move for the stone restoration industry, [Company Name], a pioneering leader in stone care solutions, has unveiled its revolutionary Granite Polishing Pads. Setting a new standard for granite surface restoration, these pads are poised to redefine the way professionals bring back the natural luster and shine of granite countertops, flooring, and other surfaces.With over two decades of experience and a relentless commitment to innovation, [Company Name] has developed this breakthrough technology to address the longstanding challenges faced by stone restoration experts. The lack of effective and durable solutions had hindered their ability to deliver consistent and superior results – until now.By leveraging cutting-edge research and advancements in material engineering, the Granite Polishing Pads from [Company Name] offer an unparalleled level of performance and shine. These pads are specially designed with a combination of advanced abrasive technology and a unique bonding system, ensuring maximum efficiency and durability.One of the key highlights of these pads is their versatility. Developed to cater to a wide range of granite types, they adapt to the specific needs of each surface. No longer will professionals have to search for multiple polishing tools to accommodate different granite finishes. The Granite Polishing Pads from [Company Name] remove the hassle of trial and error, offering a one-stop solution for an array of granite surfaces.Furthermore, these pads are specifically engineered to address common issues faced during the polishing process. Scratches, unevenness, and dullness are expertly tackled by the advanced abrasive particles embedded within the pad's structure. This results in a flawless and uniform finish, elevating the beauty and elegance of every granite surface.Unlike conventional polishing pads, the Granite Polishing Pads from [Company Name] boast exceptional durability and longevity. This groundbreaking attribute significantly reduces downtime and ensures a high return on investment for stone restoration professionals. Laboratories have rigorously tested these pads under rigorous conditions, confirming their ability to withstand prolonged and repeated use without losing their effectiveness."Continuous innovation is at the heart of our company," stated [Company Spokesperson]. "We understand the challenges faced by professionals in the stone restoration industry, and we are committed to providing them with cutting-edge solutions. Our Granite Polishing Pads are a testament to this commitment, and we firmly believe they will revolutionize the way people restore and care for granite surfaces."The launch of these Granite Polishing Pads marks a significant milestone for [Company Name] and the stone restoration industry as a whole. This new technology not only enhances the efficiency and effectiveness of granite restoration but also empowers professionals to deliver unmatched results, surpassing their clients' expectations.As [Company Name] continues to push the boundaries of innovation, they remain committed to delivering superior stone care solutions and setting new industry standards. With the Granite Polishing Pads, stone restoration professionals can now harness the power of advanced technology to transform any granite surface into a work of art.About [Company Name]:[Company Name] is a pioneering leader in stone care solutions, specializing in the development and distribution of innovative products for stone restoration, maintenance, and protection. With over two decades of industry experience, [Company Name] is committed to delivering superior results and revolutionizing the stone care industry through continuous innovation and exceptional customer service.

Car Polisher Pads - Get the Best Quality for your Needs

Auto Xs, a leading manufacturer of car care products, has recently introduced a new line of car polisher pads that are set to revolutionize the automotive detailing industry. These high-quality pads are designed to deliver exceptional results and make the process of polishing cars more efficient and effective.The new car polisher pads from Auto Xs are made from premium materials that are durable and long-lasting. The specially formulated foam ensures that the pads can withstand the rigors of car polishing, while still maintaining their shape and effectiveness. This means that users can rely on these pads for multiple applications, making them a cost-effective solution for both professional detailers and car enthusiasts.In addition to their durability, the car polisher pads from Auto Xs have been engineered to deliver outstanding results. The unique design of the pads ensures that they can effectively remove surface imperfections, swirl marks, and other blemishes, leaving behind a flawless finish. Whether used with a dual-action polisher or a rotary polisher, these pads are capable of achieving a level of shine and smoothness that was previously only possible with professional-grade equipment.One of the key features of the new car polisher pads is their versatility. Available in a range of sizes and firmness levels, these pads can be used for a variety of polishing and buffing tasks. From paint correction to wax and sealant application, the pads are adaptable to different detailing techniques and products, giving users the flexibility to achieve their desired results.The introduction of these car polisher pads further strengthens Auto Xs' commitment to providing innovative and high-quality car care products. With a focus on performance and user experience, the company continually strives to develop solutions that meet the evolving needs of car enthusiasts and professionals in the automotive industry.“We are excited to introduce our new line of car polisher pads, which we believe will set a new standard for automotive detailing,” said a spokesperson for Auto Xs. “We have invested significant time and resources into research and development to ensure that these pads deliver exceptional performance and durability. We are confident that our customers will be impressed with the results they can achieve using our pads.”In addition to the car polisher pads, Auto Xs offers a comprehensive range of car care products, including polishes, waxes, sealants, and detailing tools. The company's commitment to quality and innovation has earned it a strong reputation among car enthusiasts and professionals alike.The new car polisher pads from Auto Xs are now available for purchase through the company's website and select retailers. With their exceptional performance, durability, and versatility, these pads are set to become a must-have tool for anyone who is passionate about maintaining the appearance of their vehicle.For more information about Auto Xs and its range of car care products, visit their website or contact their customer service team. With a dedication to customer satisfaction and product excellence, Auto Xs continues to be a trusted name in the automotive detailing industry.

Low-Priced Honeycomb Dry Diamond Flexible Polishing Pad for Efficient Stone Polishing

, Diamond Polishing Pads, Stone Polishing Pads, Dry Polishing Pads, Flexi Polishing PadsThe demand for Honeycomb Dry Diamond Flexible Polishing Pads has been on the rise due to their excellent performance and efficiency in polishing surfaces. They are versatile, user-friendly, durable, and easy to use in both dry and wet applications. The Honeycomb design provides more contact points on the material being polished, which translates to faster and smoother polishing.At (brand name removed), we understand the importance of high-quality polishing pads for both professionals and DIY enthusiasts. This has driven us to develop premium-grade Honeycomb Dry Diamond Flexible Polishing Pads, which are suitable for use on different types of materials such as granite, marble, concrete, and engineered stone.Our Honeycomb Polishing Pads are designed to provide a consistent finish without leaving swirl marks or scratches on the surface being polished. They are available in different grits ranging from coarse to fine, which makes them ideal for both heavy stock removal and light polishing. With our high-quality Diamond Polishing Pads, achieving a high gloss finish is easy and effortless.One of the benefits of our Honeycomb Dry Diamond Flexible Polishing Pads is that they are compatible with different types of hand polishers and portable grinders. This allows you to use the same pad for different applications, which saves you money and time. Additionally, our Flexi Polishing Pads are versatile and can be used for both dry and wet polishing applications.Another benefit of our Honeycomb Polishing Pads is that they are long-lasting and wear-resistant. This is because they are made from high-quality diamonds that are evenly distributed on the pad's surface. Additionally, they have a flexible foam backing that conforms to the shape of the surface being polished, which ensures uniform and consistent pressure distribution.One of the challenges that most polishing pad users face is clogging. This happens when the pad's pores get filled with debris, which reduces its efficiency and performance. However, our Honeycomb Dry Diamond Flexible Polishing Pads have an open-cell design that reduces clogging and allows for easy debris removal. This ensures that you get more use out of each pad and saves you money in the long run.In conclusion, our Honeycomb Dry Diamond Flexible Polishing Pads are the ideal choice for achieving a high gloss finish on different types of surfaces. They are versatile, user-friendly, and compatible with different types of hand polishers and portable grinders. Additionally, their long-lasting and wear-resistant design ensures that you get maximum value for your money. Contact us today for low prices and high-quality Diamond Polishing Pads, Stone Polishing Pads, Dry Polishing Pads, and Flexi Polishing Pads.

Different Types of Grinding Wheel Dressers: A Comprehensive Guide

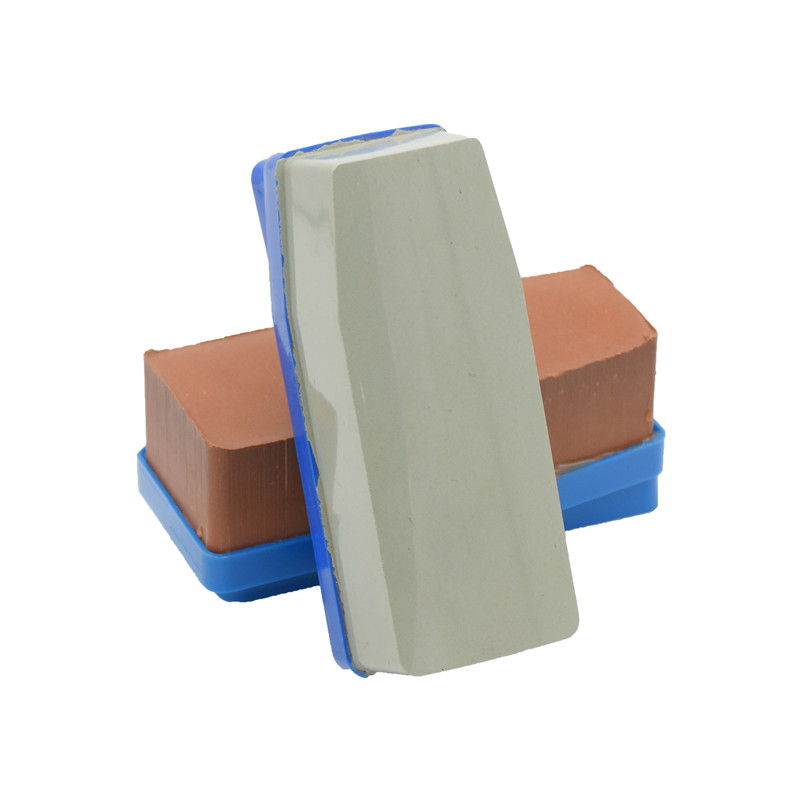

Grinding Wheel Dresser Types: Enhancing Efficiency and Precision in ManufacturingIn today's rapidly advancing manufacturing industry, efficiency and precision are of paramount importance. One of the key tools used for achieving these goals is the grinding wheel dresser. A grinding wheel dresser is a vital device used to shape and clean abrasive wheels in order to maintain their optimal performance. With various types of grinding wheel dressers available in the market, companies are constantly seeking the most appropriate type to enhance productivity and quality. Grinding wheel dressers come in different forms and serve unique purposes. One popular type is the diamond dresser. Incorporating diamond grains on its surface, this dresser offers unparalleled hardness and durability. Diamonds are known for their exceptional strength in cutting, shaping, and cleaning abrasive materials, making them the ideal choice for grinding wheel dressers. By utilizing diamonds, the dresser is able to maintain its sharpness even after extensive use, resulting in consistent and precise grinding.Another commonly used grinding wheel dresser is the star dresser. This type features multiple hardened steel discs with raised points in a star-like pattern. These points, often made from either high-speed steel or carbide, are crucial for truing and straightening the grinding wheel. The star dresser works by cutting into the wheel surface, creating grooves and channels, which ultimately improve its cutting efficiency and provide a smoother grinding action. This type of dresser is highly effective for removing excess material on the grinding wheel and achieving the desired shape.Yet another important type of grinding wheel dresser is the dressing stick or block. This dresser is made of abrasive grains, typically silicon carbide or aluminum oxide, adhered together with a bonding agent. The dressing stick is primarily used for cleaning and reshaping the grinding wheel by removing any debris or unevenness. It is especially useful in removing built-up metal shavings, known as glazing, which can significantly decrease the wheel's effectiveness. The dressing stick is an economical option that ensures the grinding wheel remains in optimal condition for prolonged usage.In light of these various grinding wheel dresser types, manufacturers are constantly seeking the most suitable option for their specific needs. This is where the company {}, a renowned leader in manufacturing solutions, comes into play. With a wealth of experience and expertise in the field, {} offers a wide range of grinding wheel dressers that cater to diverse industrial requirements.For instance, {} specializes in producing diamond dressers that are not only highly durable but also available in different sizes and shapes to accommodate various grinding wheel specifications. With their diamond dressers, customers can expect improved grinding efficiency, reduced dressing times, and increased precision in their manufacturing processes. By adopting diamond dressers from {}, manufacturers can achieve higher productivity, prolonged tool life, and enhanced overall quality.Furthermore, {} also offers an extensive selection of star dressers that can effectively dress a wide range of abrasive wheels, including vitrified, resin-bonded, and diamond grinding wheels. The company's star dressers are made from premium-quality materials, ensuring long-lasting performance and excellent truing capabilities. By utilizing {}'s star dressers, manufacturers can achieve optimal wheel conditions, resulting in enhanced surface finishes and reduced cycle times in their operations.Additionally, {} provides a comprehensive range of dressing sticks that are tailor-made for different grinding wheel materials and applications. Through their selection of dressing sticks, manufacturers can maintain the sharpness and efficiency of their grinding wheels, leading to consistent and precise results. {}'s dressing sticks are known for their durability and cost-effectiveness, making them a reliable solution in the grinding industry.In conclusion, grinding wheel dressers play a crucial role in maintaining the effectiveness and precision of abrasive grinding wheels. With a variety of types available, ranging from diamond dressers to star dressers and dressing sticks, manufacturers have multiple options to choose from based on their specific needs. By utilizing high-quality grinding wheel dressers from {}, companies can significantly enhance their manufacturing efficiency, improve product quality, and stay at the forefront of the rapidly evolving industry.

Durable and Efficient Cutting Tools for Diamond Processing

Diamond cutting tools are an essential component in a wide range of industries, including construction, automotive, aerospace, and mining. These tools are renowned for their strength, durability, and precision, making them an indispensable asset for companies in need of high-quality cutting solutions. One company that has been at the forefront of producing top-notch diamond cutting tools is (remove brand name). With a rich history dating back over 50 years, (remove brand name) has established itself as a leader in the manufacturing and distribution of diamond cutting tools. The company's commitment to innovation, quality, and customer satisfaction has earned them a strong reputation in the industry.One of the key factors that sets (remove brand name) apart from its competitors is its use of advanced technology and state-of-the-art machinery in the production process. The company's manufacturing facilities are equipped with the latest machinery and equipment, allowing for the precise and efficient production of diamond cutting tools. This commitment to technological advancement ensures that (remove brand name) remains at the forefront of the industry, constantly delivering cutting-edge solutions to its customers.In addition to its technological prowess, (remove brand name) is also known for its emphasis on research and development. The company boasts a team of highly skilled engineers and designers who are dedicated to creating innovative and efficient cutting tool solutions. Through extensive research and testing, (remove brand name) is able to develop cutting tools that are not only durable and reliable but also tailored to meet the specific needs of its customers.Furthermore, (remove brand name) takes great pride in its commitment to quality control and assurance. The company's rigorous quality control measures ensure that every single cutting tool produced meets the highest standards of performance and reliability. This dedication to quality has earned (remove brand name) the trust and loyalty of countless customers around the world.Another distinguishing factor of (remove brand name) is its dedication to customer service. The company's team of professionals is committed to providing unparalleled customer support, offering technical expertise, personalized solutions, and prompt assistance to ensure that every customer's needs are met. This customer-centric approach has been a driving force behind (remove brand name)'s success and has solidified its position as a trusted partner in the industry.Looking ahead, (remove brand name) is poised to continue its legacy of excellence in the production of diamond cutting tools. With a relentless focus on innovation, quality, and customer satisfaction, the company is well-equipped to meet the evolving needs of industries that rely on cutting-edge cutting solutions. (remove brand name) remains steadfast in its commitment to delivering top-quality products and services, ensuring that it will remain a leader in the diamond cutting tool industry for years to come.In conclusion, (remove brand name) is a company that exemplifies excellence in the production of diamond cutting tools. With its cutting-edge technology, commitment to research and development, emphasis on quality control, and dedication to customer service, (remove brand name) has earned a stellar reputation as a leader in the industry. As the company continues to innovate and expand its offerings, it is poised to remain a top choice for businesses in need of high-quality diamond cutting tools.

Types of Polishing Pads for Diamond Polishing

Title: The Ultimate Guide to Diamond Polishing Pads: Discover the Power of Diamond Hand Polishing PadsIntroduction (100 words):When it comes to achieving a perfect finish on your precious gemstones or hard surfaces, nothing quite matches the effectiveness and versatility of diamond polishing pads. Among the various types available in the market, one type that stands out is the diamond hand polishing pad. In this comprehensive guide, we will delve into the world of diamond hand polishing pads and explore how they can transform your polishing projects, whether you're a professional stone mason, a DIY enthusiast, or someone looking to enhance the beauty of their cherished possessions.Section 1: What Makes Diamond Hand Polishing Pads Unique (200 words):Diamond hand polishing pads are designed to offer precise control and ease of use, making them a popular choice for artisans and craftsmen. Their lightweight and compact design enables users to navigate tight spots, polish intricate details, and achieve remarkable results.The secret behind the efficiency of diamond hand polishing pads lies in their diamond-infused abrasive surface. Diamonds, being the hardest naturally occurring substance, are incredibly effective at grinding, smoothing, and shining various materials. By utilizing these pads, you can ensure unparalleled results in terms of both speed and quality.Section 2: Understanding the Categories of Diamond Polishing Pads (200 words):Diamond polishing pads are available in various categories designed to suit different materials and finishes. Based on the type of grinding or polishing required, you can find pads specifically formulated for concrete, granite, marble, glass, engineered stone, and more. These categories ensure that you can achieve the desired finish without compromising the integrity of the surface.For instance, if you're working with delicate stones like marble or glass, you'll require a finer grit diamond hand polishing pad to avoid excess abrasion. On the other hand, when dealing with tougher surfaces, such as granite or concrete, a coarser grit pad will be better suited to remove stubborn imperfections and achieve a smooth finish.Section 3: The Advantages of Diamond Hand Polishing Pads (300 words):1. Versatility: Diamond hand polishing pads can be used for a wide range of applications, including removing scratches, polishing edges, cleaning stains, and restoring a glossy finish to various materials.2. Precision: The handheld design of these pads enables you to target specific areas with precision, ensuring even polishing and consistent results.3. Portability: Diamond hand polishing pads are lightweight, making them highly portable. Whether you're working on-site or on a small DIY project, you can easily bring these pads along, ensuring convenience and ease of use.4. Cost-effective: Compared to other polishing methods, diamond hand pads offer a cost-effective solution. They are durable and can be reused multiple times, resulting in long-term savings.Section 4: Tips for Using Diamond Hand Polishing Pads (200 words):To achieve optimal results with diamond hand polishing pads, follow these tips:1. Select the right grit size: Different grit sizes are suitable for specific materials and the desired finish. Ensure you choose the appropriate grit to avoid damaging the surface or achieving an inconsistent result.2. Apply the right pressure: Applying excessive pressure can cause the pad to wear out quickly or create uneven finishes. Use a steady and gentle hand to maintain control throughout the polishing process.3. Regularly clean the pad: The accumulation of debris or residue can reduce the pad's effectiveness. Keep cleaning the pad regularly during the polishing process to maintain optimal performance.Conclusion (100 words):Diamond hand polishing pads are essential tools for any polishing project, offering versatility, precision, and cost-effectiveness. By understanding the unique advantages of these pads, selecting the right category for your specific needs, and following the proper techniques, you can achieve outstanding results with your polishing endeavors. So, whether you're a professional stonemason or a DIY enthusiast, harness the power of diamond hand polishing pads to embrace the joy of transforming ordinary surfaces into extraordinary works of art.