Understanding the Science Behind Metal Coordination Bonds: A Comprehensive Guide

By:Admin

In a significant breakthrough in material science, researchers at {} have developed a new Metal Coordination Bond that has the potential to revolutionize various industries, including electronic devices, aerospace, and medical implants.

Metal Coordination Bonds, also known as metal-organic frameworks, are a class of materials with a wide range of applications due to their unique properties, including high porosity, large surface area, and chemical stability. However, the challenge has always been finding a way to make these materials more stable and flexible for widespread use.

The team of researchers at {} has successfully addressed this challenge by developing a new Metal Coordination Bond that is stronger and more flexible than traditional metal-organic frameworks. This breakthrough has the potential to open up a host of new possibilities for these materials, making them more versatile and practical for various applications.

Metal Coordination Bonds are widely used in the electronics industry for the development of advanced sensors, catalysts, and energy storage devices. With the new and improved Metal Coordination Bond developed by {} researchers, these applications can be further enhanced, leading to more efficient and durable electronic devices.

Furthermore, the aerospace industry can benefit from this breakthrough, as Metal Coordination Bonds are used in the development of lightweight and durable materials for aircraft and spacecraft. The new Metal Coordination Bond developed by {} can significantly improve the strength and stability of these materials, leading to safer and more efficient aerospace technologies.

In addition to electronics and aerospace, the medical industry can also benefit from the advancements made in Metal Coordination Bond technology. Metal Coordination Bonds are commonly used in the development of medical implants and drug delivery systems. With the new and improved Metal Coordination Bond, these medical applications can be made more reliable and long-lasting, leading to better patient outcomes.

With their expertise in material science and engineering, {} has been at the forefront of developing innovative solutions for various industries. The company has a long history of creating cutting-edge materials and technologies that have had a significant impact on society and the economy.

{} has a team of highly skilled researchers and engineers who are dedicated to pushing the boundaries of what is possible in material science. Their commitment to innovation and excellence has led to numerous breakthroughs, including the development of the new Metal Coordination Bond.

The development of the new Metal Coordination Bond is a testament to {}'s ongoing commitment to advancing the field of material science and engineering. With this breakthrough, the company is poised to make a significant impact on the electronics, aerospace, and medical industries, among others.

The new Metal Coordination Bond developed by {} has the potential to revolutionize various industries, making electronic devices more efficient, aerospace technologies safer and more advanced, and medical implants more reliable and durable. This breakthrough is a testament to the innovative spirit and expertise of {} in the field of material science and engineering.

Company News & Blog

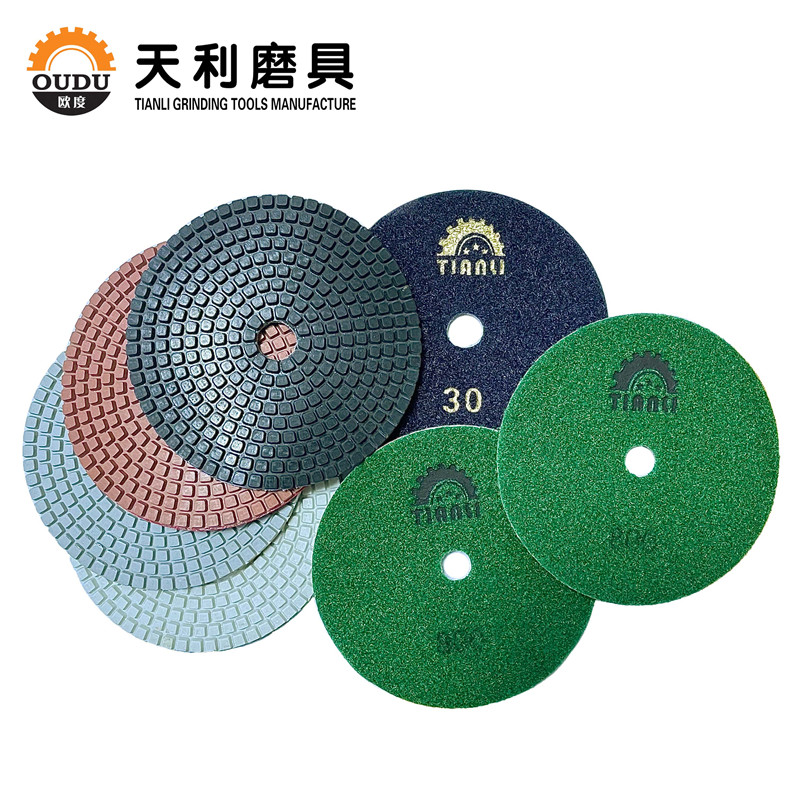

High-Quality 100mm Polishing Pads for Professional Detailing

The company, a leading provider of industrial tools, has recently introduced a new line of 100mm Polishing Pads to its wide range of products. These high-quality polishing pads are designed to meet the growing demand for precision and efficiency in the industrial sector.The 100mm Polishing Pads are made with top-grade materials and advanced technology to ensure superior performance and durability. These pads are suitable for use on a variety of surfaces, including metal, concrete, granite, and marble. The company's commitment to quality and innovation is reflected in the design and manufacturing process of these polishing pads, making them an ideal choice for professionals and DIY enthusiasts alike.The company has a long-standing reputation for delivering reliable and efficient industrial tools, and the addition of the 100mm Polishing Pads further solidifies its position as a trusted provider in the industry. With a focus on continuous improvement and customer satisfaction, the company has invested significant resources in research and development to bring cutting-edge products to the market.In addition to their exceptional performance, the 100mm Polishing Pads are also designed for ease of use. The company understands the importance of user-friendly tools in enhancing productivity, and these pads are engineered to provide a smooth and hassle-free polishing experience. Whether for heavy-duty industrial applications or intricate detailing work, these pads deliver consistent results with minimal effort.Furthermore, the 100mm Polishing Pads are part of the company's broader commitment to sustainability. By utilizing eco-friendly materials and energy-efficient manufacturing processes, the company strives to minimize its environmental footprint while delivering products that meet the highest standards of quality and safety.To support the launch of the 100mm Polishing Pads, the company is offering comprehensive customer support and technical assistance. With a team of experienced professionals, customers can rely on the company for expert guidance and assistance in choosing the right polishing pads for their specific requirements. This dedication to customer care is an integral part of the company's philosophy, ensuring that every customer receives the support they need to achieve optimal results.The introduction of the 100mm Polishing Pads is a testament to the company's ongoing commitment to innovation and excellence. By leveraging its expertise and resources, the company continues to expand its product offerings and provide solutions that meet the evolving needs of the industrial sector. With a strong emphasis on quality, performance, and sustainability, these polishing pads are poised to make a significant impact in the market.As the industrial sector continues to evolve, the demand for high-quality tools and equipment remains constant. The release of the 100mm Polishing Pads represents a major milestone for the company and reinforces its position as a leader in the industry. With a focus on innovation and customer satisfaction, the company is well-positioned to meet the diverse needs of its clientele and maintain its reputation as a trusted provider of industrial tools.

Discover the Strength of Metal Bonds: Which Alloys Are the Strongest?

Replace brand name with [Metal Manufacturer]Strongest Metal Bonds Combine with [Metal Manufacturer]'s Cutting-Edge Technology[City, Date] - [Metal Manufacturer], a leading global innovator in the field of metal engineering, announced today the development of a revolutionary technology that enables the creation of the strongest metal bonds ever seen. Leveraging their cutting-edge expertise, [Metal Manufacturer] has broken new ground, offering a game-changing solution for various industries that rely on durable metal structures. This groundbreaking achievement has the potential to redefine the way we think about metal bonds and revolutionize the world of engineering.[Metal Manufacturer] is renowned for its commitment to excellence and its relentless pursuit of technological advancement. With a highly experienced team of metallurgists and engineers, the company has continuously pushed the boundaries of what is possible in the field of metal fabrication. Now, they have taken a significant leap forward with their latest innovation: the creation of the strongest metal bonds to date.For decades, engineers and scientists have strived to develop metal bonds with unparalleled strength and durability. Existing bonding methods often fell short of meeting the demanding requirements of industries such as aerospace, automotive, and construction. [Metal Manufacturer]'s groundbreaking technology has changed the game entirely.The key to [Metal Manufacturer]'s success lies in their proprietary bonding process, which combines cutting-edge metallurgical techniques with state-of-the-art equipment. Through meticulous research and rigorous testing, their team has developed a method that enables the formation of incredibly strong metal-to-metal bonds. These bonds exhibit outstanding tensile strength, resistance to external forces, and long-term stability, surpassing anything previously achieved in the industry.The applications of this breakthrough technology are vast. In the aerospace industry, for instance, the ability to create reliable metal bonds is crucial. The newly developed bonds by [Metal Manufacturer] open doors for the production of lightweight yet robust components for aircraft and spacecraft, leading to enhanced fuel efficiency and improved performance. Similarly, the automotive sector can tap into this innovation to develop safer vehicles with strengthened structural integrity.Moreover, this advancement has the potential to revolutionize the construction industry. By implementing [Metal Manufacturer]'s technology, builders and architects could construct buildings, bridges, and other infrastructure with increased durability and resilience, ensuring their longevity even in harsh environmental conditions. This breakthrough can significantly reduce maintenance costs and increase the safety of critical structures."We are extremely proud of the progress we have made in creating the strongest metal bonds ever achieved," remarked [Spokesperson], a senior engineer at [Metal Manufacturer]. "This breakthrough is the result of years of dedicated research, and we believe it will have a transformative impact on various industries. From aerospace to automotive, our technology will enable engineers to push boundaries and usher in a new era of durability and reliability."The groundbreaking innovation by [Metal Manufacturer] also comes at a critical time of growing momentum in sustainable engineering. With a strong focus on environmental responsibility, [Metal Manufacturer]'s technology offers the potential to reduce waste and enhance resource efficiency. By creating stronger, more durable metal bonds, products built with this technology will have a longer life span, reducing the need for frequent replacements and, consequently, minimizing the environmental footprint.[Metal Manufacturer] plans to license this technology to industry partners across the globe, ensuring widespread access to this groundbreaking innovation. The company invites interested parties to get in touch to explore potential collaborations and discuss opportunities for adoption in a wide range of sectors.In conclusion, [Metal Manufacturer]'s breakthrough in creating the strongest metal bonds ever seen is set to revolutionize various industries. The technology's potential impact cannot be overstated, from creating safer aircraft and more durable cars to constructing resilient infrastructure. Moreover, the innovation aligns with the increasing focus on sustainability, offering a solution that reduces waste and enhances resource efficiency. [Metal Manufacturer] continues to push the boundaries of what is possible in metal engineering, setting new standards for durability and reliability in the process.

Shop high-quality polishing and buffing pads for car detailing

: Tips and Tricks for Effective Auto DetailingAuto detailing enthusiasts know that one of the most important tools in their arsenal is a good set of polishing pads. These small but mighty accessories can help you achieve the perfect shine on your car's exterior, and can make a big difference in your overall detailing results. But with so many types of polishing pads on the market, how do you know which ones to choose? And once you have your pads, how do you use them effectively? In this blog post, we'll explore some tips and tricks for cleaning car polishing pads, as well as how to select the best pads for your specific detailing needs.Types of Polishing PadsBefore we dive into the specifics of polishing pad maintenance and use, let's take a quick look at the different types of pads available on the market. Some of the most common types include:- Foam pads: These pads are made of foam and are available in a variety of colors and densities. The softer the foam, the gentler the pad will be on your car's paint. Some foam pads are designed for cutting or heavy polishing, while others are better suited for finishing work.- Microfiber pads: These pads are made of small fibers that can help to buff out scratches and swirls. They are often used in conjunction with a polishing compound to remove light imperfections in the paint.- Wool pads: These pads are made from natural or synthetic wool fibers. They are typically used for heavy polishing or compounding, as their abrasive nature can remove deep scratches or other defects in the paint.When selecting polishing pads for your detailing kit, consider the type of work you will be performing. If you're just looking to do some light polishing and finishing work, a soft foam or microfiber pad is likely your best bet. For more intensive work, such as removing deep scratches or heavy oxidation, a wool pad may be necessary.Cleaning Car Polishing PadsOnce you have your polishing pads, it's important to keep them clean and free of debris. Over time, polishing pads can become clogged with excess polish or dirt, which can reduce their effectiveness. To clean your pads, follow these simple steps:- Rinse the pad with cool water to remove any loose debris.- Apply a small amount of pad cleaner or degreaser to the pad.- Massage the cleaner into the pad using a soft bristled brush.- Rinse the pad thoroughly with cool water.- Squeeze out any excess water and allow the pad to air dry.Some polishing pad manufacturers also recommend machine washing their pads in a gentle cycle, but be sure to check the manufacturer's instructions before doing so.Tips for Effective Polishing Pad UseNow that your polishing pads are clean and free of debris, it's time to put them to use. Here are some tips for effective polishing pad usage:- Use the right pad for the job: As we mentioned earlier, different types of pads are better suited for different types of detailing work. Make sure you select the appropriate pad for the task at hand.- Use the right amount of product: Too much polish or compound can clog your pad and reduce its effectiveness. Use small amounts of product and build up as needed.- Keep your pad level: When using your buffer, be sure to keep your pad level to the surface of your car. Tilting the pad can cause uneven results and potentially damage your paint.- Work in small sections: Focus on one small section at a time, working the polish into the paint until the scratches or defects are removed.- Clean your pad frequently: As you work, your polishing pad will accumulate debris and excess product. Clean it frequently to prevent clogging and maintain optimal performance.By following these tips and tricks, you can effectively use and maintain your polishing pads for optimal auto detailing results. Happy buffing!

Suppliers of Abrasives and Welding Equipment: Reviews and Product Info

Title: Enhancing Metal Finishing Processes with High-Quality AbrasivesIntroduction (approx. 100 words):When it comes to achieving stellar results in metal finishing processes, using top-notch abrasives is crucial. From sandpapers and grinding wheels to polishing compounds, these abrasive materials play a significant role in refining metal surfaces, removing imperfections, and ensuring a smooth end result. In this blog, we will delve into the world of abrasives, shedding light on the importance of choosing reputable suppliers and the benefits of utilizing high-quality metal abrasives. Join us as we explore the key factors to consider when selecting abrasives and learn how they can elevate your metal finishing processes to new heights.1. Understanding the Role of Abrasives in Metal Finishing (approx. 200 words):Metal finishing encompasses a wide range of processes, such as abrasive blasting, grinding, sanding, and polishing. These techniques aim to improve the appearance, functionality, and longevity of metal surfaces. At the core of each process lies the abrasive materials, which streamline the entire metal finishing journey.Abrasives serve as the key agents of change in metal finishing by removing unwanted material layers, leveling imperfections, and ensuring a uniform surface. They can be categorized based on their composition, size, and intended purpose. From natural abrasive minerals like garnet and diamond to synthetic options like aluminum oxide and silicon carbide, suppliers offer an extensive range of metal abrasives suitable for various applications.2. The Importance of Reliable Abrasive Suppliers (approx. 250 words):When selecting a supplier for your metal abrasives, it is crucial to prioritize reliability, quality, and customer service. Choosing the wrong supplier can lead to subpar products, delays, and overall dissatisfaction. Therefore, thorough research and consideration are necessary to make an informed decision.Reliable suppliers boast impeccable track records and positive customer reviews. These indicators of customer satisfaction are a testament to the supplier's commitment to quality. By collaborating with established suppliers, you gain access to a wide range of high-quality metal abrasives that will enhance your metal finishing processes.Additionally, reputable suppliers often provide ample product and service information, empowering customers to make well-informed purchasing decisions. Detailed profiles of suppliers allow you to understand their expertise, experience, and capabilities, enabling you to choose a partner that aligns with your specific needs.3. Benefits of High-Quality Metal Abrasives (approx. 250 words):Investing in high-quality metal abrasives can transform your metal finishing processes and yield remarkable results. Here are some key benefits of using premium abrasives:- Enhanced Efficiency: High-quality abrasives exhibit superior cutting, grinding, and polishing capabilities, allowing you to accomplish tasks more efficiently, saving both time and resources.- Superior Surface Finish: Premium abrasives enable you to achieve impeccable surface finishes by removing imperfections, scratches, and roughness efficiently, resulting in aesthetically pleasing and durable metal surfaces.- Extended Abrasive Lifespan: Top-notch metal abrasives often boast increased durability and longevity, reducing the need for frequent replacements and leading to cost savings in the long run.- Consistency and Precision: Reliable suppliers ensure consistent quality across their abrasive products, promoting precise performance and predictable outcomes in your metal finishing processes.Conclusion (approx. 150 words):Choosing the right supplier for your metal abrasive needs is paramount to achieve exceptional results in metal finishing processes. By selecting reputable suppliers and investing in high-quality metal abrasives, you can enhance efficiency, improve surface finishes, extend abrasives' lifespan, and achieve consistent and precise outcomes. Take advantage of the wide array of metal abrasives available in the market and revolutionize your metal finishing processes today.

Versatile Diamond Polishing Pads for Granite, Marble, Stone, and More

Diamond Resin Dry Polishing Pads: Perfecting the Art of Stone PolishingDiamond polishing pads have become an indispensable tool in the field of stone polishing. With their ability to enhance the appearance of various types of surfaces such as granite, marble, engineered and natural stone, concrete, terrazzo, countertops, and floors, these pads have revolutionized the way we finish and beautify these materials. Among the many options available, Diamond Resin Dry Polishing Pads stand out as one of the best choices for achieving impeccable results. In this blog, we will explore the features, benefits, and applications of these remarkable pads that have taken the industry by storm.The first thing that sets Diamond Resin Dry Polishing Pads apart is their composition. Crafted using the finest quality of diamonds and resin, these pads are designed to deliver exceptional polishing performance. The diamonds embedded in the resin matrix provide the necessary cutting power, while the resin acts as a bonding agent, ensuring durability and longevity.One of the primary advantages of using Diamond Resin Dry Polishing Pads is their versatility. They can be used on a variety of surfaces, ranging from granite to marble, engineered and natural stone, concrete, terrazzo, countertops, and floors. This gives contractors and polishing professionals the flexibility to work on different projects without the need for multiple sets of pads. Whether you are polishing a kitchen countertop or a luxurious marble floor, Diamond Resin Dry Polishing Pads are your go-to solution.Another remarkable feature of these pads is their ability to perform effectively in dry polishing applications. Traditionally, wet polishing has been the preferred method due to its cooling effect, dust suppression, and easier debris removal. However, dry polishing offers its own set of advantages, such as convenience, versatility, and cost-effectiveness. Diamond Resin Dry Polishing Pads excel in this area, providing a superior dry polishing experience by delivering exceptional results without the need for water or slurry.Additionally, Diamond Resin Dry Polishing Pads offer enhanced flexibility and adaptability. Their design allows them to conform to the shape and contours of the surface being polished, ensuring even distribution of pressure and an immaculate finish. This makes them an ideal choice for intricate designs and curved surfaces, where achieving a perfect polish can be quite challenging.When it comes to achieving a high-gloss shine, Diamond Resin Dry Polishing Pads are second to none. The combination of diamond and resin creates a synergy that not only removes scratches and imperfections but also imparts a lustrous and reflective finish to the surface. This property is particularly significant in applications where aesthetics play a crucial role, such as luxury hotels, high-end residential properties, and commercial spaces.In terms of performance, Diamond Resin Dry Polishing Pads offer exceptional efficiency and endurance. The diamonds embedded in the pads ensure consistent cutting power, allowing for faster material removal and uniform polishing. This, coupled with their exceptional durability, makes them a cost-effective investment that can withstand rigorous use and produce superior results over an extended period.In conclusion, Diamond Resin Dry Polishing Pads have become a game-changer in the world of stone polishing. Their ability to polish various surfaces, adapt to different shapes, and deliver impeccable results without the need for water or slurry make them an essential tool for contractors and polishing professionals. Whether you are looking to enhance the beauty of your granite countertop, transform your marble floors, or revamp your terrazzo surfaces, Diamond Resin Dry Polishing Pads are your trusted companion. Invest in these pads and elevate your stone polishing projects to new heights of perfection.

Diamond Holder Tool: The Ultimate SEO Title to Optimize Your Strategies

**Title: Revolutionary Diamond Holder Tool Revolutionizes Jewelry Manufacturing****Introduction**Diamond Holder Tool, a revolutionary piece of equipment in the jewelry manufacturing industry, is set to transform the way diamonds are handled and set in jewelry. This innovative tool, developed by a leading jewelry equipment manufacturer, aims to optimize the stone-setting process by improving precision, efficiency, and safety. With its unique design and advanced features, the Diamond Holder Tool promises to streamline manufacturing processes, reduce costs, and elevate the overall quality of diamond-set jewelry. This article delves into the key features and benefits of this groundbreaking tool, emphasizing its potential to revolutionize the jewelry manufacturing industry.**Enhanced Precision and Efficiency**The Diamond Holder Tool's design centers around its ability to securely hold diamonds of various sizes while granting jewelers maximum control and precision during the setting process. Unlike traditional diamond holders, this tool combines a specialized gripping mechanism with state-of-the-art micro-adjustment technology, enabling jewelers to securely position diamonds with unrivaled accuracy. The tool's intuitive design ensures that diamonds remain firmly in place throughout the setting process, eliminating the risk of accidental displacement or damage.This heightened precision not only decreases the possibility of mistakes but also significantly reduces the time and effort required for precise stone placement. With the Diamond Holder Tool, jewelers can execute intricate diamond setting designs with ease, expediting the manufacturing timeline and increasing overall productivity. The tool's efficiency-enhancing features make it an indispensable asset for high-volume jewelry manufacturers, enabling them to meet demanding production deadlines without compromising quality.**Enhanced Safety and Security**Jewelers often grapple with the precarious task of securing diamonds while minimizing the risk of injury. The Diamond Holder Tool incorporates cutting-edge safety features that are designed to protect both the jewelers and the valuable gems they work with. Equipped with a comprehensive locking mechanism, the tool ensures that diamonds remain firmly in place at all times, reducing the risk of accidental slippage or falling. This eliminates the need for jewelers to hold and maneuver the diamonds manually, minimizing the potential for accidental injury.Furthermore, the Diamond Holder Tool's ergonomically designed grip enhances comfort and reduces hand strain during extended work periods. The tool's lightweight construction and optimized handle design contribute to a seamless and effortless user experience, allowing jewelers to maintain focus and attentiveness while working. By prioritizing worker safety, the Diamond Holder Tool establishes itself as a key asset in the pursuit of injury-free, efficient, and productive jewelry manufacturing processes.**Streamlined Manufacturing Process and Cost Reduction**The incorporation of the Diamond Holder Tool into existing jewelry manufacturing workflows can result in significant cost savings. Its innovative design eliminates the need for additional equipment or intricate setups, simplifying the manufacturing process and reducing investment costs. Moreover, the tool's efficiency and precision contribute to a reduction in labor costs, as jewelers can complete stone-setting tasks in a shorter amount of time. This not only accelerates the production cycle but also allows manufacturers to allocate resources more efficiently, boosting profitability.By empowering jewelers to achieve higher levels of precision and efficiency, the Diamond Holder Tool facilitates the production of high-quality diamond-set jewelry at a faster pace. This not only enables manufacturers to meet growing market demands but also provides them with a competitive edge within the industry. Moreover, the tool's user-friendly design requires minimal training, allowing manufacturers to seamlessly integrate it into their existing workflows without significant disruptions or downtime.**Conclusion**The Diamond Holder Tool's introduction into the jewelry manufacturing industry promises to revolutionize the way diamonds are set in jewelry. With its focus on precision, efficiency, safety, and cost reduction, this groundbreaking tool is set to become an essential asset for jewelers and manufacturers worldwide. The Diamond Holder Tool's impact on the industry is expected to be transformative, promoting streamlined manufacturing processes, enhancing worker safety, and ultimately elevating the overall quality of diamond-set jewelry. As the jewelry manufacturing industry continues to evolve, this innovative tool is poised to play an instrumental role in its advancement.

High-Quality Wet Polishing Pads for Granite: What You Need to Know

In the world of granite and stone fabrication, having the right tools and equipment is essential for achieving high-quality results. One of the most critical tools in this industry is wet polishing pads, which are used for grinding, honing, and polishing granite and other natural stones to achieve a smooth and glossy finish. One of the leading providers of wet polishing pads for granite is a company that has been at the forefront of the stone fabrication industry for over a decade. With a commitment to providing high-quality products and exceptional customer service, this company has become a trusted name among fabricators and contractors.The wet polishing pads offered by this company are designed to deliver outstanding performance and durability, allowing fabricators to achieve precise and consistent results with every use. These pads are engineered to minimize heat generation during the polishing process, reducing the risk of thermal shock to the stone and ensuring a superior finish.In addition to their exceptional performance, the wet polishing pads offered by this company are also designed for ease of use, featuring a quick and easy attachment system that allows for fast pad changes during the fabrication process. This not only improves efficiency but also reduces downtime, allowing fabricators to complete their projects in a timely manner.With a strong focus on innovation, this company is constantly working to improve and expand its product line to meet the evolving needs of the stone fabrication industry. They are committed to staying ahead of the curve and are always looking for ways to enhance the performance and durability of their wet polishing pads.To ensure the quality and reliability of their products, this company conducts rigorous testing and quality control measures at every stage of the manufacturing process. This dedication to quality has earned them a reputation for excellence within the industry, making them a go-to source for wet polishing pads for granite and other natural stones.Moreover, this company is dedicated to providing exceptional customer service, offering expert guidance and support to help fabricators choose the right tools and equipment for their specific needs. Their team of knowledgeable professionals is always available to answer questions and provide assistance, ensuring that their customers have a positive experience with every purchase.In addition to wet polishing pads, this company also offers a wide range of other essential tools and equipment for stone fabrication, including diamond blades, grinding wheels, and polishing compounds. Their comprehensive product line makes them a one-stop shop for fabricators looking to stock up on high-quality supplies for their projects.Overall, the wet polishing pads offered by this company are a testament to their commitment to quality, innovation, and customer satisfaction. With a focus on performance, durability, and ease of use, these pads are an essential tool for any fabricator looking to achieve professional results in granite and stone fabrication.As the stone fabrication industry continues to evolve, this company remains dedicated to staying at the forefront, offering cutting-edge products and exceptional service to meet the needs of fabricators and contractors. With a solid reputation for excellence and a track record of success, they are a trusted partner for professionals in the industry.

New Study Reveals Metal Bonding Properties Between Multiple Metal Types

Metal Bonds With MetalIn the dynamic and constantly evolving world of manufacturing, the search for innovative solutions to improve the efficiency and strength of metal bonds has led to a breakthrough development. A new technology introduced by {Company Name} is revolutionizing the way metals bond with each other, offering a promising solution for various industries including automotive, aerospace, and construction.{Company Name} is a leading manufacturer of advanced materials and technology solutions, specializing in creating high-performance products for a wide range of applications. With a strong emphasis on research and development, the company has managed to stay ahead of the curve by consistently introducing cutting-edge innovations that address the complex needs of its customers.The latest breakthrough from {Company Name} comes in the form of a proprietary metal bonding technology that offers superior strength, durability, and performance compared to traditional bonding methods. By leveraging the unique properties of {Company Name}'s advanced materials, this new technology enables a seamless and robust bond between different metals, providing a significant advantage for manufacturers seeking to enhance the structural integrity of their products.One of the key features of this technology is its ability to create bonds that are not only strong and reliable but also highly resistant to corrosion, fatigue, and extreme temperatures. This makes it an ideal solution for a wide range of applications where the integrity of metal bonds is critical, such as in the construction of high-performance vehicles, aircraft, industrial machinery, and infrastructure.In addition to its exceptional performance characteristics, {Company Name}'s metal bonding technology is also designed to be environmentally friendly, meeting the growing demand for sustainable manufacturing practices. The technology eliminates the need for harsh chemicals and excessive energy consumption, contributing to a more eco-friendly production process while delivering superior results.The development of this groundbreaking technology is the result of {Company Name}'s unwavering commitment to innovation and continuous improvement. The company's team of research and development engineers, material scientists, and industry experts have worked tirelessly to push the boundaries of what is possible in metal bonding, leveraging their deep expertise and technical know-how to create a game-changing solution for the industry.{Company Name} has also invested significantly in state-of-the-art manufacturing facilities and quality control processes to ensure that its metal bonding technology meets the highest standards of performance and reliability. By maintaining a rigorous focus on quality, the company aims to provide its customers with a product that delivers consistent results and exceeds their expectations.The introduction of {Company Name}'s metal bonding technology is poised to have a transformative impact on the manufacturing industry, offering a versatile and cost-effective solution for enhancing the performance and durability of metal bonds across various applications. As industries continue to push the boundaries of what is possible, the demand for advanced bonding solutions that can meet the rigorous requirements of modern manufacturing will only continue to grow.With its unwavering commitment to excellence and a track record of successful innovation, {Company Name} is well-positioned to lead the industry into a new era of metal bonding. The company's dedication to pushing the boundaries of material science and engineering has enabled it to deliver a breakthrough technology that has the potential to reshape the way metals bond with each other, opening up new possibilities for manufacturers looking to elevate the performance of their products.As {Company Name} continues to advance its technology and explore new frontiers in material science, the future looks bright for the industry, with innovative solutions like its metal bonding technology paving the way for unprecedented advancements in manufacturing. With its proven track record of success and a strong commitment to driving progress, {Company Name} is set to play a pivotal role in shaping the future of metal bonding and the manufacturing industry as a whole.

On-Site Dry Polishing Pads for Stone and Concrete Surfaces: An Effective Solution for Marble, Granite, and More

Dry diamond polishing pads are a versatile and cost-effective solution for on-site dry polishing of marble, granite, and other natural stones. These pads are perfect for the DIY enthusiast, contractor, or anyone looking for an inexpensive and efficient way to polish stone surfaces.Dry diamond polishing pads are designed for use on the most common types of stone, including granite, marble, and concrete. They can be used on walls, floors, countertops, and other surfaces, making them a great option for a variety of residential and commercial applications.The benefits of using dry diamond polishing pads for granite and other stone surfaces are numerous. First, they offer excellent performance at a low cost. Because they are designed for dry use, there is no need to pay for costly water and electricity. Additionally, since dry diamond polishing pads are lightweight and easy to use, they do not require the use of heavy machinery or specialized equipment.Another benefit of using dry diamond polishing pads is their versatility. They come in a variety of different grits, which makes it easy to achieve the desired level of finish. From rough grinding to fine polishing, there is a pad available to suit every need.Finally, dry diamond polishing pads are a great choice for environmentally-conscious consumers. Since they are designed for use without water, there is no need to worry about water runoff or other environmental concerns.In conclusion, if you are looking for an efficient, cost-effective, and eco-friendly way to polish your stone surfaces, look no further than dry diamond polishing pads. With their versatility, affordability, and ease of use, these pads are the perfect solution for anyone looking to achieve a beautiful and professional-looking finish on their granite or other natural stone surfaces.

High-Quality Polishing Pads for Angle Grinders - Perfect for Marble, Granite, Concrete, and Glass - Global Shipping Available

Polishing Pads for Angle Grinder: The Ultimate Guide for Polishing Various MaterialsAre you looking for a versatile and efficient way to polish materials such as marble, granite, concrete, or even glass? Look no further! In this comprehensive guide, we will explore the world of polishing pads for angle grinders, providing valuable insights and tips on how to achieve a flawless finish. Whether you are a professional stone fabricator or simply an avid DIY enthusiast, understanding the different types of grinder pads for polishing will undoubtedly take your polishing game to the next level.Before diving into the details of grinder pads for polishing, let's take a moment to appreciate the significance of the angle grinder itself. Owing to its compact size and high rotational speed, the angle grinder has become a popular choice among professionals and amateurs alike. Its versatile nature allows it to perform a plethora of tasks, including cutting, grinding, and, of course, polishing. Pairing this mighty tool with the right polishing pad can transform it into a powerful weapon for achieving spectacular results.Now, let's shift our focus to the star of our discussion – polishing pads. Polishing pads are essential tools used to refine and bring out the natural beauty of various materials. These pads consist of a base material with an abrasive surface designed to work effectively on different surfaces. There are several factors to consider when selecting the appropriate pad for a specific material, such as hardness, grit size, and pad composition.When it comes to hardness, it is crucial to match the pad to the material you are working on. For instance, softer pads are recommended for delicate surfaces like glass, while harder ones are more suitable for granite or concrete. This careful selection ensures optimal results without causing any damage to the material.Another crucial aspect to consider is the grit size of the pad. Grit size refers to the size of the abrasive particles embedded in the pad. The general rule of thumb is to start with larger grit sizes and progressively move to finer ones for a flawless finish. Coarser grit sizes, such as 50 or 100, are ideal for initial material removal or leveling uneven surfaces, while finer grit sizes like 400 or 800 are perfect for achieving a mirror-like shine.In terms of pad composition, there are several options available on the market. Diamond polishing pads, for example, are widely recognized for their durability and effectiveness. These pads use diamond particles bonded to the pad surface to perform efficient material removal and polishing. Their high quality ensures a longer lifespan and superior performance compared to traditional pads.Additionally, resin polishing pads are gaining popularity due to their versatility and user-friendliness. These pads utilize a combination of resin and diamond particles to provide excellent polishing results. Their flexible nature allows them to adapt to irregular surfaces, making them ideal for rounded edges or curved areas.One noteworthy feature of many polishing pads is the presence of water holes. These holes play a crucial role in cooling down the pad during the polishing process, reducing the risk of overheating and ensuring smoother operations. It is advisable to select pads with a suitable number and arrangement of water holes, depending on the intensity and duration of the polishing job at hand.Now that we have covered the essentials of polishing pads for angle grinders, it's time to highlight the significance of international shipping. If you are a professional stone fabricator or a passionate DIYer, sourcing high-quality grinder pads for polishing locally might not always be possible or financially feasible. Nevertheless, many reputable online platforms offer international shipping services, enabling you to access a wide range of polishing pads at competitive prices, irrespective of your geographic location.In conclusion, grinder pads for polishing are indispensable tools for achieving exceptional results when working with materials like marble, granite, concrete, and glass. By understanding the importance of hardness, grit size, and pad composition, you can select the perfect pad for your specific needs. Furthermore, considering the advantages of online marketplaces that offer international shipping, you can effortlessly access high-quality and affordable polishing pads from anywhere in the world. So, gear up your angle grinder, grab the appropriate polishing pads, and get ready to transform ordinary surfaces into stunning masterpieces!