Understanding the Concept of Nonmetal Bonds in Chemistry

By:Admin

The company, {} is a global leader in the production and supply of nonmetal bonds. With a strong focus on innovation and quality, they have established themselves as a trusted partner for businesses in various industries. Their nonmetal bonds are designed to provide superior adhesion and bonding strength for a wide range of materials, including plastics, composites, rubber, and other nonmetal substrates. This has made {} a preferred choice for companies looking for reliable and efficient nonmetal bonding solutions.

One of the key advantages of nonmetal bonds is their versatility. They can be used in a wide range of industries, including automotive, aerospace, electronics, construction, and more. This makes them an essential component in the production of various products, from automotive parts to electronic devices. With the increasing demand for lightweight and durable materials, nonmetal bonds have become an indispensable part of modern manufacturing processes.

The nonmetal bonds produced by {} are designed to meet the highest standards of quality and performance. Their team of experienced engineers and researchers work tirelessly to develop innovative bonding solutions that cater to the evolving needs of the industry. This dedication to excellence has earned {} a reputation for delivering superior nonmetal bonds that exceed customer expectations.

In addition to their high-quality products, {} also provides exceptional technical support and customer service. Their team of experts is on hand to provide guidance and assistance to companies looking to incorporate nonmetal bonds into their manufacturing processes. This ensures that their customers are able to optimize the use of nonmetal bonds and achieve the best possible results in their production operations.

As a responsible corporate citizen, {} is also committed to environmental sustainability. They have invested in research and development to create nonmetal bonding solutions that are environmentally friendly and safe for use. This dedication to sustainability has made {} a preferred partner for companies looking to minimize their environmental impact while maintaining high standards of quality and performance.

The future of nonmetal bonds looks promising, with a growing demand for these innovative bonding solutions across various industries. Companies like {} are poised to lead the way in the development and production of nonmetal bonds that are tailored to meet the specific needs of their customers. With their unwavering commitment to innovation, quality, and sustainability, {} is well-positioned to continue making significant contributions to the advancement of nonmetal bonding technology.

In conclusion, nonmetal bonds have emerged as a game-changing technology in the field of industrial manufacturing. With their exceptional strength, versatility, and environmental sustainability, nonmetal bonds are set to become an essential component in the production of a wide range of products. Companies like {} are at the forefront of this innovation, providing high-quality nonmetal bonds and exceptional technical support to their customers. As the demand for nonmetal bonding solutions continues to grow, {} is well-prepared to meet the evolving needs of the industry and drive the continued advancement of nonmetal bonding technology.

Company News & Blog

Borazon Grinding Wheels: A Comprehensive GuideWhen it comes to high-performance grinding, it's essential to use the right tools for the job. That's where Borazon grinding wheels come in. These wheels are made from cubic boron nitride (CBN), a material that is second only to diamond in terms of hardness. In this blog, we'll explore everything you need to know about Borazon grinding wheels, including their advantages, applications, and how to choose the right one for your needs.Advantages of Borazon Grinding WheelsThe main advantage of Borazon grinding wheels is their exceptional hardness. This makes them ideal for grinding hard materials that are difficult to process with traditional grinding wheels. Borazon wheels also have high abrasive resistance, which means they last longer and require less frequent replacement. Other advantages of these wheels include:• Excellent heat resistance: Borazon wheels can withstand high temperatures without cracking or degrading, making them ideal for applications that generate a lot of heat.• Superior surface finish: Borazon wheels create a smooth, precise surface finish that is free from burrs and other imperfections.• Versatile applications: Borazon wheels can be used to grind a wide range of materials, including hardened steels, cast iron, and superalloys.Applications of Borazon Grinding WheelsBorazon grinding wheels are used in a variety of applications, including:• Aerospace: Borazon wheels are used to grind turbine blades, engine parts, and other components used in the aerospace industry.• Automotive: These wheels are also used in the automotive industry to grind crankshafts, camshafts, and other engine components.• Medical: Borazon wheels are used to grind medical implants, such as hip replacements and dental implants, to ensure a precise fit.• Tool and die: These wheels can be used to grind cutting tools, such as drill bits, taps, and end mills, as well as dies and molds.Choosing the Right Borazon Grinding WheelChoosing the right Borazon grinding wheel depends on several factors, including the material you're grinding, the desired finish, and the type of machine you're using. Here are some tips to help you choose the right wheel:• Determine the hardness of the material you're grinding: Borazon wheels are best suited for grinding hard materials, so if you're grinding a soft material, you may want to consider a different type of wheel.• Consider the grit size: Borazon wheels come in a range of grit sizes, which determine how coarse or fine the abrasive particles are. Choose a finer grit for a smoother finish and a coarser grit for a more aggressive cut.• Check the compatibility with your machine: Make sure that the wheel you choose is compatible with your grinding machine. This includes checking the wheel diameter, arbor size, and maximum RPM.• Consult with a supplier: If you're unsure which wheel to choose, consult with a supplier who specializes in Borazon grinding wheels. They can help you determine the best option based on your specific needs.ConclusionBorazon grinding wheels are an essential tool for grinding hard materials to a precise finish. With their exceptional hardness, heat resistance, and abrasive resistance, these wheels offer many advantages over traditional grinding wheels. When choosing a Borazon wheel, consider the material you're grinding, the desired finish, and the compatibility with your machine. With the right wheel, you can achieve superior results and increase productivity in your grinding operations.

Durable Tool Holder Options for Your Needs - Find the Best Solution Here

Diamond Tool Holder Revolutionizes Cutting Efficiency in Manufacturing IndustryIn the ever-evolving world of manufacturing, efficiency is key. Companies are constantly seeking new technologies and tools to improve their productivity and ultimately their bottom line. One company leading the charge in this endeavor is (company name). With their revolutionary Diamond Tool Holder, they are changing the game when it comes to cutting efficiency in the manufacturing industry.The Diamond Tool Holder, as the name suggests, is a cutting-edge tool holder that utilizes diamond technology to improve cutting efficiency and performance. This innovative tool is designed to provide a longer tool life, improved surface finish, and increased productivity for a wide range of manufacturing applications.The (company name) is a leading manufacturer of high-precision tools and tooling systems, with a strong focus on innovation and technology. Their team of expert engineers and designers are dedicated to developing cutting-edge solutions that meet the ever-growing demands of the manufacturing industry. With a commitment to quality and performance, they have earned a reputation as a trusted partner for companies looking to improve their manufacturing processes.The Diamond Tool Holder is the latest addition to their impressive portfolio of products. It is designed to address the common challenges faced by manufacturers when it comes to cutting tools, such as tool wear, chip control, and surface finish. By using diamond technology, the tool holder is able to provide a superior cutting experience that delivers exceptional results.One of the key advantages of the Diamond Tool Holder is its extended tool life. The use of diamond technology significantly reduces tool wear, allowing for longer-lasting performance and fewer tool changes. This not only saves time but also reduces the overall cost of tooling for manufacturers. Additionally, the improved surface finish achieved with the Diamond Tool Holder helps to enhance the quality of the end product, providing a competitive edge in the market.Moreover, the Diamond Tool Holder offers increased productivity by delivering faster cutting speeds and improved chip control. This allows manufacturers to complete jobs more efficiently, ultimately leading to a higher output and a more streamlined production process.The Diamond Tool Holder is suitable for a wide range of materials, including metals, composites, and ceramics. Its versatility makes it an ideal choice for various industries, including aerospace, automotive, medical, and general manufacturing. Whether it's milling, turning, or drilling, the Diamond Tool Holder delivers exceptional performance across the board.In addition to its cutting-edge technology, the Diamond Tool Holder is also designed with user-friendly features that make it easy to install and use. Its ergonomic design and simple operation ensure that manufacturers can seamlessly integrate it into their existing processes without any hassle.As the manufacturing industry continues to evolve, the demand for advanced cutting tools that can keep up with the pace is only going to grow. With the Diamond Tool Holder, (company name) is at the forefront of this change, providing a solution that not only meets the current needs of manufacturers but also sets the stage for future advancements in cutting technology.The Diamond Tool Holder is a testament to (company name)'s commitment to innovation and excellence. By leveraging the power of diamond technology, they have created a tool that is set to revolutionize cutting efficiency in the manufacturing industry. As companies strive to stay ahead of the competition, the Diamond Tool Holder offers a clear advantage, delivering superior performance, extended tool life, and increased productivity. With this breakthrough tool, (company name) continues to solidify its position as a leader in the world of high-precision tools and tooling systems.

Rewrite for SEO optimization: Supplier for Wet Polishing Pads - Weihai Chengxun Import & Export Co., Ltd., offering a wide range of granite slabs, tombstones, granite countertops, vanity tops, monuments, slate and marble fireplaces, wooden shutters, film faced plywood, garden fountains, water pots, marble carvings, diamond tools, cutting blades, and polishing pads.

Diamond Wet Polishing Pads: The Ultimate Guide to Achieving Perfect Stone FinishPolishing is an important process in the production of stone surfaces. It is the final step that helps improve the aesthetic value of the stone. Because of the huge demand for stone products, manufacturers are always looking for ways to improve their production processes to ensure they deliver top-quality products. This has led to the production of different types of polishing pads. Diamond wet polishing pads are currently the most popular type of polishing pads on the market. In this article, we’ll take a closer look at diamond wet polishing pads.What are diamond wet polishing pads?Diamond wet polishing pads are polishing tools used to polish stone surfaces, such as granite, marble, and concrete. They are called "diamond" wet polishing pads because they are made of diamond particles. This means that they are designed to handle tougher materials, unlike traditional polishing pads. They are called "wet" polishing pads because they are used in combination with water. The water acts as a lubricant and helps to reduce heat generated during the polishing process.What makes diamond wet polishing pads unique?Diamond wet polishing pads are unique because they are designed to last longer than traditional polishing pads. This is because they are made of diamond particles, which are durable and wear-resistant. This allows them to handle even the toughest materials, providing a consistent and flawless finish. They are also the best choice when it comes to polishing edges and corners, as they provide excellent precision, and leave no scratches or marks.What are the different types of diamond wet polishing pads?There are different types of diamond wet polishing pads available on the market. They vary in terms of their size, quality, and intended use. Some popular types include:1. Electroplated diamond polishing pads: These are diamond pads that are attached to the backing plate with an electroplating process. They are durable and provide excellent results when polishing granite and other hard materials.2. Resin diamond polishing pads: These are diamond pads that use a resin binder to hold the diamond particles together. They are suitable for use on softer stones, such as marble or travertine.3. Metal bond diamond polishing pads: These are diamond pads that are designed to handle the toughest materials, such as concrete. They are the most aggressive type of diamond polishing pad and will leave scratches that can be removed by finer grits.How to use diamond wet polishing pads?Using diamond wet polishing pads is a fairly simple process. Here are some steps to follow:1. Choose the right pad grit: Depending on the type of stone you are polishing, you will need to choose the correct grit. Start with a coarser grit and work your way up to finer grits until you achieve the desired finish.2. Attach the pad: Attach the diamond pad to a polisher. Ensure that the polisher is water-fed to keep the surface of the stone cool and to avoid dust.3. Begin polishing: Start polishing the surface of the stone, moving the polisher in a circular motion. Keep the surface wet at all times to prevent overheating.4. Change the pads: As you move from coarser to finer grits, change to a new pad. This is to avoid cross-contamination and to achieve the desired finish.ConclusionDiamond wet polishing pads are a must-have for anyone looking to achieve a perfect, polished finish on stone surfaces. They are durable and long-lasting, providing a consistent finish every time. With the right technique and grit sequence, you can achieve an excellent finish on any stone material. Make sure to always choose the right grit for the stone you are working on, and to keep the surface wet to avoid overheating. With diamond wet polishing pads, you can achieve a stunning, polished finish that will last for years to come.

New Heavy Duty Deck Brush for Efficient Cleaning

Diamond Deck Brush: The Ultimate Solution for Efficient CleaningAre you tired of having to scrub your deck for hours and still experiencing an unsatisfactory job, or worse, having to replace your deck frequently because of damage caused by improper cleaning techniques? The Diamond Deck Brush (brand name removed), developed through years of research and innovation by our company, is the ultimate solution to all your deck cleaning woes. Read on to find out more about how our product can transform your cleaning process.At our company, we understand the importance of having not only a clean deck but also one that is well-maintained and long-lasting. We have therefore invested time and resources to develop a product that not only saves time and money but also provides the most efficient cleaning solution on the market. The Diamond Deck Brush is a product of this investment and our commitment to providing top-quality cleaning solutions.The Diamond Deck Brush features a unique diamond-patterned bristle design that ensures that no spot on your deck is left untouched during the cleaning process. This design also ensures that the bristles are gentle on your deck while still effectively removing dirt, grime, and any other stubborn stains. The brush is suitable for use on all types of decks, including wood, PVC, composite, and concrete, making it a versatile solution for all your cleaning needs.The design of the Diamond Deck Brush ensures that it can be used with any standard broom handle, allowing you to reach all areas of your deck with ease. Its lightweight design also ensures that you can use it for extended periods without experiencing fatigue.One of the best features of the Diamond Deck Brush is its ability to clean not only the surface of your deck but also the gaps between the deck boards. The bristles can get in between the gaps, removing any dirt or debris that may have accumulated. This feature is especially essential for wooden decks, where debris accumulation between boards can cause rotting and decay.At our company, we understand that cleaning your deck can often be tiring and time-consuming, which is why we have developed the Diamond Deck Brush to save you time and effort. The brush's design ensures that it requires minimal effort to remove even the most stubborn stains while still providing excellent results. You can clean your deck effortlessly and quickly, leaving you with ample time to engage in other activities.The Diamond Deck Brush is also a sustainable solution for all your cleaning needs. Its durable design ensures that you can use it for extended periods without having to replace it frequently, saving you money in the long run. The brush is also easy to clean, ensuring that it requires minimal maintenance and is always ready for use.In conclusion, the Diamond Deck Brush is the ultimate solution to all your deck cleaning needs. Its unique diamond-patterned bristle design ensures that you get maximum cleaning efficiency while still protecting your deck from damage during the cleaning process. Its lightweight design makes it easy to use, and its ability to clean the gaps between boards ensures that your deck is well-maintained. If you want a sustainable, efficient, and affordable solution for your deck cleaning needs, the Diamond Deck Brush is the product for you.

Discover the Latest Innovation in Polishing Tools with Diamond Pads

[Brand Name] Launches Revolutionary Diamond Pads - Redefining Floor Care[City], [Date] - [Brand Name], a leading innovator in floor care solutions, has introduced its groundbreaking Diamond Pads. These technologically advanced floor maintenance tools promise to revolutionize the way businesses and homeowners clean and care for their floors.[Brand Name] has built a reputation for creating high-quality products that combine innovation, functionality, and durability. Their latest offering, the Diamond Pads, aims to provide an exceptional cleaning experience while extending the lifespan of floors.The Diamond Pads utilize a unique combination of diamond-embedded pads and cutting-edge design to deliver superior results. Unlike traditional floor-cleaning tools, these pads are specifically engineered to remove tough stains, grime, and scuff marks effectively.With the increased focus on sustainability and eco-friendly practices, [Brand Name] has ensured that its Diamond Pads are environmentally responsible. These pads are crafted using eco-friendly materials, reducing their impact on the environment while providing an efficient cleaning solution.The innovative technology used in the Diamond Pads not only allows for effortless cleaning but also offers impressive durability. The diamond-embedded surface, combined with the high-quality materials, ensures long-lasting performance, saving users time and money in the long run.Furthermore, the Diamond Pads are designed for versatile use across a wide range of flooring types, including hardwood, laminate, vinyl, tile, and more. This flexibility makes them an ideal choice for both residential and commercial spaces.According to [Brand Name]'s CEO, [CEO's Name], "We are thrilled to introduce the Diamond Pads to our customers. Our team has put in countless hours of research and development to create a product that revolutionizes floor care. We believe that the Diamond Pads will truly elevate the cleaning experience for our users."Apart from their exceptional cleaning capabilities, the Diamond Pads are also designed with user comfort in mind. The ergonomic, non-slip handle ensures a secure grip, preventing any accidental slips during the cleaning process.In addition to the pads' outstanding performance, [Brand Name] has also established an extensive network of support services to cater to its customers. The company's team of floor care experts is available to provide guidance and advice on the best practices for using the Diamond Pads to achieve optimal results.To celebrate the launch of the Diamond Pads, [Brand Name] is offering an introductory discount of 20% to all customers who purchase the product within the first month. This limited-time offer presents an excellent opportunity for homeowners and businesses to experience the future of floor care at an affordable price.The introduction of [Brand Name]'s Diamond Pads showcases the company's commitment to innovation and customer satisfaction. With its revolutionary technology, eco-friendly design, and exceptional performance, these pads are set to become the go-to solution for floor maintenance.For more information on the Diamond Pads and to place an order, please visit [Brand Name]'s official website or contact their customer service representatives at [contact information].About [Brand Name]:[Brand Name] is a renowned company specializing in innovative floor care solutions. With a focus on quality, functionality, and customer satisfaction, [Brand Name] continues to lead the industry by providing cutting-edge products that redefine the way we care for our floors.

Different Types of Grinding Wheels: A Complete Guide

Title: Exploring the Different Types of Grinding Wheels Revolutionizing Industrial ApplicationsIntroduction:In today's industrial revolution, grinding wheels play a fundamental role in various sectors, including manufacturing, construction, automotive, and metalworking. These indispensable tools are crucial for precision cutting, shaping, and finishing, enabling businesses to enhance productivity and achieve superior workpiece quality. This article aims to shed light on the various types of grinding wheels available in the market and their importance in revolutionizing industrial applications.1. Straight Grinding Wheels:Straight grinding wheels, also known as Type 1 wheels, are the most common and straightforward type used for surface grinding. These wheels have a flat outer periphery and deliver precise grinding performance on flat surfaces. Typically made from aluminum oxide or silicon carbide abrasive grains, straight grinding wheels are versatile and suitable for a wide array of materials, including steel, cast iron, brass, and non-ferrous metals.2. Cylinder Wheels:Cylinder wheels, designated as Type 2 wheels, possess a unique shape resembling a straight grinding wheel with a cylindrical face. These wheels are primarily used for grinding cylinders, bearings, and other rounded surfaces. The rounded design allows for easy and efficient grinding with reduced friction, resulting in excellent surface finishes.3. Tapered Grinding Wheels:Tapered grinding wheels, commonly referred to as Type 4 wheels, are specially designed for grinding operations that require precision and control. These wheels have a tapered shape, gradually narrowing towards the arbor hole. The tapering enables the wheel to penetrate the workpiece effectively, making them ideal for intricate grinding tasks such as internal grinding.4. Dish Grinding Wheels:Dish grinding wheels, known as Type 11 wheels, possess a dish-shaped design with a roundish outer rim and a depressed center. These wheels are widely used for contour grinding, grinding complex shapes, and removing excess material from the workpiece. The recessed center allows for a higher degree of flexibility, making them suitable for both large and small-scale applications.5. Diamond Wheels:Diamond grinding wheels are the epitome of grinding wheel technology, offering exceptional hardness, durability, and precision. Utilizing diamond abrasives, these wheels excel in cutting and grinding extremely hard materials such as carbides, ceramics, glass, and stones. Their fine grit allows for a smooth finish and minimal material wastage, making diamond wheels ideal for demanding applications.6. CBN Wheels:Cubic Boron Nitride (CBN) grinding wheels are similar to diamond wheels in terms of their exceptional hardness and longevity. These wheels are specifically formulated for grinding ferrous materials, including hardened steels and cast iron. With their heat resistance and ability to retain sharpness, CBN wheels are perfect for high-speed grinding operations, resulting in improved productivity and reduced downtime.Conclusion:Grinding wheels are indispensable tools in the industrial sector, revolutionizing various applications, from metalworking to automotive and construction. This article explored different types of grinding wheels, highlighting their characteristics and applications. The versatility and precision offered by these wheels allow businesses to improve productivity, achieve superior workpiece quality, and ultimately drive the industrial revolution forward. As technology advances further, we can expect the development of innovative grinding wheel types, continually pushing the boundaries of what can be achieved in industrial grinding.

Discover the Many Uses and Benefits of an 800 Grit Polishing Pad

Title: Revolutionary 800 Grit Polishing Pad Set to Transform the Polishing IndustryIntroduction:In today's fast-paced world, where appearances matter immensely, maintaining the shine and luster of our prized possessions has become crucial. In this regard, the introduction of the remarkable 800 Grit Polishing Pad brings a revolutionary change to the polishing industry. This cutting-edge product, developed by a leading technology company, promises to redefine the way we approach polishing, delivering impeccable results and unleashing the potential to transform the appearance of various surfaces.Product Features and Benefits:The 800 Grit Polishing Pad is a state-of-the-art product that leverages advanced technology and superior materials to revolutionize the polishing process. This pad has been meticulously designed to withstand the rigors of multi-surface polishing, making it ideal for use on automobiles, boats, and household items.1. High-Quality Materials:The 800 Grit Polishing Pad is constructed using the finest materials available, ensuring durability and long-lasting effectiveness. The pad's premium quality delivers outstanding results, leaving surfaces with a remarkable shine.2. Efficiency and Versatility:This polishing pad showcases exceptional efficiency, allowing users to achieve flawlessly shiny surfaces with ease. Its versatility extends to various applications, making it suitable for polishing plastic, wood, metal, and even glass.3. Unique Grit Size:The 800 grit represents the pad's abrasiveness, striking the perfect balance between coarseness and effectiveness. This proprietary grit size ensures optimal polishing, removing defects and imperfections without causing damage to the surface material.4. Easy to Use:To facilitate user convenience, the 800 Grit Polishing Pad is designed for effortless attachment to a variety of polishing tools. Its lightweight design allows for comfortable handling, ensuring a seamless polishing experience for both professionals and hobbyists.Company Overview:Committed to delivering groundbreaking technological solutions, the company behind the development of the 800 Grit Polishing Pad has an illustrious track record. As an industry leader in manufacturing and innovation, they have consistently pushed boundaries and delivered products that transform the way we approach polishing and surface maintenance.With a team of dedicated engineers and product designers, the company aims to revolutionize the industry by constantly staying ahead of the curve. Their commitment to research and development ensures that end-users benefit from cutting-edge advancements in surface care technology.Environmental Responsibility:The company takes pride in its commitment to environmental sustainability. It follows stringent sustainability practices and regulations throughout the production process, ensuring that the 800 Grit Polishing Pad is eco-friendly. Minimizing waste, reducing energy consumption, and utilizing recyclable materials are just a few examples of the company's dedication to preserving the planet.Market Response and Industry Impact:Since its introduction to the market, the 800 Grit Polishing Pad has garnered considerable attention from professionals and enthusiasts alike. The product's exceptional performance and unparalleled results have quickly solidified its reputation as a game-changer in the polishing industry.Polishing professionals praise the ease of use and the pad's ability to deliver consistent, top-tier results across various surfaces. Enthusiasts find its versatility appealing, as they can achieve professional-grade shine from the comfort of their own homes. Consequently, demand for the 800 Grit Polishing Pad is soaring, and the industry is taking notice.Looking Ahead:As the 800 Grit Polishing Pad continues to make waves in the market, the company is already working on expanding the product line and introducing new polishing solutions to meet growing consumer demand. Further advancements in their cutting-edge technology are expected to push the boundaries of what is possible, ultimately transforming the way we approach surface polishing.Conclusion:The revolutionary 800 Grit Polishing Pad has emerged as a game-changer in the industry, providing professionals and enthusiasts with a groundbreaking solution for achieving impeccable shine. With its advanced technology, unparalleled efficiency, and commitment to environmental sustainability, this product marks a turning point in the world of polishing. As the company behind it continues to innovate, the future looks bright for both the industry and those seeking to enhance the appearance of their prized possessions.

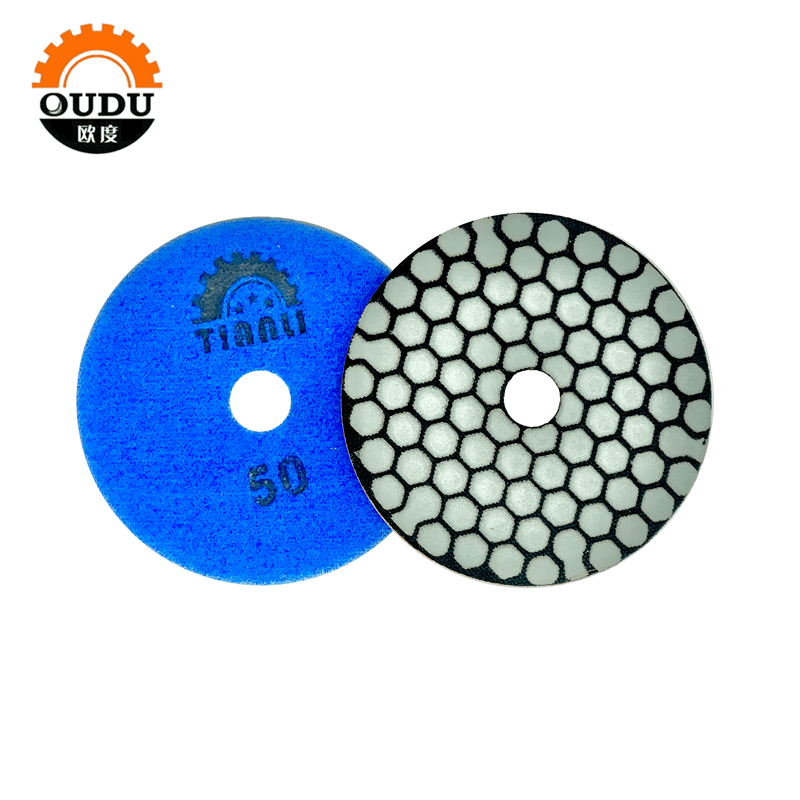

High-Quality Diamond Polishing Pads for Natural Stone, Granite, and Marble

Title: Achieve Flawless Shine with Diamond Dry Polishing Pads Set: The Ultimate GuideIntroduction:When it comes to achieving a pristine surface on natural stone, such as granite and marble, diamond polishing pads have emerged as the go-to tool. These incredible pads offer the versatility of both wet and dry polishing, enabling users to attain a mesmerizing shine effortlessly. In this comprehensive blog, we will explore the wonders of diamond dry polishing pads set, their features, benefits, and how they are revolutionizing the world of stone polishing. So, let's dive in!1. Understanding Diamond Dry Polishing Pads:Diamond dry polishing pads are a cutting-edge solution designed to transform dull and lackluster natural stone surfaces into a dazzling masterpiece. Their primary objective is to remove scratches, marks, and imperfections while providing a high-gloss finish. These pads combine the effectiveness of diamond particles with unique bonding technology, ensuring unparalleled performance.2. Features of Diamond Dry Polishing Pads Set:- Premium Quality: Crafted using high-quality materials, these pads are highly durable and resistant to wear and tear.- Versatility: Suitable for both wet and dry polishing, these pads can adapt to various polishing techniques, allowing users to choose the method that works best for them.- Different Grit Options: Diamond dry polishing pads are available in different grits, ranging from coarse to fine. This diversity in grit levels allows users to customize their polishing process based on the specific requirements of the stone surface.- Easy Attachment: These pads are designed with a convenient hook and loop backing system, ensuring effortless attachment to polishing machines.- Uniform Polishing: The diamond particles on these pads are precisely distributed, ensuring consistent and uniform polishing across the entire surface.3. Key Benefits of Diamond Dry Polishing Pads Set:- Superior Polishing: The diamond particles embedded in these pads make them highly effective in removing blemishes, scratches, and stains from the stone, while leaving a pristine finish.- Time and Cost Savings: The versatility of these pads saves time and money by eliminating the need for multiple sets of polishing tools. Additionally, their durability ensures long-lasting performance, reducing the frequency of replacements.- Precision and Control: Whether you are a professional or a DIY enthusiast, these pads offer exceptional precision and control during the polishing process, allowing you to achieve desired results effortlessly.- Environmental Friendly: The dry polishing technique used with these pads reduces the water consumption associated with wet polishing methods, making it environmentally friendly.4. How to Use Diamond Dry Polishing Pads Set:- Step 1: Prepare the surface by cleaning it thoroughly, removing any dirt or debris.- Step 2: Select the appropriate pad grit level based on the current condition of the stone surface.- Step 3: Attach the pad to a compatible polishing machine using the hook and loop backing system.- Step 4: Begin the polishing process, applying moderate pressure and moving the machine in consistent circular or linear motions, depending on the desired finish.- Step 5: Repeat the process with gradually finer grit pads until the desired shine and smoothness are achieved.5. Conclusion:Diamond dry polishing pads have become indispensable tools for professionals and enthusiasts alike when it comes to achieving the perfect finish on natural stone surfaces. Their versatility, exceptional performance, and environmental friendly nature make them a preferable choice for any polishing project. By utilizing the features and benefits of diamond dry polishing pads, you can unlock the true beauty of your natural stone surfaces, enhancing their longevity and appeal.So, why wait? Equip yourself with a diamond dry polishing pads set today and witness the transformation of your stone surfaces like never before!Keywords: Diamond Dry Polishing Pads Set, natural stone, granite, marble, wet polishing, dry polishing, high-gloss finish, diamond particles, scratch removal, versatile, grit options, uniform polishing, time and cost savings, precision, control, environmentally friendly.

6-1/2" x 7/8" Hook & Loop Standard Duty Orbital (SDO) Polishing Pad for Orange Polishing

Title: LK SDO-22650 Orange Polishing Pad: The Ultimate Standard Duty Hook & Loop Polishing SolutionIntroduction:Established in [year], [Company Name] has become a trusted name in the automotive detailing industry, known for its high-quality products and innovative solutions. As a frontrunner in providing cutting-edge polishing accessories, [Company Name] is proud to introduce the all-new LK SDO-22650 Orange Polishing Pad. This revolutionary 6-1/2" x 7/8" Hook & Loop SDO Pad is designed to redefine the standard duty polishing experience. With a focus on eliminating imperfections and enhancing the overall aesthetic appeal of any surface, the LK SDO-22650 Orange Polishing Pad is set to become an indispensable tool for automotive enthusiasts and professionals alike.Unleashing Advanced Technology:The LK SDO-22650 Orange Polishing Pad utilizes state-of-the-art Hook & Loop technology, providing effortless attachment and removal on compatible orbital polishers. This advanced technology ensures a secure grip, enabling users to tackle even the most demanding polishing tasks with ease.Superior Foam Construction:Built to surpass industry standards, the LK SDO-22650 Orange Polishing Pad incorporates high-quality foam that guarantees exceptional performance. The pad boasts the same superior foam found in the highly acclaimed HDO line but without the dual-layer construction. This innovative design allows for an optimal balance of flexibility and firmness, facilitating efficient polishing while minimizing the risk of introducing new defects to the surface.Unmatched Versatility:The LK SDO-22650 Orange Polishing Pad is engineered to excel in various polishing applications. Whether restoring faded paintwork, removing light scratches, or enhancing the gloss and depth of a surface, this pad delivers unparalleled results. Its unique cell structure ensures a controlled distribution of polishing agents, preventing product wastage while maximizing efficiency. Furthermore, the pad's shape and size make it ideal for tackling both flat and contoured surfaces, ensuring consistent and uniform results across the entire work area.Effective Defect Removal:The orange foam featured in the LK SDO-22650 Polishing Pad is specifically designed for moderate defect removal. It excels at eliminating light to medium swirl marks, oxidation, holograms, and other imperfections, leaving surfaces flawlessly refined. By harnessing the excellent cutting ability of this pad, automotive professionals can achieve a high level of perfection in their work, taking the pride of ownership to a whole new level.Ease of Use:One of the key benefits of the LK SDO-22650 Orange Polishing Pad is its ease of use. The Hook & Loop attachment system allows for quick pad changes, minimizing downtime and increasing productivity. The pad's ergonomic design and optimal weight distribution enable users to maintain excellent control and maneuverability during the polishing process. Additionally, the pad's compatibility with a wide range of automotive polishing compounds ensures that users can effortlessly achieve their desired results, whether using heavy-cutting, all-in-one, or finishing products.Longevity and Durability:The LK SDO-22650 Orange Polishing Pad is designed to withstand rigorous and extended usage, reflecting the company's commitment to delivering products built to last. By utilizing high-quality materials, this pad offers superb heat resistance, reducing the risk of foam disintegration and prolonging its lifespan. Whether used by detailing enthusiasts or professionals during frequent or occasional use, the LK SDO-22650 Orange Polishing Pad will retain its performance and integrity, providing exceptional value for money.Conclusion:With the introduction of the LK SDO-22650 Orange Polishing Pad, [Company Name] continues to demonstrate its commitment to revolutionizing the automotive detailing industry. The combination of the cutting-edge Hook & Loop technology and its superior foam construction makes this pad a game-changer in the standard duty polishing category. Providing outstanding defect removal capabilities, ease of use, and durability, the LK SDO-22650 Orange Polishing Pad is set to become an indispensable tool for enthusiasts and professionals alike. Explore the versatility and precision of the LK SDO-22650 Orange Polishing Pad and elevate your detailing experience to new heights.

Revolutionary Floor Grinders that Mimic Manual Grinding Movements for Optimal Polishing

Title: Diamond Grinding Machine Floor: Revolutionizing Construction with Cutting-Edge TechnologyIntroduction Paragraph:In a bid to enhance efficiency and empower construction professionals, the groundbreaking Diamond Grinding Machine Floor presents a technological marvel that is set to redefine the industry standards. Its novel design effectively mimics the rocking sidetoside movements traditionally made manually by operators, making it a game-changer in the construction arena. Developed by Husqvarna, a globally recognized industry leader in providing construction solutions, the Diamond Grinding Machine Floor encompasses a wide range of machines and diamond tools, enabling professionals to leverage advanced technology for precision grinding and polishing.Body:1. Pioneering Technology for Enhanced Efficiency (100 words)The Diamond Grinding Machine Floor is equipped with cutting-edge technology, providing construction professionals with an unparalleled solution for their grinding and polishing needs. One of its standout features is its capability to seamlessly mimic the traditional sidetoside movements performed manually by operators. This unique feature eliminates the physical strain on operators, reducing fatigue and enhancing overall productivity. By automating this process, the Diamond Grinding Machine Floor ensures consistent and precise results, delivering a level of efficiency that was previously unattainable with traditional grinding machines.2. Three Main Benefits of Diamond Grinding Machine Floor (200 words)The Diamond Grinding Machine Floor offers three primary benefits that are set to revolutionize construction practices:a. Reduced Operator Fatigue: Traditional grinding machines require the operator to perform repetitive sidetoside movements manually. This repetitive motion can lead to fatigue and strain injuries. With the Diamond Grinding Machine Floor, operators can now experience reduced fatigue as the machine mimics the manual rocking movements, eliminating strain and optimizing overall operational efficiency.b. Superior Precision and Consistency: By automating the sidetoside movements, the Diamond Grinding Machine Floor ensures a consistently level and even grinding or polishing surface. This results in superior precision and a flawless finish, a crucial factor in meeting strict industry standards and client expectations.c. Increased Productivity: The automation of the rocking sidetoside movements provides an immense boost to productivity. Construction professionals can now accomplish more in less time, translating into improved profitability and quicker turnaround times for projects.3. The Support and Expertise of Husqvarna (150 words)The Diamond Grinding Machine Floor is an achievement brought to you by Husqvarna, a renowned name in the construction industry. Husqvarna has established itself as a leader in providing innovative solutions, including a diverse range of machines and diamond tools. Backed by decades of experience and a deep-rooted passion for excellence, Husqvarna offers complete support and service to construction professionals, helping them make the most of the Diamond Grinding Machine Floor. From consultation to training and ongoing assistance, Husqvarna stands as an unwavering partner for all construction needs. The company's commitment to delivering top-notch solutions, along with a focus on sustainable practices, has earned it a well-deserved reputation and the trust of professionals worldwide.4. Beyond Diamond Grinding Machine Floor: Husqvarna's Comprehensive Solutions (250 words)Husqvarna caters to a vast array of construction requirements, providing a comprehensive range of machines, diamond tools, and associated services. Their extensive portfolio encompasses cutting, grinding, and drilling equipment, along with advanced technologies for surface preparation and polishing. The company's commitment to pushing boundaries and meeting customer demands drives continuous innovation and elevates the industry standards. Husqvarna's diamond tools are designed to tackle all surfaces and materials, ensuring outstanding performance even in the most demanding conditions. With their relentless focus on research and development, Husqvarna consistently introduces groundbreaking designs, enabling professionals to achieve exceptional results.Additionally, Husqvarna's commitment towards sustainability is evident in their products. The Diamond Grinding Machine Floor, like many other machines, is designed to minimize energy consumption and reduce environmental impact. This environmentally conscious approach aligns with Husqvarna's vision of providing sustainable solutions that not only benefit the construction industry but also contribute to creating a greener future.Conclusion Paragraph:The Diamond Grinding Machine Floor by Husqvarna is a technological wonder that is set to reshape the construction landscape. With its ability to mimic sidetoside movements traditionally made manually, this innovative machine brings a newfound level of efficiency, precision, and productivity to the industry. Backed by Husqvarna's expertise, support, and comprehensive range of machines and diamond tools, construction professionals now have the means to achieve flawless results while reducing fatigue and maximizing their project's profitability. With the Diamond Grinding Machine Floor, Husqvarna continues to spearhead advancements in construction technology, revolutionizing the way professionals approach grinding and polishing tasks.