Understanding the Chemistry of Metallic Bonds and Their Properties

By:Admin

The field of material science has been revolutionized with the development of metallic bonds chemistry, a groundbreaking innovation that has potential applications across a wide range of industries. This new technology, developed by a team of researchers at {}, promises to unlock new possibilities in the creation of advanced materials with exceptional strength, flexibility, and conductivity.

Metallic bonds are a type of chemical bond that occurs between atoms of metallic elements. Unlike other types of chemical bonds, such as covalent or ionic bonds, metallic bonds are unique in that the electrons are not tied to any specific atoms and are instead free to move throughout the structure. This gives metallic materials their characteristic properties, such as high electrical and thermal conductivity, malleability, and luster.

The development of metallic bonds chemistry has been a focus of research and development at {} for several years. The company, a leading innovator in the field of material science, has dedicated substantial resources to understanding the fundamental principles of metallic bonding and harnessing this knowledge to create new materials with superior performance characteristics.

One of the key advantages of metallic bonds chemistry is the ability to tailor the properties of materials by controlling the arrangement of atoms and the nature of the bonding interactions. By manipulating these factors, researchers can design materials with specific attributes, such as enhanced strength, improved corrosion resistance, or optimized electrical conductivity. This level of control over material properties opens up a myriad of possibilities for the creation of innovative products across various industries, from electronics and aerospace to automotive and construction.

The potential applications of metallic bonds chemistry are vast and far-reaching. For instance, in the electronics industry, materials with superior electrical conductivity and thermal stability are in high demand for the development of high-performance electronic devices and components. Metallic bonds chemistry offers a pathway to create such materials, paving the way for more efficient and durable electronic products.

Similarly, the aerospace and automotive industries stand to benefit from the use of advanced materials derived from metallic bonds chemistry. The unparalleled strength and lightweight nature of these materials make them ideal for use in the construction of aircraft, spacecraft, and automobiles, where the demand for high-performance, durable materials is paramount.

The construction industry is also poised to benefit from the advancements in metallic bonds chemistry. The development of materials with enhanced structural integrity and corrosion resistance can lead to the creation of more resilient and long-lasting infrastructure, ranging from bridges and buildings to pipelines and offshore structures.

In addition to its applications in various industries, metallic bonds chemistry also holds promise for enabling sustainable and environmentally friendly solutions. By developing materials with improved durability and longevity, the need for frequent replacements and repairs can be reduced, leading to significant cost savings and minimizing the environmental impact associated with the production and disposal of materials.

The emergence of metallic bonds chemistry as a leading technology in material science exemplifies the commitment of {} to pushing the boundaries of innovation and driving positive change across industries. The company's dedication to research and development, combined with its expertise in material science, positions it at the forefront of this cutting-edge technology, poised to deliver groundbreaking solutions that have the potential to reshape the future of materials and manufacturing.

As the applications of metallic bonds chemistry continue to expand, it is clear that this innovative technology will play a crucial role in advancing the capabilities of materials and driving progress across diverse sectors. With its far-reaching implications and transformative potential, metallic bonds chemistry stands as a testament to the power of scientific innovation and the ability to create a brighter, more sustainable future through the development of advanced materials.

Company News & Blog

Durable and Efficient Grinding Discs for Your Needs

Grinding Disc Company Introduces New and Improved ProductGrinding Disc Company, a leading manufacturer and distributor of high-quality grinding discs, has recently announced the launch of their new and improved product line. The company, which has been in the industry for over 20 years, is known for its commitment to delivering top-notch grinding solutions to meet the needs of various industries.The newly introduced grinding discs come with several advanced features and are designed to provide superior performance and durability. These discs are suitable for a wide range of applications, including metal fabrication, construction, and automotive repair. With the introduction of these new products, Grinding Disc Company aims to further solidify its position as a trusted supplier of grinding solutions in the market.The new grinding discs boast a number of enhancements that set them apart from the competition. Firstly, they are manufactured using premium quality materials that have been rigorously tested to ensure excellent performance and longevity. The discs are also designed to deliver maximum precision and efficiency, allowing users to achieve high-quality results in their grinding operations.In addition, the new grinding discs feature an innovative design that minimizes heat generation and reduces the risk of overheating during prolonged use. This is a crucial benefit for users who rely on grinding discs for extended periods, as it helps to prevent damage to the workpiece and prolong the lifespan of the discs.Furthermore, the new grinding discs are equipped with a special coating that enhances their resistance to friction and wear. This ensures that the discs maintain their sharpness and cutting performance even when used in demanding applications. As a result, users can expect consistent and reliable performance from the discs, leading to improved productivity and cost savings.Grinding Disc Company is renowned for its dedication to customer satisfaction, and the introduction of the new product line is a testament to this commitment. The company understands the evolving needs of its customers and has invested significant resources in research and development to create grinding discs that are tailored to meet these requirements.“We are excited to introduce our new and improved grinding discs to the market,” said the spokesperson for Grinding Disc Company. “These discs have been meticulously engineered to deliver exceptional performance, and we believe that they will become a valuable asset for our customers. We are confident that the new product line will further cement our reputation as a trusted provider of high-quality grinding solutions.”As part of the launch, Grinding Disc Company has also announced special promotional offers to allow customers to experience the benefits of the new grinding discs. These offers include discounted pricing and bundled packages that provide added value to customers. With these promotions, the company hopes to encourage more users to try out the new products and witness the difference for themselves.The new product line is now available for purchase through Grinding Disc Company’s official distributors and authorized resellers. Customers can also reach out to the company directly to inquire about the availability of the new grinding discs and to learn more about their specifications and applications.Over the past two decades, Grinding Disc Company has built a strong reputation for delivering innovative grinding solutions that meet the highest standards of quality and performance. With the launch of the new product line, the company is poised to continue its legacy of excellence and remain at the forefront of the industry.For more information about Grinding Disc Company and its new and improved grinding discs, visit their official website or contact their customer service team.

Ultimate Guide: Top 10 Ceramic Sanding Discs for Effective Polishing - Expert Buying Tips

IntroductionSanding is an essential task in mechanical workshops, and selecting the right disc is crucial to ensure high precision, accuracy, and quality. Among the vast list of available sanding discs, Norton ceramic sanding discs are unparalleled in terms of longevity and efficiency. With exceptional performance, Norton ceramic sanding discs are designed to provide unmatched quality, making them perfect for all sanding tasks in any mechanical setting. This article will cover the top 10 best Norton ceramic sanding discs available in the market, along with a buying guide for prospective buyers. Top 10 Best Norton Ceramic Sanding Discs 1. Norton Abrasives 66254498067 Red Heat Sanding Discs The Norton Abrasives 66254498067 Red Heat Sanding Discs is an excellent choice for removing rust, burrs, and scaling in heavy metal fabrication. With Ceramic Plus Grain, this disc runs cool and resists wear and tear, making it ideal for heavy-duty sanding tasks. 2. Norton 66261138870 Neon F726 Sanding Discs The Norton 66261138870 Neon F726 Sanding Discs offer an improved cutting action with a zirconia alumina/ceramic blend for long life and rapid cut. The unique microcrystalline structure of ceramic abrasive grains makes these discs fast, sharp, and durable while removing metal quickly and efficiently. 3. Norton 66261163609 Blaze F980 Ceramic Sanding Discs The Norton 66261163609 Blaze F980 Ceramic Sanding Discs are engineered for heavy-pressure and high-speed applications in the metalworking industry. These discs feature a unique self-sharpening zirconia alumina abrasive grain, allowing fast stock removal with minimal pressure. 4. Norton 66261132091 BlueFire F826P Ceramic Sanding Discs The Norton 66261132091 BlueFire F826P Ceramic Sanding Discs are ideal for sanding and grinding ferrous and non-ferrous metals with a premium ceramic abrasive grain for longer life and faster cut rate. This disc reduces heat buildup due to its ceramic grain, minimizing discoloration of the workpiece. 5. Norton 66261135683 BlueFire F726 Rapid Prep Ceramic Sanding Discs The Norton 66261135683 BlueFire F726 Rapid Prep Ceramic Sanding Discs feature a waterproof design for excellent resistance to heat, ensuring long-lasting performance and minimal downtime. With a specialized blend of ceramic and aluminum oxide abrasive grains, this disc provides an exceptionally fast cut and rapid material removal. 6. Norton 66261101152 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101152 Blaze Rapid Strip Ceramic Sanding Discs offer an ultra-fast cut, resulting in high productivity and efficiency. These discs are perfect for paint and rust removal, blending, and finishing with minimal clogging and reduced discoloration of the workpiece. 7. Norton 66261101156 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101156 Blaze Rapid Strip Ceramic Sanding Discs are suitable for use on various metals, including stainless steel, aluminum, and non-ferrous metals, for rapid rust and paint removal. These discs feature an open web design to prevent clogging, maintaining maximum effectiveness and grit retention. 8. Norton 66261101154 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101154 Blaze Rapid Strip Ceramic Sanding Discs are perfect for surface preparation, rust removal, and blending, smooth out rough textures, welded seams, and more. These discs have an open web design that minimizes fiber breakage and clogging while maintaining a high level of durability and life span. 9. Norton 66261101158 Blaze Rapid Strip Ceramic Sanding Discs The Norton 66261101158 Blaze Rapid Strip Ceramic Sanding Discs are a premium choice for heavy stock removal applications. Their highly durable design with ceramic abrasive grains provides an aggressive cut for swift material removal. These discs have a long life span, reducing replacement time and costs. 10. Norton 66623383033 SG Blaze Plus F980 Ceramic Sanding Discs The Norton 66623383033 SG Blaze Plus F980 Ceramic Sanding Discs are specifically engineered for high-pressure applications, such as grinding, sanding, and blending with a blend of Ceramic Plus grain. These discs offer the best combination of life span, performance, consistency, and speed for maximum efficiency. Buying Guide for Norton Ceramic Sanding Discs Before making a purchase for Norton ceramic sanding discs, it is crucial to take the following factors into consideration; 1. Material: Check the material compatibility to avoid damages to the workpiece during sanding. Ensure that the discs you're purchasing are designed for use on specific materials, whether it be metal, wood, or plastic. 2. Grit Size: Select the appropriate grit size depending on the project at hand. For light sanding and finishing, a lower grit size is ideal, while for heavy-duty sanding tasks, a larger grit size is best. 3. Size: The size of the sanding disc should correspond to the size of the workpiece to ensure effective sanding and minimize wastage. 4. Durability: Check the durability of the disc to ensure longevity and reduce replacement costs. 5. Brand: Norton is a well-known and reliable brand in the sanding industry. However, ensure you're purchasing from a verified supplier to avoid counterfeit products. Conclusion With the above top 10 Norton ceramic sanding discs and buying guide, selecting the best disc for your project should be more manageable. Ensure you review the manufacturer's recommendations before making a purchase and take your time to read product reviews from other users. Norton ceramic sanding discs are top-rated for their longevity, efficiency and selecting the right type should ensure high precision, accuracy, and quality for all your sanding tasks.

Suppliers of Abrasives and Welding Equipment: Reviews and Product Info

Title: Enhancing Metal Finishing Processes with High-Quality AbrasivesIntroduction (approx. 100 words):When it comes to achieving stellar results in metal finishing processes, using top-notch abrasives is crucial. From sandpapers and grinding wheels to polishing compounds, these abrasive materials play a significant role in refining metal surfaces, removing imperfections, and ensuring a smooth end result. In this blog, we will delve into the world of abrasives, shedding light on the importance of choosing reputable suppliers and the benefits of utilizing high-quality metal abrasives. Join us as we explore the key factors to consider when selecting abrasives and learn how they can elevate your metal finishing processes to new heights.1. Understanding the Role of Abrasives in Metal Finishing (approx. 200 words):Metal finishing encompasses a wide range of processes, such as abrasive blasting, grinding, sanding, and polishing. These techniques aim to improve the appearance, functionality, and longevity of metal surfaces. At the core of each process lies the abrasive materials, which streamline the entire metal finishing journey.Abrasives serve as the key agents of change in metal finishing by removing unwanted material layers, leveling imperfections, and ensuring a uniform surface. They can be categorized based on their composition, size, and intended purpose. From natural abrasive minerals like garnet and diamond to synthetic options like aluminum oxide and silicon carbide, suppliers offer an extensive range of metal abrasives suitable for various applications.2. The Importance of Reliable Abrasive Suppliers (approx. 250 words):When selecting a supplier for your metal abrasives, it is crucial to prioritize reliability, quality, and customer service. Choosing the wrong supplier can lead to subpar products, delays, and overall dissatisfaction. Therefore, thorough research and consideration are necessary to make an informed decision.Reliable suppliers boast impeccable track records and positive customer reviews. These indicators of customer satisfaction are a testament to the supplier's commitment to quality. By collaborating with established suppliers, you gain access to a wide range of high-quality metal abrasives that will enhance your metal finishing processes.Additionally, reputable suppliers often provide ample product and service information, empowering customers to make well-informed purchasing decisions. Detailed profiles of suppliers allow you to understand their expertise, experience, and capabilities, enabling you to choose a partner that aligns with your specific needs.3. Benefits of High-Quality Metal Abrasives (approx. 250 words):Investing in high-quality metal abrasives can transform your metal finishing processes and yield remarkable results. Here are some key benefits of using premium abrasives:- Enhanced Efficiency: High-quality abrasives exhibit superior cutting, grinding, and polishing capabilities, allowing you to accomplish tasks more efficiently, saving both time and resources.- Superior Surface Finish: Premium abrasives enable you to achieve impeccable surface finishes by removing imperfections, scratches, and roughness efficiently, resulting in aesthetically pleasing and durable metal surfaces.- Extended Abrasive Lifespan: Top-notch metal abrasives often boast increased durability and longevity, reducing the need for frequent replacements and leading to cost savings in the long run.- Consistency and Precision: Reliable suppliers ensure consistent quality across their abrasive products, promoting precise performance and predictable outcomes in your metal finishing processes.Conclusion (approx. 150 words):Choosing the right supplier for your metal abrasive needs is paramount to achieve exceptional results in metal finishing processes. By selecting reputable suppliers and investing in high-quality metal abrasives, you can enhance efficiency, improve surface finishes, extend abrasives' lifespan, and achieve consistent and precise outcomes. Take advantage of the wide array of metal abrasives available in the market and revolutionize your metal finishing processes today.

High-Quality Ceramic Alumina Grinding Wheel for Precision Grinding Applications

Ceramic Alumina Grinding Wheel Offers Superior Performance and Durability{Company} is proud to introduce their latest innovation in grinding technology - the Ceramic Alumina Grinding Wheel. This new product is designed to provide superior performance and durability, making it the ideal choice for a wide range of grinding applications.The Ceramic Alumina Grinding Wheel is made from a high-quality ceramic alumina abrasive material, which is known for its exceptional hardness and toughness. This makes the wheel highly resistant to wear and deformation, ensuring that it maintains its cutting edge for longer periods of time. As a result, users can expect consistent, high-quality results and extended wheel life, ultimately reducing the need for frequent wheel changes and improving overall productivity.In addition to its impressive durability, the Ceramic Alumina Grinding Wheel also offers outstanding performance in terms of material removal rate and surface finish. Its sharp cutting edges and self-sharpening properties enable it to efficiently grind and shape various materials, including steel, stainless steel, and other metals. This makes it a versatile solution for a wide range of industrial grinding applications, from heavy-duty metal fabrication to precision surface grinding.Furthermore, the Ceramic Alumina Grinding Wheel is designed for optimal heat dissipation, reducing the risk of thermal damage to the workpiece and prolonging the wheel's lifespan. This feature is particularly advantageous in high-speed grinding operations, where maintaining a cool cutting temperature is essential for achieving consistent results and preventing thermal stress on the workpiece.Another key benefit of the Ceramic Alumina Grinding Wheel is its low vibration and noise levels during operation. This not only contributes to a more comfortable working environment for the operator but also helps to minimize the risk of workpiece damage caused by excessive vibration.{Company} has integrated state-of-the-art manufacturing techniques and quality control processes to ensure that the Ceramic Alumina Grinding Wheel meets the highest standards of performance and safety. Each wheel undergoes rigorous testing to verify its dimensional accuracy, balance, and overall integrity, providing customers with a reliable and consistent grinding solution they can trust.In line with {Company}'s commitment to sustainability, the Ceramic Alumina Grinding Wheel is also engineered for minimal environmental impact. By optimizing the wheel's material utilization and energy efficiency during manufacturing, the company aims to reduce waste and energy consumption, ultimately contributing to a more eco-friendly production process.The introduction of the Ceramic Alumina Grinding Wheel further cements {Company}'s position as a leading provider of innovative and high-performance abrasive solutions. With a strong emphasis on quality, reliability, and customer satisfaction, the company continues to strive for excellence in meeting the diverse needs of its customers across various industries.In conclusion, {Company} is proud to unveil the Ceramic Alumina Grinding Wheel as a testament to its ongoing dedication to delivering cutting-edge grinding solutions. Offering exceptional durability, performance, and environmental responsibility, this new product is set to make a significant impact in the field of industrial grinding. As the demand for high-quality, efficient grinding tools continues to grow, {Company} remains at the forefront of driving technological advancements in the abrasive industry.

The Latest Advances in Hardware Machines: A Look at the Future of Technology

Hardware Machine Unveils New Cutting-Edge Technology[Company Name] has once again showcased its innovative prowess with the unveiling of a new cutting-edge technology that is set to revolutionize the industry. The new technology, which was recently launched at a high-profile industry event, has been heralded as a game-changer by industry experts and is expected to set a new standard for hardware machinery.The highly-anticipated technology, which is the result of years of research and development, represents a significant leap forward in the field of hardware machinery. By incorporating the latest advancements in engineering and design, [Company Name] has succeeded in creating a machine that delivers unparalleled performance, precision, and efficiency.One of the key features of the new technology is its state-of-the-art automation capabilities, which streamline the manufacturing process and significantly reduce the need for manual intervention. This not only improves the overall productivity of the machine but also minimizes the margin for error, ensuring that the end products meet the highest standards of quality and consistency.Furthermore, the machine is equipped with advanced sensors and control systems that enable real-time monitoring and adjustment, allowing for optimal performance and reliability. This level of automation sets a new benchmark for the industry and is expected to redefine the way hardware machinery is perceived and utilized.In addition to its cutting-edge automation, the new technology also boasts a range of other impressive features, including enhanced safety measures, user-friendly interface, and eco-friendly design. These features have been meticulously integrated to ensure that the machine not only delivers superior performance but also offers a sustainable and user-centric solution for manufacturers."The launch of our new technology represents a significant milestone for [Company Name]," said the CEO of the company. "We have always been committed to pushing the boundaries of innovation and this latest development is a testament to that commitment. We believe that this technology will set a new standard for the industry and provide our customers with a competitive edge in the market."The unveiling of the new technology has generated significant excitement within the industry, with many manufacturers expressing keen interest in integrating the technology into their production processes. The potential of the technology to revolutionize the industry has sparked a flurry of inquiries and orders, indicating a strong demand for the new machine.The launch event, which was attended by industry leaders, experts, and media representatives, provided an opportunity for [Company Name] to showcase the capabilities of the new technology through live demonstrations and technical presentations. The positive feedback from the attendees further underscored the anticipated impact of the technology on the industry.Looking ahead, [Company Name] is poised to capitalize on the momentum generated by the launch of the new technology, with plans to ramp up production and expand its market presence. The company is also committed to further advancing the technology, with ongoing research and development initiatives aimed at introducing even more cutting-edge solutions to the market.With its new technology setting a new standard for hardware machinery, [Company Name] is not only proving its capabilities as an industry leader but also reaffirming its dedication to driving innovation and progress. As the industry continues to evolve, [Company Name] remains at the forefront, delivering solutions that are not only ahead of the curve but also setting the pace for the future.

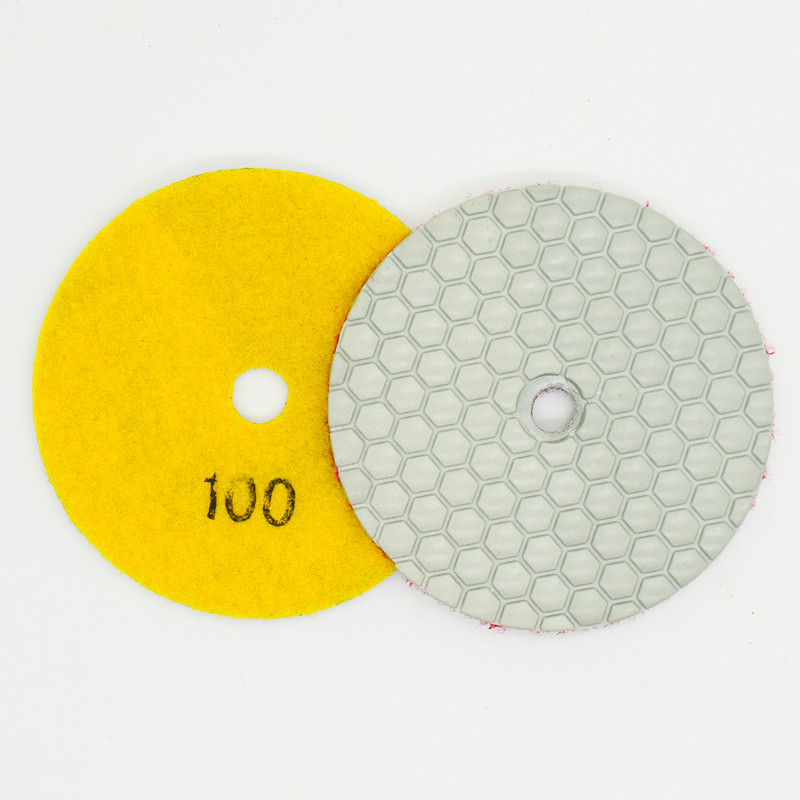

High-Quality Wet Polishing Pads for Diamonds: A Complete Guide

Diamond Wet Polishing Pads have revolutionized the way professionals in the stone fabrication industry polish and hone natural and engineered stone surfaces. A leader in the production of these cutting-edge tools, the company has been consistently providing high-quality diamond tools for a variety of applications. With a strong commitment to innovation and customer satisfaction, the company continues to be at the forefront of the industry.The Diamond Wet Polishing Pads offered by the company are designed to deliver exceptional results on a wide range of materials including granite, marble, quartz, and other stone surfaces. These pads are specially formulated to provide a smooth and glossy finish, while also ensuring long-lasting durability. The company takes pride in its ability to consistently develop and deliver products that meet the evolving needs of its customers.One of the key features of the Diamond Wet Polishing Pads is their unique diamond pattern, which allows for efficient and precise polishing. The pads are also designed to minimize the risk of scratching or damaging the surface of the stone, ensuring a flawless finish every time. In addition, the company offers a variety of grit sizes to accommodate different levels of polishing and honing, making it a versatile solution for professionals in the industry.The company's commitment to quality is evident in its manufacturing process, which involves strict quality control measures to ensure that each pad meets the highest standards. By using only the finest quality diamonds and other materials, the company is able to produce pads that are not only effective but also reliable and long-lasting. This dedication to quality has earned the company a strong reputation among professionals in the stone fabrication industry.In addition to its commitment to quality, the company also places a strong emphasis on customer satisfaction. It provides exceptional customer service and support, ensuring that customers are able to find the right solutions for their specific needs. Whether it's providing expert advice on product selection or offering technical support, the company goes above and beyond to ensure that its customers are completely satisfied with their purchases.The company's dedication to innovation and customer satisfaction has allowed it to establish a strong presence in the stone fabrication industry. Its Diamond Wet Polishing Pads have become a preferred choice for professionals who demand the best results for their projects. With a focus on quality, reliability, and exceptional customer service, the company continues to set the standard for diamond tools in the industry.Overall, the company's Diamond Wet Polishing Pads have truly revolutionized the way professionals in the stone fabrication industry approach polishing and honing tasks. With a strong commitment to quality, innovation, and customer satisfaction, the company has solidified its position as a leader in the industry. As it continues to develop and deliver cutting-edge solutions, the company is poised to further elevate the standards of excellence in the stone fabrication industry.

The Importance of Polish: How to Achieve a Smooth and Glossy Finish

article highlighting the benefits and applications of these products.Polishes have been around for centuries, helping people to achieve a smooth and glossy finish on different surfaces. Today, there are many different types of polishes available in the market, each designed for specific applications. One of the most popular types of polish is the (brand name) Buff Polish Pad.(Company Name), the manufacturer of Buff Polish Pad, is a leading name in the polishing industry. The company has been providing high-quality polishing products to its customers for over (number) years. Buff Polish Pad is one of their most popular products, used by people all over the world to achieve a high-quality finish on different surfaces.So, what exactly is Buff Polish Pad, and what makes it so special? Buff Polish Pad is an abrasive pad made of high-quality materials that are designed to work with a wide range of surfaces. The pad is made up of tiny abrasive particles that help to remove scratches, stains, and other imperfections from surfaces while also leaving a smooth and glossy finish behind.One of the biggest advantages of using Buff Polish Pad is that it is versatile. It can be used on different types of surfaces, such as wood, metal, plastic, and more. This makes it an excellent choice for professionals and DIY enthusiasts alike.Another advantage of Buff Polish Pad is that it is easy to use. All you need to do is apply the pad to the surface you want to polish and work it in using a circular motion. The pad does the rest of the work for you, leaving behind a smooth and glossy finish.Additionally, Buff Polish Pad is environmentally friendly. It is made from natural and biodegradable materials, which means it is safe for the environment and does not harm the surface being polished.So, what are some of the applications of Buff Polish Pad? The product is widely used by woodworkers, auto mechanics, metalworkers, and others who need to polish different surfaces. Woodworkers use Buff Polish Pad to achieve a smooth and glossy finish on their wooden projects. Auto mechanics use it to polish car bodies and other metal parts. Metalworkers use it to polish metal surfaces to a high luster finish.In conclusion, Buff Polish Pad is an excellent choice for anyone who needs a high-quality polish for their surfaces. Its versatility, ease of use, environmental friendliness, and wide range of applications make it an extremely popular choice in the polishing industry. So, if you need to achieve a smooth and glossy finish on any surface, try Buff Polish Pad today!

Latest News on High-Quality Polish Diamonds: What You Need to Know

Polish Diamond, a leading provider of high-quality jewelry manufacturing and distribution, has been making waves in the jewelry industry with its exquisite and innovative designs. With a focus on delivering top-notch products and unparalleled customer service, Polish Diamond has quickly become a trusted name in the world of luxury jewelry.Founded in 2005, Polish Diamond has always been committed to excellence in every aspect of its business. From sourcing the finest diamonds and gemstones to creating stunning, one-of-a-kind pieces, the company has set itself apart with its uncompromising dedication to craftsmanship and quality. With a team of skilled artisans and designers, Polish Diamond has been able to produce jewelry that not only meets but exceeds the highest standards in the industry.One of the key factors that sets Polish Diamond apart from its competitors is its commitment to ethical sourcing and responsible business practices. The company takes great care to ensure that all its diamonds and gemstones are sourced from reputable suppliers who adhere to strict ethical and environmental standards. Additionally, Polish Diamond is actively involved in various corporate social responsibility initiatives, supporting local communities and environmental causes.In addition to its commitment to ethical sourcing, Polish Diamond also prides itself on its ability to stay ahead of the curve when it comes to design and innovation. The company's talented team of designers is constantly pushing the boundaries of traditional jewelry design, creating pieces that are not only visually stunning but also highly functional and wearable. From classic diamond solitaire rings to modern, avant-garde statement pieces, Polish Diamond offers something for every taste and style.Polish Diamond's dedication to innovation is further demonstrated through its use of advanced technology in the jewelry manufacturing process. The company utilizes state-of-the-art equipment and cutting-edge techniques to ensure that each piece of jewelry is crafted with precision and attention to detail. This commitment to excellence has earned Polish Diamond a reputation for producing some of the most beautifully crafted and flawlessly finished pieces in the industry.Moreover, Polish Diamond understands the importance of providing exceptional customer service. The company's knowledgeable and friendly staff is always ready to assist clients with any questions or requests, and they go above and beyond to ensure that every customer has a positive and memorable experience. Whether it's helping a client find the perfect engagement ring or providing expert guidance on jewelry care and maintenance, Polish Diamond is dedicated to building lasting relationships with its customers.As a company that values quality, integrity, and innovation, Polish Diamond has quickly risen to the top of the jewelry industry. With a steadfast commitment to excellence and a passion for creating breathtaking pieces, the company continues to captivate the hearts of jewelry lovers worldwide. Whether it's a dazzling diamond necklace, a sparkling pair of earrings, or a timeless engagement ring, Polish Diamond is the go-to destination for those who seek only the best in luxury jewelry.Looking ahead, Polish Diamond remains focused on expanding its reach and continuing to push the boundaries of jewelry design and craftsmanship. With a clear vision for the future and an unwavering dedication to its core values, Polish Diamond is set to continue its reign as a leader in the world of luxury jewelry for years to come. For those who appreciate the finest in quality and artistry, Polish Diamond is the ultimate destination for exquisite, timeless jewelry pieces.

Understanding the Concept of Metal Coordination Bonds in Chemistry

Metal Coordination Bond (MCB) is known for its exceptional strength and durability in the construction industry. The innovative technology has been widely recognized and used in various construction projects, providing a reliable and cost-effective solution for bonding metal substrates.With the increasing demand for high-quality construction materials, the development of Metal Coordination Bond has revolutionized the way metal substrates are bonded together. The unique chemical composition and bonding properties of MCB make it ideal for use in a wide range of applications, including structural steel, metal roofing, and metal cladding.The company behind this groundbreaking technology, {}, has been at the forefront of research and development in the construction industry for over a decade. Founded by a team of experienced engineers and materials scientists, {} has dedicated its resources to creating innovative solutions that address the needs of the construction industry.Driven by a commitment to excellence and a passion for innovation, {} has developed a strong reputation for delivering high-quality products that meet the highest standards of performance and reliability. The company's extensive research and development efforts have led to the successful commercialization of Metal Coordination Bond, which has been widely adopted by leading construction companies around the world.One of the key advantages of Metal Coordination Bond is its superior bonding strength, which far exceeds that of traditional adhesives and sealants. This makes it a preferred choice for demanding construction applications where the durability and longevity of the bonding material are paramount. Additionally, MCB's resistance to corrosion and weathering makes it an ideal solution for outdoor construction projects, providing long-lasting performance in even the harshest environments.Furthermore, Metal Coordination Bond offers significant cost savings for construction projects, as it eliminates the need for welding or mechanical fastening methods. This not only reduces labor and material costs but also streamlines the construction process, leading to greater efficiency and productivity on the job site.In addition to its exceptional bonding properties, Metal Coordination Bond is also environmentally friendly, as it contains no harmful chemicals or volatile organic compounds (VOCs). This aligns with the industry's growing emphasis on sustainable construction practices, making it a preferred choice for eco-conscious builders and developers.Looking ahead, the future of Metal Coordination Bond looks promising, as {} continues to invest in research and development to expand its product line and explore new applications for the technology. With a strong focus on innovation and a commitment to meeting the evolving needs of the construction industry, {} remains dedicated to providing cutting-edge solutions that drive the industry forward.As the construction industry continues to evolve, Metal Coordination Bond is poised to play a key role in shaping the future of construction materials and techniques. With its exceptional strength, durability, and environmental benefits, MCB offers a versatile and reliable solution for a wide range of construction applications, making it a preferred choice for builders, contractors, and developers worldwide.

Explore the Extensive Hand Pad Collection from a Leading Supplier in China

When it comes to perfecting your craftsmanship and achieving impeccable results, having the right tools can make all the difference. One such tool that has gained immense popularity in recent times is the Diamond Hand Pad. This revolutionary accessory has transformed the way artisans and DIY enthusiasts approach their projects, making it a must-have in every toolbox.Before we delve into the remarkable features and benefits of Diamond Hand Pads, let's briefly understand their significance. You see, in the world of precision work, conventional tools may not always provide the desired outcome. Finishing delicate surfaces or smoothing rough edges can be quite challenging without the appropriate tools. This is where Diamond Hand Pads come to the rescue.Now, what makes Diamond Hand Pads so special? The answer lies in the utilization of advanced diamond technology. These hand pads are designed with diamond particles infused into their surface, enabling them to effortlessly cut through various materials with precision and finesse. Whether you're working with glass, porcelain, stone, or even metals, these pads are an absolute game-changer.Diamond Hand Pads are renowned for their unmatched durability, ensuring that they will last you a lifetime. The diamond particles embedded in the pads deliver consistent and uniform performance, guaranteeing exceptional results with every use. Additionally, the long lifespan of these pads makes them a cost-effective investment for both professionals and DIY enthusiasts alike.One of the standout features of Diamond Hand Pads is their versatility. They can be used for a wide range of applications, including shaping, beveling, and polishing. These pads come in various grades, allowing users to achieve different levels of surface smoothness. Whether you're looking to create a high-gloss finish on a countertop or refine intricate details on a sculpture, Diamond Hand Pads have got you covered.To ensure superior ease of use, Diamond Hand Pads are ergonomically designed with a comfortable grip. The handle provides firm control, allowing you to maneuver the pad effortlessly. This level of control is essential, especially when working on delicate surfaces that require meticulous attention. The non-slip grip minimizes the risk of accidents, ensuring a seamless and hassle-free experience.Another notable advantage of Diamond Hand Pads is their water compatibility. Unlike conventional sanding tools, which often require messy lubricants, these pads can be used effectively with water alone. The water acts as a coolant, preventing overheating, and simultaneously washes away debris, keeping the pad clean and maintaining its efficiency. This eliminates the need for additional cleaning agents, making your work environment safer and more environmentally friendly.Furthermore, Diamond Hand Pads are designed to be lightweight and compact, making them ideal for both professional workshops and on-the-go projects. Their portability allows users to carry them effortlessly, ensuring that they have the right tool at their disposal wherever they go. The compact design also enables easy storage and organization, avoiding clutter and maximizing workspace efficiency.When it comes to hand pads, quality and reliability are crucial factors. This is why it is essential to choose a reputable supplier and manufacturer. In China, a leading manufacturer of hand pads stands out from the rest. With their unwavering commitment to excellence, they specialize in producing top-notch Diamond Hand Pads that meet the highest industry standards.In conclusion, Diamond Hand Pads have revolutionized the world of precision work. With their advanced diamond technology, exceptional durability, and unbeatable versatility, these hand pads have become an indispensable tool for artisans and DIY enthusiasts alike. Their water compatibility, ergonomic design, and portability further enhance their popularity. So, whether you're working on a small DIY project or a large-scale professional assignment, Diamond Hand Pads are bound to elevate your craftsmanship to the next level. Choose quality and choose the best when it comes to hand pads – choose Diamond Hand Pads.