Top-rated Cutting and Grinding Wheels for Precision Cutting

By:Admin

In the ever-evolving world of manufacturing and construction, having access to reliable and efficient tools is paramount. Cutting Edge Tools, a leader in innovative cutting and grinding solutions, is proud to announce the launch of their new cutting wheel and grinding wheel, designed to deliver enhanced performance and reliability.

With decades of experience in producing high-quality tools, Cutting Edge Tools has been committed to meeting the evolving needs of their customers. The introduction of the cutting wheel and grinding wheel demonstrates their dedication to providing the most efficient and effective options in the market.

The newly launched cutting wheel is equipped with state-of-the-art technology that ensures precision and durability. The wheel's design allows for smooth and quick cuts across a variety of materials, including metal, wood, and plastic. The use of premium quality materials guarantees long-lasting performance, reducing the need for frequent replacements.

One of the key features of the cutting wheel is its versatility. It offers compatibility with a range of power tools, making it an ideal choice for professionals in various industries. Whether it's for construction, automotive repair, or DIY projects, this cutting wheel proves to be an essential tool for any cutting application.

In addition to the cutting wheel, Cutting Edge Tools has also developed a grinding wheel that delivers outstanding results. The grinding wheel is designed to provide a consistent and uniform finish on different surfaces. Its superior abrasive properties allow for efficient material removal, saving both time and effort.

The grinding wheel has been engineered with user convenience in mind. It features an ergonomic design for comfortable handling and reduced fatigue during extended use. Additionally, its exceptional heat dissipation properties prevent overheating, ensuring optimal performance even under intense working conditions.

The launch of the cutting wheel and grinding wheel marks Cutting Edge Tools' commitment to innovation and customer satisfaction. With extensive research and development, they have successfully created tools that not only meet but exceed industry standards.

"We are thrilled to introduce our cutting wheel and grinding wheel to the market," said {Company Representative}. "These tools are a testament to our dedication to excellence and provide our customers with efficient and reliable solutions for their cutting and grinding needs. We believe that these products will enhance productivity and assist professionals in achieving high-quality results."

As a company, Cutting Edge Tools aims to deliver products of exceptional quality that are also environmentally sustainable. The cutting wheel and grinding wheel are manufactured using eco-friendly materials and production processes, reducing their impact on the environment.

To ensure customer satisfaction, Cutting Edge Tools provides prompt customer service support and offers a warranty on all their tools. They are determined to maintain their reputation as a trustworthy and reliable provider of cutting and grinding solutions.

"Customer satisfaction is at the core of our business values," stated {Company Representative}. "We believe in building long-lasting relationships with our customers by providing them with top-notch products and exceptional service. Our cutting wheel and grinding wheel are a testament to our commitment to their success."

Cutting Edge Tools continues to lead the industry with their dedication to innovation and their drive to meet the evolving needs of their customers. The cutting wheel and grinding wheel are just the beginning of a series of groundbreaking products set to revolutionize the cutting and grinding industry.

With the launch of these advanced tools, Cutting Edge Tools remains at the forefront of the industry, providing professionals with reliable, efficient, and durable solutions for their cutting and grinding requirements.

Company News & Blog

Effortlessly Tackle Wood Floor Sanding with Electric Sanding Machines

Wood Floor Sanding Made Easy with Electric MachinesWood floor sanding is a crucial step in maintaining and restoring the beauty of your wooden floors. Whether you are refinishing old flooring or preparing new wood floors for a finish, sanding plays a vital role in achieving a smooth and flawless surface. While sanding can be done manually, the process becomes much more efficient and time-saving with the help of electrically driven sanding machines.DoItYourself.com, a leading online resource for DIY projects and home improvement, recognizes the significance of using electric sanding machines in large-scale wood floor sanding projects. With their power and versatility, these machines have revolutionized the way professionals and homeowners tackle flooring projects.One such highly regarded machine in the industry is the Wood Floor Sanding Edging Machine, produced by a renowned company (brand name removed). This powerful machine has earned a reputation for its exceptional performance and user-friendly features. Equipped with state-of-the-art technology, it enables efficient sanding along the edges of wood floors, reaching corners and tight spaces with ease.The Wood Floor Sanding Edging Machine boasts a robust motor that delivers high-speed sanding, effectively removing old finishes, stains, and scratches. Its ergonomic design ensures comfortable handling, reducing operator fatigue during extended sanding sessions. The machine is also equipped with a dust extraction system, keeping the work area clean and minimizing the risk of respiratory issues caused by wood dust.One of the standout features of this machine is its adjustable sanding depth, allowing users to achieve precise sanding results according to their unique requirements. The maneuverability of the Wood Floor Sanding Edging Machine is another notable advantage, as it effortlessly glides over the surface, creating a uniform finish without leaving any swirl marks or gouges.A notable advantage of using electric sanding machines for wood floor sanding is the significant reduction in project time. Compared to manual sanding, which requires extensive physical effort and a multitude of sanding pads, electric machines can accomplish the task in a fraction of the time. This makes them ideal for both professional contractors with tight deadlines and homeowners looking to complete their DIY projects efficiently.Furthermore, electric sanding machines ensure consistent results across the entire wood floor surface. The design of these machines allows for uniform pressure distribution, minimizing the risk of uneven sanding or overworking certain areas. This guarantees a smooth and level surface, ready for the application of finishes or sealants.In conclusion, electrically driven sanding machines have become an essential tool for wood floor sanding projects. Their power, efficiency, and ease of use make them indispensable for professionals and DIY enthusiasts alike. The Wood Floor Sanding Edging Machine, provided by the reputable company (brand name removed), exemplifies the cutting-edge technology and user-centric design that has propelled sanding machines to new heights. So, whether you are embarking on a large-scale flooring project or simply restoring a single room, utilizing electric sanding machines will undoubtedly streamline the process and leave your wood floors looking stunning.

Understanding Metallic Bonding: What You Need to Know

article on the importance of metallic bonding in modern technology.Metallic Bonding and Its Importance in Modern TechnologyMetallic bonding is a fundamental concept in the world of chemistry and materials science. The unique properties of metals like strength, ductility, thermal and electrical conductivity, and luster can be attributed to the special bonding arrangement between the positively charged metal ions and the delocalized electrons.In recent years, metallic bonding has paved the way for several technological advancements that have transformed the way we live, work, and communicate. From advanced alloys used in aerospace and defense to high-precision components in electronics and renewable energy systems, metallic bonding plays a crucial role in shaping modern technology.One company that is leading the charge in metallic bonding technology is {metal bond}, a renowned name in the field of materials science and engineering. The company specializes in the development of high-performance alloys and composite materials that offer unparalleled strength, durability, and resistance to harsh environments.One of {metal bond}'s flagship products is its proprietary metal matrix composite (MMC) technology. MMCs are a unique class of materials that combine the desirable properties of metals and ceramics, making them ideal for a wide range of applications in the aerospace, defense, and automotive industries.MMC technology utilizes the principles of metallic bonding to create a high-strength matrix of metal ions reinforced with ceramic particles. The result is a material that is exceptionally strong and lightweight while retaining excellent thermal and electrical conductivity.MMC materials are used in critical components such as turbines, engine parts, and brake systems in high-performance cars and aircraft. These components require materials that can withstand extreme temperatures, pressures, and mechanical stresses without failure. MMCs provide the necessary strength and durability needed for such challenging applications, making them an indispensable tool in modern engineering.In addition to MMCs, metallic bonding is also utilized in other advanced materials such as shape-memory alloys (SMAs) and superalloys. SMAs are a class of materials that exhibit unique elasticity and shape-changing properties at specific temperatures, making them ideal for use in medical implants, aerospace, and robotics.Superalloys, on the other hand, are a specific class of alloys that exhibit exceptional heat resistance and mechanical strength, making them ideal for use in high-temperature applications such as gas turbines, jet engines, and nuclear reactors.The widespread use of metallic bonding in modern technology has undoubtedly transformed many industries and opened up new avenues for innovation and advancement. However, this is just the tip of the iceberg, as researchers continue to explore new ways to harness the unique properties of metallic bonding to create even more advanced materials and technologies.In conclusion, metallic bonding is an essential concept that has revolutionized the fields of materials science and engineering. The special bonding arrangement between the positively charged metal ions and the delocalized electrons is responsible for the unique properties of metals, making them indispensable in modern technology. With the advent of advanced materials like MMCs, SMAs, and superalloys, the potential applications of metallic bonding are virtually limitless, paving the way for even more exciting advances in the future.

Quality Diamond Tools for Granite: Order Online or Call Today 01452 751123

**Title: Revolutionizing Granite Cutting with Premium Diamond Tools**Introduction:Diamond Tool Granites, a leading player in the diamond tool industry, is set to transform the granite cutting landscape with its innovative range of Granite Blades tools. With a focus on delivering exceptional performance and unmatched precision, these diamond saw blades are essential for professionals and hobbyists alike. Offering a wide range of options and the convenience of online ordering, Diamond Tool Granites is revolutionizing the way granite is processed.Enhancing Cutting Efficiency:One of the primary challenges in granite cutting is finding tools that can effectively cut through the hard and abrasive nature of the material. Diamond Tool Granites’ Granite Blades have been engineered specifically to tackle this problem. By utilizing high-quality diamonds that are either embedded or welded into the blade, the cutting speed and efficiency are significantly enhanced. This allows professionals to complete their projects with greater ease, saving both time and effort.Precision and Durability:Apart from ensuring efficient cutting, Diamond Tool Granites understands the need for precision in the granite cutting industry. Imperfections during cutting not only affect the aesthetics but can also compromise the structural integrity of the final product. The company’s Granite Blades are designed with precision in mind, ensuring clean and accurate cuts every time. With their durability, these blades are built to withstand the rigors of daily use, maintaining their sharpness and effectiveness over extended periods.Versatility and Application:Diamond Tool Granites offers a diverse range of Granite Blades, each catering to specific applications. Whether it's cutting slabs for countertops or shaping intricate designs, their extensive product line has a solution for every requirement. With varying sizes, including diameters ranging from 4 inches to 14 inches, professionals can choose the ideal blade to match their project needs. Diamond Tool Granites takes pride in the versatility of its products, providing tools suitable for both wet and dry cutting, ensuring compatibility with different cutting machines and techniques.Expert Guidance and Online Ordering:Diamond Tool Granites understands that professionals and hobbyists alike may require expert guidance to select the appropriate tools for their projects. With a team of knowledgeable professionals, the company provides personalized assistance, guiding customers through the selection process based on their unique requirements. In addition to this, Diamond Tool Granites offers the convenience of online ordering, ensuring customers can quickly and easily purchase the necessary tools without leaving their workspace. Their user-friendly website allows customers to browse the product range, compare specifications, and place orders securely and efficiently.Customer Satisfaction and Support:Diamond Tool Granites prides itself on its unwavering commitment to customer satisfaction. With an emphasis on product quality and performance, the company has garnered a loyal customer base over the years. Alongside their exceptional products, they provide reliable after-sales support, including troubleshooting assistance and warranty coverage. Customers can reach out to Diamond Tool Granites via phone or email, where their dedicated customer service team is always ready to address any concerns or queries promptly.Conclusion:Diamond Tool Granites has redefined the standards of granite cutting with its range of Granite Blades. Combining efficiency, precision, versatility, and durability, these diamond tools provide professionals with an edge in their work. With the added convenience of online ordering and expert guidance, Diamond Tool Granites is bridging the gap between high-quality diamond tools and the needs of the market. As the industry continues to advance, Diamond Tool Granites remains at the forefront, setting new benchmarks for innovation and customer satisfaction.

Accelerating Growth and Unlocking Potential: Insights from GEM 2011

article with the following headline:"GEM 2011: Accelerating Growth and Unlocking the Potential of Developing Countries"The fourth edition of the Global Entrepreneurship Monitor (GEM) conference was held in[location]on [date], bringing together some of the most influential policy makers, business leaders, development experts and academics from around the world. The conference was focused on discussing new strategies for accelerating growth and unlocking the potential of developing countries.The discussions at the GEM 2011 conference were centered on various topics such as the role of entrepreneurship in the economic development of developing countries, identifying key drivers of success, and overcoming challenges in promoting entrepreneurship in different regions.One of the key highlights of the conference was the presentation by [company introduction] Stone Tools which highlighted its innovative approach towards promoting entrepreneurship in developing countries. The presentation emphasized the crucial role of technology and innovation in promoting entrepreneurial growth in developing countries. Stone Tools also showcased its state-of-the-art digital platform which makes entrepreneurship resources, tools, and insights accessible to entrepreneurs all around the world.The discussion panel at the conference, which included leading experts and entrepreneurs, underlined the importance of creating an enabling environment for entrepreneurship and innovation in developing countries. They stressed upon the need for governments to invest in infrastructure, education, and policies that support entrepreneurship and innovation. The panel also discussed the importance of building strong networks among entrepreneurs, investors, and policymakers to create a vibrant entrepreneurship ecosystem.Another key takeaway from the GEM 2011 conference was the emphasis on the need for a multidisciplinary approach towards entrepreneurship research. The conference highlighted the importance of integrating insights from various fields such as economics, sociology, psychology, and history, to gain a deeper understanding of the complex factors that shape entrepreneurial behavior in different regions.The conference also addressed some of the key challenges faced by entrepreneurs in developing countries such as access to finance, regulatory barriers, cultural and social norms, and limited access to technology and innovation. The experts emphasized upon the need for collaborative efforts between governments, entrepreneurs, and development agencies to overcome these challenges and promote entrepreneurship in developing countries.In conclusion, the GEM 2011 conference provided an excellent platform for discussions on accelerating growth and unlocking the potential of developing countries. The conference showcased some of the latest innovations and insights in the field of entrepreneurship and highlighted the importance of creating a supportive ecosystem for entrepreneurship to thrive in developing countries. The conference also emphasized the need for continued research and collaboration to tackle some of the critical challenges faced by entrepreneurs in the developing world.

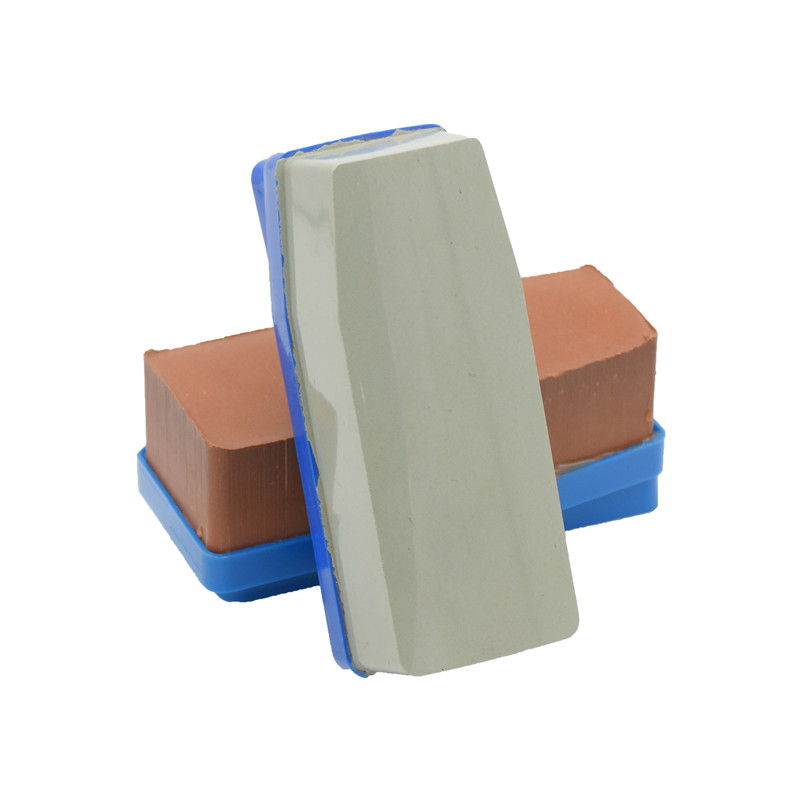

Economical Wet Polishing Pads for Effective Granite Polishing

: Achieving a Perfect FinishGranite surfaces are remarkable in providing the perfect blend of style and durability. From kitchen countertops to floors, walls, and statues, granite is a popular material used in homes and commercial buildings. However, to ensure that your surfaces are always looking their best, you need to invest in a high-quality granite wet polisher. In this blog post, we will discuss achieving a perfect finish using a granite wet polisher.Why Use a Granite Wet Polisher?A wet polisher is an essential tool for polishing granite surfaces. As the name implies, a wet polisher works with water, which acts as a lubricant and cooling agent to prevent overheating of the granite. Wet polishing also helps to remove dust particles, ensuring a smoother and cleaner finish. A granite wet polisher removes scratches, brings out the natural shine of the stone, and eliminates any imperfections on the surface.Choosing the Right Polishing PadsWhen it comes to polishing granite, you need the right polishing pads. The Puma Economy Wet Polishing Pads are an excellent choice for achieving a perfect finish. These pads are designed to perform well at a great price, making them an economic option. Additionally, the Puma polishing system features exclusive Geo patterns that help displace and channel water during use, ensuring a smoother and more polished finish.The 7 Step Puma Polishing SystemThe 7 Step Puma polishing system includes seven different grits of polishing pads that help achieve a mirror-like polished surface. The grit progression starts from coarsest to finest, starting at 50, 100, 200, 400, 800, 1500, and ending with 3000. You need to follow each step of the polishing process with care, ensuring that you remove any scratches or rough spots before proceeding to the next step. Remember that each step prepares the surface for the next, so take time to complete each one before moving on.Steps to Achieving a Perfect Granite Polished SurfaceStep 1: Clean the SurfaceThe first step is to clean the granite surface thoroughly. Use a soft brush or vacuum to remove any dirt or debris on the surface.Step 2: Start with Coarse GritsAttach the 50-grit polishing pad to the granite wet polisher and start polishing the surface. Work in sections, keeping the pad flat and applying even pressure. Once the surface is smooth and free of scratches, move on to the next finer grit.Step 3: Progress to Finer GritsContinue working through the finer grits until you reach the 3000-grit polishing pad. At each stage, ensure that the surface is clean and free of scratches before moving on to the next grit.Step 4: Rinse the SurfaceOnce you've completed each stage, rinse the surface with water to remove any debris. Check that the surface is completely clean and free of scratches.Step 5: Apply Granite SealerAfter polishing, it's advisable to apply granite sealer to protect the surface from stains and water damage.Step 6: Buff the SurfaceUse a soft buffing pad on the granite wet polisher to buff the surface to a high shine. Use water to lubricate the surface and prevent heat damage.Step 7: Clean the Surface Once AgainFinally, clean the surface one last time to remove any buffing residue and leave the surface sparkling.ConclusionAchieving a perfect finish on granite surfaces requires patience, attention to detail, and the right equipment. By using a granite wet polisher with the correct polishing pads and following each step of the polishing process, you can achieve a mirror-like polished finish. The Puma Economy Wet Polishing Pads are an economic, quality option for achieving a perfect finish on granite surfaces. So the next time you're looking to polish granite surfaces, invest in quality tools, and you'll be proud of your finished product.

Rewrite for SEO optimization: Supplier for Wet Polishing Pads - Weihai Chengxun Import & Export Co., Ltd., offering a wide range of granite slabs, tombstones, granite countertops, vanity tops, monuments, slate and marble fireplaces, wooden shutters, film faced plywood, garden fountains, water pots, marble carvings, diamond tools, cutting blades, and polishing pads.

Diamond Wet Polishing Pads: The Ultimate Guide to Achieving Perfect Stone FinishPolishing is an important process in the production of stone surfaces. It is the final step that helps improve the aesthetic value of the stone. Because of the huge demand for stone products, manufacturers are always looking for ways to improve their production processes to ensure they deliver top-quality products. This has led to the production of different types of polishing pads. Diamond wet polishing pads are currently the most popular type of polishing pads on the market. In this article, we’ll take a closer look at diamond wet polishing pads.What are diamond wet polishing pads?Diamond wet polishing pads are polishing tools used to polish stone surfaces, such as granite, marble, and concrete. They are called "diamond" wet polishing pads because they are made of diamond particles. This means that they are designed to handle tougher materials, unlike traditional polishing pads. They are called "wet" polishing pads because they are used in combination with water. The water acts as a lubricant and helps to reduce heat generated during the polishing process.What makes diamond wet polishing pads unique?Diamond wet polishing pads are unique because they are designed to last longer than traditional polishing pads. This is because they are made of diamond particles, which are durable and wear-resistant. This allows them to handle even the toughest materials, providing a consistent and flawless finish. They are also the best choice when it comes to polishing edges and corners, as they provide excellent precision, and leave no scratches or marks.What are the different types of diamond wet polishing pads?There are different types of diamond wet polishing pads available on the market. They vary in terms of their size, quality, and intended use. Some popular types include:1. Electroplated diamond polishing pads: These are diamond pads that are attached to the backing plate with an electroplating process. They are durable and provide excellent results when polishing granite and other hard materials.2. Resin diamond polishing pads: These are diamond pads that use a resin binder to hold the diamond particles together. They are suitable for use on softer stones, such as marble or travertine.3. Metal bond diamond polishing pads: These are diamond pads that are designed to handle the toughest materials, such as concrete. They are the most aggressive type of diamond polishing pad and will leave scratches that can be removed by finer grits.How to use diamond wet polishing pads?Using diamond wet polishing pads is a fairly simple process. Here are some steps to follow:1. Choose the right pad grit: Depending on the type of stone you are polishing, you will need to choose the correct grit. Start with a coarser grit and work your way up to finer grits until you achieve the desired finish.2. Attach the pad: Attach the diamond pad to a polisher. Ensure that the polisher is water-fed to keep the surface of the stone cool and to avoid dust.3. Begin polishing: Start polishing the surface of the stone, moving the polisher in a circular motion. Keep the surface wet at all times to prevent overheating.4. Change the pads: As you move from coarser to finer grits, change to a new pad. This is to avoid cross-contamination and to achieve the desired finish.ConclusionDiamond wet polishing pads are a must-have for anyone looking to achieve a perfect, polished finish on stone surfaces. They are durable and long-lasting, providing a consistent finish every time. With the right technique and grit sequence, you can achieve an excellent finish on any stone material. Make sure to always choose the right grit for the stone you are working on, and to keep the surface wet to avoid overheating. With diamond wet polishing pads, you can achieve a stunning, polished finish that will last for years to come.

Top-Quality Diamond Grinding Wheels for Superior Performance, Precision and Durability

Diamond CBN Grinding Wheels: Benefits and ApplicationsGrinding wheels are highly essential in the manufacturing industry for a wide range of applications ranging from shaping, cutting, and grinding. While there are various types of grinding wheels, diamond and CBN grinding wheels offer immense benefits in terms of exceptional performance, precision, and longevity. Diamond CBN grinding wheels, also known as Superabrasive wheels, are efficient and highly effective materials for cutting and shaping different materials, especially those that are hard to machine.What are Diamond CBN Grinding Wheels?A diamond grinding wheel is a type of abrasive tool that features diamond-coated abrasive beads that are used for grinding, cutting, and shaping different materials. On the other hand, CBN (cubic boron nitride) grinding wheels feature abrasive beads coated with CBN, another common superabrasive material.Diamond and CBN Grinding Wheels are DifferentDiamond and CBN grinding wheels feature different properties that make them ideal for specific applications. For example, the diamond grinding wheel is suitable for grinding materials such as carbides, ceramics, glass, and other hard materials. CBN grinding wheels, on the other hand, are ideal for grinding materials such as high-speed steels and super alloys.Applications of Diamond CBN Grinding WheelsDiamond and CBN grinding wheels have a wide range of applications in different industries, including:1. Aerospace Industry: Diamond CBN grinding wheels are widely used in the aerospace industry for grinding materials such as nickel-based alloys, titanium alloys, and aluminum alloys. These materials are commonly used in the manufacture of aircraft engines, blades, and other components.2. Automotive Industry: In the automotive industry, diamond CBN grinding wheels are used for grinding and shaping the engine components, such as camshafts, crankshafts, and valves, among others. This helps to improve the durability, performance, and efficiency of these components.3. Medical Industry: The medical industry uses diamond CBN grinding wheels for grinding medical implants, surgical tools, and other precision components. Diamond CBN grinding wheels are ideal for materials such as tungsten carbide, ceramics, and titanium, among others.4. Glass Industry: Diamond CBN grinding wheels are used in the glass industry for grinding and polishing glass surfaces such as lenses, mirrors, and optical components. Diamond grinding wheels are preferred due to their ability to produce high-quality finishes and precision.Benefits of Diamond CBN Grinding Wheels1. Longevity: Diamond CBN grinding wheels are highly durable and can last longer than other types of grinding wheels. They are designed to provide consistent performance over extended periods, making them cost-effective solutions for various applications.2. High Performance: Diamond CBN grinding wheels are designed to provide high levels of precision and performance. They are capable of producing high-quality finishes and sharp edges that are ideal for precision grinding applications.3. Versatility: Diamond CBN grinding wheels can be used for grinding a wide range of materials, including carbides, ceramics, glass, and other hard materials. They are highly versatile and can be used in different industries.4. Reduced Downtime: Diamond CBN grinding wheels require minimal maintenance, resulting in less downtime and increased productivity. They are designed to provide consistent performance even in high-pressure applications.ConclusionDiamond CBN grinding wheels offer immense benefits in terms of longevity, precision, and performance. They are widely used in different industries, including aerospace, automotive, medical, and glass. If you are in the manufacturing industry and looking for high-quality grinding wheels, consider purchasing diamond CBN grinding wheels. They are cost-effective solutions that offer consistent performance over extended periods.

Low-Priced Honeycomb Dry Diamond Flexible Polishing Pad for Efficient Stone Polishing

, Diamond Polishing Pads, Stone Polishing Pads, Dry Polishing Pads, Flexi Polishing PadsThe demand for Honeycomb Dry Diamond Flexible Polishing Pads has been on the rise due to their excellent performance and efficiency in polishing surfaces. They are versatile, user-friendly, durable, and easy to use in both dry and wet applications. The Honeycomb design provides more contact points on the material being polished, which translates to faster and smoother polishing.At (brand name removed), we understand the importance of high-quality polishing pads for both professionals and DIY enthusiasts. This has driven us to develop premium-grade Honeycomb Dry Diamond Flexible Polishing Pads, which are suitable for use on different types of materials such as granite, marble, concrete, and engineered stone.Our Honeycomb Polishing Pads are designed to provide a consistent finish without leaving swirl marks or scratches on the surface being polished. They are available in different grits ranging from coarse to fine, which makes them ideal for both heavy stock removal and light polishing. With our high-quality Diamond Polishing Pads, achieving a high gloss finish is easy and effortless.One of the benefits of our Honeycomb Dry Diamond Flexible Polishing Pads is that they are compatible with different types of hand polishers and portable grinders. This allows you to use the same pad for different applications, which saves you money and time. Additionally, our Flexi Polishing Pads are versatile and can be used for both dry and wet polishing applications.Another benefit of our Honeycomb Polishing Pads is that they are long-lasting and wear-resistant. This is because they are made from high-quality diamonds that are evenly distributed on the pad's surface. Additionally, they have a flexible foam backing that conforms to the shape of the surface being polished, which ensures uniform and consistent pressure distribution.One of the challenges that most polishing pad users face is clogging. This happens when the pad's pores get filled with debris, which reduces its efficiency and performance. However, our Honeycomb Dry Diamond Flexible Polishing Pads have an open-cell design that reduces clogging and allows for easy debris removal. This ensures that you get more use out of each pad and saves you money in the long run.In conclusion, our Honeycomb Dry Diamond Flexible Polishing Pads are the ideal choice for achieving a high gloss finish on different types of surfaces. They are versatile, user-friendly, and compatible with different types of hand polishers and portable grinders. Additionally, their long-lasting and wear-resistant design ensures that you get maximum value for your money. Contact us today for low prices and high-quality Diamond Polishing Pads, Stone Polishing Pads, Dry Polishing Pads, and Flexi Polishing Pads.

Shop Top-Quality Supplies for Concrete Countertops and Floors: Polishing Pads, Sealers, Stains, and More

Concrete Exchange: The One-Stop Shop for All Your Concrete NeedsConcrete has grown in popularity as a material for interior and exterior design in recent years. From polished concrete floors to concrete countertops, it’s hard to miss the sleek and modern look it lends to any space.At Concrete Exchange, we are passionate about helping you create beautiful and functional concrete surfaces. Our extensive collection of supplies includes everything you need to make concrete countertops, decorative concrete sealers, stains, and epoxy floor coating. We also offer floor leveling and patch products along with moisture mitigation and subfloor primers from trusted brands like Schonox, USG Durock, Surecrete, Sika, Cheng, and Interstar – to name a few.But why choose Concrete Exchange over other suppliers?Quality ProductsWe pride ourselves on providing high-quality products that deliver consistent results. Our diamond polishing pads, for instance, are made from high-quality materials and are specially designed to polish concrete surfaces to perfection. They come in various grit levels, making it easy to achieve the desired level of polish for your project.Easy Online OrderingOur website is user-friendly, making it easy to find what you need and place your order. We offer fast and reliable shipping, with most orders delivered within a few business days. And if you need assistance, our team is always ready to help.Expert AdviceWe don’t just provide products, we also offer expert advice on how to use them. Whether you’re a seasoned pro or new to the world of concrete, our team is always available to provide guidance and answer any questions you may have.SustainabilityWe believe in sustainability and reducing waste, which is why we offer reusable silicone molds for creating concrete countertops and other surfaces. This not only reduces waste but also saves you money in the long run.Final ThoughtsAt Concrete Exchange, we are committed to providing quality products, easy ordering, expert advice, and sustainability. Whether you’re a homeowner or a contractor, we have everything you need to create beautiful and functional concrete surfaces. So, if you’re looking for diamond floor polishing pads or any other concrete supplies, look no further than Concrete Exchange – your one-stop shop for all your concrete needs!

Secure Your Home with a Heavy-Duty Copper and Steel Safety Door

Metal Copper Bonds: The Strength of Steel and the Elegance of CopperWhen it comes to home security, one of the most important considerations is the entry door. A strong and durable door not only provides protection from intruders, but also adds to the aesthetic appeal of your home. If you are looking for a door that combines strength and elegance, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is the perfect choice for you. With its unique combination of steel and copper, this door offers both security and style.The door is made of heavy-duty steel which provides unparalleled strength and durability. The steel construction ensures that the door cannot be easily broken into, making it an ideal choice for those concerned about home security. The steel material also makes the door highly resistant to weather, ensuring that it will withstand harsh conditions for years to come.While steel offers superior strength, sometimes it lacks in aesthetic appeal. That is where the copper element comes in. Copper is one of the oldest building materials in the world, and has been used for thousands of years because of its beauty and durability. The copper gives the door a classic and elegant look, which can add to the overall aesthetic appeal of your home. The copper element also adds a layer of protection to the door. Copper has natural anti-bacterial and anti-microbial properties which help to prevent the growth of bacteria and other harmful microorganisms on the surface of the door.The Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is also equipped with a metal screen which further enhances the security features of the door. The screen is made of high-quality steel which is designed to prevent intruders from entering your home. The screen also provides an added layer of protection against insects and pests, without compromising the flow of fresh air into your home.Another important feature of the door is the stop mechanism. The door is designed with a built-in stop which prevents it from opening too far and causing damage to the hinges. This will help to keep the door in good condition for years to come, and prevent the need for costly repairs in the future.Overall, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is an excellent choice for those who want to increase the security of their home. The combination of steel and copper makes it a highly durable and attractive option, while the metal screen and stop mechanism provide additional layers of protection. Whether you are looking to enhance the aesthetic appeal of your home, or simply want to feel more secure, this door is an excellent investment. So why not add some metal copper bonds to your home today?