Top Diamond Tools for Granite - The Ultimate Guide

By:Admin

With the increasing demand for high-quality granite products in construction and interior design, the need for advanced cutting tools has also grown. {Company Name} has recognized this need and has invested heavily in research and development to create tools that are both efficient and durable. Their new line of diamond tools for granite is a result of this commitment to innovation and excellence.

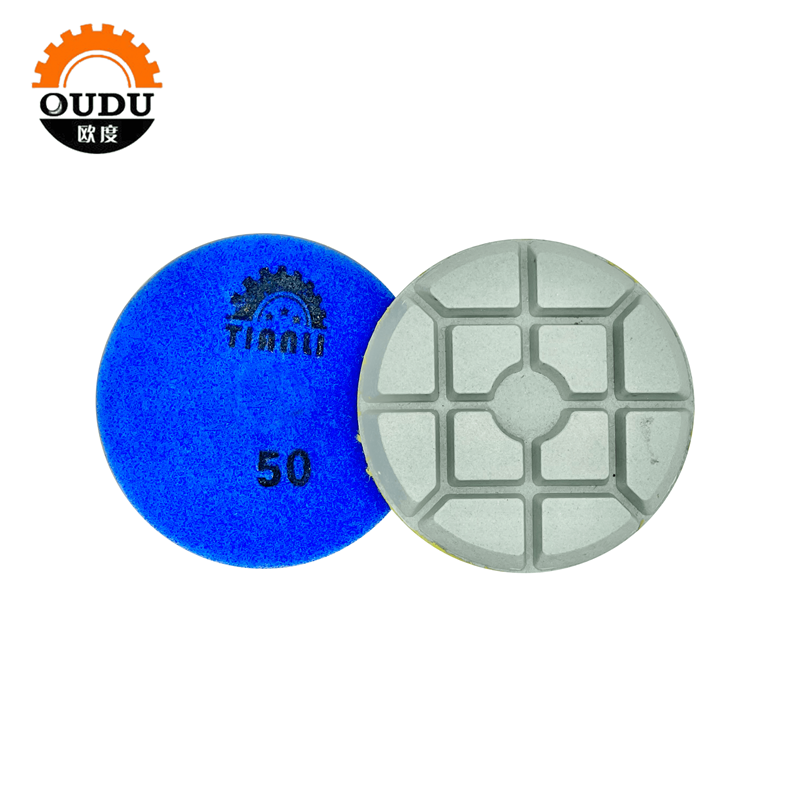

The new products include diamond saw blades, core drills, grinding wheels, and polishing pads, all of which are designed to achieve precise and smooth cuts on granite. These tools are made from high-quality diamond particles that are bonded to the cutting edge, ensuring long-lasting performance and consistent results. Additionally, {Company Name} has incorporated advanced technologies such as laser welding and precision engineering to further enhance the performance of their tools.

One of the key features of the new line of diamond tools is the ability to cut through granite with minimal chipping and breakage. This is achieved through the use of specially designed diamond segments that are engineered to deliver clean and precise cuts, even on the toughest granite surfaces. The tools also offer excellent heat resistance, ensuring that they maintain their cutting performance even in high-temperature environments.

In addition to cutting, the new line of diamond tools for granite also includes products for shaping and polishing. The diamond grinding wheels and polishing pads are designed to provide a smooth and glossy finish on granite surfaces, enhancing their aesthetic appeal. These tools are also engineered to be long-lasting and resistant to wear and tear, making them ideal for heavy-duty applications.

{Company Name} has also focused on ergonomics and user-friendliness in the design of their new products. The tools are lightweight and balanced, allowing for easy handling and precise control during operation. This ergonomic design not only enhances the performance of the tools but also reduces operator fatigue, resulting in more efficient and comfortable working conditions.

As a leading manufacturer of diamond tools for granite, {Company Name} is committed to providing comprehensive support to its customers. The company offers technical assistance, training, and after-sales service to ensure that their products are used to their full potential. This dedication to customer satisfaction has earned {Company Name} a strong reputation in the industry, making them a trusted partner for businesses involved in granite processing.

The launch of the new line of diamond tools for granite represents a significant milestone for {Company Name} and is poised to strengthen their position as a leading provider of cutting-edge solutions for the granite industry. With their unwavering commitment to innovation, quality, and customer satisfaction, {Company Name} is set to make a lasting impact in the world of diamond tools for granite.

In conclusion, {Company Name}'s new line of diamond tools for granite is a testament to their dedication to delivering high-quality, innovative products to the market. With advanced technologies, precision engineering, and a focus on user-friendly design, these tools are set to redefine the standards for cutting, shaping, and polishing granite. As the demand for high-quality granite products continues to grow, {Company Name} is well-positioned to meet the needs of the industry and surpass expectations with their cutting-edge solutions.

Company News & Blog

Adopt DiaMEND Orange Diamond Restoration Screens to Repair Traffic Patterns and Stains on Concrete and Stone Floors

Title: Diamond Concrete Buffer Pads: The Ultimate Solution for Flooring RestorationIntroduction:Maintaining the pristine condition of concrete and stone floors is crucial for businesses and homeowners alike. Constant foot traffic, scratches, and stains can quickly mar the appearance of these surfaces, ultimately resulting in costly repairs. However, with the advent of advanced technology, solutions such as the DiaMEND Orange Diamond Concrete & Stone Restoration Screens have emerged to address these issues effectively. In this blog post, we will delve into the benefits of using these 400 Grit Orange Diamond Round Screens, which are compatible with existing floor buffers and auto scrubbers. Let's explore how Diamond Concrete Buffer Pads can revolutionize the way you restore your concrete and stone floors.1. Enhance Efficiency and Cost-effectiveness:The DiaMEND Orange Diamond Concrete & Stone Restoration Screens work wonders by tackling traffic patterns, scratches, and stains before they escalate into serious problems. By incorporating these screens into your floor maintenance routine, you'll not only save time but also mitigate the need for extensive repairs down the line, potentially saving you substantial costs.2. Premium Quality and Versatile Application:One crucial aspect of Diamond Concrete Buffer Pads is their exceptional quality. Manufactured with advanced orange diamond grit technology, these round screens provide remarkable durability and longevity. Whether you are dealing with uneven surfaces, deep stains, or light scratches, these pads prove to be an effective solution for all concrete and stone floors.3. Compatibility with Existing Floor Equipment:Integrating the DiaMEND Orange Diamond Concrete & Stone Restoration Screens into your existing floor buffers and auto scrubbers is seamless. This compatibility ensures that you don't need to invest in expensive new machinery, making it a cost-efficient and convenient solution for both commercial and residential use.4. Eco-friendly and Safe Usage:Conscious about the environment? Diamond Concrete Buffer Pads are the way to go! These pads are designed to be used with water, eliminating the need for harmful chemicals during the restoration process. With an eco-friendly approach, you can restore the beauty of your floors without causing harm to the environment or compromising on the safety of those who utilize the space.5. Unparalleled Performance:The 400 Grit Orange Diamond Round Screens exhibit remarkable performance, allowing you to achieve remarkable results. They effectively remove deep-seated stains, eliminate stubborn scratches, and restore the natural shine and smoothness of your surfaces. With consistent usage, your concrete and stone floors will regain their former glory, impressing visitors and enhancing the overall aesthetic appeal of your space.Conclusion:Investing in DiaMEND Orange Diamond Concrete & Stone Restoration Screens proves to be a game-changer in the realm of flooring restoration. By effectively addressing traffic patterns, scratches, and stains, these Diamond Concrete Buffer Pads save you from incurring costly repairs in the future. With their exceptional quality, compatibility with existing floor equipment, eco-friendly nature, and unparalleled performance, these 400 Grit Orange Diamond Round Screens become your go-to solution for concrete and stone floor maintenance. Embrace the future of flooring restoration and unlock the true potential of your surfaces with Diamond Concrete Buffer Pads!Keywords: Diamond Concrete Buffer Pad, DiaMEND Orange Diamond Concrete & Stone Restoration Screens, concrete floor restoration, stone floor restoration, floor maintenance, cost-effective solutions, versatile application, eco-friendly, compatibility with existing equipment, unparalleled performance.

High-Quality Wet/Dry Polishing Pads for a Smooth Finish

Wet/Dry Polishing Pads are gaining popularity in the construction and renovation industry due to their high effectiveness and versatility. These polishing pads are used for smoothing and polishing surfaces such as marble, granite, concrete, and other natural stones. With the ability to be used for both wet and dry applications, these pads have become a go-to tool for professional contractors and DIY enthusiasts alike.One company that has been making waves in the industry with their high-quality Wet/Dry Polishing Pads is {}. With years of experience in the field, they have established themselves as a leading manufacturer and supplier of construction and renovation tools and equipment. Their commitment to providing top-of-the-line products at competitive prices has earned them a solid reputation among their clients.The Wet/Dry Polishing Pads offered by {} are designed to deliver exceptional results, no matter the surface being worked on. Whether it's a rough concrete floor or a delicate marble countertop, their pads are engineered to provide a smooth and polished finish with minimal effort. The company understands the importance of a consistent and high-quality finish, and their products are developed with this in mind.One of the key features of {} Wet/Dry Polishing Pads is their durability. Constructed with premium materials, these pads are built to withstand the wear and tear of heavy-duty use. This durable construction ensures that the pads can be used for extended periods without losing their effectiveness, saving contractors time and money in the long run.In addition to their durability, {} Wet/Dry Polishing Pads are also known for their versatility. They can be used with water for wet polishing, which helps to minimize dust and keep the work area clean. Alternatively, they can also be used for dry polishing, offering the flexibility to adapt to different working conditions and requirements. This versatility makes them a valuable tool for a wide range of projects, from large-scale construction jobs to intricate renovation tasks.Another factor that sets {} apart from other brands is their commitment to customer satisfaction. They offer a wide range of polishing pads in different sizes and grit levels, ensuring that contractors have the right tools for any job. Their dedication to providing exceptional customer service has solidified their position as a reliable and trustworthy supplier in the industry.Moreover, {} takes pride in staying up-to-date with the latest technological advancements in polishing pad manufacturing. Their products are constantly being improved and refined to ensure that they meet the evolving needs of their customers. This dedication to continuous improvement sets {} apart as an industry leader in the development of high-quality polishing pads.With a strong track record of delivering top-quality products and excellent customer service, {} has become a trusted partner for contractors and renovation professionals across the industry. They understand the demands of the construction and renovation business and are dedicated to providing the tools and equipment needed to get the job done efficiently and effectively.In conclusion, the growing popularity of Wet/Dry Polishing Pads in the construction and renovation industry has opened up new possibilities for achieving high-quality finishes on various surfaces. Companies like {} have played a crucial role in this trend by developing and supplying top-of-the-line polishing pads that meet the needs of contractors and DIY enthusiasts alike. With their commitment to quality, durability, versatility, and customer satisfaction, {} has established itself as a leading provider of Wet/Dry Polishing Pads, and their continued dedication to innovation and excellence is sure to solidify their position in the industry for years to come.

Durable Nylon Flap Brush for Effective Surface Cleaning

The Nylon Flap Brush: A Versatile Tool for Surface PreparationAs industries continue to evolve, the demand for efficient and effective surface preparation tools has become crucial. In response to this need, {Company Name} has introduced their innovative Nylon Flap Brush, which has quickly gained recognition for its quality and performance in a variety of applications.{Company Name} is a leading manufacturer of abrasives and surface preparation tools, with a strong focus on innovation and product development. With a commitment to delivering high-quality products to their customers, {Company Name} has become a trusted name in the industry.The Nylon Flap Brush is just one example of the company's dedication to innovation and quality. This versatile tool is designed for surface finishing, cleaning, and polishing of a wide range of materials, including metal, wood, plastic, and composites. The brush is made with high-quality nylon filaments that are flexible and durable, making it ideal for various surface preparation tasks.One of the key features of the Nylon Flap Brush is its flexibility, which allows it to conform to irregular surfaces and contours. This makes it particularly useful for applications where a uniform finish is essential, such as deburring, edge blending, and surface blending. Additionally, the brush is designed to provide consistent performance and long service life, making it a cost-effective solution for many industries.The Nylon Flap Brush is available in a range of sizes and configurations to suit different applications. Whether it is used on a hand-held grinder or a stationary machine, the brush can be easily adapted to meet specific requirements. This flexibility has made it a popular choice among manufacturers and fabricators who value efficiency and versatility in their surface preparation tools.In addition to its performance, the Nylon Flap Brush is also designed with operator safety in mind. The brush is engineered to reduce the risk of kickback and vibration, helping to minimize operator fatigue and improve overall productivity. This focus on safety is reflective of {Company Name}'s commitment to providing solutions that not only deliver exceptional results but also prioritize the well-being of the user.{Company Name} takes pride in the rigorous testing and quality control measures that are implemented throughout the manufacturing process of the Nylon Flap Brush. As a result, customers can have confidence in the reliability and consistency of the product, knowing that it has been thoroughly evaluated to meet the company's high standards.Furthermore, {Company Name} offers comprehensive technical support and customer service to assist with product selection and application recommendations. This level of support ensures that customers can maximize the value of the Nylon Flap Brush and achieve the best possible results in their surface preparation processes.Overall, the Nylon Flap Brush from {Company Name} represents a significant advancement in surface preparation technology. With its superior performance, versatility, and commitment to quality, this innovative tool has quickly become a preferred choice for manufacturers and fabricators across various industries. As {Company Name} continues to push the boundaries of what is possible in surface preparation, the Nylon Flap Brush stands as a testament to their ongoing dedication to excellence.

Top Replacement Pads for Auto Spa Polishers: Enhance Your Vehicle's Shine

Auto Spa is a leading name in the automotive industry, renowned for producing high-quality car cleaning and maintenance products. With an unmatched commitment to innovation and customer satisfaction, Auto Spa has recently announced the launch of its newest product – the Polisher Replacement Pads.With its state-of-the-art manufacturing facility and team of dedicated professionals, Auto Spa has established itself as a global leader in the automotive industry. The company offers a wide range of cleaning and maintenance solutions, including car wash accessories, tire care products, and interior cleaning supplies, among others.Recognizing the need for efficient and reliable car polishers, Auto Spa has invested significant time and resources in developing the Polisher Replacement Pads. This new addition to their product line is designed to enhance the performance and longevity of their existing range of polishers.The Polisher Replacement Pads are manufactured using premium-quality materials to ensure durability and effectiveness. The pads are specifically engineered to provide a smooth, swirl-free polishing experience that delivers stunning results every time. With their innovative design, these replacement pads significantly reduce the risk of damaging the vehicle's paint surface, ensuring a flawless, showroom-quality finish.Auto Spa understands the importance of variety and versatility in the automotive industry. Hence, the Polisher Replacement Pads come in different sizes and densities, catering to various polishing requirements. Whether it's removing minor scratches, restoring dull paint, or creating a mirror-like shine, these pads offer the perfect solution for all car enthusiasts and professionals alike.One of the key features of the Auto Spa Polisher Replacement Pads is their ease of use. Designed for both beginners and seasoned professionals, these pads can be easily attached and detached from the polishers, making the polishing process hassle-free and time-efficient. The pads also feature a Velcro backing that ensures a secure and stable connection, enabling precise control and maneuverability during the polishing process.Another noteworthy aspect of the Auto Spa Polisher Replacement Pads is their durability. Crafted to withstand intense pressure and frequent use, these pads are built to last. The high-quality materials used in their construction ensure that they maintain their shape and performance even after prolonged and rigorous use.Additionally, Auto Spa prioritizes environmental consciousness and sustainability. The Polisher Replacement Pads are designed to be reusable, reducing waste and contributing to a greener planet. By minimizing the need for constant replacement, these pads not only save customers money but also make a positive impact on the environment.In conclusion, Auto Spa's latest offering, the Polisher Replacement Pads, exemplifies the company's commitment to excellence and innovation in the automotive industry. With their dedication to customer satisfaction, Auto Spa has introduced a versatile and high-performing solution for car enthusiasts and professionals alike. These pads, with their superior quality, ease of use, and durability, are set to revolutionize the car polishing experience, providing an unparalleled level of convenience and effectiveness. As Auto Spa continues to expand its product range, customers can expect nothing short of exceptional quality and groundbreaking innovation from this industry-leading brand.

Ceramic Grinding Wheels: A Guide to Blue Options

Blue Ceramic Grinding Wheels: The Ultimate Solution for Precision GrindingIn the world of precision grinding, the right choice of grinding wheel can make all the difference. For industries such as automotive, aerospace, and tool manufacturing, achieving precise and high-quality grinding is essential for producing top-notch products. This is where the Blue Ceramic Grinding Wheels from [company name] come into play, offering a cutting-edge solution for all grinding needs.[Company name] is a leading manufacturer of abrasives and grinding tools, with a strong commitment to innovation and quality. With decades of experience in the industry, they have established a reputation for delivering premium products that meet the highest standards of performance and durability. Their Blue Ceramic Grinding Wheels are no exception, as they have quickly become the top choice for professionals in various fields.What sets the Blue Ceramic Grinding Wheels apart from conventional grinding wheels is the use of advanced ceramic abrasives. These ceramic grains are renowned for their exceptional hardness and strength, making them ideal for heavy-duty grinding applications. The wheels are designed to withstand high pressure and heat, allowing for longer wheel life and consistent performance throughout the grinding process.In addition to their superior abrasive material, these grinding wheels are also engineered with a high-performance bond system. This bond system is designed to securely hold the ceramic abrasives in place while ensuring minimal vibration and chatter during grinding. As a result, users can expect smooth and precise grinding with minimal surface damage, ultimately leading to higher workpiece quality and lower production costs.One of the key advantages of the Blue Ceramic Grinding Wheels is their ability to maintain sharpness and cutting efficiency over time. Unlike conventional wheels that tend to wear down quickly, these ceramic wheels retain their sharpness for extended periods, reducing the need for frequent wheel changes and associated downtime. This not only enhances productivity but also contributes to cost savings for businesses in the long run.Furthermore, the Blue Ceramic Grinding Wheels are suitable for a wide range of materials, including stainless steel, high-carbon steel, and exotic alloys. This versatility makes them a go-to choice for manufacturers who work with diverse materials and require consistent grinding results across different applications. Whether it's surface grinding, cylindrical grinding, or tool sharpening, these wheels deliver exceptional performance across the board.To ensure optimal performance, [company name] offers a variety of specifications and sizes for their Blue Ceramic Grinding Wheels, catering to the specific needs of different grinding operations. This allows customers to choose the right wheel dimensions, grit sizes, and bond types to suit their unique grinding requirements, ultimately maximizing efficiency and precision in their operations.Customer satisfaction is at the forefront of [company name]'s mission, and they go the extra mile to provide expert technical support and guidance to users of their grinding wheels. From selecting the right wheel for a specific application to troubleshooting and maintenance tips, their team of specialists is dedicated to helping customers get the most out of their grinding operations with the Blue Ceramic Grinding Wheels.In conclusion, the Blue Ceramic Grinding Wheels from [company name] represent a game-changing solution for precision grinding. With their advanced ceramic abrasives, high-performance bond system, and unmatched durability, these wheels have set a new standard for grinding performance in various industries. As the demand for high-precision components continues to grow, these grinding wheels are poised to play a pivotal role in helping businesses achieve superior grinding results with efficiency and reliability.

The Secrets Behind Highly Effective Diamond Polishing Pads for Concrete

Title: Innovative Diamond Polishing Pad Revolutionizes Surface Polishing ProcessSubtitle: Company Name's technologically advanced product, the Diamond Polishing Pad, emerges as a game-changer in the industryIntroduction:In the world of surface polishing, constant innovation is essential to meet the growing demands for efficiency and quality. Recognizing this, Company Name, a renowned leader in the manufacturing industry, has released its latest groundbreaking product - the Diamond Polishing Pad. This revolutionary offering promises to transform the surface polishing process, exceeding industry standards and delivering exceptional results across various applications. The Diamond Polishing Pad: Unmatched Performance and VersatilityThe primary aspect that sets Company Name's Diamond Polishing Pad apart from its competitors is its utilization of cutting-edge diamond technology. This advanced approach guarantees outstanding performance and durability, making it a superior choice for both small-scale and large-scale polishing projects. Moreover, its unique design caters to an extensive array of materials, including concrete, marble, granite, and even engineered stone surfaces.Beyond its versatility, the Diamond Polishing Pad demonstrates exceptional durability, enabling extended usage without compromising its effectiveness. Its dense and compact construction, coupled with the precision-engineered diamond particles, ensures a longer lifespan, reducing frequent pad replacements and ultimately enhancing cost-effectiveness for users.Further enhancing its usability, the Diamond Polishing Pad exhibits remarkable adaptability across varying polishing speeds and conditions. Regardless of the speed or intensity required, this innovative tool guarantees consistent and high-quality results, catering to the diverse needs of professionals in the construction, automotive, and home renovation sectors.Environmental Responsibility and Sustainable ManufacturingIn addition to its remarkable performance features, Company Name has prioritized environmental sustainability in the manufacturing process of the Diamond Polishing Pad. The company's commitment to reducing environmental impact has led to the development of a sustainable manufacturing protocol that minimizes waste generation and maximizes resource efficiency.By utilizing eco-friendly materials and adhering to stringent industry standards, Company Name ensures that the Diamond Polishing Pad aligns with global sustainability goals. Professionals who utilize this product can enjoy its exceptional performance while knowing that they are contributing to a greener future.Industry Adoption and Customer TestimonialsThe Diamond Polishing Pad has received widespread acclaim from professionals across different sectors. Accredited contractors, construction firms, and DIY enthusiasts have expressed their satisfaction with the product's ability to achieve remarkable surface finishes efficiently. The pad's consistent performance and versatility have drastically reduced project completion times, resulting in heightened productivity and customer satisfaction.Furthermore, professionals have praised the Diamond Polishing Pad for its ease of use, regardless of the user's level of expertise. With its ergonomic design and user-friendly features, even novice users can achieve professional-quality results.Conclusion:As consumer demands for polished surfaces continue to rise, Company Name's Diamond Polishing Pad emerges as a groundbreaking solution that revolutionizes the surface polishing process. By combining cutting-edge diamond technology, exceptional durability, versatility, and a commitment to sustainability, this innovative product is poised to become an industry standard for professionals and DIY enthusiasts alike. With Company Name's Diamond Polishing Pad, achieving impeccable surface finishes has never been easier or more effective.

Innovative Nylon Flap Brush for Effective Cleaning and Polishing

The Nylon Flap Brush is a versatile and effective tool for a wide range of industrial and commercial applications. This innovative product has been developed and manufactured by a leading company in the industrial equipment industry, known for its commitment to quality, efficiency, and performance.The Nylon Flap Brush is designed to provide a superior finish on a variety of surfaces, including metal, wood, plastic, and composites. Its unique flap design and high-quality nylon bristles ensure a consistent and uniform finish, making it ideal for surface preparation, deburring, and cleaning applications. The brush is available in a range of sizes and configurations to suit different tools and equipment, making it a highly adaptable solution for a diverse range of industries.The company behind the Nylon Flap Brush is a well-established and respected manufacturer of industrial equipment, with a strong reputation for innovation and excellence. With state-of-the-art facilities and a team of experienced engineers and technicians, the company is at the forefront of developing cutting-edge products that meet the evolving needs of its customers. The Nylon Flap Brush is a testament to the company's dedication to continuous improvement and its ability to deliver high-quality, reliable solutions to the market.In addition to its commitment to product development, the company places a strong emphasis on environmental sustainability and corporate social responsibility. It adheres to stringent manufacturing processes and quality control measures to ensure that its products are not only efficient and effective but also environmentally friendly. The Nylon Flap Brush is no exception, with materials and processes carefully selected to minimize its environmental impact while maximizing its performance.With a global presence and a diverse customer base, the company is dedicated to providing exceptional service and support to its clients. It has a team of knowledgeable and experienced professionals who work closely with customers to understand their unique requirements and provide tailored solutions that deliver outstanding results. The Nylon Flap Brush is just one example of the company's ability to develop products that address the specific needs of its customers, demonstrating its commitment to delivering value and exceeding expectations.As the industrial equipment industry continues to evolve, the company remains dedicated to staying at the forefront of innovation and technology. It invests in ongoing research and development to ensure that its products remain at the cutting edge of performance and efficiency. The Nylon Flap Brush is a testament to this commitment, and the company continues to explore new materials, technologies, and processes to further improve its product offerings and expand its capabilities.In conclusion, the Nylon Flap Brush is a superior and versatile tool developed by a leading company in the industrial equipment industry. With its commitment to quality, innovation, and customer satisfaction, the company has established itself as a trusted and reliable partner for a wide range of industrial and commercial applications. The Nylon Flap Brush is just one example of the company's ability to deliver innovative solutions that meet the evolving needs of its customers, and it is poised to continue making a positive impact in the industry for years to come.

Discover the Secrets of the Efficient and Precise Cutting Saw

Cutting Saw Revolutionizes the Manufacturing Industry with Innovative Features and Increased Efficiency[City, Date] - The manufacturing industry is set to witness a groundbreaking transformation with the introduction of a cutting-edge cutting saw, developed by a pioneering company at the forefront of industrial innovation. This state-of-the-art machine is designed to revolutionize the way industries across the globe operate by offering unparalleled precision, efficiency, and productivity.The anonymous company, recognized for its commitment to engineering excellence, has harnessed cutting-edge technology to develop a cutting saw that surpasses industry standards. With an unwavering dedication to providing solutions tailored to the evolving needs of manufacturers, this revolutionary machine encapsulates the company's mission to enhance productivity and deliver superior results.One of the key features that sets this cutting saw apart from its competitors is its unmatched precision. Equipped with advanced laser-guided technology, this machine ensures precise and accurate cuts, eliminating any room for error. By incorporating this precise cutting mechanism, manufacturers can significantly reduce waste and optimize the use of raw materials, thereby driving greater efficiency and cost-effectiveness.Furthermore, this cutting saw boasts an efficient and intuitive user interface, allowing operators to streamline their workflow effortlessly. The company's commitment to user-friendly design ensures that both skilled operators and those new to the manufacturing field can readily adapt to this cutting-edge machinery. Such accessibility empowers manufacturers to boost productivity and meet escalating demands, without sacrificing quality or safety.Another notable feature of this cutting saw is its versatility. The machine's modular design enables seamless integration within existing industrial infrastructures, providing manufacturers with an efficient and effective means of upgrading their operations. Additionally, this flexibility allows for easy customization, enabling manufacturers from different sectors to tailor the machine to their specific requirements.The safety of workers is of paramount importance in any manufacturing environment. Recognizing this, the cutting saw has been engineered with several safety features that guarantee the protection of operators. This ensures that manufacturers can uphold industry regulatory standards, minimize accidents, and create a safe working environment for their workforce.In line with its commitment to sustainability, the anonymous company has also prioritized energy efficiency while designing this cutting saw. By employing state-of-the-art energy-saving technologies, manufacturers can reduce their carbon footprint and contribute to a greener manufacturing landscape, while simultaneously benefiting from reduced operating costs.The introduction of this cutting saw marks a significant milestone in the evolution of the manufacturing industry, as it combines precision, efficiency, versatility, user-friendliness, safety, and sustainability in one groundbreaking machine. Manufacturers can now leverage this cutting-edge technology to enhance their operations, meet growing demands, and remain competitive in an ever-evolving global market.The anonymous company's commitment to innovation and continuous improvement has elevated it to the forefront of the industry. With its cutting saw, the company has disrupted traditional manufacturing practices and paved the way for a new era of productivity and efficiency. Manufacturers around the world can now explore the immense possibilities and attain unparalleled success with this state-of-the-art cutting saw.About the Company:{Insert company introduction here}With their cutting-edge machine, the anonymous company is reshaping the manufacturing landscape, offering solutions that exceed industry expectations. By prioritizing precision, efficiency, versatility, user-friendliness, safety, and sustainability, this company is transforming the way manufacturers across the globe operate. With their unwavering commitment to innovation, this anonymous company is poised to lead the manufacturing industry into a more productive, efficient, and sustainable future.

Ultimate Guide to Resin Bond: Everything You Need to Know

[T-140 Resin Bond] - The Next Generation in Bonding TechnologyIn the world of industrial adhesives, the quest for a bonding solution that combines durability, versatility, and ease of use has been ongoing for decades. Now, [Company Name], a leading innovator in the field of adhesive technology, has introduced a groundbreaking new product that promises to revolutionize the way industries bond materials together. The T-140 Resin Bond is a next-generation adhesive that offers unmatched strength, flexibility, and reliability, making it ideal for a wide range of industrial applications.The T-140 Resin Bond is the result of years of research and development by [Company Name]'s team of experts who have worked tirelessly to create an adhesive that meets the ever-evolving demands of modern industry. The result is a product that is not only stronger and more durable than traditional adhesives, but also easier to use and more environmentally friendly. These qualities make the T-140 Resin Bond an ideal choice for manufacturers across various sectors, from automotive and aerospace to construction and electronics.One of the standout features of the T-140 Resin Bond is its exceptional strength. Thanks to its advanced formula, this adhesive can create bonds that are up to three times stronger than those produced by conventional adhesives. This means that manufacturers can have confidence in the durability of their products, whether they are producing high-performance automotive components, cutting-edge electronic devices, or sturdy construction materials.Another key advantage of the T-140 Resin Bond is its exceptional flexibility. Unlike many adhesives on the market, this product does not become brittle or weak over time, even when subjected to extreme temperatures and environmental conditions. This makes it an ideal choice for applications where flexibility and resilience are crucial, such as in the manufacturing of components for aerospace or defense industries.In addition to its impressive strength and flexibility, the T-140 Resin Bond is also incredibly easy to use. Its fast-curing formula means that manufacturers can significantly reduce production times, while its excellent adhesion properties ensure a reliable bond every time. This makes it a versatile and practical solution for companies looking to improve their manufacturing processes and enhance the quality of their products.Furthermore, [Company Name] is committed to sustainability, and the T-140 Resin Bond reflects this dedication. This adhesive is free from volatile organic compounds (VOCs) and other harmful chemicals, making it an environmentally friendly choice for companies that are conscious of their ecological impact. By choosing the T-140 Resin Bond, manufacturers can not only improve the performance of their products, but also contribute to a cleaner and more sustainable future for the planet.The introduction of the T-140 Resin Bond represents a significant milestone for [Company Name], solidifying its reputation as a leader in adhesive technology. With its unrivaled strength, flexibility, and ease of use, this next-generation adhesive is set to transform the way industries bond materials together, providing a new level of reliability and performance.As [Company Name] continues to push the boundaries of adhesive technology, it remains dedicated to delivering innovative solutions that meet the evolving needs of its customers. The T-140 Resin Bond is a shining example of this commitment, and it is poised to become a game-changer for manufacturers around the world. With its exceptional qualities and practical benefits, this revolutionary adhesive is set to make a lasting impact on the industrial landscape, offering a new standard in bonding technology.

Versatile Grinding Wheels for Industrial Metal Work and Deburring Applications

s, Bonded Grinding Wheels, Industrial Applications, Metal Work, Deburring, Bench Mounted Applications, Surface Grinding Wheels, Carbide BurrsGrinding Wheels and Tooling for Industrial ApplicationsGrinding wheels are essential tools for metalworking, deburring, and machine-mounted works. They come in various shapes and sizes and are known to be one of the most versatile abrasive tools available in the market. They are made of abrasive grains, bonding materials, and fillers, and can be used for a wide range of tasks. In this article, we will discuss the different types of grinding wheels and tooling for industrial applications.Bonded Grinding WheelsBonded grinding wheels are the most commonly used type of grinding wheel. They are made of a composite material that consists of abrasive grains held together by a bonding material. The abrasive grains are usually made of aluminum oxide, silicon carbide, or diamond, depending on the type of material being ground and the desired finish. The bonding material can be resin, metal, or vitrified.Resin-bonded wheels are commonly used for precision grinding, surface grinding, and tool and cutter grinding. They are versatile and affordable, making them suitable for most applications. Metal-bonded wheels are used for grinding harder materials, such as high-speed steel and carbide. They are also used for rough grinding and form grinding. Vitrified-bonded wheels are used for precision grinding and sharpening of carbide tools.Wire BrushesWire brushes are another type of abrasive tool that is used for cleaning, deburring, and finishing metal surfaces. They are made of metal wire bristles that are mounted on a rotating shaft. The wire bristles can be made of different materials, including steel, brass, and stainless steel. Wire brushes are used for removing rust, paint, and other surface contaminants from metal surfaces. They are also used for cleaning welds and deburring edges.Bench Mounted ApplicationsBench-mounted grinding wheels are used for precision grinding, sharpening, and polishing of metal parts. They are mounted on a bench or pedestal and can be used for a wide range of tasks, such as grinding, deburring, and sanding. Bench-mounted wheels are available in various sizes and materials, depending on the application.Surface Grinding WheelsSurface grinding wheels are used for precision grinding of flat surfaces. They are typically used on a reciprocating table, where the workpiece is moved back and forth against the grinding wheel. Surface grinding wheels are available in different sizes and materials, depending on the type of material being ground and the desired finish.Carbide BurrsCarbide burrs are used for shaping, deburring, and finishing metal surfaces. They are made of carbide, a hard and brittle material that is ideal for grinding and cutting. Carbide burrs are available in various shapes and sizes, depending on the application. They can be used on a variety of materials, including steel, aluminum, and cast iron.In conclusion, grinding wheels and tooling for industrial applications are essential tools for metalworking, deburring, and machine-mounted works. Bonded grinding wheels, wire brushes, bench-mounted applications, surface grinding wheels, and carbide burrs are just some of the available options. When choosing a grinding wheel or tool, it is important to consider the type of material being ground, the desired finish, and the application.