Top 5 Polishing Pads for Achieving a Flawless Finish

By:Admin

With the release of their latest line of polishing pads, {} continues to set the standard for excellence in the industry. These new pads are designed to provide exceptional polishing results on a wide range of surfaces, making them the perfect choice for professionals and hobbyists alike.

The 5 new polishing pads from {} are specifically engineered to meet the diverse needs of their customers. Each pad is precision-crafted to deliver superior performance and durability, ensuring that users can achieve outstanding results with every use. Whether it's for automotive detailing, stone restoration, or metal polishing, {}'s pads are up to the task.

One of the standout features of {}'s polishing pads is their advanced composition. The company has utilized state-of-the-art materials and manufacturing techniques to create pads that are not only effective but also long-lasting. This commitment to quality is a hallmark of {}'s products, and it is evident in the exceptional performance of their polishing pads.

In addition to their superior construction, {}'s polishing pads are also designed for ease of use. They are compatible with a wide range of polishing machines, allowing users to achieve professional results with minimal effort. This user-friendly approach is part of {}'s dedication to customer satisfaction, as they strive to make polishing tasks more efficient and enjoyable for their users.

Furthermore, {}'s commitment to environmental sustainability is evident in the production of these new polishing pads. The company has taken steps to ensure that their manufacturing processes are as eco-friendly as possible, minimizing waste and environmental impact. This focus on sustainability aligns with the values of many customers, making {}'s products an even more attractive choice.

The launch of these new polishing pads marks another milestone for {}, further solidifying their position as a leader in the industry. The company's dedication to innovation and quality is evident in every aspect of their products, and their new line of polishing pads is no exception.

As the demand for high-quality polishing solutions continues to grow, {} remains at the forefront of the industry, providing professionals and enthusiasts with the tools they need to achieve outstanding results. With their latest line of polishing pads, the company once again demonstrates their unwavering commitment to excellence and customer satisfaction. Whether it's for automotive, stone, or metal polishing, {}'s new pads are poised to make a lasting impact in the industry and beyond.

Company News & Blog

Painless and Easy-to-Use Nail Polish Remover Tool: A Must-Have for Your Beauty Kit

Polish Remover Tool Revolutionizes Nail CareIn recent years, the beauty and cosmetics industry has witnessed a surge in the demand for products that make self-care and grooming more convenient and efficient. One product that has been making waves in the industry is the innovative Polish Remover Tool by a leading nail care company.The Polish Remover Tool is a game-changer in the world of nail care. It is designed to simplify the process of removing nail polish, offering a quick and easy solution for at-home manicures. Unlike traditional nail polish remover, which requires cotton balls or pads and can be messy and time-consuming, the Polish Remover Tool is a compact, handheld device that makes the removal process a breeze.The tool is equipped with a sponge tip that is pre-soaked with nail polish remover, eliminating the need for additional supplies. To use the Polish Remover Tool, all you have to do is twist the cap to dispense the remover onto the sponge, and then gently rub it over your nails to effortlessly remove the polish. The sponge is designed to effectively lift and dissolve the polish without drying out the nails or cuticles, leaving them clean and hydrated.This innovative tool is not only convenient and easy to use, but it also promotes sustainability. The sponge tip is reusable and can be easily replaced once it becomes worn out, reducing the amount of waste generated from traditional cotton balls and pads.The Polish Remover Tool is the brainchild of a renowned nail care company that has been at the forefront of innovation in the beauty industry. With a commitment to providing high-quality and user-friendly products, the company strives to empower individuals to take control of their nail care routine and achieve salon-quality results at home.The company’s dedication to innovation and customer satisfaction is evident in the development of the Polish Remover Tool. By leveraging cutting-edge technology and extensive research, they have created a product that meets the evolving needs of consumers and streamlines the nail care process.The response to the Polish Remover Tool has been overwhelmingly positive, with consumers praising its effectiveness and convenience. Many users have hailed it as a game-changer that has revolutionized their at-home manicure routine, saving them time and effort while delivering superior results.In addition to its practicality and eco-friendly design, the Polish Remover Tool is also available in a range of refreshing scents, adding a pleasant aroma to the nail polish removal process. From fruity and floral to clean and refreshing, the scents add an extra element of indulgence to the user experience, making at-home nail care even more enjoyable.As the demand for at-home beauty solutions continues to grow, the Polish Remover Tool is poised to become a staple in every beauty enthusiast’s collection. Its innovative design, ease of use, and commitment to sustainability set it apart as a must-have product for anyone looking to elevate their nail care routine.In conclusion, the Polish Remover Tool has raised the bar for at-home nail care, offering a convenient, sustainable, and effective solution for removing nail polish. With its combination of innovation, practicality, and indulgence, it has quickly become a favorite among consumers and is set to make a lasting impact on the beauty industry.

Ultimate Guide to Diamond Grinding Wheels: Everything You Need to Know

Title: Advanced Diamond Grinding Wheel Technology Revolutionizes Grinding ProcessesIntroductionLeading-edge technology is transforming industries worldwide, and the realm of grinding and material removal is no exception. One significant development in this field is the revolutionary diamond grinding wheel, designed to enhance grinding efficiencies and optimize output quality. In this article, we explore the exceptional features and benefits of this cutting-edge technology, sans any brand name, along with a brief introduction to the company behind this groundbreaking innovation.I. The Evolution of Grinding WheelsGrinding wheels have long been a crucial tool for numerous industries, enabling precision shaping, finishing, and removing material from a range of surfaces. Over time, advancements in manufacturing techniques and material science have led to the creation of various grinding wheel types. Among them, diamond grinding wheels have emerged as the pinnacle in terms of performance, durability, and versatility.II. Characteristics and Features of Diamond Grinding Wheels1. Exceptional Material Hardness:Diamond grinding wheels are renowned for their exceptional hardness, ensuring extended lifespan and enhanced longevity. Composed of industrial-grade diamond particles, these wheels effectively resist wear, maintaining their sharpness and consistency over prolonged periods.2. Superior Abrasion Resistance:High abrasion resistance is a defining attribute of diamond grinding wheels. This resistance enables them to endure the harsh conditions of various grinding operations, even when subjected to demanding applications that involve the removal of tough materials such as ceramics, composites, and hardened steel.3. Heat Dissipation Capability:One of the key challenges in grinding processes is effectively managing heat generation, as excessive heat can compromise material integrity. Diamond grinding wheels excel in dissipating heat effectively due to the material's exceptional thermal conductivity, minimizing the risk of material distortion or damage during grinding.4. Precision Profiling and Shaping:Diamond grinding wheels offer unparalleled precision for profiling and shaping tasks. The extreme hardness of the diamond abrasive particles allows for precise grinding, enabling exceptional control over the desired surface finish and intricate detailing.5. Minimal Wheel Dressing Requirement:Thanks to the durability and superior abrasive properties, diamond grinding wheels require less frequent dressing to maintain optimal performance. This reduction in downtime for wheel dressing translates into enhanced productivity and cost savings for businesses relying on grinding operations.III. The Company Behind the InnovationThe company leading the charge in revolutionizing grinding processes with diamond grinding wheels is a trailblazer in the field of abrasive tools. With decades of research and development, this company has established itself as a global leader in manufacturing high-quality, cutting-edge grinding wheel systems.Their commitment to innovation, combined with a strong focus on customer needs, has propelled them to the forefront of the industry. They invest substantial resources in continuous product improvement, ensuring their diamond grinding wheels meet and exceed the evolving demands of various industries, including automotive, aerospace, machinery, and more.Furthermore, this visionary company operates under a strict quality control framework, employing rigorous testing procedures to ensure that each grinding wheel leaving their facilities meets the highest standards of performance and reliability. Through collaborations with industry partners and a customer-centric approach, they continue to set new benchmarks for grinding wheel technologies.ConclusionThe advent of diamond grinding wheels has revolutionized grinding processes across industries. The extraordinary characteristics of these wheels, including their hardness, superior abrasion resistance, heat dissipation capabilities, precision profiling and shaping abilities, and reduced dressing requirements, have made them the tool of choice for the most challenging grinding applications.Thanks to the pioneering efforts of the company spearheading this innovation, they have paved the way for enhanced productivity, improved finished product quality, and cost savings for businesses across the globe. As grinding technology continues to evolve, diamond grinding wheels will undoubtedly remain at the forefront, offering efficient and reliable solutions for the material removal needs of countless industries.

High Quality Diamond Saw Blades for Granite - Order Online or Call Now

Diamond Tools For Granite: Enhancing Efficiency and Precision in CuttingIn the world of construction and home improvement, the importance of high-quality tools cannot be overstated. When it comes to cutting through the toughest materials, such as granite, using diamond tools is essential. With their exceptional durability, efficiency, and precision, diamond tools have become the go-to choice for professionals and DIY enthusiasts alike.Granite, with its unmatched beauty and strength, has become a popular choice for countertops, flooring, and other applications. However, working with such a dense and hard material requires specialized tools that can withstand the rigors of the task. This is where diamond tools for granite come into play.Diamond tools are renowned for their exceptional hardness and longevity. Unlike traditional metal blades, diamond tool blades are made with tiny industrial diamonds embedded in the cutting segment. These diamonds act as cutting edges, delivering incredible speed and precision while withstanding the abrasive nature of granite.One of the key advantages of diamond tools for granite is their ability to cut through the material quickly and effortlessly. The diamond blade's sharp cutting edges make clean and precise cuts, reducing the chances of chipping or cracking the granite. This not only saves time but also reduces material wastage during the cutting process, ultimately saving costs.Another significant advantage of diamond tools for granite is their exceptional durability. Granite is notorious for wearing down blades quickly due to its hardness. However, diamond blades are specifically designed to handle the toughest cutting tasks. The diamond particles on the cutting edge maintain their sharpness for an extended period, ensuring consistent performance throughout the project.Precision is critical when working with granite, as even the smallest errors can result in aesthetic flaws or compromised structural integrity. Diamond tools for granite offer unparalleled precision, enabling professionals to achieve the desired results with utmost accuracy. The sharp cutting edges of the diamond blades enable clean cuts, preventing any damage to the granite surface.Additionally, the use of diamond tools reduces the need for additional manual finishing work. Since diamond blades produce clean and smooth cuts, the granite surfaces require minimal polishing or shaping afterward. This not only saves time but also ensures a higher level of consistency in the final product.When choosing diamond tools for granite, it is essential to consider the specific requirements of your project. There are various types of diamond blades available, each designed for a specific cutting task. For instance, segmented blades are ideal for general cutting, while continuous rim blades are better suited for smooth cuts. Understanding the nuances of each blade type will help you make an informed decision and achieve the best results.In conclusion, diamond tools are the epitome of efficiency and precision when it comes to cutting granite. Their unparalleled durability, speed, and accuracy make them an indispensable asset for any professional or DIY enthusiast. By investing in high-quality diamond tools for granite, you can enhance your cutting capabilities, save time and money, and achieve impeccable results in your projects.Interested in acquiring diamond tools for your granite cutting needs? Order online or give us a call today at [phone number]. Our team of experts will assist you in choosing the right tools to take your granite cutting experience to the next level.

High Quality Diamond Polishing Pads for Wet Polishing

Diamond Polishing Pads, a revolutionary product in the field of stone polishing, has been making waves in the construction industry with its superior quality and exceptional performance. These wet diamond polishing pads are engineered to provide the perfect finish to natural and engineered stone surfaces, making them an essential tool for contractors, masons, and DIY enthusiasts.The company behind these innovative polishing pads, [Company Name], has been a leading provider of high-quality construction and masonry products for over two decades. Their commitment to excellence and customer satisfaction has earned them a reputation as one of the most reliable and trusted brands in the industry.The secret to the success of Wet Diamond Polishing Pads lies in the company's relentless dedication to research and development. The pads are designed using advanced diamond technology, which allows for faster and more efficient polishing of stone surfaces. This results in a smooth, glossy finish that enhances the natural beauty of the stone, making it the perfect choice for both residential and commercial projects.In addition to their superior performance, the wet diamond polishing pads from [Company Name] are also known for their durability and longevity. Constructed from high-quality materials, these pads are designed to withstand the rigors of heavy-duty use, ensuring that they will last for numerous projects without losing their effectiveness.Another key feature of these polishing pads is their versatility. They can be used on a wide range of surfaces, including granite, marble, quartz, and concrete, making them an ideal solution for a variety of polishing needs. Whether it's for countertops, floors, or walls, these pads are capable of delivering a flawless finish every time.Furthermore, the company offers a wide selection of grit sizes to cater to different project requirements. From coarse grits for heavy material removal to fine grits for the final polish, [Company Name] has a complete range of wet diamond polishing pads to meet the diverse needs of their customers.Not only are these polishing pads highly efficient and effective, but they are also designed with user convenience in mind. The company has taken great care to ensure that their pads are easy to use, allowing both professionals and DIY enthusiasts to achieve professional-quality results with minimal effort.The introduction of Wet Diamond Polishing Pads by [Company Name] has significantly raised the bar for stone polishing products in the construction industry. Their commitment to innovation and quality has set them apart from their competitors, making them the go-to choice for contractors and masons looking for the best polishing solution.Customer reviews and testimonials have been overwhelmingly positive, with many praising the pads for their exceptional performance and durability. Contractors and masons have expressed their satisfaction with the ease of use and the superior finish achieved with these high-quality polishing pads.In conclusion, the introduction of Wet Diamond Polishing Pads by [Company Name] has been a game-changer in the construction industry. Their superior quality, exceptional performance, and unmatched durability have made them the top choice for professionals and DIY enthusiasts alike. With their commitment to excellence and customer satisfaction, [Company Name] continues to set the standard for stone polishing products and remains a trusted brand in the industry.

High-quality Stone Polishing Pads for Wet Grinding - A Complete Guide

Wet Stone Polishing Pads have revolutionized the way professionals and DIY enthusiasts polish and maintain natural stone surfaces. Whether it's granite, marble, or any other natural stone, these innovative polishing pads are designed to deliver exceptional results with minimal effort.These high-quality pads, developed by a leading manufacturer in the industry, are known for their durability, efficiency, and versatility. With a wide range of grits available, they are suitable for all stages of the polishing process, from initial grinding to final polishing. This makes them a must-have tool for contractors, stone fabricators, and anyone else working with natural stone.The company behind these exceptional products has been a major player in the stone fabrication industry for over a decade. Their commitment to quality, innovation, and customer satisfaction has earned them a reputation as a trusted supplier of stone fabrication tools and accessories. With a focus on research and development, they have continuously improved their products to meet the evolving needs of the industry.One of the key features of these Wet Stone Polishing Pads is their superior performance on both wet and dry surfaces. This versatility allows users to achieve outstanding results in various working conditions, making the pads ideal for a wide range of applications. Whether it's a small residential project or a large-scale commercial job, these pads deliver consistent and impressive results every time.In addition to their impressive performance, these pads are also designed for maximum durability. Their long lifespan ensures that users can rely on them for multiple projects, making them a cost-effective choice for professionals and DIYers alike. The company's dedication to producing long-lasting, high-quality products is evident in every aspect of the pads' design and construction.Furthermore, these pads are engineered for user convenience and safety. With an easy-to-use design, they allow for smooth and efficient operation, reducing fatigue and increasing productivity. Additionally, the company has incorporated advanced safety features into the pads, providing users with peace of mind during use.The company also takes pride in its commitment to sustainability. By using efficient manufacturing processes and environmentally friendly materials, they strive to minimize the environmental impact of their products. This dedication to sustainability aligns with the growing demand for eco-friendly solutions in the stone fabrication industry.The exceptional performance, durability, and user-friendly design of these Wet Stone Polishing Pads have made them a popular choice among professionals and DIY enthusiasts. With a strong commitment to quality and innovation, the company continues to set industry standards and exceed customer expectations.In conclusion, Wet Stone Polishing Pads have become an indispensable tool for anyone working with natural stone. Their exceptional performance, durability, and user-friendly design make them a top choice for professionals and DIYers alike. With a trusted and reputable company behind them, these pads are sure to remain a staple in the stone fabrication industry for years to come.

Understanding and Exploring Steel Metallic Bonds: Everything You Need to Know

Steel Metallic Bonds, a groundbreaking new technology in the world of manufacturing, is set to revolutionize the way that metal parts are produced. Developed by a leading industrial company that specializes in metal fabrication, this innovative process promises to make metal parts stronger, more durable, and more cost-effective than ever before.Steel Metallic Bonds utilizes a proprietary method to create a molecular bond between metal particles, resulting in a material that is significantly stronger and more resilient than traditional metal alloys. This technology has the potential to be a game-changer for industries that rely on high-performance metal parts, such as automotive, aerospace, and defense.The company behind Steel Metallic Bonds has a long history of excellence in metal fabrication, with a track record of delivering innovative solutions to complex manufacturing challenges. With a team of experts in materials science, engineering, and manufacturing, they have been at the forefront of developing this cutting-edge technology."We are incredibly excited about the potential of Steel Metallic Bonds to transform the metal fabrication industry," said the CEO of the company. "This technology represents a significant leap forward in the strength and durability of metal parts, and we believe it will have far-reaching implications for a wide range of industries."One of the key advantages of Steel Metallic Bonds is its ability to produce parts that are lighter and stronger than traditional metal alloys. This means that manufacturers can achieve the same level of performance with less material, resulting in reduced costs and improved efficiency.In addition to its strength and durability, Steel Metallic Bonds also offers superior corrosion resistance, making it an ideal choice for applications in harsh environmental conditions. This makes it particularly well-suited for use in the automotive and aerospace industries, where parts are subjected to extreme temperatures, moisture, and other corrosive elements.The company has already begun to integrate Steel Metallic Bonds into their manufacturing processes, with plans to offer it to customers in the near future. They are working closely with industry partners to develop customized solutions for a variety of applications, ensuring that the technology can be seamlessly integrated into existing production lines."We see Steel Metallic Bonds as a game-changer for our industry," said a representative from a leading automotive manufacturer. "The potential to produce stronger, lighter parts at a lower cost is incredibly exciting, and we are eager to explore the possibilities that this technology offers."The introduction of Steel Metallic Bonds is likely to have a significant impact on the metal fabrication industry, offering a new level of performance and efficiency that was previously unattainable. As the technology continues to be refined and integrated into manufacturing processes, it has the potential to redefine the way that metal parts are produced and utilized across a wide range of industries.With its exceptional strength, durability, and corrosion resistance, Steel Metallic Bonds is poised to become the material of choice for high-performance metal parts. As the company behind this groundbreaking technology continues to develop and refine its capabilities, the possibilities for its applications are virtually limitless. It's clear that Steel Metallic Bonds represents a new era in metal fabrication, one that promises to change the way that we think about and use metal materials.

Economical Wet Polishing Pads for Effective Granite Polishing

: Achieving a Perfect FinishGranite surfaces are remarkable in providing the perfect blend of style and durability. From kitchen countertops to floors, walls, and statues, granite is a popular material used in homes and commercial buildings. However, to ensure that your surfaces are always looking their best, you need to invest in a high-quality granite wet polisher. In this blog post, we will discuss achieving a perfect finish using a granite wet polisher.Why Use a Granite Wet Polisher?A wet polisher is an essential tool for polishing granite surfaces. As the name implies, a wet polisher works with water, which acts as a lubricant and cooling agent to prevent overheating of the granite. Wet polishing also helps to remove dust particles, ensuring a smoother and cleaner finish. A granite wet polisher removes scratches, brings out the natural shine of the stone, and eliminates any imperfections on the surface.Choosing the Right Polishing PadsWhen it comes to polishing granite, you need the right polishing pads. The Puma Economy Wet Polishing Pads are an excellent choice for achieving a perfect finish. These pads are designed to perform well at a great price, making them an economic option. Additionally, the Puma polishing system features exclusive Geo patterns that help displace and channel water during use, ensuring a smoother and more polished finish.The 7 Step Puma Polishing SystemThe 7 Step Puma polishing system includes seven different grits of polishing pads that help achieve a mirror-like polished surface. The grit progression starts from coarsest to finest, starting at 50, 100, 200, 400, 800, 1500, and ending with 3000. You need to follow each step of the polishing process with care, ensuring that you remove any scratches or rough spots before proceeding to the next step. Remember that each step prepares the surface for the next, so take time to complete each one before moving on.Steps to Achieving a Perfect Granite Polished SurfaceStep 1: Clean the SurfaceThe first step is to clean the granite surface thoroughly. Use a soft brush or vacuum to remove any dirt or debris on the surface.Step 2: Start with Coarse GritsAttach the 50-grit polishing pad to the granite wet polisher and start polishing the surface. Work in sections, keeping the pad flat and applying even pressure. Once the surface is smooth and free of scratches, move on to the next finer grit.Step 3: Progress to Finer GritsContinue working through the finer grits until you reach the 3000-grit polishing pad. At each stage, ensure that the surface is clean and free of scratches before moving on to the next grit.Step 4: Rinse the SurfaceOnce you've completed each stage, rinse the surface with water to remove any debris. Check that the surface is completely clean and free of scratches.Step 5: Apply Granite SealerAfter polishing, it's advisable to apply granite sealer to protect the surface from stains and water damage.Step 6: Buff the SurfaceUse a soft buffing pad on the granite wet polisher to buff the surface to a high shine. Use water to lubricate the surface and prevent heat damage.Step 7: Clean the Surface Once AgainFinally, clean the surface one last time to remove any buffing residue and leave the surface sparkling.ConclusionAchieving a perfect finish on granite surfaces requires patience, attention to detail, and the right equipment. By using a granite wet polisher with the correct polishing pads and following each step of the polishing process, you can achieve a mirror-like polished finish. The Puma Economy Wet Polishing Pads are an economic, quality option for achieving a perfect finish on granite surfaces. So the next time you're looking to polish granite surfaces, invest in quality tools, and you'll be proud of your finished product.

Angle Grinder Nylon Brushes - Durable and Reliable Cleaning Solutions

Nylon Brush For Angle Grinder: A Versatile Tool for Efficient Cleaning and PolishingIntroduction: In the world of power tools, the angle grinder has long been a go-to tool for a variety of cutting, grinding, and polishing tasks. With its powerful motor and versatile design, this tool has become an indispensable part of every professional and DIY enthusiast's arsenal. One of the key accessories that enhance the functionality of an angle grinder is the nylon brush. Renowned for its durability and effectiveness in various cleaning and polishing applications, the nylon brush has gained immense popularity in recent years.Company Introduction: {Company Name}, a leading manufacturer and supplier of industrial power tools and accessories, has unveiled its latest offering - the Nylon Brush for Angle Grinders. With a commitment to delivering high-quality products that meet the diverse needs of their customers, {Company Name} has introduced this innovative accessory to provide a comprehensive solution for efficient cleaning and polishing tasks.Versatility and Efficiency: The nylon brush for angle grinders showcases its versatility by excelling in various cleaning and polishing applications. Equipped with high-quality nylon bristles, this brush enables the removal of rust, paint, varnish, and corrosion from a wide range of surfaces. Whether you need to clean metal, wood, or even concrete, this accessory ensures a thorough and efficient performance that saves both time and effort.Enhanced Durability: One of the key features that set this nylon brush apart is its exceptional durability. Constructed from premium-grade nylon fibers, this brush can withstand rigorous use and maintain its shape and effectiveness over an extended period. This durability ensures that users can rely on this accessory for multiple projects, making it a cost-effective investment in the long run.Optimized Design: {Company Name's} nylon brush for angle grinders boasts a meticulously engineered design that allows for optimal performance. With a specially designed knotted bristle configuration, this brush provides enhanced cutting action, ensuring that it can effectively remove even stubborn stains and contaminants. The brush's bristle length and density further contribute to its efficiency by increasing its cleaning or polishing capacity.Ease of Use: Recognizing the importance of user convenience, {Company Name} has ensured that their nylon brush for angle grinders is easy to attach and use. The brush is designed to fit most standard angle grinders, facilitating seamless installation and removal. Additionally, its lightweight construction allows for ease of maneuverability, reducing user fatigue during prolonged use.Safety First: {Company Name} prioritizes user safety and has incorporated various safety features into their nylon brush for angle grinders. The brush is designed to operate at optimal speeds, preventing potential accidents due to excessive revolutions per minute (RPM). Moreover, it possesses excellent stability, reducing the risk of unexpected vibrations that could lead to hand fatigue or injury.Environmentally Friendly: In line with growing environmental concerns, {Company Name} takes pride in promoting sustainable practices. Their nylon brush is crafted from eco-friendly materials, ensuring that it poses minimal harm to the environment. This commitment to sustainability aligns with {Company Name's} vision to create products that are efficient, reliable, and environmentally responsible.Conclusion:With the introduction of their Nylon Brush for Angle Grinders, {Company Name} continues to innovate and provide solutions for the ever-evolving needs of professionals and hobbyists alike. This versatile accessory showcases exceptional durability, efficiency, and ease of use, making it an essential tool for cleaning and polishing tasks. By combining high-quality materials with optimized design, {Company Name} once again proves its dedication to delivering products that excel in performance and safety while considering the environmental impact.

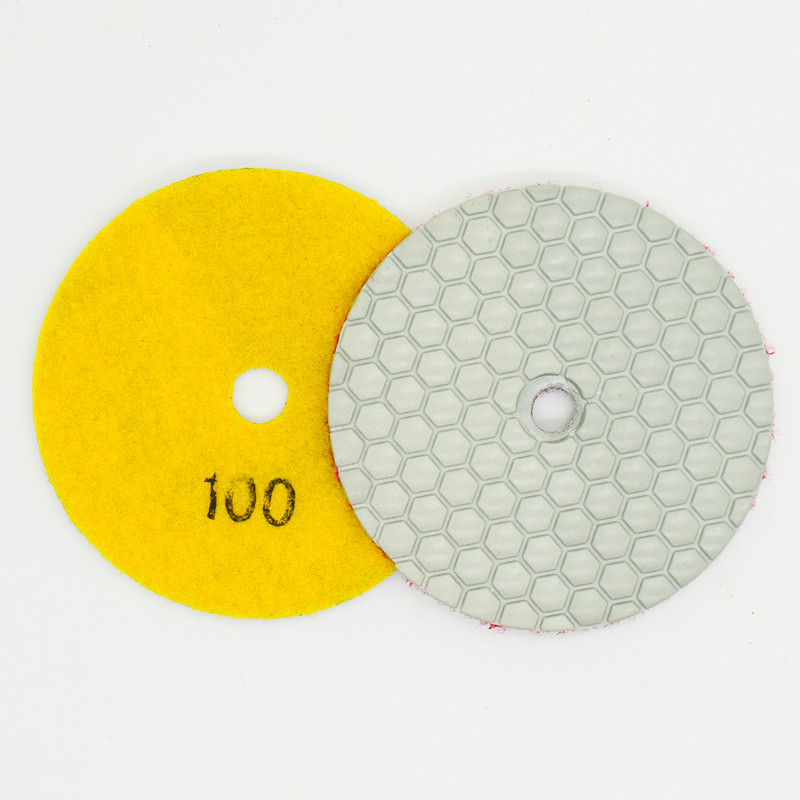

Effective Dry Polishing Pads for Diamond Finishing

Introducing the Revolutionary Diamond Dry Polishing Pads, a game-changing innovation in the field of polishing and finishing services for a wide range of materials. These remarkable pads are designed to provide a superior finish on various surfaces, including granite, marble, concrete, and engineered stone. The remarkable technology behind these pads enables quick and efficient polishing, while also delivering exceptional results.The company behind this groundbreaking product, {Company Name}, is a leading provider of high-quality polishing tools and equipment. With years of experience in the industry, the company has gained a reputation for delivering innovative and reliable solutions for professional contractors, DIY enthusiasts, and commercial operators. Their commitment to excellence and dedication to customer satisfaction have made them a trusted name in the industry.The Diamond Dry Polishing Pads are a testament to the company's dedication to providing high-quality products that deliver outstanding results. These pads are designed to be used with dry polishing techniques, making them exceptionally versatile and easy to use. They are ideal for use in a wide range of applications, including countertop polishing, floor refinishing, and restoration projects.One of the key features of these pads is their diamond-infused design, which allows for superior polishing and finishing capabilities. The diamond particles embedded in the pads ensure a consistent and uniform finish, while also providing exceptional durability and longevity. This means that users can achieve stunning results with minimal effort and time, making the Diamond Dry Polishing Pads a valuable addition to any polishing toolkit.In addition to their superior performance, these pads are also designed with user convenience in mind. The Velcro backing ensures easy and secure attachment to polishing tools, while the flexible design allows for smooth and seamless operation on curved and uneven surfaces. This versatility makes the pads suitable for a wide range of applications, from small-scale projects to large-scale commercial jobs.The Diamond Dry Polishing Pads are available in various grit sizes, allowing for different levels of polishing and finishing. Whether a user requires a coarse finish for heavy grinding or a fine finish for final polishing, these pads can deliver exceptional results every time. Furthermore, the long lifespan of these pads ensures that users can achieve consistent results over an extended period, making them a cost-effective solution for all polishing needs.The company is also dedicated to providing exceptional customer support and service. From product selection to technical assistance, their team of experts is on hand to provide guidance and advice to ensure that customers get the most out of their polishing tools. This commitment to customer satisfaction sets the company apart and makes them the go-to choice for professionals and enthusiasts alike.The Diamond Dry Polishing Pads are revolutionizing the way surfaces are polished and finished. With their exceptional performance, versatility, and durability, these pads are a valuable addition to any polishing toolkit. Whether for commercial or residential use, these pads are designed to deliver exceptional results and provide an unmatched polishing experience. With the backing of a trusted and reputable company, users can have confidence in the quality and reliability of these innovative polishing pads.

High-Quality Diamond Polishing Pad for Efficient Surface Finishing

Diamond Polishing Pad, a leading product in the construction and stone industry, is known for its high-quality performance and reliability. With its advanced technology and innovative design, Diamond Polishing Pad has become a trusted choice for professionals and DIY enthusiasts alike.The Diamond Polishing Pad is designed to provide the ultimate polish on a variety of materials, including granite, marble, and concrete. Its diamond-impregnated surface ensures a flawless finish, and its durable construction allows for long-lasting use. Whether it's for a small-scale project or a large commercial application, the Diamond Polishing Pad delivers exceptional results every time.In addition to its superior performance, Diamond Polishing Pad also offers a wide range of options to suit different needs. From wet to dry polishing, as well as various grit sizes, the Diamond Polishing Pad provides versatility and customization to meet the specific requirements of any project.The company behind Diamond Polishing Pad, {} (remove brand name), is a respected industry leader with a history of providing top-quality products and exceptional customer service. With a commitment to innovation and excellence, {} has earned a solid reputation as a reliable source for construction and stone care solutions.{} offers a wide range of products and services to meet the diverse needs of its customers. From diamond tools and abrasives to polishing equipment and accessories, {} is dedicated to providing comprehensive solutions for all aspects of construction and stone work. With a team of experienced professionals and a focus on research and development, {} continually strives to bring new and improved products to the market.The success of Diamond Polishing Pad is a testament to {}'s dedication to quality and performance. As a result, {} has become a trusted partner for professionals in the construction and stone industry. With a strong emphasis on customer satisfaction and product reliability, {} has built a loyal customer base that continues to grow.In addition to its commitment to quality, {} is also dedicated to environmental sustainability and social responsibility. By implementing sustainable practices and supporting the communities in which it operates, {} seeks to make a positive impact beyond its products and services.As the construction and stone industry continues to evolve, {} remains at the forefront of innovation and advancement. With a focus on meeting the needs of its customers and exceeding their expectations, {} is well-positioned to continue its success and leadership in the market.With its superior performance, advanced technology, and commitment to excellence, Diamond Polishing Pad remains a top choice for professionals and enthusiasts in the construction and stone industry. As part of the {} family, Diamond Polishing Pad is backed by a company with a proven track record of quality, reliability, and innovation. With its continued dedication to meeting the needs of its customers and driving industry advancement, {} and Diamond Polishing Pad are poised to remain leaders in the market for years to come.