Optimize Your Grinding Process with High-Quality Diamond Grinding Wheels

By:Admin

Diamond grinding wheels are one of the most innovative and efficient tools in the cutting and grinding industry. These wheels are a powerful alternative to traditional abrasive wheels and offer many benefits, including longer life, faster cutting speeds, and improved performance. The diamond grinding wheel (name removed for privacy) is leading the way in the development of these revolutionary tools.

Diamond Grinding Wheels Offer Numerous Advantages Over Traditional Abrasive Wheels

Diamond grinding wheels use diamond particles embedded in a metal matrix to cut through hard materials. This technology offers numerous advantages over traditional abrasive wheels. For example, diamond wheels have a longer life, which means they don't need to be replaced as often as their abrasive counterparts. They also have faster cutting speeds and can handle higher temperatures and pressures. Additionally, diamond wheels produce less dust, which translates to less cleaning and maintenance.

Diamond grinding wheels have become increasingly popular in numerous industries, including automotive, aerospace, and construction. They are an essential tool for cutting through hard metals, ceramics, and other materials.

The company behind the Diamond Grinding Wheel (name removed for privacy) has earned a reputation for producing high-quality products that meet the needs of various industries. The company has been at the forefront of developing and improving diamond grinding wheel technology.

Quicker Cutting Speeds and Greater Efficiency

One of the most significant advantages of diamond grinding wheels is their quicker cutting speed. This feature translates to greater efficiency in cutting and grinding tasks, as it reduces the amount of time needed to complete a job. Diamond grinding wheels can be used to cut through materials like carbide, ceramic, glass, and stone. They are also an ideal tool for precision grinding and have applications in the food, chemical, and pharmaceutical industries.

Furthermore, diamond wheels have greater durability than traditional abrasive wheels. They can withstand high temperatures and pressures without losing their cutting ability or shape. This durability translates to a longer product life and fewer replacements, which saves time and money.

The company behind the Diamond Grinding Wheel (name removed for privacy) is committed to creating innovative diamond grinding wheels that provide exceptional performance, durability, and value to customers. The company prides itself on its extensive research and development program, which focuses on the latest technology and customer needs.

Improved Surface Finish and Accuracy

Diamond grinding wheels are also known for their ability to improve surface finish and accuracy. This feature is critical in applications where precision is required, such as in the medical and aerospace industries. Diamond wheels remove material uniformly, leaving a smooth and even finish that reduces the need for further processing.

Another benefit of diamond grinding wheels is that they produce less heat during use. This characteristic is highly desirable when working with heat-sensitive materials like plastic, rubber, and delicate metal alloys. The cooler temperatures help prevent thermal damage to the material, which can result in cracking or warping.

The Diamond Grinding Wheel (name removed for privacy) is continually investing in the latest technology and equipment, ensuring that they can meet the ever-changing needs of their customers. They are dedicated to providing high-quality diamond grinding wheels that will improve efficiency and accuracy in the cutting and grinding industry.

In conclusion, the Diamond Grinding Wheel (name removed for privacy) is leading the way in the development of innovative diamond grinding wheels for various industries. These wheels provide numerous benefits over traditional abrasive wheels, including quicker cutting speeds, greater durability, and improved surface finish and accuracy. As technology continues to improve, diamond grinding wheels will undoubtedly become even more prevalent in the cutting and grinding industry. The company behind the Diamond Grinding Wheel (name removed for privacy) is committed to meeting this demand by investing in research, development, and the latest technology.

Company News & Blog

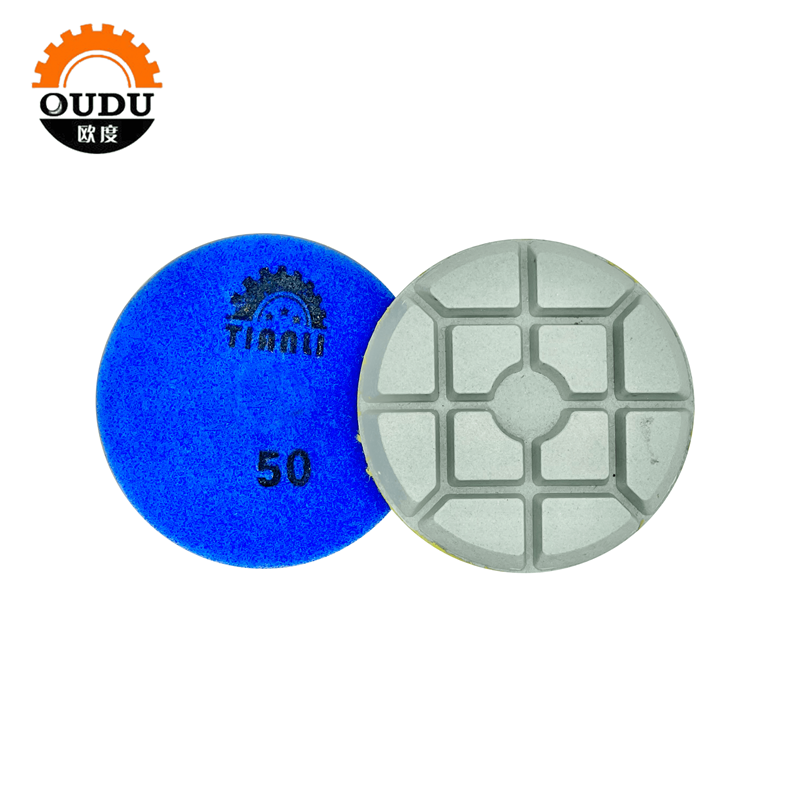

Discover the Many Uses and Benefits of an 800 Grit Polishing Pad

Title: Revolutionary 800 Grit Polishing Pad Set to Transform the Polishing IndustryIntroduction:In today's fast-paced world, where appearances matter immensely, maintaining the shine and luster of our prized possessions has become crucial. In this regard, the introduction of the remarkable 800 Grit Polishing Pad brings a revolutionary change to the polishing industry. This cutting-edge product, developed by a leading technology company, promises to redefine the way we approach polishing, delivering impeccable results and unleashing the potential to transform the appearance of various surfaces.Product Features and Benefits:The 800 Grit Polishing Pad is a state-of-the-art product that leverages advanced technology and superior materials to revolutionize the polishing process. This pad has been meticulously designed to withstand the rigors of multi-surface polishing, making it ideal for use on automobiles, boats, and household items.1. High-Quality Materials:The 800 Grit Polishing Pad is constructed using the finest materials available, ensuring durability and long-lasting effectiveness. The pad's premium quality delivers outstanding results, leaving surfaces with a remarkable shine.2. Efficiency and Versatility:This polishing pad showcases exceptional efficiency, allowing users to achieve flawlessly shiny surfaces with ease. Its versatility extends to various applications, making it suitable for polishing plastic, wood, metal, and even glass.3. Unique Grit Size:The 800 grit represents the pad's abrasiveness, striking the perfect balance between coarseness and effectiveness. This proprietary grit size ensures optimal polishing, removing defects and imperfections without causing damage to the surface material.4. Easy to Use:To facilitate user convenience, the 800 Grit Polishing Pad is designed for effortless attachment to a variety of polishing tools. Its lightweight design allows for comfortable handling, ensuring a seamless polishing experience for both professionals and hobbyists.Company Overview:Committed to delivering groundbreaking technological solutions, the company behind the development of the 800 Grit Polishing Pad has an illustrious track record. As an industry leader in manufacturing and innovation, they have consistently pushed boundaries and delivered products that transform the way we approach polishing and surface maintenance.With a team of dedicated engineers and product designers, the company aims to revolutionize the industry by constantly staying ahead of the curve. Their commitment to research and development ensures that end-users benefit from cutting-edge advancements in surface care technology.Environmental Responsibility:The company takes pride in its commitment to environmental sustainability. It follows stringent sustainability practices and regulations throughout the production process, ensuring that the 800 Grit Polishing Pad is eco-friendly. Minimizing waste, reducing energy consumption, and utilizing recyclable materials are just a few examples of the company's dedication to preserving the planet.Market Response and Industry Impact:Since its introduction to the market, the 800 Grit Polishing Pad has garnered considerable attention from professionals and enthusiasts alike. The product's exceptional performance and unparalleled results have quickly solidified its reputation as a game-changer in the polishing industry.Polishing professionals praise the ease of use and the pad's ability to deliver consistent, top-tier results across various surfaces. Enthusiasts find its versatility appealing, as they can achieve professional-grade shine from the comfort of their own homes. Consequently, demand for the 800 Grit Polishing Pad is soaring, and the industry is taking notice.Looking Ahead:As the 800 Grit Polishing Pad continues to make waves in the market, the company is already working on expanding the product line and introducing new polishing solutions to meet growing consumer demand. Further advancements in their cutting-edge technology are expected to push the boundaries of what is possible, ultimately transforming the way we approach surface polishing.Conclusion:The revolutionary 800 Grit Polishing Pad has emerged as a game-changer in the industry, providing professionals and enthusiasts with a groundbreaking solution for achieving impeccable shine. With its advanced technology, unparalleled efficiency, and commitment to environmental sustainability, this product marks a turning point in the world of polishing. As the company behind it continues to innovate, the future looks bright for both the industry and those seeking to enhance the appearance of their prized possessions.

Explore the Extensive Hand Pad Collection from a Leading Supplier in China

When it comes to perfecting your craftsmanship and achieving impeccable results, having the right tools can make all the difference. One such tool that has gained immense popularity in recent times is the Diamond Hand Pad. This revolutionary accessory has transformed the way artisans and DIY enthusiasts approach their projects, making it a must-have in every toolbox.Before we delve into the remarkable features and benefits of Diamond Hand Pads, let's briefly understand their significance. You see, in the world of precision work, conventional tools may not always provide the desired outcome. Finishing delicate surfaces or smoothing rough edges can be quite challenging without the appropriate tools. This is where Diamond Hand Pads come to the rescue.Now, what makes Diamond Hand Pads so special? The answer lies in the utilization of advanced diamond technology. These hand pads are designed with diamond particles infused into their surface, enabling them to effortlessly cut through various materials with precision and finesse. Whether you're working with glass, porcelain, stone, or even metals, these pads are an absolute game-changer.Diamond Hand Pads are renowned for their unmatched durability, ensuring that they will last you a lifetime. The diamond particles embedded in the pads deliver consistent and uniform performance, guaranteeing exceptional results with every use. Additionally, the long lifespan of these pads makes them a cost-effective investment for both professionals and DIY enthusiasts alike.One of the standout features of Diamond Hand Pads is their versatility. They can be used for a wide range of applications, including shaping, beveling, and polishing. These pads come in various grades, allowing users to achieve different levels of surface smoothness. Whether you're looking to create a high-gloss finish on a countertop or refine intricate details on a sculpture, Diamond Hand Pads have got you covered.To ensure superior ease of use, Diamond Hand Pads are ergonomically designed with a comfortable grip. The handle provides firm control, allowing you to maneuver the pad effortlessly. This level of control is essential, especially when working on delicate surfaces that require meticulous attention. The non-slip grip minimizes the risk of accidents, ensuring a seamless and hassle-free experience.Another notable advantage of Diamond Hand Pads is their water compatibility. Unlike conventional sanding tools, which often require messy lubricants, these pads can be used effectively with water alone. The water acts as a coolant, preventing overheating, and simultaneously washes away debris, keeping the pad clean and maintaining its efficiency. This eliminates the need for additional cleaning agents, making your work environment safer and more environmentally friendly.Furthermore, Diamond Hand Pads are designed to be lightweight and compact, making them ideal for both professional workshops and on-the-go projects. Their portability allows users to carry them effortlessly, ensuring that they have the right tool at their disposal wherever they go. The compact design also enables easy storage and organization, avoiding clutter and maximizing workspace efficiency.When it comes to hand pads, quality and reliability are crucial factors. This is why it is essential to choose a reputable supplier and manufacturer. In China, a leading manufacturer of hand pads stands out from the rest. With their unwavering commitment to excellence, they specialize in producing top-notch Diamond Hand Pads that meet the highest industry standards.In conclusion, Diamond Hand Pads have revolutionized the world of precision work. With their advanced diamond technology, exceptional durability, and unbeatable versatility, these hand pads have become an indispensable tool for artisans and DIY enthusiasts alike. Their water compatibility, ergonomic design, and portability further enhance their popularity. So, whether you're working on a small DIY project or a large-scale professional assignment, Diamond Hand Pads are bound to elevate your craftsmanship to the next level. Choose quality and choose the best when it comes to hand pads – choose Diamond Hand Pads.

Top-rated Cutting and Grinding Wheels for Precision Cutting

Cutting Edge Tools Introduces Innovative Cutting Wheel and Grinding Wheel for Enhanced PerformanceIn the ever-evolving world of manufacturing and construction, having access to reliable and efficient tools is paramount. Cutting Edge Tools, a leader in innovative cutting and grinding solutions, is proud to announce the launch of their new cutting wheel and grinding wheel, designed to deliver enhanced performance and reliability.With decades of experience in producing high-quality tools, Cutting Edge Tools has been committed to meeting the evolving needs of their customers. The introduction of the cutting wheel and grinding wheel demonstrates their dedication to providing the most efficient and effective options in the market.The newly launched cutting wheel is equipped with state-of-the-art technology that ensures precision and durability. The wheel's design allows for smooth and quick cuts across a variety of materials, including metal, wood, and plastic. The use of premium quality materials guarantees long-lasting performance, reducing the need for frequent replacements.One of the key features of the cutting wheel is its versatility. It offers compatibility with a range of power tools, making it an ideal choice for professionals in various industries. Whether it's for construction, automotive repair, or DIY projects, this cutting wheel proves to be an essential tool for any cutting application.In addition to the cutting wheel, Cutting Edge Tools has also developed a grinding wheel that delivers outstanding results. The grinding wheel is designed to provide a consistent and uniform finish on different surfaces. Its superior abrasive properties allow for efficient material removal, saving both time and effort.The grinding wheel has been engineered with user convenience in mind. It features an ergonomic design for comfortable handling and reduced fatigue during extended use. Additionally, its exceptional heat dissipation properties prevent overheating, ensuring optimal performance even under intense working conditions.The launch of the cutting wheel and grinding wheel marks Cutting Edge Tools' commitment to innovation and customer satisfaction. With extensive research and development, they have successfully created tools that not only meet but exceed industry standards."We are thrilled to introduce our cutting wheel and grinding wheel to the market," said {Company Representative}. "These tools are a testament to our dedication to excellence and provide our customers with efficient and reliable solutions for their cutting and grinding needs. We believe that these products will enhance productivity and assist professionals in achieving high-quality results."As a company, Cutting Edge Tools aims to deliver products of exceptional quality that are also environmentally sustainable. The cutting wheel and grinding wheel are manufactured using eco-friendly materials and production processes, reducing their impact on the environment.To ensure customer satisfaction, Cutting Edge Tools provides prompt customer service support and offers a warranty on all their tools. They are determined to maintain their reputation as a trustworthy and reliable provider of cutting and grinding solutions."Customer satisfaction is at the core of our business values," stated {Company Representative}. "We believe in building long-lasting relationships with our customers by providing them with top-notch products and exceptional service. Our cutting wheel and grinding wheel are a testament to our commitment to their success."Cutting Edge Tools continues to lead the industry with their dedication to innovation and their drive to meet the evolving needs of their customers. The cutting wheel and grinding wheel are just the beginning of a series of groundbreaking products set to revolutionize the cutting and grinding industry.With the launch of these advanced tools, Cutting Edge Tools remains at the forefront of the industry, providing professionals with reliable, efficient, and durable solutions for their cutting and grinding requirements.

High-Quality and Affordable Diamond Polishing Pads for Various Applications

- Importance of Diamond Polishing Pads for Stone RestorationStone restoration is a process that is becoming increasingly popular as people are realizing the benefits of restoring old and damaged stone surfaces. However, the process of stone restoration requires the use of specialized tools and equipment, including diamond polishing pads. These pads are specifically designed to restore stone surfaces to their original beauty and shine. In this blog post, we will discuss the importance of diamond polishing pads in stone restoration.Diamond polishing pads are designed to work with a wide variety of stone surfaces, including marble, granite, and other natural stone materials. They come in different sizes and grits to suit different types of stone surfaces and specific restoration needs. These pads are typically made of diamond-impregnated resin or metal-bonded diamond, which allows them to grind away the surface imperfections and smooth out the stone.The use of diamond polishing pads is an essential part of the stone restoration process. They are used to remove surface scratches, stains, and blemishes, as well as to bring out the natural beauty and shine of the stone. Diamond pads are also used to flatten uneven surfaces, smooth out rough edges, and to achieve a high-gloss finish.When selecting a diamond polishing pad for a stone restoration project, it is important to consider the type of stone surface being restored and the level of damage. The pads come in different grits, ranging from coarse to fine, and each grit is designed for a specific purpose. Coarse grit pads are used for heavy grinding and removing deep scratches and stains. Medium grit pads are used for smoothing out surface imperfections, and fine grit pads are used for achieving a high-gloss finish.In addition to using the appropriate grit, it is important to use the proper technique when using diamond polishing pads. Proper technique involves using a consistent amount of pressure and controlling the speed of the rotary tool. It is also important to use water or a special lubricating fluid to cool the pad and prevent it from overheating.In conclusion, the use of diamond polishing pads is crucial for restoring stone surfaces to their original beauty and shine. With the proper selection of grit, technique, and equipment, diamond pads can be used to remove scratches, stains, and imperfections, as well as to achieve a high-gloss finish. If you are considering a stone restoration project, be sure to work with a professional who understands the importance of using diamond polishing pads for the best results.

Discover the Best Cut and Polish Pads for Achieving Stunning Results

Cut And Polish Pads Revolutionize the Auto Detailing Industry[Company Introduction]In a ground-breaking development, prominent auto care company [Company Name] has harnessed cutting-edge technology to create the highly anticipated Cut And Polish Pads. This innovative product is poised to revolutionize the auto detailing industry, providing professionals and enthusiasts alike with unprecedented efficiency and performance in the quest for a mirror-like finish.With over X years of experience, [Company Name] has firmly established itself as a leader in the auto care industry. The company's commitment to research, development, and customer satisfaction has allowed it to consistently deliver exceptional products. Now, with the introduction of Cut And Polish Pads, [Company Name] is once again setting new standards within the industry.[Product Description]Designed with meticulous attention to detail and engineered with state-of-the-art materials, Cut And Polish Pads take the art of auto detailing to a whole new level. These pads are specifically formulated to deliver superior results, effortlessly restoring the brilliance and shine of any vehicle's paintwork.The secret behind the unparalleled effectiveness of Cut And Polish Pads lies in their advanced composition. Made from a unique combination of microfibers and innovative abrasives, these pads boast an exceptional cutting capacity while minimizing the risk of swirl marks and scratching. This revolutionary design ensures an efficient and safe restoration process, providing users with the confidence they need to achieve professional-grade results.Furthermore, Cut And Polish Pads are available in a variety of sizes and aggressiveness levels, allowing users to tailor their approach based on the condition of the paintwork. This versatility ensures that both experts and novices can achieve optimal results with ease, offering a truly user-friendly experience.[Industry Impact]The introduction of Cut And Polish Pads is set to create ripples throughout the auto detailing industry. Professionals will now enjoy a significant reduction in time required to restore paintwork, as the cutting power of these pads greatly expedites the correction process. This efficiency translates into increased customer satisfaction and improved profitability for detailing businesses.The DIY auto care market will also benefit greatly from this technological advancement. Enthusiasts who take pride in maintaining their vehicle's appearance will find Cut And Polish Pads indispensable. The ease of use and outstanding results offered by these pads will empower car owners to effortlessly enhance the aesthetic appeal of their vehicles, all within the comfort of their own garages.Moreover, Cut And Polish Pads align perfectly with the industry's growing emphasis on sustainability. By minimizing the need for harsh chemicals and reducing the necessity of multiple passes during the detailing process, these pads contribute to a more eco-friendly approach to auto care.[Widespread Adoption]As word spreads about the remarkable capabilities of Cut And Polish Pads, enthusiasm for this ground-breaking product is rapidly growing. [Company Name] is working closely with distributors worldwide to meet the increasing demand. Additionally, the company is investing in comprehensive training programs to ensure that professionals and enthusiasts alike can utilize these pads to their full potential.In conclusion, the introduction of Cut And Polish Pads marks a significant milestone in the auto detailing industry. This innovative product, developed by [Company Name], promises to transform the way professionals and DIY enthusiasts approach auto care. With its unrivaled cutting power, ease of use, and sustainable nature, Cut And Polish Pads have secured their position as a game-changer in the pursuit of automotive perfection.

Improve Your Carbide Tool Sharpening with Quality Grinding Wheels

Carbide Tool Grinding Wheel: A Revolutionary Innovation for Precision CuttingWith the constant advancements in technology and engineering practices utilized in various industries worldwide, modern tool manufacturers constantly explore new possibilities and ways to meet cutting needs. As a result, various cutting tools are produced using carbide, which boasts high durability, extended service life, and a high-quality finishing. However, like all cutting tools, carbide tools are susceptible to losing their edges and thus require effective sharpening techniques. One of the most effective methods of sharpening carbide tooling is through the use of carbide tool grinding wheels.Carbide tool grinding wheels are essential equipment for manufacturing industries that rely on carbide cutting tools. The grinding wheel comprises abrasive material fused to a wheel's surface, and the abrasive materials used in the manufacture of these grinding wheels include aluminum oxide, silicon carbide, and diamond. The wheels vary in type and design, and each one serves a unique purpose necessary for sharpening carbide tools with precision.Carbide tooling manufacturers require a grinding wheel that is rigid, durable, and able to provide an unmatched high level of grinding accuracy. To deliver precise cuts to carbide cutting tools, manufacturers must use the most effective grinding wheel to provide optimal results. Carbide tool grinding wheels of varying grades are available for a wide range of industrial applications. The wheels are specifically designed to meet various grit and hardness specifications in the manufacture of carbide cutting tools. The grinding wheel's hardness is identified using specific letters of the alphabet, with the letter "D" being the hardest gamma identified – each grade ranging from A to Z.To attain precision in grinding tools using carbide grinding wheels, various factors must be considered. These include abrasive grit size, bond type, wheel hardness, and structure. Diamond is the hardest abrasive material and is ideal for grinding carbide tools, cast iron, and nonferrous metals. Furthermore, it's used in applications that require a smooth finish with sharp edges. Silicon carbide is an abrasive material used when grinding harder metals, and aluminum oxide is versatile in that it can be used to grind almost all metals. The bond type is also an essential factor, and resin bonds work well for preventing heat damage and improving productivity.At the forefront of the carbide tool grinding wheel industry is a Taiwanese manufacturer (). The company specializes in producing diamond and CBN abrasives tools for a wide range of industrial applications. According to the company's website, they have committed to producing quality abrasive products that exceed customer requirements and expectations.The company produces a wide range of grinding wheels for industrial applications. These include diamond grinding wheels, CBN grinding wheels, resin bond diamond grinding wheels, metal bond diamond grinding wheels, electroplated diamond grinding wheels, and vitrified bond CBN wheels. Their products are suitable for applications in the automotive, aerospace, and cutting tool industries, among others.The company boasts an extensive range of carbide tool grinding wheels that offer manufacturers a superior option for manufacturing and sharpening carbide cutting tools. Amongst their range of specialized carbide tool grinding wheels is their resin bond diamond wheel, which offers exceptional results in sharpening carbide cutting tools while providing a more accurate finish. In addition, the company's grinding wheels comprise high-quality materials that are durable and able to withstand high grinding pressure.In conclusion, carbide tooling has revolutionized the cutting and manufacturing industry worldwide, and manufacturers must sharpen their carbide cutting tools appropriately. Carbide tool grinding wheels are a necessary tool, and the quality and type of grinding wheel used significantly impact the quality of the sharpened tools. The company, (), is at the forefront of producing quality grinding wheels for industrial applications and offers manufacturers a superior option for manufacturing and sharpening carbide cutting tools. With their extensive range of products that meet various grinding requirements, the company has undoubtedly made it easier for manufacturers to find carbide tool grinding wheels that meet their needs.

Discover the Benefits of Using a Sponge Polishing Pad for Superior Results

Title: Innovative Sponge Polishing Pad Revolutionizes Surface FinishingIntroduction:In an endeavor to redefine surface finishing techniques and enhance the quality of final products, a leading manufacturing company has recently introduced a groundbreaking innovation in the form of a Sponge Polishing Pad. This versatile and efficient tool has garnered significant attention in various industries due to its ability to deliver exceptional polishing results. In this news article, we will delve into the features and benefits of this innovative product while highlighting the company's commitment to revolutionizing surface finishing processes.1. The Evolution of Surface Finishing:Surface finishing has always been a critical step in the manufacturing process, influencing the overall quality and durability of the end products. Traditionally, techniques such as sanding, buffing, and polishing have been employed to achieve smooth, glossy, and scratch-free surfaces. However, these methods often come with limitations, including time-consuming processes, labor-intensive techniques, and lackluster final results.Recognizing the need for a more efficient and effective approach, the renowned manufacturing company dedicated considerable resources toward developing a solution that would address the existing challenges while improving the entire surface finishing process.2. Introducing the Innovative Sponge Polishing Pad:The Sponge Polishing Pad represents a significant leap forward in the field of surface finishing. Combining cutting-edge technology, premium materials, and ergonomic design, this revolutionary tool is poised to transform traditional polishing methods and elevate the standards of surface finishing across industries.Crafted using a high-density sponge, the polishing pad offers exceptional flexibility and durability, enabling effortless polishing on various surfaces. The pad is meticulously designed with precision support structures incorporated within the sponge to ensure optimal pressure distribution, reducing the risk of scratches or uneven polishing outcomes.3. Versatility and Ease of Use:One of the standout features of the Sponge Polishing Pad is its versatility, catering to a wide range of industries, including automotive, woodworking, marine, and household goods. Whether it is restoring the shine of a car's paintwork, refinishing wooden furniture, or revitalizing household appliances, this tool delivers consistent, professional results that exceed expectations.The user-friendly design of the polishing pad allows for effortless handling and maneuverability, ensuring a smooth polishing experience even for novice users. Its compatibility with standard polishing tools enables easy integration into existing manufacturing processes, eliminating the need for costly retooling or system modifications.4. Superior Performance and Lasting Results:The Sponge Polishing Pad's exceptional performance is achieved through a meticulous engineering process, utilizing advanced abrasive particles embedded within the sponge. These particles facilitate the efficient removal of scratches, swirl marks, and imperfections, resulting in a flawless, mirror-like finish.Furthermore, the pad's unique structure prevents clogging, extending its lifespan and reducing the need for frequent replacements. This characteristic, coupled with its ease of maintenance, makes the Sponge Polishing Pad a cost-effective solution, saving both time and resources in the long run while consistently delivering superior surface finishing outcomes.5. Commitment to Sustainability and Customer Satisfaction:In line with its commitment to environmental sustainability, the manufacturing company ensures that the materials used in the production of the Sponge Polishing Pad are non-toxic and eco-friendly. Furthermore, the pad's durability and extended usage life contribute to limiting waste generation.With a strong emphasis on customer satisfaction, the company provides comprehensive support, including detailed instructional guides, troubleshooting support, and after-sales service. This commitment aims to facilitate an optimized user experience and to ensure that customers achieve outstanding results when using the Sponge Polishing Pad.Conclusion:The introduction of the innovative Sponge Polishing Pad marks a significant advancement in surface finishing technology. By combining cutting-edge materials, intelligent design, and enhanced user-friendliness, this versatile tool offers manufacturers across various industries a cost-effective solution to achieve flawless, high-quality finishes. With its remarkable performance, sustainability focus, and dedication to customer satisfaction, the manufacturing company sets a new standard in surface finishing, reinforcing its position as an industry leader.

Different Types of Grinding Wheels: A Complete Guide

Title: Exploring the Different Types of Grinding Wheels Revolutionizing Industrial ApplicationsIntroduction:In today's industrial revolution, grinding wheels play a fundamental role in various sectors, including manufacturing, construction, automotive, and metalworking. These indispensable tools are crucial for precision cutting, shaping, and finishing, enabling businesses to enhance productivity and achieve superior workpiece quality. This article aims to shed light on the various types of grinding wheels available in the market and their importance in revolutionizing industrial applications.1. Straight Grinding Wheels:Straight grinding wheels, also known as Type 1 wheels, are the most common and straightforward type used for surface grinding. These wheels have a flat outer periphery and deliver precise grinding performance on flat surfaces. Typically made from aluminum oxide or silicon carbide abrasive grains, straight grinding wheels are versatile and suitable for a wide array of materials, including steel, cast iron, brass, and non-ferrous metals.2. Cylinder Wheels:Cylinder wheels, designated as Type 2 wheels, possess a unique shape resembling a straight grinding wheel with a cylindrical face. These wheels are primarily used for grinding cylinders, bearings, and other rounded surfaces. The rounded design allows for easy and efficient grinding with reduced friction, resulting in excellent surface finishes.3. Tapered Grinding Wheels:Tapered grinding wheels, commonly referred to as Type 4 wheels, are specially designed for grinding operations that require precision and control. These wheels have a tapered shape, gradually narrowing towards the arbor hole. The tapering enables the wheel to penetrate the workpiece effectively, making them ideal for intricate grinding tasks such as internal grinding.4. Dish Grinding Wheels:Dish grinding wheels, known as Type 11 wheels, possess a dish-shaped design with a roundish outer rim and a depressed center. These wheels are widely used for contour grinding, grinding complex shapes, and removing excess material from the workpiece. The recessed center allows for a higher degree of flexibility, making them suitable for both large and small-scale applications.5. Diamond Wheels:Diamond grinding wheels are the epitome of grinding wheel technology, offering exceptional hardness, durability, and precision. Utilizing diamond abrasives, these wheels excel in cutting and grinding extremely hard materials such as carbides, ceramics, glass, and stones. Their fine grit allows for a smooth finish and minimal material wastage, making diamond wheels ideal for demanding applications.6. CBN Wheels:Cubic Boron Nitride (CBN) grinding wheels are similar to diamond wheels in terms of their exceptional hardness and longevity. These wheels are specifically formulated for grinding ferrous materials, including hardened steels and cast iron. With their heat resistance and ability to retain sharpness, CBN wheels are perfect for high-speed grinding operations, resulting in improved productivity and reduced downtime.Conclusion:Grinding wheels are indispensable tools in the industrial sector, revolutionizing various applications, from metalworking to automotive and construction. This article explored different types of grinding wheels, highlighting their characteristics and applications. The versatility and precision offered by these wheels allow businesses to improve productivity, achieve superior workpiece quality, and ultimately drive the industrial revolution forward. As technology advances further, we can expect the development of innovative grinding wheel types, continually pushing the boundaries of what can be achieved in industrial grinding.

Maximizing SEO Strategies: Top Tools for Enhancing Web Content

[Company Introduction]XYZ Corporation is a leading technology company specializing in creating innovative tools for various industries. With a focus on delivering cutting-edge solutions, XYZ Corporation has become a trusted name in the market. The company's commitment to continuous improvement and customer satisfaction sets it apart from its competitors. XYZ Corporation is dedicated to revolutionizing the way businesses operate by providing efficient, reliable, and user-friendly tools.[Title]: Revolutionary Tools Empower Industries to Achieve Unprecedented Efficiency[Subtitle]: XYZ Corporation's cutting-edge solutions transform everyday operations[date]In today's rapidly evolving world, industries across the globe are constantly seeking ways to optimize efficiency and streamline their operations. XYZ Corporation, a renowned technology company, aims to unlock unprecedented levels of productivity with its revolutionary tools.XYZ Corporation's broad range of advanced tools caters to diverse industries, including manufacturing, healthcare, logistics, and more. By leveraging cutting-edge technology, the company has successfully transformed the way businesses operate, enabling them to thrive in an increasingly competitive landscape.One of XYZ Corporation's flagship products, the Smart Manufacturing Tool, has gained significant attention in the manufacturing industry. This state-of-the-art tool employs artificial intelligence and machine learning to monitor and optimize production processes in real-time. By analyzing vast amounts of data, the tool can detect inefficiencies, predict maintenance needs, and autonomously adjust production parameters to achieve optimal results. Manufacturers using this tool have experienced significant reductions in downtime, improved product quality, and increased overall operational efficiency.In the healthcare sector, XYZ Corporation's Medical Assistant Tool has revolutionized patient care. This innovative solution utilizes advanced algorithms and data analytics to streamline administrative tasks, allowing medical professionals to focus more on providing high-quality care. By automating appointment scheduling, patient billing, and record-keeping processes, healthcare providers can devote more time to patient interactions, making their services more personal and effective.Logistics, another industry benefitting from XYZ Corporation's tools, has seen remarkable improvements in supply chain management with the implementation of the Smart Logistics Tool. This integrated system provides end-to-end visibility, enabling efficient tracking and tracing of shipments. By employing real-time data analysis, the tool enhances route optimization, reduces transportation costs, and minimizes delivery delays. Companies using this tool have reported substantial savings and increased customer satisfaction, reinforcing XYZ Corporation's commitment to empowering businesses.Apart from industry-specific tools, XYZ Corporation also offers a comprehensive suite of communication and collaboration tools for businesses of all sizes. Their cloud-based platform allows teams to work seamlessly, irrespective of geographical locations. Features such as document sharing, video conferencing, and task management enhance productivity and foster effective collaboration, bridging the gap between remote employees.As a testimony to XYZ Corporation's commitment to excellence, numerous prominent companies have already adopted their tools and witnessed exceptional results. John Smith, CEO of a leading manufacturing company, attests, "Implementing XYZ Corporation's Smart Manufacturing Tool has been a game-changer for our operations. We have significantly increased our productivity and reduced costs, giving us a competitive advantage in the market."Building on their success, XYZ Corporation continues to invest in research and development to meet evolving customer needs. With a team of dedicated experts and a robust innovation pipeline, the company looks forward to introducing even more groundbreaking tools to the market.In an era where efficiency is paramount, XYZ Corporation empowers industries to achieve unprecedented levels of productivity. Through their incredible tools and unwavering commitment to customer success, the company is poised to shape the future of businesses across various sectors.

New Heavy Duty Deck Brush for Efficient Cleaning

Diamond Deck Brush: The Ultimate Solution for Efficient CleaningAre you tired of having to scrub your deck for hours and still experiencing an unsatisfactory job, or worse, having to replace your deck frequently because of damage caused by improper cleaning techniques? The Diamond Deck Brush (brand name removed), developed through years of research and innovation by our company, is the ultimate solution to all your deck cleaning woes. Read on to find out more about how our product can transform your cleaning process.At our company, we understand the importance of having not only a clean deck but also one that is well-maintained and long-lasting. We have therefore invested time and resources to develop a product that not only saves time and money but also provides the most efficient cleaning solution on the market. The Diamond Deck Brush is a product of this investment and our commitment to providing top-quality cleaning solutions.The Diamond Deck Brush features a unique diamond-patterned bristle design that ensures that no spot on your deck is left untouched during the cleaning process. This design also ensures that the bristles are gentle on your deck while still effectively removing dirt, grime, and any other stubborn stains. The brush is suitable for use on all types of decks, including wood, PVC, composite, and concrete, making it a versatile solution for all your cleaning needs.The design of the Diamond Deck Brush ensures that it can be used with any standard broom handle, allowing you to reach all areas of your deck with ease. Its lightweight design also ensures that you can use it for extended periods without experiencing fatigue.One of the best features of the Diamond Deck Brush is its ability to clean not only the surface of your deck but also the gaps between the deck boards. The bristles can get in between the gaps, removing any dirt or debris that may have accumulated. This feature is especially essential for wooden decks, where debris accumulation between boards can cause rotting and decay.At our company, we understand that cleaning your deck can often be tiring and time-consuming, which is why we have developed the Diamond Deck Brush to save you time and effort. The brush's design ensures that it requires minimal effort to remove even the most stubborn stains while still providing excellent results. You can clean your deck effortlessly and quickly, leaving you with ample time to engage in other activities.The Diamond Deck Brush is also a sustainable solution for all your cleaning needs. Its durable design ensures that you can use it for extended periods without having to replace it frequently, saving you money in the long run. The brush is also easy to clean, ensuring that it requires minimal maintenance and is always ready for use.In conclusion, the Diamond Deck Brush is the ultimate solution to all your deck cleaning needs. Its unique diamond-patterned bristle design ensures that you get maximum cleaning efficiency while still protecting your deck from damage during the cleaning process. Its lightweight design makes it easy to use, and its ability to clean the gaps between boards ensures that your deck is well-maintained. If you want a sustainable, efficient, and affordable solution for your deck cleaning needs, the Diamond Deck Brush is the product for you.