High-Quality Ceramic Sanding Belts for Smoother Finishes

By:Admin

The Ceramic Sanding Belts offered by (company name) are made with premium ceramic grains that provide consistent cutting action and a long-lasting performance. These belts are designed to work with high-speed sanding applications, making them ideal for heavy-duty sanding and grinding tasks. Whether it's metal fabrication, welding, or wood shaping, these sanding belts are able to deliver exceptional results, making them a top choice for professionals and hobbyists alike.

One of the key features of the Ceramic Sanding Belts is their ability to stay sharp and durable even under high heat and pressure. This is especially important in industrial settings where sanding belts are subjected to demanding conditions. The superior heat-resistance of these belts ensures that they maintain their cutting efficiency and longevity, ultimately leading to cost savings for businesses.

In addition to their durability, the Ceramic Sanding Belts offered by (company name) are known for their aggressive cutting action. This allows users to achieve faster material removal and a more efficient sanding process, ultimately increasing productivity and reducing downtime. With their superior performance, these belts enable users to complete their sanding and grinding tasks with precision and speed.

The (company name) takes pride in the quality and reliability of their Ceramic Sanding Belts. With a focus on innovation and craftsmanship, the company has consistently delivered products that meet the evolving needs of the industry. Their commitment to research and development has led to the creation of cutting-edge sanding belts that outperform traditional abrasive options, making them a preferred choice among professionals.

Furthermore, the (company name) offers a wide range of Ceramic Sanding Belts to cater to various applications and requirements. Whether it's coarse grinding, detailed sanding, or finishing work, the company provides sanding belts in different grit sizes and dimensions to suit different equipment and project needs. This versatility and customization options allow customers to find the perfect sanding belt for their specific job, ultimately leading to better results and efficiency.

As a leading manufacturer and supplier of Ceramic Sanding Belts, (company name) has established a strong reputation for providing top-quality products and exceptional customer service. The company's dedication to excellence has earned them the trust and loyalty of numerous clients in the industrial sector. From small businesses to large-scale manufacturers, (company name) has been a go-to source for reliable and high-performance sanding belts.

In conclusion, Ceramic Sanding Belts offered by (company name) are a testament to the company's commitment to quality, innovation, and customer satisfaction. With their superior durability, cutting efficiency, and versatility, these sanding belts have become indispensable tools for professionals across various industries. As the demand for high-performance sanding solutions continues to grow, (company name) remains at the forefront of delivering excellence in abrasive technology.

Company News & Blog

Ultimate Guide to Diamond Grinding Wheels: Everything You Need to Know

Title: Advanced Diamond Grinding Wheel Technology Revolutionizes Grinding ProcessesIntroductionLeading-edge technology is transforming industries worldwide, and the realm of grinding and material removal is no exception. One significant development in this field is the revolutionary diamond grinding wheel, designed to enhance grinding efficiencies and optimize output quality. In this article, we explore the exceptional features and benefits of this cutting-edge technology, sans any brand name, along with a brief introduction to the company behind this groundbreaking innovation.I. The Evolution of Grinding WheelsGrinding wheels have long been a crucial tool for numerous industries, enabling precision shaping, finishing, and removing material from a range of surfaces. Over time, advancements in manufacturing techniques and material science have led to the creation of various grinding wheel types. Among them, diamond grinding wheels have emerged as the pinnacle in terms of performance, durability, and versatility.II. Characteristics and Features of Diamond Grinding Wheels1. Exceptional Material Hardness:Diamond grinding wheels are renowned for their exceptional hardness, ensuring extended lifespan and enhanced longevity. Composed of industrial-grade diamond particles, these wheels effectively resist wear, maintaining their sharpness and consistency over prolonged periods.2. Superior Abrasion Resistance:High abrasion resistance is a defining attribute of diamond grinding wheels. This resistance enables them to endure the harsh conditions of various grinding operations, even when subjected to demanding applications that involve the removal of tough materials such as ceramics, composites, and hardened steel.3. Heat Dissipation Capability:One of the key challenges in grinding processes is effectively managing heat generation, as excessive heat can compromise material integrity. Diamond grinding wheels excel in dissipating heat effectively due to the material's exceptional thermal conductivity, minimizing the risk of material distortion or damage during grinding.4. Precision Profiling and Shaping:Diamond grinding wheels offer unparalleled precision for profiling and shaping tasks. The extreme hardness of the diamond abrasive particles allows for precise grinding, enabling exceptional control over the desired surface finish and intricate detailing.5. Minimal Wheel Dressing Requirement:Thanks to the durability and superior abrasive properties, diamond grinding wheels require less frequent dressing to maintain optimal performance. This reduction in downtime for wheel dressing translates into enhanced productivity and cost savings for businesses relying on grinding operations.III. The Company Behind the InnovationThe company leading the charge in revolutionizing grinding processes with diamond grinding wheels is a trailblazer in the field of abrasive tools. With decades of research and development, this company has established itself as a global leader in manufacturing high-quality, cutting-edge grinding wheel systems.Their commitment to innovation, combined with a strong focus on customer needs, has propelled them to the forefront of the industry. They invest substantial resources in continuous product improvement, ensuring their diamond grinding wheels meet and exceed the evolving demands of various industries, including automotive, aerospace, machinery, and more.Furthermore, this visionary company operates under a strict quality control framework, employing rigorous testing procedures to ensure that each grinding wheel leaving their facilities meets the highest standards of performance and reliability. Through collaborations with industry partners and a customer-centric approach, they continue to set new benchmarks for grinding wheel technologies.ConclusionThe advent of diamond grinding wheels has revolutionized grinding processes across industries. The extraordinary characteristics of these wheels, including their hardness, superior abrasion resistance, heat dissipation capabilities, precision profiling and shaping abilities, and reduced dressing requirements, have made them the tool of choice for the most challenging grinding applications.Thanks to the pioneering efforts of the company spearheading this innovation, they have paved the way for enhanced productivity, improved finished product quality, and cost savings for businesses across the globe. As grinding technology continues to evolve, diamond grinding wheels will undoubtedly remain at the forefront, offering efficient and reliable solutions for the material removal needs of countless industries.

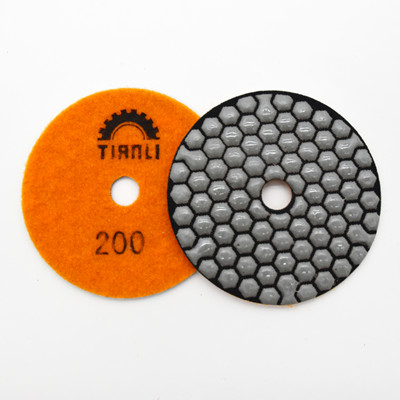

Polishing Concrete Floors: Tips for Cost, Equipment, and a Successful Finish

Concrete Floor Polishing for a High-End FinishGone are the days when concrete floors were simply a utilitarian option for warehouses and industrial spaces. Today, concrete floors are used not only for their durability but also as a stylish feature for modern homes and commercial buildings. With the process of concrete floor polishing, you can make a concrete floor look and feel like a high-end finished product.Concrete floor polishing involves grinding, honing, and polishing the surface of a concrete floor to achieve a smooth, glossy finish. The process is carried out using specialized equipment, including concrete polishing pads for floor buffer.If you are considering polishing your concrete floor, here are some things to consider before you start:1. The condition of your floor: The first thing to consider before polishing your concrete floor is its condition. The surface must be free of cracks, holes, and other damages.2. The level of smoothness you want: Concrete floor polishing can be done to different levels of smoothness depending on your preference. The smoother the floor, the more reflective it will be.3. The color of the floor: Polishing brings out the natural color of your concrete floor. You can choose to have a natural look or enhance the color using dyes or stains.4. The level of maintenance required: Polished concrete floors are easy to maintain, but you need to keep them clean and free of debris to retain their glossy finish.5. The cost: The cost of concrete floor polishing varies depending on the size of the floor, the level of polishing, and other factors.To achieve success with concrete floor polishing, you need the right equipment. This includes concrete polishing pads for floor buffer, which play a crucial role in the process. These pads come in different grits, which determine the level of polishing. The higher the grit, the smoother the finish.When it comes to concrete floor polishing, you should consider hiring a professional contractor. They have the expertise, experience, and equipment needed to achieve a high-quality finish. However, if you want to do it yourself, you can rent the equipment and purchase the necessary materials, including concrete polishing pads for floor buffer.In conclusion, concrete floor polishing is an excellent way to improve the look and feel of your space. It is a durable, low-maintenance option that can last for many years. Make sure you consider all the factors before embarking on the project, and use the right equipment, including concrete polishing pads for floor buffer.

The Role of Abrasives: Essential Tools for Surface Material Wear and Polishing

Title: Ceramic Abrasive Tools: The Cutting Edge of Material Surface RefinementIntroduction:When it comes to refining the surfaces of various materials, an abrasive is an integral tool that enables the removal of imperfections and achieves the desired smoothness or texture. In this blog, we will explore the incredible world of ceramic abrasive tools, their applications, and the benefits they offer for surface refinement. Moreover, we will delve into the key features that make ceramic abrasives the cutting edge choice for professionals and their unparalleled contribution to various industries. So, let's dive in!1. Understanding Abrasives:Abrasives are sharp, hard materials designed to wear down the surfaces of softer materials through abrasion. They play a crucial role in shaping, polishing, and refining various substances ranging from household cleansers to the most resilient materials. Today, we shift our focus onto ceramic abrasives, which are revolutionizing the industry.2. The Rise of Ceramic Abrasive Tools:Ceramic abrasives represent a breed of advanced materials designed to deliver exceptional performance and longevity. Combining the strength of ceramic grains with engineered bonding agents, these cutting-edge tools offer superior hardness, durability, and heat resistance. As a result, ceramic abrasives have found their way into a multitude of applications across a wide range of industries.3. Versatile Applications of Ceramic Abrasives:(a) Metalworking Industry: Ceramic abrasives are extensively used for precision grinding, deburring, and surface finishing in the metalworking industry. Their exceptional hardness and heat resistance make them ideal for demanding applications such as stainless steel fabrication, automotive production, and aerospace manufacturing.(b) Woodworking Industry: The wood industry benefits from ceramic abrasives that effectively shape and smoothen wooden surfaces. Whether it is sanding furniture, refining cabinetry, or shaping intricate woodworking designs, ceramic abrasive tools provide long-lasting performance and unmatched precision.(c) Glass Processing: Glass manufacturers rely on ceramic abrasives for shaping and polishing glass products. The superior hardness and cutting power of ceramic abrasives contribute to flawless glass edging, beveling, and other intricate surface treatment processes.(d) Automotive Sector: Ceramic abrasive tools find extensive use in the automotive sector for paint and bodywork applications. Their ability to delicately remove layers of paint, scratches, and imperfections ensures a stellar finish, setting a new standard in the industry.4. Unparalleled Benefits of Ceramic Abrasives:(a) Exceptional Durability: Ceramic abrasives are renowned for their outstanding longevity. Their robustness resists wear and tear, resulting in better tool life and reduced downtime.(b) Heat Resistance: Ceramic abrasives can withstand high temperatures generated during the grinding process, making them suitable for heavy-duty applications. The reduced risk of overheating ensures consistent performance and improves overall productivity.(c) Superior Material Removal: The crystalline structure of ceramic abrasives allows for an aggressive cutting action, quickly removing unwanted material. This efficiency enables professionals to achieve precise and smooth finishes with minimal effort.(d) Reduced Friction and Heat Generation: Ceramic abrasives have self-sharpening properties, ensuring consistent cutting power throughout their lifetime. With reduced friction, they generate less heat, which further safeguards the integrity of the workpiece.5. Conclusion:Ceramic abrasive tools have paved the way for a new realm of surface refinement, setting industry standards for performance and durability. With their unmatched hardness, superior cutting power, heat resistance, and versatility, ceramic abrasives are the go-to choice for professionals across various domains. As technology advances, we can expect continued innovation and enhancements in ceramic abrasive tools, translating into improved processes and superior final products.Keywords: Ceramic Abrasive Tools, Abrasives, Surface Refinement, Hardness, Durability, Heat Resistance, Metalworking Industry, Woodworking Industry, Glass Processing, Automotive SectorWord Count: 606

High-Quality Ceramic Alumina Grinding Wheel for Precision Grinding Applications

Ceramic Alumina Grinding Wheel Offers Superior Performance and Durability{Company} is proud to introduce their latest innovation in grinding technology - the Ceramic Alumina Grinding Wheel. This new product is designed to provide superior performance and durability, making it the ideal choice for a wide range of grinding applications.The Ceramic Alumina Grinding Wheel is made from a high-quality ceramic alumina abrasive material, which is known for its exceptional hardness and toughness. This makes the wheel highly resistant to wear and deformation, ensuring that it maintains its cutting edge for longer periods of time. As a result, users can expect consistent, high-quality results and extended wheel life, ultimately reducing the need for frequent wheel changes and improving overall productivity.In addition to its impressive durability, the Ceramic Alumina Grinding Wheel also offers outstanding performance in terms of material removal rate and surface finish. Its sharp cutting edges and self-sharpening properties enable it to efficiently grind and shape various materials, including steel, stainless steel, and other metals. This makes it a versatile solution for a wide range of industrial grinding applications, from heavy-duty metal fabrication to precision surface grinding.Furthermore, the Ceramic Alumina Grinding Wheel is designed for optimal heat dissipation, reducing the risk of thermal damage to the workpiece and prolonging the wheel's lifespan. This feature is particularly advantageous in high-speed grinding operations, where maintaining a cool cutting temperature is essential for achieving consistent results and preventing thermal stress on the workpiece.Another key benefit of the Ceramic Alumina Grinding Wheel is its low vibration and noise levels during operation. This not only contributes to a more comfortable working environment for the operator but also helps to minimize the risk of workpiece damage caused by excessive vibration.{Company} has integrated state-of-the-art manufacturing techniques and quality control processes to ensure that the Ceramic Alumina Grinding Wheel meets the highest standards of performance and safety. Each wheel undergoes rigorous testing to verify its dimensional accuracy, balance, and overall integrity, providing customers with a reliable and consistent grinding solution they can trust.In line with {Company}'s commitment to sustainability, the Ceramic Alumina Grinding Wheel is also engineered for minimal environmental impact. By optimizing the wheel's material utilization and energy efficiency during manufacturing, the company aims to reduce waste and energy consumption, ultimately contributing to a more eco-friendly production process.The introduction of the Ceramic Alumina Grinding Wheel further cements {Company}'s position as a leading provider of innovative and high-performance abrasive solutions. With a strong emphasis on quality, reliability, and customer satisfaction, the company continues to strive for excellence in meeting the diverse needs of its customers across various industries.In conclusion, {Company} is proud to unveil the Ceramic Alumina Grinding Wheel as a testament to its ongoing dedication to delivering cutting-edge grinding solutions. Offering exceptional durability, performance, and environmental responsibility, this new product is set to make a significant impact in the field of industrial grinding. As the demand for high-quality, efficient grinding tools continues to grow, {Company} remains at the forefront of driving technological advancements in the abrasive industry.

Highly Popular Glass Polishing Kit with 8 Wool Buffing Pads - Effective Household Cleaning Solution

Title: Revitalize your Glass Surfaces with the Great Interest Glass Polishing Kit 8pcsIntroductionGlass is a key component of modern architecture and interior design. Its sleek and transparent appearance adds elegance and sophistication to any space. However, over time, glass surfaces can become dull, scratched, or stained, diminishing their overall aesthetic appeal. Fortunately, there is a solution – the Great Interest Glass Polishing Kit 8pcs. In this blog post, we will explore how this innovative kit, featuring Wool Buffing Pads and Polishing Pads, can transform the health and hygiene of your household’s glass surfaces. Furthermore, we will dive into the benefits of using a Solar Buffing Pad, to ensure you achieve the best possible results.Chapter 1: Unleash the Power of the Great Interest Glass Polishing Kit1.1 Introducing the Great Interest Glass Polishing KitThe Great Interest Glass Polishing Kit is a comprehensive solution for restoring the sparkle and shine to your glass surfaces. This kit includes eight different Wool Buffing Pads and Polishing Pads, each with a specific purpose. These pads are designed to remove scratches, stains, water marks, and other imperfections, bringing your glass surfaces back to their original glory.1.2 Understanding the BenefitsThe Glass Polishing Kit is not limited to glass surfaces alone. It is also effective on various materials like acrylic, ceramic, and even metal surfaces, making it a versatile tool for your household cleaning needs. The kit is designed to be used with a polishing machine, providing consistent and effortless results.Chapter 2: The Key Components of the Great Interest Glass Polishing Kit2.1 Wool Buffing Pads – Why They MatterThe Wool Buffing Pads are the heart of the Great Interest Glass Polishing Kit. Made from high-quality wool fibers, these pads effectively remove minor scratches, swirl marks, and oxidation from your glass surfaces. Their soft and delicate nature ensures that they do not damage the surface while providing a thorough clean. With the Wool Buffing Pads, you can say goodbye to dull and lifeless glass.2.2 Polishing Pads – Enhancing the ShineTo achieve that extra level of shine, the Polishing Pads play a crucial role. These pads are made from a combination of wool and microfiber materials, providing a gentle but effective polishing action. They remove fine imperfections, restore clarity, and bring out the brilliance of your glass. The Polishing Pads are the perfect finishing touch to your glass cleaning process.Chapter 3: Taking it a Step Further with Solar Buffing Pad3.1 Unveiling the Solar Buffing PadTo maximize the effectiveness of the Great Interest Glass Polishing Kit, the Solar Buffing Pad is the perfect addition. This pad harnesses the energy of the sun, allowing for the removal of stubborn stains and marks that regular pads cannot reach. The Solar Buffing Pad utilizes innovative technology to deliver outstanding results, effortlessly.3.2 The Benefits of Solar Buffing PadThe Solar Buffing Pad is eco-friendly, as it reduces the need for electricity while utilizing solar energy. It is also extremely simple to use – just place it under direct sunlight for a few minutes and it's ready to go. This pad can even be used for outdoor glass surfaces, such as windows, glass patio furniture, and solar panels. Its versatility and convenience offer endless possibilities for maintaining the sparkle of your glass.ConclusionWith the Great Interest Glass Polishing Kit 8pcs, consisting of Wool Buffing Pads, Polishing Pads, and the Solar Buffing Pad, you can easily restore the beauty of your glass surfaces. Its innovative design, combined with high-quality materials, ensures efficient cleaning and impressive results. By using these products, you can transform your household cleaning routine while also promoting environmental sustainability. Say goodbye to dull and stained glass, and let the Great Interest Glass Polishing Kit illuminate your home with sparkling brilliance.Keywords: Glass Polishing Kit, Wool Buffing Pad, Polishing Pad, Solar Buffing Pad, household cleaning, household supplies, glass polish, shiny glass, glass maintenance, glass cleaning tools.

High-Quality Wet Polishing Pads for Granite - A Complete Guide

Wet Polishing Pads For Granite Revolutionizing the Stone IndustryIn the world of stone fabrication, quality equipment is essential to achieving a superior finish. This is particularly true when working with materials like granite, which require precision and care to bring out their natural beauty. One company that has been at the forefront of providing high-quality tools and equipment to stone fabricators is {}. With a long-standing reputation for excellence, {} has recently introduced a new line of wet polishing pads for granite that is sure to revolutionize the industry.The new wet polishing pads are specifically designed to provide a superior finish on granite surfaces. Made with the highest quality materials and using the latest technology, these pads are able to achieve a level of polish that is unmatched in the industry. The unique composition of the pads allows for maximum water absorption, which prevents overheating and ensures a smooth, even finish. Additionally, the pads are engineered to reduce the amount of dust and residue produced during the polishing process, creating a cleaner and healthier working environment.The introduction of these wet polishing pads for granite is a testament to {}'s commitment to innovation and excellence. With over 20 years of experience in the stone fabrication industry, {} has consistently delivered high-quality products that meet the evolving needs of their customers. By staying at the forefront of technological advancements and continually seeking out ways to improve their offerings, {} has solidified its position as a leader in the industry.In addition to their dedication to providing top-of-the-line products, {} is also known for their exceptional customer service. With a team of knowledgeable and experienced professionals, they are able to provide expert guidance and support to their customers, ensuring that they have the right tools and equipment to achieve the best results. Whether it's helping customers select the right polishing pads for a specific job or providing technical assistance, {} goes above and beyond to ensure customer satisfaction.The release of the new wet polishing pads for granite is a testament to {}'s ongoing commitment to innovation and excellence. By continually pushing the boundaries of what is possible in the stone fabrication industry, they are able to provide their customers with the tools and equipment they need to succeed. The new pads are already generating a buzz in the industry, with many fabricators eager to get their hands on this game-changing product.Feedback from early users of the wet polishing pads has been overwhelmingly positive, with many praising the pads for their exceptional performance and durability. Fabricators have noted that the pads are able to achieve a level of polish that was previously unattainable, allowing them to produce stunning finished products that exceed their customers' expectations.As the industry continues to evolve, {} remains committed to providing innovative solutions that empower stone fabricators to produce exceptional work. With the introduction of the new wet polishing pads for granite, they have once again demonstrated their ability to anticipate and meet the needs of their customers. As the popularity of these pads continues to grow, it is clear that {} is setting a new standard for excellence in the stone fabrication industry.In conclusion, the introduction of the new wet polishing pads for granite by {} is a game-changer for the industry. With their unparalleled performance and quality, these pads are sure to become an essential tool for stone fabricators looking to achieve superior results. As {} continues to lead the way in innovation and excellence, it is clear that they will remain a trusted partner for fabricators seeking the best tools and equipment for their craft.

How to Polish Your Floor to a Diamond Shine: A Comprehensive Guide

Title: Industry Leader Unveils Cutting-Edge Diamond Solution for Floor PolishingIntroduction:In a bid to revolutionize the floor polishing industry, a renowned industry leader has introduced an innovative diamond solution that promises to redefine the standards of floor finishing and achieve unmatched results. Backed by years of research and development, this groundbreaking technology aims to deliver exceptional shine and durability, effortlessly transforming ordinary surfaces into stunning masterpieces. The company behind this breakthrough is committed to pushing the boundaries of flooring solutions, propelling the industry forward into a new era of excellence.Body:1. Expanding the Horizons of Diamond Floor Polishing:The quest for a superior diamond solution for floor polishing has prompted our industry leader to invest significant time and resources into perfecting their product. Utilizing state-of-the-art technology and cutting-edge manufacturing processes, they have successfully developed a diamond that outshines any other competitor in terms of quality and performance. This advancement in floor polishing is set to transform the way we perceive and approach surface treatment.2. Unparalleled Durability:The newly unveiled diamond for floor polishing stands out due to its exceptional hardness and resilience. It is engineered to withstand heavy foot traffic, scratches, stains, and general wear and tear. The advanced composition and highly compressed structure of the diamond enable it to maintain its shine and luster over an extended period, making it ideal for high-traffic areas like shopping malls, offices, and hotels.3. Unmatched Aesthetic Appeal:Apart from its unparalleled durability, the diamond solution also promises unrivaled aesthetic beauty. Its unique formulation enhances the natural color and patterns of various types of surfaces, such as granite, marble, concrete, and terrazzo. This means that clients can now achieve a flawless, mirror-like finish that not only adds value to their spaces but also exudes elegance and sophistication.4. Eco-Friendly and Sustainable:The company's commitment to sustainability and environmental responsibility is reflected in the production process of their diamond solution. The manufacturing of this product involves minimal waste generation and employs eco-friendly techniques. In addition, the diamond's exceptional longevity means that the need for frequent refurbishments or replacements is significantly reduced, thereby reducing material consumption and overall environmental impact.5. Versatility and Ease of Use:The diamond solution is designed to be compatible with a wide array of floor polishing equipment, allowing professionals to seamlessly integrate it into their existing workflows. This versatile nature, combined with the diamond's user-friendly application process, ensures that the product can be easily adopted by professionals across the industry. Whether it's a small residential project or a large commercial undertaking, this ground-breaking diamond offers a hassle-free experience while delivering remarkable results.6. Collaborative Approach:The company's journey towards perfecting this diamond solution involved close collaboration with renowned architects, designers, and flooring professionals. This collaborative approach allowed for the exchange of ideas and expertise, resulting in a product that meets the diverse needs and expectations of clients. The company firmly believes that such partnerships are essential in driving innovation and promoting continuous improvement within the flooring industry.Conclusion:The unveiling of this cutting-edge diamond for floor polishing marks a significant milestone in the industry. With its unprecedented durability, aesthetic appeal, and commitment to sustainability, this innovative solution promises to reshape how floors are treated, taking them to new heights of beauty and resilience. As this industry leader continues to innovate, the future of floor polishing looks brighter than ever before.

High-Quality Backing Pad Polisher for Professional Use

[Company Introduction][Company] is a leading manufacturer and distributor of high-quality automotive and industrial products. With years of experience in the industry, our company is dedicated to providing customers with innovative and reliable solutions for their polishing and surface finishing needs. Our team of experts is committed to delivering superior products that meet the highest standards of quality and performance. We take pride in our ability to consistently exceed the expectations of our customers, and we are constantly striving to enhance our product offerings to better serve our clients.[Backing Pad Polisher]One of the latest additions to our product line is the Backing Pad Polisher, a cutting-edge tool designed to optimize the polishing process for automotive and industrial applications. This innovative polisher is engineered to deliver unparalleled performance and efficiency, making it an essential asset for professionals and enthusiasts alike.Featuring a durable and ergonomic design, the Backing Pad Polisher is built to withstand the rigors of heavy-duty use while providing operators with maximum comfort and control. Its high-quality construction ensures long-lasting durability, reducing the need for frequent replacements and minimizing downtime. With a powerful motor and variable speed settings, this polisher offers versatility and precision, allowing users to achieve the desired finish with ease.The Backing Pad Polisher is equipped with advanced features that set it apart from other polishers on the market. Its innovative backing pad design ensures secure attachment of polishing pads, minimizing slippage and enhancing overall safety. Additionally, the polisher incorporates a vibration reduction system to reduce operator fatigue and enhance user comfort during extended use.In addition to its exceptional performance, the Backing Pad Polisher is designed with user convenience in mind. Its lightweight and balanced construction make it easy to maneuver, reducing strain on the operator and enhancing overall productivity. The polisher also features an intuitive control interface, allowing for seamless operation and adjustment of speed settings.Furthermore, the Backing Pad Polisher is compatible with a wide range of polishing pads, making it a versatile tool for various applications. Whether used for automotive paint correction, metal polishing, or surface refinishing, this polisher delivers consistent and professional results. Its versatility and adaptability make it an indispensable asset for professionals in the automotive and industrial sectors.As a part of our commitment to customer satisfaction, [Company] offers comprehensive support and resources for the Backing Pad Polisher. Our team of professionals is available to provide guidance and assistance to ensure that our customers derive the maximum benefit from this innovative tool. We stand behind the quality and performance of our products, and the Backing Pad Polisher is no exception.In conclusion, the introduction of the Backing Pad Polisher represents [Company]'s dedication to providing cutting-edge solutions for polishing and surface finishing needs. With its exceptional performance, versatility, and user-friendly design, this polisher sets a new standard for quality and reliability in the industry. As [Company] continues to innovate and expand its product offerings, customers can expect to benefit from the superior quality and performance of our products.

Ultimate Guide to Sponge Polishing Pads: How to Achieve a Flawless Finish

Sponge Polishing Pads are the latest innovation in the automotive industry, designed to provide a superior finish to vehicles while making the polishing process more efficient and convenient. These pads are made from high-quality sponge material that is capable of effectively removing scratches, swirls, and other imperfections from the surface of a vehicle. The introduction of Sponge Polishing Pads has revolutionized the way car enthusiasts and professionals approach the task of polishing and maintaining their vehicles.One company that has been at the forefront of this innovation is [Company Name], a leading manufacturer of automotive detailing products. With a strong focus on research and development, [Company Name] has been able to create Sponge Polishing Pads that deliver exceptional results, allowing car owners to achieve a showroom-quality finish without having to rely on professional detailing services.The Sponge Polishing Pads produced by [Company Name] are designed to be compatible with a wide range of polishing machines, making them suitable for both professional and DIY use. The pads are available in different sizes and densities, allowing users to choose the most suitable option for their specific polishing needs. Whether it's removing deep scratches or creating a high-gloss shine, these pads are engineered to deliver consistent results with minimal effort.In addition to their superior performance, [Company Name]'s Sponge Polishing Pads are also designed with durability in mind. The high-quality sponge material is capable of withstanding the rigors of regular use, ensuring that the pads maintain their effectiveness over time. This durability not only ensures long-term cost savings for car owners but also reduces the environmental impact of disposable polishing pads.Furthermore, [Company Name] is committed to providing a comprehensive polishing solution, offering a range of complementary products to enhance the overall polishing experience. From cutting compounds to finishing polishes, the company's product line is designed to work seamlessly with their Sponge Polishing Pads, allowing users to achieve professional-quality results with ease.The introduction of Sponge Polishing Pads has undoubtedly raised the bar in the automotive detailing industry, and [Company Name] has established itself as a key player in this innovation. By combining cutting-edge technology with a commitment to quality and performance, the company has been able to provide car owners and detailing professionals with a game-changing polishing solution.The positive reception of [Company Name]'s Sponge Polishing Pads is a testament to the company's dedication to meeting the needs of its customers. With a focus on continuous improvement and innovation, [Company Name] is well-positioned to remain a leader in the automotive detailing industry, offering products that set new standards for quality and performance.As the demand for high-quality detailing products continues to grow, [Company Name]'s Sponge Polishing Pads are poised to become a staple in the arsenal of car enthusiasts and professionals alike. With their proven effectiveness and durability, these pads are set to redefine the polishing experience, allowing users to achieve stunning results with confidence and ease.In conclusion, [Company Name] has cemented its position as a driving force behind the innovation of Sponge Polishing Pads, setting a new benchmark for quality and performance in the automotive detailing industry. With a commitment to meeting the needs of its customers and a dedication to excellence, [Company Name] is well-positioned to continue leading the way in delivering innovative and effective products that make car care more efficient and enjoyable.