Different Types of Grinding Wheel for Various Applications

By:Admin

Grinding wheels are essential tools in the manufacturing and metalworking industries, used for shaping and finishing metals and other materials. They are available in a variety of types, each designed for specific applications and materials. Understanding the different types of grinding wheels can help manufacturers and metalworkers choose the right tool for their needs.

A leading player in the manufacturing industry, {company name} is a renowned provider of grinding wheels and other abrasive products. With a strong emphasis on quality and innovation, {company name}'s extensive range of grinding wheels caters to various industries and applications.

{company name} offers a diverse selection of grinding wheel types, each tailored to meet the needs of different materials and applications. The following are some of the most commonly used grinding wheel types and their respective applications:

1. Straight Grinding Wheels: These are the most common type of grinding wheel, featuring a simple, flat design. They are used for surface grinding, cylindrical grinding, and tool sharpening.

2. Cylinder Wheels: These wheels have a long, cylindrical shape, making them suitable for grinding long, narrow surfaces.

3. Tapered Grinding Wheels: As the name suggests, these wheels have a tapered shape, making them ideal for grinding threads and gear teeth.

4. Dish Grinding Wheels: These wheels have a slightly concave shape, making them suitable for grinding tools and cutters.

5. Diamond Wheels: Diamond grinding wheels are made with synthetic diamonds, making them extremely durable and suitable for grinding hard materials such as carbides, ceramics, and glass.

6. CBN Wheels: Cubic Boron Nitride (CBN) wheels are designed for grinding ferrous materials such as steel and cast iron, offering high thermal conductivity and chemical stability.

7. Segmented Grinding Wheels: These wheels are made up of multiple segments, allowing for aggressive material removal and improved cooling during grinding.

8. Mounted Points: These small, specialized grinding wheels are used for precision grinding in hard-to-reach areas.

{company name} is committed to delivering high-quality grinding wheels that meet the diverse needs of its customers. With a focus on innovation and technological advancement, {company name} continuously develops new grinding wheel types and formulations to address the evolving needs of the industry.

In addition to offering a wide range of grinding wheel types, {company name} provides expert guidance and technical support to help customers choose the right wheel for their specific applications. Through its extensive industry experience and technical expertise, {company name} ensures that its customers achieve optimal grinding results and maximize productivity.

The use of high-quality grinding wheels is essential for achieving precision and efficiency in metalworking and manufacturing processes. {company name} is dedicated to providing solutions that enable its customers to enhance their productivity, reduce operating costs, and improve the quality of their finished products.

As a leading provider of grinding wheels and abrasive products, {company name} has built a strong reputation for its commitment to quality, innovation, and customer satisfaction. With a comprehensive range of grinding wheel types and a dedication to technical excellence, {company name} continues to be at the forefront of the abrasive industry.

In conclusion, choosing the right grinding wheel is crucial for achieving optimal results in metalworking and manufacturing processes. With its extensive range of grinding wheel types and a focus on quality and innovation, {company name} is the preferred choice for customers seeking high-performance abrasive solutions. Whether it's surface grinding, cylindrical grinding, or precision grinding, {company name} has the right grinding wheel for every application.

Company News & Blog

Floor Polishing with Diamond: A Complete Guide and Tips

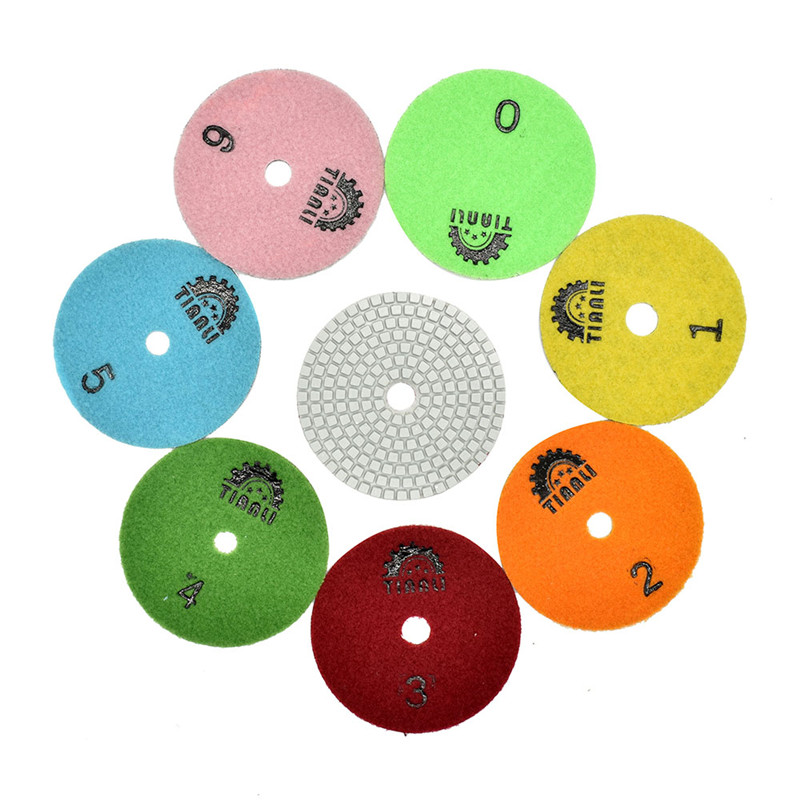

Polishing and maintaining the appearance of floors is a critical aspect of keeping any space looking attractive and presentable. Whether it's for a residential or commercial property, ensuring that floors are kept in top condition is essential. This is where diamond for floor polishing comes in. [Company Name] is a leading manufacturer and supplier of diamond for floor polishing products that are designed to provide effective and efficient polishing solutions for a wide range of flooring materials.Established in [year], [Company Name] has accumulated a wealth of expertise and experience in the development and production of high-quality diamond for floor polishing tools. The company boasts a state-of-the-art manufacturing facility, equipped with advanced technology and machinery, allowing them to create superior products that meet the needs of their customers.The diamond for floor polishing products offered by [Company Name] are known for their exceptional performance, durability, and cost-effectiveness. Whether it's for polishing concrete, marble, granite, or any other type of hard flooring material, [Company Name] has the right solution to ensure that the job is done efficiently and to the highest standard.One of the key advantages of using diamond for floor polishing is the superior finish it provides. Diamond polishing pads are able to achieve a level of shine and smoothness that is unparalleled by other types of polishing tools. This makes them ideal for use in high-traffic areas such as commercial buildings, retail spaces, and industrial facilities where maintaining a clean and professional appearance is crucial.In addition to their effectiveness, diamond for floor polishing products also offer long-term cost savings. Their durability and performance mean that they require less frequent replacement compared to other types of polishing tools, resulting in reduced maintenance costs for property owners and managers.Moreover, [Company Name] takes pride in its commitment to sustainability. The company has integrated environmentally-friendly practices into its manufacturing processes, minimizing waste and reducing its carbon footprint. This means that customers can have peace of mind knowing that they are investing in products that are not only effective but also eco-friendly.Furthermore, [Company Name] offers a range of diamond for floor polishing products to cater to the diverse needs of its customers. Whether it's for heavy-duty industrial applications or smaller residential projects, the company has a comprehensive selection of polishing tools to suit different requirements.The customer service provided by [Company Name] is another aspect that sets the company apart. Their knowledgeable and friendly team is always on hand to provide expert advice and assistance, ensuring that customers are able to find the right diamond for floor polishing product for their specific needs.As the demand for high-quality floor polishing solutions continues to grow, [Company Name] is dedicated to staying at the forefront of the industry. The company invests in research and development to innovate new products and improve existing ones, allowing them to consistently deliver the best solutions to their customers.In conclusion, diamond for floor polishing is an essential component of maintaining the appearance and quality of floors in various settings. With [Company Name] being a trusted leader in the industry, customers can expect top-notch products that offer exceptional performance, durability, and cost-effectiveness. As the company continues to prioritize sustainability and customer satisfaction, it is well-positioned to remain a key player in the floor polishing market for years to come.

New Wire Brush Grinding Wheel Technology for Improved Grinding Performance

Wire brush grinding wheels are a must-have for anyone who wants to keep their metal materials in top condition. They are particularly useful in removing rust, paint, and other types of corrosion from the surface of metalwork. These wheels are designed to be used with a wide range of angle grinders and are easily adaptable for use in a variety of industrial settings.One company that produces high-quality wire brush grinding wheels is a leading manufacturer in the industry. They have been in the business of producing abrasive products for over 30 years, and they have built a reputation for themselves through their commitment to quality and their ability to customize their products to suit the unique needs of their customers.According to a company spokesperson, their wire brush grinding wheels are made from the highest quality materials. The wire bristles are constructed from tough, durable metal alloys that are specifically designed to withstand harsh industrial environments. Their wheels are also available in a range of different sizes and shapes, making them suitable for use with various types of angle grinders.One of the main advantages of using these wire brush grinding wheels is that they are highly versatile. They can be used for everything from cleaning up welds to preparing surfaces for painting or other types of finishing. They are also ideal for removing rust or any other type of corrosion.In addition to their quality products, the company also places a high value on customer service. This is evident in their ability to customize their products to meet the needs of each individual customer. Whether a client requires a specific size or shape of wheel, or they need a specialized type of wire bristle to suit their specific application, this company has the expertise and resources to deliver customized products that meet their customers' needs.Moreover, the company produces their wire brush grinding wheels in a highly efficient manner. This means that they are able to provide their customers with top-quality products at competitive prices. Whether a client needs a single wheel or a bulk order, they can be sure that they will receive a product that is both affordable and of the highest quality.Another key feature of these wire brush grinding wheels is their durability. The combination of high-quality materials and expert construction results in products that are built to last. They are able to withstand the rigors of heavy use and exposure to harsh environments, ensuring that they provide reliable performance for an extended period of time.Looking to the future, the company has ambitious plans to expand its operations and continue to innovate in the field of abrasive products. They are committed to staying at the forefront of their industry and providing their customers with the latest cutting-edge technology and techniques. They envision a future where their products are used in diverse industries around the world, cementing their position as a leading manufacturer of wire brush grinding wheels.In conclusion, wire brush grinding wheels are an essential tool for any industry that works with metal materials. They are highly versatile, durable, and efficient, making them the ideal choice for a range of applications. The products produced by this leading manufacturer stand out for their quality, customization, and affordability, making them a top choice for anyone in need of high-quality abrasive products. As the company continues to innovate and expand, it is sure to remain a key player in the industry for many years to come.

Ultimate Guide to Ceramic Abrasive Tools: What You Need to Know

Ceramic Abrasive Tools has been making waves in the industry with its innovative and high-quality products that have been gaining popularity among professionals and DIY enthusiasts alike. The company, which was established in 2005, has quickly grown to become a leading provider of ceramic abrasive tools that are known for their exceptional performance and durability.The company's products are designed to meet the needs of a wide range of applications, including metalworking, woodworking, and surface preparation. With a focus on quality and innovation, Ceramic Abrasive Tools has developed a reputation for delivering cutting-edge solutions that help users achieve superior results in their work.One of the key factors that sets Ceramic Abrasive Tools apart from its competitors is its use of advanced ceramic technology. The company's abrasive tools are made from high-quality ceramic grains that are engineered to deliver outstanding cutting performance and longer product life. This has made Ceramic Abrasive Tools a preferred choice for professionals who demand the best in their tools.In addition to its focus on performance, Ceramic Abrasive Tools also takes pride in its commitment to sustainability and environmental responsibility. The company's products are designed to minimize waste and reduce energy consumption, making them an eco-friendly choice for conscientious users.Another important aspect of Ceramic Abrasive Tools' success is its dedication to customer satisfaction. The company understands the importance of delivering reliable and effective tools, and it goes the extra mile to ensure that its customers receive the support and guidance they need to make the most of their products. This customer-centric approach has earned Ceramic Abrasive Tools a loyal following and a strong reputation for excellence.Recently, Ceramic Abrasive Tools introduced a new line of products that have been generating a lot of excitement in the industry. These new tools build on the company's legacy of quality and innovation, offering even better performance and versatility for a wide range of applications. With these new products, Ceramic Abrasive Tools continues to demonstrate its leadership and commitment to driving the industry forward.The new line of products includes a variety of abrasive tools that are designed to meet the diverse needs of professionals and hobbyists. Whether it's grinding, cutting, or polishing, these tools are engineered to deliver exceptional results with precision and efficiency. As with all of Ceramic Abrasive Tools' products, these new tools are made with the highest standards of quality and performance in mind.One of the standout features of the new line of products is their enhanced durability. Ceramic Abrasive Tools has incorporated advanced materials and engineering techniques to make these tools even more rugged and long-lasting, ensuring that they can stand up to the rigors of demanding applications. This durability not only helps users achieve better results, but it also reduces the need for frequent replacements, saving time and money in the long run.Ceramic Abrasive Tools' new products have also been designed with user convenience in mind. The company has paid close attention to ergonomic design and ease of use, making these tools comfortable and efficient to operate. This thoughtful approach to user experience sets Ceramic Abrasive Tools apart and makes its products a pleasure to work with.With the introduction of these new products, Ceramic Abrasive Tools is once again proving why it is a leader in the industry. By combining cutting-edge technology, superior performance, and a customer-centric approach, the company continues to set the standard for excellence in the abrasive tools market. As professionals and enthusiasts alike seek the best tools for their work, Ceramic Abrasive Tools remains the go-to choice for those who demand the highest quality and performance.

Durable Nylon Flap Brush for Effective Surface Cleaning

The Nylon Flap Brush: A Versatile Tool for Surface PreparationAs industries continue to evolve, the demand for efficient and effective surface preparation tools has become crucial. In response to this need, {Company Name} has introduced their innovative Nylon Flap Brush, which has quickly gained recognition for its quality and performance in a variety of applications.{Company Name} is a leading manufacturer of abrasives and surface preparation tools, with a strong focus on innovation and product development. With a commitment to delivering high-quality products to their customers, {Company Name} has become a trusted name in the industry.The Nylon Flap Brush is just one example of the company's dedication to innovation and quality. This versatile tool is designed for surface finishing, cleaning, and polishing of a wide range of materials, including metal, wood, plastic, and composites. The brush is made with high-quality nylon filaments that are flexible and durable, making it ideal for various surface preparation tasks.One of the key features of the Nylon Flap Brush is its flexibility, which allows it to conform to irregular surfaces and contours. This makes it particularly useful for applications where a uniform finish is essential, such as deburring, edge blending, and surface blending. Additionally, the brush is designed to provide consistent performance and long service life, making it a cost-effective solution for many industries.The Nylon Flap Brush is available in a range of sizes and configurations to suit different applications. Whether it is used on a hand-held grinder or a stationary machine, the brush can be easily adapted to meet specific requirements. This flexibility has made it a popular choice among manufacturers and fabricators who value efficiency and versatility in their surface preparation tools.In addition to its performance, the Nylon Flap Brush is also designed with operator safety in mind. The brush is engineered to reduce the risk of kickback and vibration, helping to minimize operator fatigue and improve overall productivity. This focus on safety is reflective of {Company Name}'s commitment to providing solutions that not only deliver exceptional results but also prioritize the well-being of the user.{Company Name} takes pride in the rigorous testing and quality control measures that are implemented throughout the manufacturing process of the Nylon Flap Brush. As a result, customers can have confidence in the reliability and consistency of the product, knowing that it has been thoroughly evaluated to meet the company's high standards.Furthermore, {Company Name} offers comprehensive technical support and customer service to assist with product selection and application recommendations. This level of support ensures that customers can maximize the value of the Nylon Flap Brush and achieve the best possible results in their surface preparation processes.Overall, the Nylon Flap Brush from {Company Name} represents a significant advancement in surface preparation technology. With its superior performance, versatility, and commitment to quality, this innovative tool has quickly become a preferred choice for manufacturers and fabricators across various industries. As {Company Name} continues to push the boundaries of what is possible in surface preparation, the Nylon Flap Brush stands as a testament to their ongoing dedication to excellence.

Revolutionary New Grinding Disc Technology Unveiled: A Game Changer in Surface Preparation

Title: Innovative Grinding Disc Revolutionizes Metalworking IndustryIntroduction:In today's fast-paced industrial landscape, the search for innovative tools to enhance productivity and efficiency remains constant. This quest for advancement has led to the development of a groundbreaking grinding disc by an industry-leading company. Combining cutting-edge technology with unrivaled performance, this new grinding disc is poised to revolutionize the metalworking industry.Unleashing the Power of the Grind Disc:The newly unveiled grind disc, developed by a renowned manufacturing company, is set to transform metalworking processes by offering unmatched performance, durability, and efficiency. Through extensive research and advanced engineering, the company has successfully created a tool that vastly increases productivity while reducing costs for metalworkers across various sectors.Technical Innovation:The proprietary technology behind this grind disc incorporates state-of-the-art materials and an innovative design, resulting in a truly exceptional product. The disc's abrasive composition and unique shape contribute to its ability to remove material more efficiently, delivering fast and precise results. Furthermore, the disc's enhanced durability ensures prolonged usage, reducing the downtime associated with frequent replacement.Enhanced Performance and Versatility:The grind disc's cutting-edge design guarantees superior performance across a wide range of applications. From shaping and leveling to finishing and polishing, this multi-purpose tool offers versatility for a variety of metalworking tasks. Regardless of the desired outcome, this innovative grinding disc consistently delivers exceptional results, making it an essential addition to any metalworking arsenal.Ergonomic Design:Recognizing the importance of workplace ergonomics, the grind disc incorporates a user-friendly design. The disc's lightweight construction, combined with its ergonomic handle, ensures comfortable handling during extended periods of work. This feature reduces operator fatigue and increases overall efficiency, further maximizing productivity while prioritizing worker safety.Eco-Friendly Manufacturing:The company behind this groundbreaking grinding disc is committed to responsible manufacturing practices. With sustainability at the core of their operations, they have implemented stringent measures to minimize environmental impact. From the sourcing of raw materials to the disc's production process, every stage adheres to eco-friendly guidelines, ensuring a product that meets the demands of today's environmentally conscious metalworking industry.Driving Industry Innovation:The introduction of this revolutionary grind disc signifies a significant step toward reshaping the metalworking landscape. By combining cutting-edge technology with unparalleled performance, the company responsible for this groundbreaking tool is spearheading industry innovation. This development not only improves productivity for metalworkers but also inspires further advancements in tool design and manufacturing techniques.Collaborative Approach:To ensure continuous product improvement and customer satisfaction, the company has actively engaged with metalworking professionals throughout the development process. Collaborative feedback and input from industry experts have played a crucial role in refining the grind disc's performance, making it a truly reliable and user-friendly tool.Conclusion:The metalworking industry can look forward to a transformative shift with the introduction of this groundbreaking grind disc. Boasting unrivaled performance, cutting-edge technology, and a commitment to sustainability, this innovative tool is set to revolutionize metalworking processes worldwide. As the industry embraces this advancement, productivity, efficiency, and worker satisfaction are expected to reach unprecedented heights, paving the way for a brighter future in metalworking.

Effective 3 Step Polishing Pads for High Quality Results

Introducing the Next Level of Polishing Technology: 3 Step Polishing PadsIn the ever-evolving world of automotive detailing and polishing, innovation is key to staying ahead of the competition. With this in mind, [Company Name] is proud to introduce our latest breakthrough in polishing technology - the 3 Step Polishing Pads.These new pads have been meticulously designed and engineered to provide a superior polishing experience, delivering impeccable results with minimal effort. Through extensive research and development, our team has created a product that is set to revolutionize the industry and set a new standard for excellence.The 3 Step Polishing Pads are the result of [Company Name]'s commitment to pushing the boundaries of what is possible in the world of automotive care. With a focus on quality, performance, and user-friendliness, these pads are poised to become an essential tool for professionals and enthusiasts alike.What sets the 3 Step Polishing Pads apart from traditional polishing methods is their unique three-step process. Each pad is specifically designed for a particular stage of the polishing process, allowing for a seamless and efficient workflow. From initial cutting and leveling to refining and finishing, these pads are engineered to deliver unparalleled results with precision and consistency.Furthermore, the 3 Step Polishing Pads are compatible with a wide range of polishing machines, making them a versatile and practical choice for any detailing professional. Whether you are working on paint correction, refinishing, or restoration, these pads are up to the task, delivering a flawless finish every time.In addition to their exceptional performance, the 3 Step Polishing Pads are also designed with durability in mind. Constructed from high-quality materials and engineered to withstand rigorous use, these pads are built to last. This not only ensures a reliable and consistent performance but also makes them a cost-effective choice for professionals looking to maximize their investment.At [Company Name], we take great pride in our commitment to excellence, and the introduction of the 3 Step Polishing Pads is a testament to that commitment. We are dedicated to providing our customers with the highest quality products that not only meet but exceed their expectations. With these new pads, we are confident that our customers will experience a new level of excellence in their polishing endeavors.As part of our dedication to customer satisfaction, we also offer comprehensive support and guidance to ensure that our customers get the most out of their 3 Step Polishing Pads. Whether you are a seasoned professional or a novice enthusiast, our team is ready to provide the knowledge and expertise needed to achieve outstanding results.In conclusion, the introduction of the 3 Step Polishing Pads marks a significant milestone for [Company Name] and the automotive detailing industry as a whole. By combining cutting-edge technology with unparalleled performance, these pads are set to redefine the standard for polishing excellence. Whether you are a detailing professional looking to elevate your craft or an enthusiast seeking to achieve showroom-quality results, the 3 Step Polishing Pads are the ultimate solution.With a relentless pursuit of innovation and a steadfast commitment to quality, [Company Name] is proud to present the 3 Step Polishing Pads as the next evolution in automotive polishing technology. Experience the difference for yourself and discover a new level of perfection with the 3 Step Polishing Pads from [Company Name].

Discover the Versatile Benefits of Lock Polishing Pads

article:Snail Lock Polishing Pad Revolutionizes Grinding and PolishingIn the world of grinding and polishing, efficiency and quality are two factors that cannot be compromised. Both are critical when it comes to achieving a perfect finish. One product that is quickly gaining traction in the industry is the Snail Lock Polishing Pad.Produced by a leading manufacturer of abrasives, the product is a game-changer in the world of grinding and polishing. It has been developed using the latest technology to ensure efficient and consistent grinding and polishing.The snail lock polishing pad is designed to work specifically with automatic edge polishing machines and bridge polishing machines equipped with the snail lock adapter. The pads are made from high-quality resin and diamond particles that make them durable and long-lasting. They are also easy to install and remove, making the grinding and polishing process quicker and more efficient.The unique design of the snail lock polishing pad consists of a double-layered resin and diamond grain structure that provides superior quality and consistent results. The single locking system ensures that the pad remains securely in place while in operation, reducing the risk of accidents and ensuring maximum safety for operators.According to the manufacturer, the snail lock polishing pad is suitable for use on a wide range of materials. These include natural stone, engineered stone, ceramics, and porcelain. This versatility makes it an indispensable tool for fabricators, contractors, and DIY enthusiasts.The snail lock polishing pad is also designed to reduce the need for multiple stages of grinding and polishing. Its superior quality means that it can deliver excellent results with minimal effort, time, and energy. This factor makes it a cost-effective solution for grinding and polishing professionals.The company behind the snail lock polishing pad has been in the business for over a decade and has built a strong reputation for producing high-quality abrasive products that meet the demands of the industry. Their team of experts includes experienced engineers, technicians, and customer service representatives who work tirelessly to ensure that their products are of superior quality and that they offer the best service to their clients.In addition to the snail lock polishing pad, the company produces a wide range of other abrasive products that cater to the needs of various industries. These products include diamond saw blades, diamond core bits, profiling wheels, and cup wheels, among others.The company believes that its success is driven by its commitment to quality and its willingness to go the extra mile to ensure customer satisfaction. This includes investing in research and development to improve its products' performance and quality continually.In conclusion, the snail lock polishing pad is a revolutionary product that is quickly gaining traction in the industry. Its unique design, efficiency, and durability make it a game-changer in the world of grinding and polishing. It is an indispensable tool for fabricators, contractors, and DIY enthusiasts looking for superior quality and consistent results. The manufacturer's commitment to quality and customer satisfaction make it a brand that customers can trust. With its continued investment in research and development, the company is poised to remain a leader in the abrasive products industry for years to come.

How to Deal with Irregular Abrasive and Its Impact on Your Business

Irregular Abrasive Announces New Product Line to Enhance Metal Finishing ProcessIrregular Abrasive, a leading manufacturer of abrasive products, has recently announced the launch of a new line of abrasive tools aimed at enhancing the metal finishing process. The company, which prides itself on providing high-quality and innovative solutions for industrial applications, is set to revolutionize the metalworking industry with its latest offering.Established in 1995, Irregular Abrasive has built a solid reputation for delivering superior abrasives that meet the diverse needs of its customers. With a strong commitment to research and development, the company has consistently introduced cutting-edge products that have set new standards in the industry. The addition of the new abrasive line is a testament to Irregular Abrasive's dedication to innovation and continuous improvement.The new product line promises to offer a range of benefits for metal finishing processes, including improved efficiency, better surface finish quality, and reduced production costs. With a focus on addressing the challenges faced by metalworkers, Irregular Abrasive has designed the new tools to deliver optimal performance and consistency, thereby enabling users to achieve superior results in their operations.In a statement released by the company, Irregular Abrasive's CEO expressed his excitement about the launch of the new product line, stating, "We are thrilled to introduce our latest range of abrasive tools, which are the result of extensive research and development. Our goal is to provide metalworkers with innovative solutions that not only streamline their processes but also elevate the quality of their finished products. We believe that our new abrasive line will make a significant impact in the industry and set a new benchmark for metal finishing."The newly introduced abrasive tools are tailor-made to cater to various metal finishing applications, including grinding, deburring, and polishing. Irregular Abrasive has utilized advanced manufacturing techniques and materials to ensure that the tools offer unparalleled performance and durability, thus meeting the rigorous demands of industrial operations.Moreover, the company has emphasized the importance of user-friendliness and safety in the design of the new abrasive line, incorporating features that enhance ease of use and minimize the risk of accidents. This customer-centric approach is a reflection of Irregular Abrasive's commitment to delivering value beyond just the products themselves.To coincide with the launch of the new product line, Irregular Abrasive has also launched an educational campaign to raise awareness about the benefits of using high-quality abrasives in metal finishing. The campaign aims to provide metalworkers with valuable insights and best practices for optimizing their finishing processes, ultimately enabling them to achieve better results and higher productivity.In addition to its new product offering, Irregular Abrasive has reaffirmed its commitment to sustainability and environmental responsibility. The company has integrated eco-friendly practices into its manufacturing processes, ensuring that its abrasives not only deliver exceptional performance but also adhere to the highest environmental standards.As the metalworking industry continues to evolve, Irregular Abrasive is poised to remain at the forefront of innovation, providing the tools and resources that empower metalworkers to elevate their capabilities and stay ahead of the competition. With its new abrasive line, the company is set to make a lasting impact on the metal finishing landscape, offering a solution that combines performance, quality, and sustainability.In conclusion, Irregular Abrasive's latest announcement reflects its unwavering dedication to advancing the metalworking industry through innovation and excellence. The new abrasive line is poised to bring about a positive change in metal finishing processes, setting a new standard for performance and quality. As the company continues to push the boundaries of abrasive technology, customers can expect to benefit from the superior solutions that Irregular Abrasive is renowned for delivering.

High-Quality and Reliable Universal Diamond Cutting Disc 125x22.23mm - Professional Power Tools

article on the importance and benefits of using high-quality diamond cutting discs in various industries.As technology advances and new materials are developed, the need for precise and efficient cutting tools becomes increasingly important. In many industries, the use of cutting discs is crucial for producing high-quality products and completing tasks with precision and accuracy. With so many different types of cutting discs available on the market, it can be overwhelming to choose the right one for your specific needs.One type of cutting disc that has gained popularity in recent years is the diamond cutting disc. Diamond cutting discs are quickly becoming the standard for professionals in a wide variety of industries due to their exceptional strength, durability, and precision. These discs are made with industrial diamonds that are bonded to a metal or resin matrix, which provides a superior cutting edge that can handle tough materials like concrete, metal, glass, and ceramic tiles.One of the key features of diamond cutting discs is their versatility. Thanks to their durable composition, diamond cutting discs can cut through a wide range of materials, making them a go-to tool for professionals in a variety of industries. This versatility means that contractors and tradespeople can have a single cutting disc to handle various cutting needs, which can save them both time and money.Another benefit of diamond cutting discs is their long lifespan. With regular use and proper maintenance, diamond cutting discs can last significantly longer than traditional cutting discs. This is because the industrial diamonds used to make diamond cutting discs are incredibly hard and resilient, making them more resistant to wear and tear. Additionally, the bond that holds the diamonds in place is designed to withstand high temperatures and stress, further extending the lifespan of the disc.Aside from their durability, diamond cutting discs also offer exceptional cutting speed and precision. Because the industrial diamonds are much harder and sharper than traditional cutting materials like aluminum oxide or silicon carbide, they can cut through materials much faster, with less force required. This faster cutting speed not only increases efficiency on the job but also leads to a smoother finish with fewer burrs or jagged edges.When it comes to choosing a diamond cutting disc, it's crucial to consider factors like blade size, material composition, and intended use. For example, the Metabo diamond cutting disk 125x22.23mm, "UP", Universal "professional" (628559000) is designed to be a high-quality, reliable, and durable option for professionals in various industries. Its 125mm diameter makes it suitable for cutting a wide range of materials, while its universal "professional" design means that it can handle the toughest applications with ease. As a product known for its exceptional quality and performance in the industry, using it can ensure optimal results every time.In conclusion, there are significant benefits to using high-quality diamond cutting discs in various industries, including their versatility, long lifespan, and exceptional speed and precision. Although the initial cost of diamond cutting discs may be higher than traditional cutting discs, the superior performance and longevity make them a worthwhile investment in the long run. By choosing the right diamond cutting disc for your specific needs, you can ensure optimal results and save both time and money in the process.

Powerful Angle Grinder Makes Quick Work of Cutting and Grinding

Angle Grinder Machine Revolutionizes the Industry with Innovation and Precision[City, Date] - Angle Grinder Machine, a cutting-edge product designed by the renowned machinery manufacturer, has successfully revolutionized the industry with its unprecedented innovation and precision. With its versatile features and remarkable performance, this machine has quickly become an essential tool for professionals across various sectors.The Angle Grinder Machine, with its brand's secrecy, offers a unique combination of power, durability, and ease of use. It has been engineered to meet the highest standards of quality and performance, making it the go-to choice for professionals who rely on accuracy and efficiency in their work.One of the distinct features of this Angle Grinder Machine is its powerful motor that delivers impressive speed and torque. This allows users to effortlessly cut through different materials, including metal, concrete, tiles, and more. Whether it's a heavy-duty application or a delicate task, this machine guarantees precise and consistent results every time.Furthermore, the Angle Grinder Machine incorporates advanced safety features, ensuring user protection and preventing accidents. The anti-kickback mechanism and adjustable protective guard provide a secure working environment, reducing the risk of potential injuries. This machine also includes ergonomic features such as a comfortable handle grip, minimizing operator fatigue and improving overall productivity.The versatile nature of the Angle Grinder Machine makes it suitable for a wide range of industries. With its ability to accommodate different cutting discs and accessories, professionals in construction, metalworking, and fabrication find it indispensable for tasks such as cutting, grinding, polishing, and shaping various materials. Its adaptability and performance have made it an invaluable asset for experts in these fields.The company behind the Angle Grinder Machine has a strong reputation for engineering excellence and innovation. With decades of experience in the industry, they have continuously invested in research and development to deliver cutting-edge machinery that meets and exceeds customer expectations.Their commitment to quality is evident in every aspect of the Angle Grinder Machine. Rigorous testing and quality control processes ensure that each machine leaving their production line is of the highest standard. This dedication to precision and reliability has earned the company the trust and loyalty of professionals worldwide.In addition to the outstanding performance of their products, the manufacturer also places great importance on customer satisfaction. They provide comprehensive after-sales support, including training programs and technical assistance, to ensure that users can maximize the benefits of their Angle Grinder Machine. This level of commitment to their customers sets the company apart from its competitors.With its innovative design, exceptional performance, and commitment to customer satisfaction, the Angle Grinder Machine has made a significant impact across various industries. From construction sites to metalworking shops, professionals now rely on this cutting-edge tool to achieve unparalleled efficiency and accuracy in their work.As the industry evolves, the Angle Grinder Machine continues to push boundaries and set new standards. With a strong foundation of quality and innovative design, this revolutionary product is poised to shape the future of the machinery industry. As professionals seek precision and reliability in their work, the Angle Grinder Machine stands proud as the go-to choice for all their cutting and grinding needs.About the CompanyThe manufacturer behind the Angle Grinder Machine is a leading machinery company specializing in the production of high-performance tools. With a rich history of engineering excellence and a strong commitment to innovation, they have become a trusted name in the industry. Their dedication to quality and customer satisfaction has enabled them to revolutionize various sectors with their state-of-the-art machinery.