Understanding the Significance of Metal Organic Bonds in Chemistry

By:Admin

(Company name) is a leading producer and supplier of Metal Organic Bonds, offering a wide range of high-quality products to meet the diverse needs of its customers. The company has been at the forefront of developing and improving MOBs, continuously investing in research and development to deliver cutting-edge solutions to the market.

One of the key features of MOBs is their exceptional strength and durability. These compounds provide a more robust bonding capability, making them suitable for a wide range of applications, including bonding metals, composites, and other materials. This enhanced strength allows for the construction of more resilient and long-lasting structures, contributing to overall safety and stability in various industrial settings.

Furthermore, MOBs offer unparalleled flexibility, enabling the bonding of materials with differing physical properties. This flexibility is crucial in construction projects, where different materials need to be combined without compromising the overall integrity of the structure. With MOBs, builders and manufacturers can achieve seamless integration of various components, ensuring a cohesive and reliable end product.

In addition to their superior performance, Metal Organic Bonds also offer environmental benefits. These compounds are free from harmful chemicals and solvents, reducing the impact on the environment during the bonding process. As sustainability becomes an increasingly important consideration in the construction and industrial sectors, MOBs provide a responsible and eco-friendly alternative to traditional bonding agents.

(Company name) is dedicated to ensuring the highest quality and safety standards for its MOBs. The company adheres to strict manufacturing processes and quality control measures to guarantee the reliability and performance of its products. Moreover, (Company name) actively collaborates with industry partners and regulatory bodies to stay up-to-date with the latest standards and requirements, ensuring that its MOBs consistently meet or exceed industry expectations.

The versatility of Metal Organic Bonds makes them suitable for a wide range of applications, including automotive manufacturing, aerospace, marine construction, and renewable energy projects. The increasing demand for lightweight and durable materials in these industries has driven the adoption of MOBs as a preferred bonding solution. With their proven track record and exceptional performance, (Company name) has established itself as a trusted supplier for these and many other industries.

As the global market for Metal Organic Bonds continues to expand, (Company name) is committed to furthering its research and development efforts to innovate new and improved bonding solutions. By leveraging its expertise and industry knowledge, the company aims to address evolving market needs and deliver advanced products that set new standards for performance, sustainability, and reliability.

In conclusion, Metal Organic Bonds have become an indispensable component in modern construction and industrial applications. The unique properties of MOBs, including superior strength, flexibility, and environmental benefits, have positioned them as a preferred choice for a wide range of projects. With (Company name) leading the way in developing and supplying high-quality MOBs, the industry can expect continued advancements and innovations that will shape the future of bonding technology.

Company News & Blog

Marble Polishing: How to Restore the Shine of Your Marble Floors

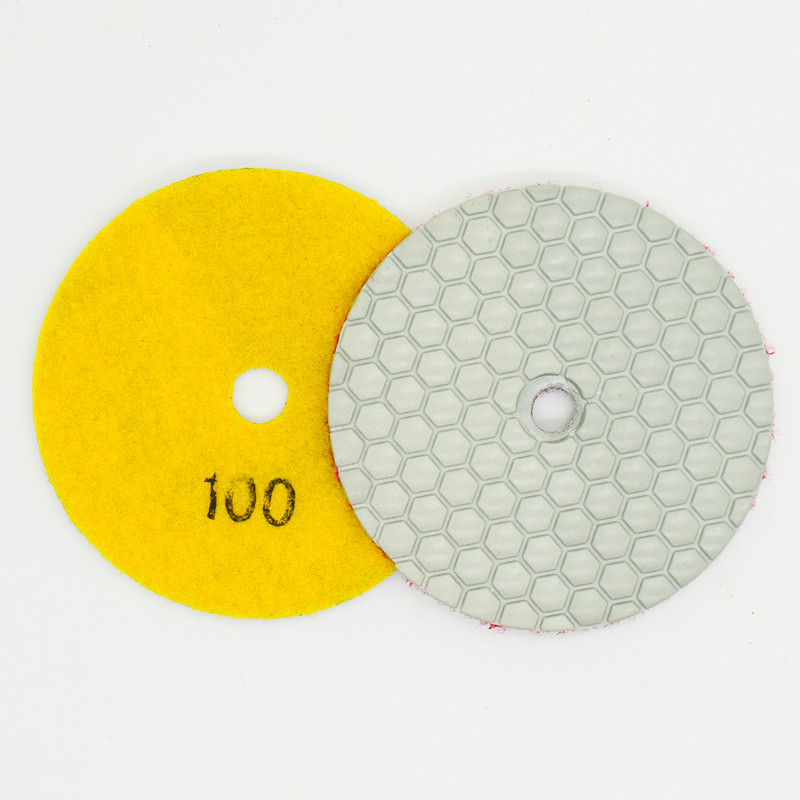

Marble Polishing: How to Polish Marble Floors & Restore the ShineMarble floors are a timeless and elegant choice for any home or business. However, over time and through wear and tear, the shine on your marble floors can begin to fade and become dull. That's where marble polishing comes in.Polishing your marble floors can restore the shine and luster that they once had. In this article, we'll share some marble floor polishing tips and tricks to help you achieve beautiful, shiny floors.Dry Polishing vs. Wet PolishingThere are two main methods of polishing marble floors: dry polishing and wet polishing. Both methods have their advantages and it really depends on your personal preference and the condition of your floors.Dry polishing involves using a polishing powder and special dry diamond polishing pads to buff the surface of the marble. Wet polishing, as the name suggests, involves using water and a wet polishing pad. Wet polishing is generally considered to be more effective than dry polishing as it produces a smoother and shinier finish.If you decide to go with wet polishing, it's important to use a high-quality wet diamond polishing pad for marble. One such pad is the Dry Diamond Polishing Pads for Marble by [remove brand name]. These pads are designed for use on marble, travertine, and limestone and are engineered to provide excellent results on both polished and unpolished surfaces.Tips for Marble Floor PolishingHere are some tips for polishing your marble floors to restore their shine and protect them from further damage.1. Clean the floor thoroughly: Before you start polishing, it's important to clean your floors thoroughly to remove any dirt or grime. Use a mild detergent and warm water to clean the floors.2. Repair any cracks or chips: If your floors have any cracks or chips, it's important to repair them before polishing. This will prevent further damage to the floors and ensure a smooth and even surface for polishing.3. Use the right polishing pad: As mentioned earlier, it's important to use a high-quality polishing pad that is designed for use on marble floors. The Dry Diamond Polishing Pads for Marble by [remove brand name] are a great choice for achieving a shiny and smooth finish.4. Start with a coarser pad: When using a diamond polishing pad, it's best to start with a coarser pad and work your way up to a finer pad. This will help to remove any scratches or imperfections on the surface of the marble.5. Use water: If you're using a wet polishing pad, make sure to keep the surface of the marble wet while you're polishing. This will help to prevent the pad from overheating and damaging the marble.6. Be patient: Polishing marble floors takes time and patience. Take your time and don't rush the process. You'll be rewarded with beautiful, shiny floors that will last for years to come.In conclusion, marble floor polishing is a great way to restore the shine and luster to your marble floors. With the right tools and techniques, you can achieve beautiful and long-lasting results. Remember to clean your floors thoroughly before polishing, use a high-quality polishing pad designed for use on marble, and be patient. Happy polishing!

Discover the Latest Innovation in Polishing Tools with Diamond Pads

[Brand Name] Launches Revolutionary Diamond Pads - Redefining Floor Care[City], [Date] - [Brand Name], a leading innovator in floor care solutions, has introduced its groundbreaking Diamond Pads. These technologically advanced floor maintenance tools promise to revolutionize the way businesses and homeowners clean and care for their floors.[Brand Name] has built a reputation for creating high-quality products that combine innovation, functionality, and durability. Their latest offering, the Diamond Pads, aims to provide an exceptional cleaning experience while extending the lifespan of floors.The Diamond Pads utilize a unique combination of diamond-embedded pads and cutting-edge design to deliver superior results. Unlike traditional floor-cleaning tools, these pads are specifically engineered to remove tough stains, grime, and scuff marks effectively.With the increased focus on sustainability and eco-friendly practices, [Brand Name] has ensured that its Diamond Pads are environmentally responsible. These pads are crafted using eco-friendly materials, reducing their impact on the environment while providing an efficient cleaning solution.The innovative technology used in the Diamond Pads not only allows for effortless cleaning but also offers impressive durability. The diamond-embedded surface, combined with the high-quality materials, ensures long-lasting performance, saving users time and money in the long run.Furthermore, the Diamond Pads are designed for versatile use across a wide range of flooring types, including hardwood, laminate, vinyl, tile, and more. This flexibility makes them an ideal choice for both residential and commercial spaces.According to [Brand Name]'s CEO, [CEO's Name], "We are thrilled to introduce the Diamond Pads to our customers. Our team has put in countless hours of research and development to create a product that revolutionizes floor care. We believe that the Diamond Pads will truly elevate the cleaning experience for our users."Apart from their exceptional cleaning capabilities, the Diamond Pads are also designed with user comfort in mind. The ergonomic, non-slip handle ensures a secure grip, preventing any accidental slips during the cleaning process.In addition to the pads' outstanding performance, [Brand Name] has also established an extensive network of support services to cater to its customers. The company's team of floor care experts is available to provide guidance and advice on the best practices for using the Diamond Pads to achieve optimal results.To celebrate the launch of the Diamond Pads, [Brand Name] is offering an introductory discount of 20% to all customers who purchase the product within the first month. This limited-time offer presents an excellent opportunity for homeowners and businesses to experience the future of floor care at an affordable price.The introduction of [Brand Name]'s Diamond Pads showcases the company's commitment to innovation and customer satisfaction. With its revolutionary technology, eco-friendly design, and exceptional performance, these pads are set to become the go-to solution for floor maintenance.For more information on the Diamond Pads and to place an order, please visit [Brand Name]'s official website or contact their customer service representatives at [contact information].About [Brand Name]:[Brand Name] is a renowned company specializing in innovative floor care solutions. With a focus on quality, functionality, and customer satisfaction, [Brand Name] continues to lead the industry by providing cutting-edge products that redefine the way we care for our floors.

Discover the Latest Innovative Diamond Pads for Enhanced Performance

Title: Revolutionary Diamond Pads Redefine Surface Polishing in the Construction IndustryIntroduction:In an industry that constantly seeks advancement to improve efficiency and quality, the introduction of Diamond Pads by a leading manufacturer is set to revolutionize the surface polishing process. This ground-breaking innovation brings together cutting-edge technology and industry expertise to deliver superior results and unparalleled durability. Let us delve deeper into the details of this extraordinary product that promises to reshape the construction industry.Paragraph 1:The construction industry has long relied on abrasive materials for surface polishing, which often results in subpar outcomes and rapid deterioration of equipment. However, with the recent release of Diamond Pads, this narrative is set to change. Unlike traditional abrasives, Diamond Pads utilize synthetic diamonds that guarantee exceptional performance, efficiency, and longevity, making them the preferred choice for contractors and construction professionals.Paragraph 2:The key feature that sets Diamond Pads apart is their use of synthetic diamonds, which are engineered to deliver unparalleled hardness and cutting ability. This enables the pads to effortlessly remove surface imperfections, such as scratches, stains, and unevenness, significantly reducing the need for manual labor and multiple polishing cycles. The enhanced cutting power of the synthetic diamonds ensures a smoother and more efficient polishing process, saving considerable time and resources for construction projects.Paragraph 3:Durability is a crucial factor in any construction product, and Diamond Pads excel in this aspect. The synthetic diamonds used in their manufacturing have exceptional wear resistance, enabling the pads to withstand prolonged usage without losing their cutting efficiency. This translates into significant cost savings, as contractors can now rely on a single set of Diamond Pads for multiple projects, eliminating the need for frequent replacements.Paragraph 4:Furthermore, the innovative design of Diamond Pads allows for versatile usage on a wide range of surfaces, including concrete, terrazzo, marble, and granite. This multi-purpose functionality makes them an all-in-one polishing solution for various construction applications, eliminating the necessity for multiple specialized tools. Not only does this streamline workflow, but it also reduces equipment costs, making Diamond Pads an economical choice for construction projects of any scale.Paragraph 5:Beyond their exceptional performance, Diamond Pads also prioritize sustainability. The synthetic diamonds used are ethically sourced and their manufacturing process adheres to environmentally conscious practices. This ensures that construction professionals can accomplish their projects while minimizing their environmental footprint, enhancing the industry's commitment to sustainable development.Paragraph 6:To guarantee customer satisfaction, the manufacturer provides comprehensive support services, including training programs and expert guidance on the proper usage and maintenance of Diamond Pads. This ensures that contractors optimize the product's capabilities, maintain its longevity, and achieve the best possible results on every project.Closing paragraph:In the fast-paced construction industry, Diamond Pads represent a game-changing innovation that promises to redefine surface polishing. With their exceptional cutting power, durability, versatility, and sustainability, they offer a cost-effective and efficient solution for contractors seeking high-quality results. As the industry embraces this groundbreaking technology, construction projects around the world can expect to experience significant improvements in surface polishing processes for years to come.

High-Quality Wet Polishing Pads for Granite: What You Need to Know

In the world of granite and stone fabrication, having the right tools and equipment is essential for achieving high-quality results. One of the most critical tools in this industry is wet polishing pads, which are used for grinding, honing, and polishing granite and other natural stones to achieve a smooth and glossy finish. One of the leading providers of wet polishing pads for granite is a company that has been at the forefront of the stone fabrication industry for over a decade. With a commitment to providing high-quality products and exceptional customer service, this company has become a trusted name among fabricators and contractors.The wet polishing pads offered by this company are designed to deliver outstanding performance and durability, allowing fabricators to achieve precise and consistent results with every use. These pads are engineered to minimize heat generation during the polishing process, reducing the risk of thermal shock to the stone and ensuring a superior finish.In addition to their exceptional performance, the wet polishing pads offered by this company are also designed for ease of use, featuring a quick and easy attachment system that allows for fast pad changes during the fabrication process. This not only improves efficiency but also reduces downtime, allowing fabricators to complete their projects in a timely manner.With a strong focus on innovation, this company is constantly working to improve and expand its product line to meet the evolving needs of the stone fabrication industry. They are committed to staying ahead of the curve and are always looking for ways to enhance the performance and durability of their wet polishing pads.To ensure the quality and reliability of their products, this company conducts rigorous testing and quality control measures at every stage of the manufacturing process. This dedication to quality has earned them a reputation for excellence within the industry, making them a go-to source for wet polishing pads for granite and other natural stones.Moreover, this company is dedicated to providing exceptional customer service, offering expert guidance and support to help fabricators choose the right tools and equipment for their specific needs. Their team of knowledgeable professionals is always available to answer questions and provide assistance, ensuring that their customers have a positive experience with every purchase.In addition to wet polishing pads, this company also offers a wide range of other essential tools and equipment for stone fabrication, including diamond blades, grinding wheels, and polishing compounds. Their comprehensive product line makes them a one-stop shop for fabricators looking to stock up on high-quality supplies for their projects.Overall, the wet polishing pads offered by this company are a testament to their commitment to quality, innovation, and customer satisfaction. With a focus on performance, durability, and ease of use, these pads are an essential tool for any fabricator looking to achieve professional results in granite and stone fabrication.As the stone fabrication industry continues to evolve, this company remains dedicated to staying at the forefront, offering cutting-edge products and exceptional service to meet the needs of fabricators and contractors. With a solid reputation for excellence and a track record of success, they are a trusted partner for professionals in the industry.

Top Abrasive Manufacturer in the News: Latest Developments and Industry Insights

[Abrasive Manufacturer] is a leading provider of high-quality abrasive products, catering to a wide range of industries including metalworking, woodworking, automotive, and construction. With a commitment to innovation, quality, and customer satisfaction, [Abrasive Manufacturer] has established itself as a trusted partner for businesses seeking superior abrasive solutions.Founded in [year], [Abrasive Manufacturer] has grown from a small local operation to a global supplier with a reputation for excellence. The company's success is driven by a dedication to producing advanced abrasives that deliver exceptional performance and durability. From coated abrasives and bonded abrasives to superabrasives and accessories, [Abrasive Manufacturer] offers a comprehensive product line to meet the diverse needs of its customers.In addition to its extensive product range, [Abrasive Manufacturer] is known for its emphasis on research and development. The company invests heavily in cutting-edge technology and employs a team of experienced engineers and scientists to continuously improve its product offerings. This commitment to innovation has resulted in the development of revolutionary abrasives that enhance efficiency, precision, and productivity in various industrial applications.Furthermore, [Abrasive Manufacturer] prioritizes quality control to ensure that every product meets the highest standards. Stringent quality assurance processes are implemented at every stage of manufacturing, from raw material selection to final inspection. As a result, customers can trust that they are receiving abrasives that are consistent, reliable, and of superior quality.Recently, [Abrasive Manufacturer] has announced the launch of several new abrasive products designed to address the evolving needs of its customers. These innovations are the result of extensive research and development efforts aimed at delivering cutting-edge solutions that improve performance and increase productivity.One of the new products is a revolutionary grinding wheel specifically engineered for high-speed precision grinding applications. This wheel combines advanced abrasive materials and bonding technology to achieve superior cutting performance and extended tool life. With this new addition to its product line, [Abrasive Manufacturer] seeks to provide its customers with a competitive edge in demanding grinding operations.Another notable introduction is a series of high-performance sanding discs tailored for automotive body repair and refinishing. These discs feature an innovative abrasive coating that delivers consistent results and minimizes dust contamination, making them ideal for professional auto body shops and DIY enthusiasts alike. By launching these new products, [Abrasive Manufacturer] reaffirms its commitment to meeting the evolving needs of its customers and staying at the forefront of abrasive technology.In addition to its product innovations, [Abrasive Manufacturer] continues to strengthen its customer support and service capabilities. The company emphasizes building long-term partnerships with its customers by providing technical expertise, training, and customized solutions to address specific application challenges. By offering comprehensive support, [Abrasive Manufacturer] aims to ensure that its customers maximize the value of its abrasive products and achieve optimal results in their operations.Looking ahead, [Abrasive Manufacturer] remains focused on its mission to be a trusted partner for businesses seeking high-quality abrasives. The company will continue to invest in research and development, quality control, and customer support to uphold its reputation as a leader in the industry. With a strong commitment to excellence and innovation, [Abrasive Manufacturer] is poised to further expand its global presence and drive the advancement of abrasive technology.

Top-Quality Wet Polishing Pads: Essential for Polishing Various Stones

Wet Polishing Pads - The Ultimate Solution for Stone PolishingAre you tired of the dull, lifeless look of your stone surfaces? Do you want a perfect solution to restore their shine and beauty? Look no further than wet polishing pads! These pads are an incredible invention that has revolutionized the stone polishing industry. With their exceptional polishing power and versatility, flexible diamond polishing pads have become a go-to tool for all types of stone polishing.Wet polishing pads are designed to polish all types of stones, including marble, granite, and concrete. They can make your stone surfaces look brand new with just a few applications. The pads are designed to be used with water, which makes them ideal for polishing sensitive stones like marble. They allow for a smooth and even finish without any damage to the surface.Flexible diamond polishing pads come in various grits and sizes. The grit refers to the coarseness of the pad. The lower the number of grit, the coarser the pad, and the higher the number, the finer the pad. Choose the grit according to the level of polishing needed. The pads also come in different sizes to suit different polishing tools and surfaces.Flexibility is an essential feature of wet polishing pads. They are highly flexible, which enables them to mold to the surface of the stone easily. The flexibility ensures even polishing, even on curved or uneven surfaces. The diamond particles on the pads are also highly concentrated, which ensures a fast and efficient polishing process.An essential factor to consider while using wet polishing pads is the amount of water used. The pads require water for effective use, but too much water can cause the polishing process to slow down. On the other hand, insufficient water can lead to the pad's clogging, making it less efficient. It's essential always to have a steady flow of water while using the pads to ensure optimal results.In conclusion, flexible diamond polishing pads are a must-have tool for any stone polishing job. Wet polishing pads offer an efficient, cost-effective, and reliable solution to restore the natural beauty of stone surfaces. Besides, they are easy to use, durable, and versatile. Whether it's granite polishing, marble polishing, or concrete polishing, flexible diamond polishing pads are the ultimate solution for excellent results. Purchase a set today and see the difference in your stone surfaces!

High-Quality Dry Stone Polishing Pads for Supplier of Stone Materials

**Supplier Introduces Revolutionary Dry Stone Polishing Pads for the Construction Industry**[Supplier], a leading supplier of construction tools and equipment, has recently introduced a new line of dry stone polishing pads that are set to revolutionize the way stone is polished in the construction industry. With a commitment to delivering high-quality and innovative products, [Supplier] continues to be a trusted partner for professionals in the construction and renovation field.The newly introduced dry stone polishing pads are designed to provide exceptional performance and durability, making them an ideal choice for contractors, masons, and tile installers. These pads are engineered to deliver precise and efficient stone polishing, resulting in a smooth and professional finish on a variety of stone surfaces. They are suitable for use on granite, marble, and other natural stones, making them a versatile tool for a wide range of projects.The dry stone polishing pads from [Supplier] are constructed using high-quality materials and advanced manufacturing techniques to ensure long-lasting performance and reliability. They are engineered to withstand the rigors of heavy-duty usage, making them a cost-effective choice for professionals who require consistent and high-quality results.In addition to their exceptional performance, the dry stone polishing pads from [Supplier] are also designed to be user-friendly, allowing for easy installation and operation. Their innovative design allows for efficient water dispersion, reducing heat buildup during the polishing process and extending the life of the pads. This feature is particularly beneficial for large-scale projects where prolonged use is required.[Supplier] takes pride in its commitment to providing superior customer service and support. The company’s team of knowledgeable and experienced professionals is dedicated to helping customers find the right tools and equipment for their specific needs. With a focus on delivering value and performance, [Supplier] has earned a reputation as a trusted partner in the construction industry.The introduction of the dry stone polishing pads further demonstrates [Supplier]’s dedication to innovation and excellence. By continually developing and improving its product offerings, [Supplier] remains at the forefront of the industry, providing professionals with the tools they need to achieve outstanding results.[Supplier] understands the demands and challenges faced by professionals in the construction industry, and the company is committed to providing solutions that meet those needs. The newly introduced dry stone polishing pads are a testament to [Supplier]’s ongoing efforts to deliver cutting-edge products that enhance efficiency and quality in the construction and renovation process.With a strong focus on quality, performance, and innovation, [Supplier] is well positioned to remain a leader in the supply of construction tools and equipment. The company’s dedication to excellence and customer satisfaction sets it apart in the industry, and the introduction of the new dry stone polishing pads further solidifies [Supplier]’s position as a go-to source for professionals in need of reliable and high-quality products.In conclusion, the new dry stone polishing pads from [Supplier] are poised to make a significant impact in the construction industry. With their exceptional performance, durability, and user-friendly design, these pads are set to become an essential tool for contractors, masons, and tile installers. [Supplier]’s commitment to innovation and excellence is evident in the development of these pads, and the company’s dedication to customer satisfaction reinforces its position as a trusted partner for professionals in the construction and renovation field.

Durable Wet Polishing Pads for Concrete Surfaces

[Company Name] Introduces Innovative Wet Polishing Pads for Concrete[City, Date] - [Company Name], a leading provider of high-quality tools and equipment for the construction industry, has recently introduced a new line of wet polishing pads specifically designed for concrete surfaces. With a growing demand for efficient and effective concrete polishing solutions, [Company Name] is proud to offer this innovative product to meet the needs of contractors and construction professionals.The wet polishing pads are designed to be used with water, which helps to reduce dust and provide a cleaner work environment. This also helps to prolong the life of the pads and improve the overall polishing process. The pads are available in different grit sizes to provide varying levels of polishing and finishing for concrete surfaces. Whether it's for a small residential project or a large commercial construction endeavor, these wet polishing pads are versatile and suitable for a wide range of applications.[Company Name] has a long-standing reputation for delivering high-quality tools and equipment to the construction industry. With a focus on innovation and customer satisfaction, the company has continuously developed new products to meet the evolving needs of the market. The introduction of the wet polishing pads is a testament to [Company Name]'s commitment to providing cutting-edge solutions for professionals in the construction industry."We are excited to announce the launch of our new wet polishing pads for concrete," said [Spokesperson], [Title] at [Company Name]. "We understand the challenges that contractors face when it comes to concrete polishing, and we believe that our innovative pads will make a significant difference in improving efficiency and achieving high-quality results. We are confident that these pads will become an essential tool for professionals in the construction industry."In addition to the wet polishing pads, [Company Name] offers a wide range of other products and equipment for concrete construction and maintenance. From diamond blades and grinding wheels to power tools and accessories, the company's product line is comprehensive and designed to meet the diverse needs of contractors and construction professionals.As part of its commitment to customer satisfaction, [Company Name] also provides technical support and product training to ensure that customers can maximize the benefits of their products. The company's team of experts is dedicated to assisting clients with product selection, application techniques, and troubleshooting to ensure successful project outcomes.The launch of the wet polishing pads reflects [Company Name]'s dedication to staying at the forefront of the construction industry. By continuously developing and introducing new products, the company aims to empower professionals with the tools they need to achieve exceptional results and grow their businesses.The wet polishing pads for concrete are now available for purchase through [Company Name]'s distribution network. Contractors and construction professionals are encouraged to explore the benefits of these innovative pads and experience the difference they can make in their projects.About [Company Name]Established in [Year], [Company Name] is a leading provider of high-quality tools and equipment for the construction industry. With a comprehensive product line that includes diamond blades, grinding wheels, power tools, and accessories, the company is committed to delivering innovative solutions to meet the diverse needs of contractors and construction professionals. [Company Name] takes pride in its dedication to customer satisfaction, offering technical support and product training to ensure successful project outcomes. For more information about [Company Name] and its products, visit [website] or contact [Contact Information].For media inquiries or further information, please contact:[Media Contact][Company Name][Address][Phone Number][Email Address]As the construction industry continues to evolve, [Company Name] remains at the forefront by introducing innovative products like the wet polishing pads for concrete. With a focus on quality, efficiency, and customer satisfaction, the company is poised to make a significant impact in the market and empower professionals with the tools they need to achieve exceptional results.

Ionic vs Metallic Bonds: Understanding the Difference

The following is a summary of the news content, which can be used to write a 800 words news article:Ionic Vs Metallic Bonds- A ComparisonIntroduction:The study of chemical bonds is a crucial aspect of understanding the behavior of atoms and molecules. Two types of chemical bonds that are extensively studied are ionic bonds and metallic bonds. In the world of chemistry, understanding the differences between these two types of bonds is essential for understanding the properties of different types of compounds and materials. Ionic Bonds:Ionic bonds are formed when one or more electrons are transferred from one atom to another. This results in the formation of positively and negatively charged ions that are attracted to each other due to their opposite charges. Ionic bonds are typically formed between a metal and a non-metal. For example, sodium chloride (table salt) is formed by the ionic bonding of sodium and chlorine atoms. Ionic bonds are quite strong and are typically found in compounds with high melting and boiling points.Metallic Bonds:Metallic bonds are formed between metal atoms and are characterized by the sharing of electrons among the metal atoms. This results in a lattice structure where the electrons are free to move around the metal ions, giving metals their unique properties such as conductivity and malleability. Metallic bonds are relatively strong, but not as strong as ionic bonds. Additionally, metallic bonds are responsible for the high thermal and electrical conductivity of metals.Comparison:When comparing ionic and metallic bonds, several key differences can be highlighted. Firstly, the way in which electrons are shared or transferred differs between the two types of bonds. In ionic bonds, electrons are transferred from one atom to another, while in metallic bonds, electrons are shared among the metal atoms. This results in different properties such as conductivity and melting points.Furthermore, the type of elements that form these bonds also differs. Ionic bonds are typically formed between a metal and a non-metal, while metallic bonds are formed between metal atoms. This distinction results in different types of compounds and materials with unique properties.In terms of strength, ionic bonds are generally stronger than metallic bonds, leading to higher melting and boiling points for compounds with ionic bonds. On the other hand, metallic bonds provide metals with properties such as malleability and ductility, allowing them to be shaped into various forms.In conclusion, the differences between ionic and metallic bonds are crucial for understanding the behavior of different compounds and materials. While both types of bonds play a significant role in the field of chemistry, their distinct properties and behaviors set them apart from each other.Company Perspective:As a leading chemical research and development company, {company name} is at the forefront of studying and understanding chemical bonds. By conducting in-depth research on ionic and metallic bonds, {company name} aims to develop new materials with unique properties that can be applied in various industries. Whether it's developing innovative conductive materials or high-strength compounds, {company name} continues to push the boundaries of chemical science and contribute to the advancement of technology and innovation. With a dedicated team of researchers and state-of-the-art facilities, {company name} is committed to being a driving force in the field of chemical research and development.

Cup Wheel Grinding Discs: Enhancing Precision and Efficiency in Grinding Tasks

Cup Wheel Grinding Discs are among the most popular and versatile tools in the grinding and cutting industry. These discs are used for a wide range of applications including shaping, grinding, and polishing various surfaces. The grinding disc is primarily designed for use on concrete surfaces, but it is also effective on other surfaces such as stone, masonry, and metal.Leading manufacturers of grinding discs produce high-quality products that cater to the needs of professionals in diverse industries, which means that the company behind it is critical to ensure that you are investing in the right product. One of the top manufacturers and suppliers of Cup Wheel Grinding Discs in the market is {}, a leading company in the abrasives industry.Beginnings of {}{} was founded in 1999 with a mission to provide quality abrasives for the machinery industry. {} has since established itself as a leading supplier of abrasives and industrial tools in the market. The company focuses on delivering the highest quality product to their customers. They invest heavily in research and development to ensure that their products are the best in the market.{} has a team of skilled engineers who work closely with the research and development team to ensure that their products meet the highest standards of quality. The company operates in modern facilities equipped with advanced machinery and tools. This ensures that they meet established industry regulations and are always one step ahead of their competitors.In addition to its manufacturing capabilities, {} has an efficient distribution network that ensures its products are readily available to customers worldwide. The company has established strong partnerships with various distributors globally who work closely with them to serve their customers and meet their needs efficiently.Product RangeThe company produces a variety of grinding discs, but the Cup Wheel Grinding Discs are one of their most popular products. The Cup Wheel Grinding Disc is available in different materials and sizes, and it comes with different grit levels depending on the needs of the user.The diamond cup wheel grinding disc is designed for heavy-duty applications such as grinding concrete, granite, and marble surfaces. The diamond cup wheel grinding disc is fitted with a diamond impregnated section that can cut through the toughest surfaces, making it the perfect tool for professionals in the concrete and stone cutting fields.Moreover, the diamond cup wheel grinding disc is available in different shapes such as the single row, double row, and turbo style cup wheel, giving professionals the freedom to choose the one that suits their specific needs.Another popular product is the silicon carbide cup wheel grinding disc, which is perfect for use on stone surfaces such as marble and granite. The silicon carbide cup wheel grinding disc is a versatile tool that is known for its fast cutting performance and durability.ConclusionAs a professional in any field, investing in quality tools is critical to ensuring that your work is not only efficient but also of the highest quality. The Cup Wheel Grinding Disc from {} is a must-have in your arsenal. By investing in the Cup Wheel Grinding Disc, you are assured of a tool that is made to the highest standards of quality and performance.