Understanding the Difference Between Nonmetal and Metal Bonds

By:Admin

As technology continues to advance, the aerospace industry is constantly seeking innovative materials and methods to improve the performance of their products. One such advancement is the development of nonmetal and metal bonds, which has the potential to revolutionize the way aircraft components are manufactured and utilized.

The use of nonmetal and metal bonds has been gaining traction in the aerospace industry due to their unique combination of properties, including high strength, light weight, and durability. These bonds are created through a process that involves the bonding of nonmetal materials, such as carbon fiber or ceramics, with metal alloys, resulting in a material that offers the best of both worlds.

One company that has been at the forefront of this technology is {}. With a strong focus on research and development, {} has been able to create a range of nonmetal and metal bonded materials that are tailored to the specific needs of the aerospace industry. These materials have been met with enthusiasm from industry professionals and are expected to play a significant role in the future of aircraft manufacturing.

The use of nonmetal and metal bonds has the potential to significantly reduce the weight of aircraft components, resulting in improved fuel efficiency and reduced carbon emissions. In addition, these materials offer greater strength and durability compared to traditional materials, which can contribute to increased safety and longevity of aircraft.

Furthermore, nonmetal and metal bonded materials are also more resistant to corrosion and fatigue, reducing the need for frequent maintenance and repair. This can lead to cost savings for airlines and contribute to improved operational efficiency.

{} has been working closely with aerospace manufacturers to integrate their nonmetal and metal bonded materials into various components of aircraft, including wings, fuselage, and engine parts. The company’s expertise in material science and engineering has allowed them to create tailored solutions that meet the stringent requirements of the aerospace industry.

The development of nonmetal and metal bonded materials also aligns with the industry’s efforts to adopt more sustainable and environmentally friendly practices. By utilizing lightweight materials that improve fuel efficiency, aerospace companies can reduce their overall carbon footprint and contribute to a greener future for air travel.

In addition to the benefits for aircraft manufacturing, nonmetal and metal bonded materials also have the potential to be utilized in other industries, such as automotive, construction, and renewable energy. This versatility makes them a valuable asset for companies like {} as they continue to explore new opportunities for their innovative materials.

As the aerospace industry continues to evolve, the adoption of nonmetal and metal bonded materials is poised to become a transformative trend. With their numerous benefits and potential applications, these materials are set to play a crucial role in the development of next-generation aircraft and pave the way for a more sustainable and efficient future for air travel.

With their expertise and dedication to innovation, {} is well-positioned to lead the charge in bringing nonmetal and metal bonded materials to the forefront of the aerospace industry. Their commitment to pushing the boundaries of material science and engineering will undoubtedly have a lasting impact on the industry and the way aircraft are designed and manufactured.

Company News & Blog

Discover the Benefits of Cutting Wheels and Grinding Wheels for Industrial Applications

article about the benefits of using cutting and grinding wheels in various industrial applications.Cutting Wheel And Grinding Wheel - Innovative Tools for Industrial ApplicationsCutting and grinding wheels have become popular tools in various industrial applications. These tools are often used in the metalworking industry, fabricated metals, construction, and other industries where cutting and grinding are required. Cutting and grinding wheels are made from abrasive materials that can cut through or grind away different types of materials such as metals, ceramics, glass, and more. Among the various brands available in the market, (BRAND NAME) brand cutting and grinding wheels are considered to be one of the most durable and effective tools. Let's discuss the benefits of using cutting and grinding wheels in different industrial applications.Metalworking Industry - Cutting and grinding wheels are often used in metalworking to shape and mold metals into specific shapes and sizes. These tools are beneficial for metal cutting and grinding operations, as they require less effort and human intervention. A good-quality cutting wheel can cut through various types of metals such as steel, aluminum, and iron. Similarly, grinding wheels are used for creating precise edges on metal surfaces and to remove rust and other impurities from metal surfaces. (BRAND NAME) brand cutting and grinding wheels are ideal for metalworking, as they are made of high-quality abrasive materials that can withstand high pressure and extreme temperatures.Fabricated Metals - Fabricated metals are often used in industry applications such as automobile manufacturing, aerospace, and construction. Cutting and grinding wheels are required to cut through such metals into desired shapes and sizes. (BRAND NAME) brand cutting and grinding wheels are an ideal choice for cutting and grinding various fabricated metals, as they are designed to withstand high pressure and heat.Construction Industry - Cutting and grinding wheels are widely used in the construction industry for cutting and grinding concrete, asphalt, and other materials. Diamond cutting wheels are often used in construction applications as they are strong and durable and can easily cut through hard materials. (BRAND NAME) brand diamond cutting wheels are made from high-quality diamond abrasive material and are ideal for cutting concrete and other hard materials.Automobile Industry - Cutting and grinding wheels are also used in the automobile industry. These tools are used in various operations such as cutting, grinding, and polishing automobile parts. (BRAND NAME) brand cutting and grinding wheels are ideal for the automobile industry, as they are designed to cut through materials used in automobile manufacturing such as aluminum, steel, and plastics.In conclusion, cutting and grinding wheels are essential tools in various industrial applications. These tools are designed to cut and grind through various materials efficiently and effectively. (BRAND NAME) brand cutting and grinding wheels are one of the most innovative tools available in the market, designed to withstand high pressure and extreme temperatures. Therefore, when choosing a cutting or grinding wheel, it is crucial to choose a brand that can provide you with durable and long-lasting tools.

High-Quality and Reliable Universal Diamond Cutting Disc 125x22.23mm - Professional Power Tools

article on the importance and benefits of using high-quality diamond cutting discs in various industries.As technology advances and new materials are developed, the need for precise and efficient cutting tools becomes increasingly important. In many industries, the use of cutting discs is crucial for producing high-quality products and completing tasks with precision and accuracy. With so many different types of cutting discs available on the market, it can be overwhelming to choose the right one for your specific needs.One type of cutting disc that has gained popularity in recent years is the diamond cutting disc. Diamond cutting discs are quickly becoming the standard for professionals in a wide variety of industries due to their exceptional strength, durability, and precision. These discs are made with industrial diamonds that are bonded to a metal or resin matrix, which provides a superior cutting edge that can handle tough materials like concrete, metal, glass, and ceramic tiles.One of the key features of diamond cutting discs is their versatility. Thanks to their durable composition, diamond cutting discs can cut through a wide range of materials, making them a go-to tool for professionals in a variety of industries. This versatility means that contractors and tradespeople can have a single cutting disc to handle various cutting needs, which can save them both time and money.Another benefit of diamond cutting discs is their long lifespan. With regular use and proper maintenance, diamond cutting discs can last significantly longer than traditional cutting discs. This is because the industrial diamonds used to make diamond cutting discs are incredibly hard and resilient, making them more resistant to wear and tear. Additionally, the bond that holds the diamonds in place is designed to withstand high temperatures and stress, further extending the lifespan of the disc.Aside from their durability, diamond cutting discs also offer exceptional cutting speed and precision. Because the industrial diamonds are much harder and sharper than traditional cutting materials like aluminum oxide or silicon carbide, they can cut through materials much faster, with less force required. This faster cutting speed not only increases efficiency on the job but also leads to a smoother finish with fewer burrs or jagged edges.When it comes to choosing a diamond cutting disc, it's crucial to consider factors like blade size, material composition, and intended use. For example, the Metabo diamond cutting disk 125x22.23mm, "UP", Universal "professional" (628559000) is designed to be a high-quality, reliable, and durable option for professionals in various industries. Its 125mm diameter makes it suitable for cutting a wide range of materials, while its universal "professional" design means that it can handle the toughest applications with ease. As a product known for its exceptional quality and performance in the industry, using it can ensure optimal results every time.In conclusion, there are significant benefits to using high-quality diamond cutting discs in various industries, including their versatility, long lifespan, and exceptional speed and precision. Although the initial cost of diamond cutting discs may be higher than traditional cutting discs, the superior performance and longevity make them a worthwhile investment in the long run. By choosing the right diamond cutting disc for your specific needs, you can ensure optimal results and save both time and money in the process.

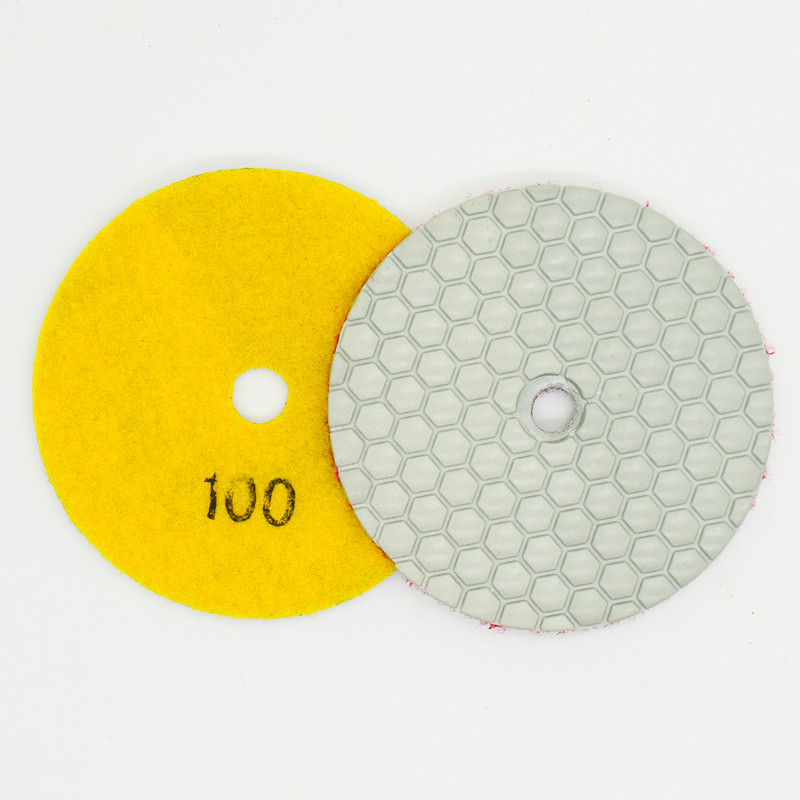

Essential Tools for Achieving a Perfect Granite Finish

Granite Finishing Tools Revolutionize Stone Industry[City, Date] – Granite Finishing Tools, a leading provider of high-quality stone finishing equipment, is transforming the stone industry with its innovative range of products. With a focus on efficiency, precision, and durability, Granite Finishing Tools has emerged as the go-to solution for professionals working with granite and other natural stones.Within a highly competitive market, Granite Finishing Tools has quickly gained recognition for its commitment to delivering top-notch tools that cater to the demanding needs of stone fabricators and craftsmen. The company's dedication to continuous research and development has allowed it to stay at the forefront of technological advancements in the industry.With an extensive product line covering every aspect of stone finishing, Granite Finishing Tools offers a comprehensive solution for all stone fabrication processes. From cutting, grinding, polishing, to edge profiling, the company provides an array of tools designed to enhance productivity while achieving exceptional quality results.One of the standout products in their range is the state-of-the-art diamond cutting blade. Known for its exceptional cutting speed and longevity, this blade transforms the cutting process, saving craftsmen time and effort. Furthermore, its superior performance ensures clean cuts with minimal chipping, resulting in a more efficient fabrication process.Granite Finishing Tools has also revolutionized the polishing stage with its highly specialized line of diamond polishing pads. These pads are engineered to deliver an unmatched level of shine while minimizing heat generation. The company's innovative pad design allows for reduced polishing time, resulting in increased productivity and cost savings for fabricators.Additionally, Granite Finishing Tools places a strong emphasis on safety in its product development. The company's range includes effective dust control systems that efficiently capture and remove harmful dust particles generated during stone processing. These systems not only protect the health of workers but also ensure a cleaner work environment, enhancing overall efficiency.Recognizing the diverse needs of its customers, Granite Finishing Tools offers personalized toolkits tailored to specific requirements. This customer-centric approach allows fabricators to optimize their processes, resulting in improved outcomes and increased customer satisfaction.With a commitment to customer support and satisfaction, Granite Finishing Tools provides comprehensive after-sales services, including technical assistance and training. By partnering with experienced professionals in the stone industry, the company ensures that fabricators can fully harness the potential of their tools and achieve outstanding results.Granite Finishing Tools' dedication to quality is reflected in the materials used for manufacturing its products. With a meticulous selection process, the company sources only premium-grade raw materials, ensuring the durability and longevity of its tools. This commitment to quality is in alignment with the company's mission to provide professionals with reliable equipment that guarantees superior performance and longevity.As Granite Finishing Tools expands its reach domestically and internationally, the company envisions a future where stone fabricators can maximize their efficiency and quality outputs with the aid of advanced tools. With a constant drive for innovation and excellence, Granite Finishing Tools remains at the forefront of the stone industry, empowering craftsmen to turn ordinary stone into remarkable works of art.About Granite Finishing Tools:Granite Finishing Tools is a leading provider of high-quality stone finishing equipment, offering a comprehensive range of tools designed to enhance productivity and deliver exceptional quality results. With a focus on innovation and customer satisfaction, Granite Finishing Tools aims to revolutionize the stone industry through cutting-edge technology and personalized solutions. For more information, please visit [company website].

Understanding Metallic Bonding: What You Need to Know

article on the importance of metallic bonding in modern technology.Metallic Bonding and Its Importance in Modern TechnologyMetallic bonding is a fundamental concept in the world of chemistry and materials science. The unique properties of metals like strength, ductility, thermal and electrical conductivity, and luster can be attributed to the special bonding arrangement between the positively charged metal ions and the delocalized electrons.In recent years, metallic bonding has paved the way for several technological advancements that have transformed the way we live, work, and communicate. From advanced alloys used in aerospace and defense to high-precision components in electronics and renewable energy systems, metallic bonding plays a crucial role in shaping modern technology.One company that is leading the charge in metallic bonding technology is {metal bond}, a renowned name in the field of materials science and engineering. The company specializes in the development of high-performance alloys and composite materials that offer unparalleled strength, durability, and resistance to harsh environments.One of {metal bond}'s flagship products is its proprietary metal matrix composite (MMC) technology. MMCs are a unique class of materials that combine the desirable properties of metals and ceramics, making them ideal for a wide range of applications in the aerospace, defense, and automotive industries.MMC technology utilizes the principles of metallic bonding to create a high-strength matrix of metal ions reinforced with ceramic particles. The result is a material that is exceptionally strong and lightweight while retaining excellent thermal and electrical conductivity.MMC materials are used in critical components such as turbines, engine parts, and brake systems in high-performance cars and aircraft. These components require materials that can withstand extreme temperatures, pressures, and mechanical stresses without failure. MMCs provide the necessary strength and durability needed for such challenging applications, making them an indispensable tool in modern engineering.In addition to MMCs, metallic bonding is also utilized in other advanced materials such as shape-memory alloys (SMAs) and superalloys. SMAs are a class of materials that exhibit unique elasticity and shape-changing properties at specific temperatures, making them ideal for use in medical implants, aerospace, and robotics.Superalloys, on the other hand, are a specific class of alloys that exhibit exceptional heat resistance and mechanical strength, making them ideal for use in high-temperature applications such as gas turbines, jet engines, and nuclear reactors.The widespread use of metallic bonding in modern technology has undoubtedly transformed many industries and opened up new avenues for innovation and advancement. However, this is just the tip of the iceberg, as researchers continue to explore new ways to harness the unique properties of metallic bonding to create even more advanced materials and technologies.In conclusion, metallic bonding is an essential concept that has revolutionized the fields of materials science and engineering. The special bonding arrangement between the positively charged metal ions and the delocalized electrons is responsible for the unique properties of metals, making them indispensable in modern technology. With the advent of advanced materials like MMCs, SMAs, and superalloys, the potential applications of metallic bonding are virtually limitless, paving the way for even more exciting advances in the future.

New Polishing Pad Provides Exceptional Results for Auto Detailing

Hard Polishing Pad: The Ultimate Solution for Exceptional Polishing PerformanceHong Kong - Hard Polishing Pad is the latest revolutionary product from one of the leading manufacturers and suppliers of polishing pads. With proven track records in producing high-quality products, the company has continued to strive hard to meet the ever-increasing demands of the market. The company is dedicated to providing customers with a wide range of innovative polishing pads that can offer optimal performance and durability. The new hard polishing pad is no exception. For customers who are looking for perfectly polished surfaces of various materials, Hard Polishing Pad is the ultimate solution that they can trust. The product is designed using the latest and most advanced technology to offer the best performance. The pad is manufactured using a unique process that makes it highly effective in polishing a wide range of surfaces, including granite, quartz, concrete, and marble. Hard Polishing Pad is a must-have for anyone who desires a smooth, polished, and mirror-like finish.The product is made from high-quality materials that are highly durable and long-lasting. The company has invested a considerable amount of time and resources in research and development to ensure that the product is of the highest quality. The result is a product that is not only highly effective but also very reliable. Hard Polishing Pad is designed to last a long time, which makes it ideal for both commercial and residential use.One of the unique features of Hard Polishing Pad is its superior performance. It has a much higher polishing ability compared to other polishing pads in the market. Using Hard Polishing Pad guarantees an exceptional polish, leaving the surface looking brand new. With the pad's superior performance, users can achieve impressive results in a shorter time than using traditional polishing methods.Another benefit of Hard Polishing Pad is its versatility. The product can polish a variety of surfaces, making it a perfect tool for professionals in the stone and concrete industry. Hard Polishing Pad can be used with different types of machines, including grinding machines, polishing machines, and floor machines. The pad is designed to work seamlessly with these machines, providing users with the flexibility they need.Hard Polishing Pad is also very user-friendly and easy to use. The product is made with a user-friendly design that can be used by both professionals and beginners. The pad is straightforward to attach and remove, and its design allows professionals to work on surfaces of different shapes and sizes. The product also comes with a detailed user manual that guides users on how to use it properly.In conclusion, Hard Polishing Pad is an exceptional product that offers the best performance and durability in the market. The product is perfect for anyone who desires a high-quality polish on various surfaces. Hard Polishing Pad is made from high-quality materials that assure users of its long-lasting performance. The pad's versatility gives users the flexibility they need to polish different surfaces, making it ideal for professionals in the stone and concrete industry. The product is also very user-friendly and easy to use, perfect for both beginners and professionals. Get your Hard Polishing Pad today and get to experience perfection in polishing surfaces.

Suppliers of Abrasives and Welding Equipment: Reviews and Product Info

Title: Enhancing Metal Finishing Processes with High-Quality AbrasivesIntroduction (approx. 100 words):When it comes to achieving stellar results in metal finishing processes, using top-notch abrasives is crucial. From sandpapers and grinding wheels to polishing compounds, these abrasive materials play a significant role in refining metal surfaces, removing imperfections, and ensuring a smooth end result. In this blog, we will delve into the world of abrasives, shedding light on the importance of choosing reputable suppliers and the benefits of utilizing high-quality metal abrasives. Join us as we explore the key factors to consider when selecting abrasives and learn how they can elevate your metal finishing processes to new heights.1. Understanding the Role of Abrasives in Metal Finishing (approx. 200 words):Metal finishing encompasses a wide range of processes, such as abrasive blasting, grinding, sanding, and polishing. These techniques aim to improve the appearance, functionality, and longevity of metal surfaces. At the core of each process lies the abrasive materials, which streamline the entire metal finishing journey.Abrasives serve as the key agents of change in metal finishing by removing unwanted material layers, leveling imperfections, and ensuring a uniform surface. They can be categorized based on their composition, size, and intended purpose. From natural abrasive minerals like garnet and diamond to synthetic options like aluminum oxide and silicon carbide, suppliers offer an extensive range of metal abrasives suitable for various applications.2. The Importance of Reliable Abrasive Suppliers (approx. 250 words):When selecting a supplier for your metal abrasives, it is crucial to prioritize reliability, quality, and customer service. Choosing the wrong supplier can lead to subpar products, delays, and overall dissatisfaction. Therefore, thorough research and consideration are necessary to make an informed decision.Reliable suppliers boast impeccable track records and positive customer reviews. These indicators of customer satisfaction are a testament to the supplier's commitment to quality. By collaborating with established suppliers, you gain access to a wide range of high-quality metal abrasives that will enhance your metal finishing processes.Additionally, reputable suppliers often provide ample product and service information, empowering customers to make well-informed purchasing decisions. Detailed profiles of suppliers allow you to understand their expertise, experience, and capabilities, enabling you to choose a partner that aligns with your specific needs.3. Benefits of High-Quality Metal Abrasives (approx. 250 words):Investing in high-quality metal abrasives can transform your metal finishing processes and yield remarkable results. Here are some key benefits of using premium abrasives:- Enhanced Efficiency: High-quality abrasives exhibit superior cutting, grinding, and polishing capabilities, allowing you to accomplish tasks more efficiently, saving both time and resources.- Superior Surface Finish: Premium abrasives enable you to achieve impeccable surface finishes by removing imperfections, scratches, and roughness efficiently, resulting in aesthetically pleasing and durable metal surfaces.- Extended Abrasive Lifespan: Top-notch metal abrasives often boast increased durability and longevity, reducing the need for frequent replacements and leading to cost savings in the long run.- Consistency and Precision: Reliable suppliers ensure consistent quality across their abrasive products, promoting precise performance and predictable outcomes in your metal finishing processes.Conclusion (approx. 150 words):Choosing the right supplier for your metal abrasive needs is paramount to achieve exceptional results in metal finishing processes. By selecting reputable suppliers and investing in high-quality metal abrasives, you can enhance efficiency, improve surface finishes, extend abrasives' lifespan, and achieve consistent and precise outcomes. Take advantage of the wide array of metal abrasives available in the market and revolutionize your metal finishing processes today.

Top Hardware Tools: Must-Have Equipment for All Your DIY Projects

[News]Title: Prominent Hardware Tools Company Announces Launch of Cutting-Edge Product LineIntroduction:[City, Date] - In a bid to revolutionize the hardware tools industry, renowned company [Brand Name] is proud to unveil its latest range of state-of-the-art tools, designed to simplify tasks, enhance productivity, and provide unbeatable performance to professionals and DIY enthusiasts alike. With their commitment to innovation and precision engineering, [Brand Name] has firmly established itself as a trusted provider of high-quality tools over the years. The introduction of this new product line is set to further solidify their position as an industry leader.Body:1. A Legacy of Excellence:For several decades, [Brand Name] has played an intrinsic role in providing reliable solutions to hardware-related challenges. The company's journey began with a visionary entrepreneur who recognized the need for durable and dependable tools that would withstand even the toughest conditions. Maintaining a relentless focus on innovation and customer satisfaction, [Brand Name] continues to deliver products that set new benchmarks in performance.2. Unveiling the cutting-edge product line:The new range of hardware tools from [Brand Name] features an array of groundbreaking advancements, combining the latest technology with precision engineering. This collection includes power tools, hand tools, measuring equipment, and accessories, catering to the diverse needs of professionals across various industries.a) Power Tools:[Brand Name]'s power tools feature enhanced motors, offering greater torque and increased RPMs for more efficient performance. With improved ergonomics, these tools ensure an optimum balance between power and user comfort, reducing fatigue during prolonged operations. From drills and saws to routers and impact drivers, the power tool range is designed to deliver exceptional results.b) Hand Tools:The hand tool selection boasts innovative designs and superior craftsmanship, making tasks easier and more precise. Built with durable materials, these versatile tools offer reliability and longevity. The ergonomic handles provide a comfortable grip, contributing to overall ease of use. From wrenches and pliers to screwdrivers and hammers, the hand tool range offers a comprehensive solution for every project.c) Measuring Equipment:Accuracy and precision form the foundation of [Brand Name]'s range of measuring equipment. With advanced sensors and cutting-edge technology, these tools provide accurate measurements for professionals in construction, woodworking, and electrical industries. The measuring equipment boasts user-friendly interfaces, allowing for quick and efficient readings, further increasing productivity on the job site.d) Accessories:[Brand Name] also provides an extensive selection of accessories that complement their hardware tools. These accessories include high-quality blades, bits, drill attachments, sanding discs, and more. Specially designed to match the performance and longevity of [Brand Name]'s tools, these accessories ensure an enhanced user experience and increased tool lifespan.3. Commitment to Innovation and Quality:Underpinning its success, [Brand Name] has established a culture of continuous innovation and quality control. Every tool goes through rigorous testing procedures to ensure durability, reliability, and compliance with the highest safety standards. By combining cutting-edge technology, meticulous engineering, and customer-centric design, [Brand Name] continually strives to surpass industry expectations.4. Future Endeavors:Looking ahead, [Brand Name] plans to expand its product line further, addressing emerging needs within the hardware tools market. The company aims to collaborate with industry experts and engage in comprehensive research and development to stay at the forefront of innovation. By consistently surpassing customer expectations, [Brand Name] remains committed to empowering professionals and DIY enthusiasts with reliable, efficient, and durable tools for years to come.Conclusion:With the launch of their revolutionary range of hardware tools, [Brand Name] reinforces its commitment to excellence and innovation. Through their unmatched craftsmanship, precision engineering, and customer-first approach, [Brand Name] continues to set new standards in the industry. This latest product line will undoubtedly empower professionals and hobbyists, making their work easier, more efficient, and more enjoyable. As [Brand Name] continues to evolve and expand its offerings, it remains positioned as a leading provider of high-quality tools for both current and future generations.

Why customised cricket bats are gaining popularity among professional players

Title: Industry-Leading Sanding Solution Enhances Efficiency and Precision in Surface PreparationIntroduction:In an ever-evolving manufacturing landscape, companies are constantly on the lookout for innovative solutions to enhance their operations. As surface preparation continues to play a crucial role in various industries, renowned manufacturer has revolutionized the market with their cutting-edge sanding solution. Developed through years of research and technological expertise, this industry-leading product promises to deliver exceptional efficiency and precision in surface preparation processes.Paragraph 1:Surface preparation is a critical step in numerous industries, including woodworking, metalworking, automotive, and construction. Regardless of the application, achieving a flawless finish often involves sanding. Traditionally, sanding has been a time-consuming and labor-intensive process. However, the introduction of the revolutionary sanding solution by is set to change the game. Incorporating advanced materials and technology, their product offers a perfect balance of efficiency, effectiveness, and durability.Paragraph 2:One of the key distinguishing features of this sanding solution lies in its unique composition. Developed using a blend of high-quality abrasives and adhesive materials, the sandpaper exhibits exceptional durability and longevity. This ensures that the abrasive particles stay firmly attached to the backing material for extended periods, minimizing the need for frequent replacement. Customers can thus enjoy prolonged usage and cost savings, making it a highly sought-after choice in the market.Paragraph 3:Furthermore, the sandpaper's abrasive composition is designed to maximize efficiency in surface preparation. Each abrasive particle is precisely engineered to provide consistent and uniform sanding results. This results in an even removal of material and reduces the occurrence of imperfections such as scratches or uneven surfaces. Whether used for sanding wooden surfaces, smoothing metal edges, or preparing automotive parts, this solution guarantees superior outcomes.Paragraph 4:Additionally, the sandpaper's backing material is carefully selected to complement its abrasive capabilities. Constructed from a durable yet flexible material, it ensures optimal conformability to different surface contours. This feature is particularly crucial when working with intricate or curved surfaces, as it allows for efficient sanding without compromising precision. As a result, users can achieve consistent and professional finishes on a wide range of projects.Paragraph 5:In response to evolving customer needs and preferences, offers their sanding solution in a variety of grit options. Ranging from coarse to fine, these grits cater to different sanding requirements, ensuring versatility across industries. Whether it's initial surface removal, intermediate smoothing, or final finishing, users have the flexibility to choose the ideal grit for their intended application, maximizing time and efficiency.Paragraph 6:To enhance the user experience further, the sandpaper comes with a hook and loop (Velcro) backing system. This feature simplifies the sandpaper attachment and removal process, eliminating the need for adhesives or cumbersome setups. It enables quick and effortless exchanges between different grits or replacement of worn-out sandpaper, saving valuable time during projects.Paragraph 7:To meet the diverse demands of global markets, the sanding solution by is available in various sizes, allowing it to align with different tools and equipment. From handheld sanders to power sanders and even machine sanders, compatibility is ensured, enabling seamless integration into existing setups. This positions the product as an industry-standard for surface preparation across numerous sectors.Conclusion:As surface preparation continues to be a crucial aspect of manufacturing processes, the introduction of sanding solution revolutionizes efficiency, accuracy, and durability. With its advanced composition, superior abrasive performance, and innovation in backing material, this product sets new benchmarks in the industry. By catering to a wide range of grit options and offering a user-friendly hook and loop system, the solution ensures versatility and seamless integration across various tools. In conclusion, the sanding solution by proves to be a game-changer, providing companies across industries with an unparalleled surface preparation solution.

125mm Hook & Loop Backing Pad for Sanders & Polishers: Perfect Fit for 125mm Grinders, Polishers | M14 Thread For Hook and Loop Sanding Discs and Polishing Bonnets | Max12,250rpm

article discussing the benefits of using a 125mm Hook & Loop Backing Pad for sanders and polishers in various industries.The use of Hook & Loop Backing Pads has become increasingly popular in the sanding and polishing industries due to its versatility and ease of use. Backing pads make sanding and polishing tasks easier and more efficient by providing a stable surface for abrasive discs and polishing bonnets to attach to. The 125mm Hook & Loop Backing Pad is one such example that has caught the attention of professionals and DIY enthusiasts alike.Officially known as the ABS Backing Pad for Polisher, this 125mm Hook & Loop Backing Pad fits 125mm Grinders, Polishers, and can operate at a maximum speed of 12,250 RPMs. The M14 Thread for Hook and Loop Sanding Discs and Polishing Bonnets also ensures easy and secure attachment and detachment of sanding and polishing discs.According to industry experts, the 125mm Hook & Loop Backing Pad is one of the most versatile backing pads in the market. It can accommodate a wide range of sanding discs and polishing bonnets, making it suitable for use in various industries like automotive, woodworking, metalworking, and more. In the automotive industry, this backing pad is commonly used for polishing car surfaces, preparing paint surfaces, and sanding metal parts.In woodworking, the 125mm Hook & Loop Backing Pad is perfect for sanding wood surfaces. The Hook & Loop attachment allows for easy and quick change of sanding discs, ensuring that the woodworking process remains uninterrupted. With the added stability provided by the backing pad, sanding can be done with greater accuracy and precision, leading to smoother finishes.Metalworking is another industry where the 125mm Hook & Loop Backing Pad comes in handy. When used in conjunction with abrasive discs, it can quickly remove rust, paint, and other coatings from metal surfaces. The Hook & Loop attachment ensures that the abrasive discs remain attached to the backing pad during use, reducing the risk of accidents.Apart from its versatility, the 125mm Hook & Loop Backing Pad also offers several benefits to users. Its ABS material provides durability and prevents deformation during use, ensuring consistent performance throughout. The Hook & Loop attachment also makes it easy to change sanding and polishing discs, reducing downtime during the sanding and polishing process.Furthermore, the 125mm Hook & Loop Backing Pad ensures that abrasive discs and polishing bonnets remain firmly attached to the backing pad during use, preventing slippage and improving user safety. The maximum speed of 12,250 RPMs also ensures efficient sanding and polishing, saving precious time for professionals.In conclusion, the 125mm Hook & Loop Backing Pad is a versatile and efficient tool that offers numerous benefits to professionals and DIY enthusiasts. Its ability to accommodate a wide range of sanding discs and polishing bonnets, combined with its ease of use, durability, and safety features, makes it an indispensable tool for numerous industries. With its affordable price point, this backing pad is a great addition to any sanding and polishing toolkit.

Dry Polishing Pads: Achieve Diamond-like Results with this Revolutionary Technique

Title: Revolutionizing Stone Polishing: Diamond Dry Polishing Pads Deliver Superior ResultsIntroduction:In the competitive field of stone polishing, a breakthrough has been achieved with the development of the innovative Diamond Dry Polishing Pads. These pads, specifically designed for stone polishing tasks, have quickly gained recognition for their exceptional performance and ability to deliver superior results. Pioneered by a leading industry player specializing in diamond tool manufacturing, this revolutionary product has the potential to transform the stone polishing industry for professionals and enthusiasts alike.Company Introduction: [Company Name]With over two decades of industry experience, [Company Name] has emerged as a leading entity in the field of diamond tool manufacturing. The company prides itself on its extensive research and development to create cutting-edge products that cater to the requirements of various industries. Utilizing state-of-the-art technology and a highly skilled team, [Company Name] consistently delivers innovative solutions that are at the forefront of the industry.Article Body:The quest for a precise and effective stone polishing method has led [Company Name] to develop Diamond Dry Polishing Pads, a game-changer in the field. By honing the perfect combination of advanced materials and groundbreaking manufacturing techniques, these pads have managed to set a new benchmark for stone polishing.The unique composition of Diamond Dry Polishing Pads ensures exceptional durability and longevity. The pads are crafted using high-quality diamond particles that are meticulously embedded into a resin matrix, enabling them to withstand the most demanding polishing applications. This design promotes consistent performance throughout the polishing process, resulting in a flawlessly polished stone surface every time.One of the standout features of the Diamond Dry Polishing Pads is their ability to function without the need for water or any other lubricating agent. This characteristic significantly expedites the polishing process, eliminates the mess associated with traditional methods, and reduces water consumption. The eco-friendly nature of these pads aligns perfectly with the growing demand for sustainable practices within various industries.Compatibility across an extensive range of stone types is another noteworthy advantage of Diamond Dry Polishing Pads. Whether it's marble, granite, quartz, or even engineered stone, these pads deliver exceptional results on any surface. This versatility has made them a favorite among professionals in the stonework industry, ensuring that each project is executed with precision and efficiency.Furthermore, Diamond Dry Polishing Pads are designed to operate at optimal speeds, reducing the overall polishing time without compromising on the quality of the finish. The superior heat dissipation of these pads not only enhances efficiency but also extends their lifespan, ultimately providing cost-effective solutions for businesses in the stone polishing sector.In addition to their remarkable polishing capabilities, Diamond Dry Polishing Pads also boast an innovative design that guarantees ease of use. The flexible and lightweight construction ensures comfortable handling, thereby reducing operator fatigue and enhancing overall productivity. The gripping technology incorporated within the pads minimizes slippage and ensures stable control, allowing for smooth and consistent polishing motions.Recognizing the industry's changing dynamics and the need for continuous improvement, [Company Name] remains committed to further enhancing the performance of their Diamond Dry Polishing Pads. The team is constantly investing in research and development, exploring new advancements in materials and manufacturing techniques to stay at the forefront of an ever-evolving industry.Conclusion:In conclusion, the introduction of Diamond Dry Polishing Pads by [Company Name] has marked a significant milestone in the stone polishing industry. Achieving unparalleled results, these innovative pads have revolutionized stone polishing techniques with their durability, compatibility, eco-friendliness, and exceptional performance. With the constant pursuit of perfection, [Company Name] continues to redefine industry standards, cementing its position as a leading player in the diamond tool manufacturing sector.