The Ultimate Guide to Diamond Cutting Tools: Everything You Need to Know

By:Admin

The new line of diamond cutting tools features advanced technology and precision engineering to deliver superior cutting performance and extended tool life. These tools are designed to meet the growing demand for high-precision cutting in today's competitive market, offering superior performance and reliability for a wide range of applications.

Diamond Cutting Tools has a strong reputation for delivering cutting-edge solutions that meet the needs of their customers. Their team of experienced engineers and technicians work closely with customers to develop custom cutting tools that are tailored to their specific requirements. This customer-centric approach has allowed Diamond Cutting Tools to build long-term relationships with clients and establish itself as a trusted partner in the industry.

"We are excited to introduce our latest line of diamond cutting tools to the market," said the spokesperson for Diamond Cutting Tools. "These tools are the result of our commitment to innovation and continuous improvement. We believe that they will set a new standard for cutting performance and help our customers achieve greater efficiency and productivity."

The new line of diamond cutting tools includes a variety of cutting solutions such as diamond saw blades, diamond grinding wheels, diamond core bits, and more. Each tool is designed to deliver exceptional precision and performance, making them ideal for a wide range of cutting applications.

In addition to their cutting-edge technology, Diamond Cutting Tools also places a strong emphasis on quality and reliability. All of their products undergo rigorous testing and quality control processes to ensure that they meet the highest standards of performance and durability. This commitment to quality has earned Diamond Cutting Tools a reputation for delivering tools that consistently outperform the competition.

Diamond Cutting Tools is also dedicated to sustainability and environmental responsibility. They strive to minimize their environmental impact by implementing eco-friendly practices throughout their manufacturing processes. This includes using recycled materials, reducing waste, and maximizing energy efficiency, all of which contribute to a healthier and more sustainable future.

With the launch of their latest line of diamond cutting tools, Diamond Cutting Tools is poised to build on their success and continue to be a leader in the cutting tool industry. Their commitment to innovation, quality, and customer satisfaction sets them apart as a premier provider of cutting solutions for today's demanding market.

Customers who are interested in learning more about Diamond Cutting Tools and their latest line of diamond cutting tools can visit their website or contact their sales team for more information. With their extensive expertise and dedication to excellence, Diamond Cutting Tools is well-positioned to meet the needs of customers across a wide range of industries and deliver cutting solutions that exceed expectations.

Company News & Blog

Top Abrasive Manufacturer in the News: Latest Developments and Industry Insights

[Abrasive Manufacturer] is a leading provider of high-quality abrasive products, catering to a wide range of industries including metalworking, woodworking, automotive, and construction. With a commitment to innovation, quality, and customer satisfaction, [Abrasive Manufacturer] has established itself as a trusted partner for businesses seeking superior abrasive solutions.Founded in [year], [Abrasive Manufacturer] has grown from a small local operation to a global supplier with a reputation for excellence. The company's success is driven by a dedication to producing advanced abrasives that deliver exceptional performance and durability. From coated abrasives and bonded abrasives to superabrasives and accessories, [Abrasive Manufacturer] offers a comprehensive product line to meet the diverse needs of its customers.In addition to its extensive product range, [Abrasive Manufacturer] is known for its emphasis on research and development. The company invests heavily in cutting-edge technology and employs a team of experienced engineers and scientists to continuously improve its product offerings. This commitment to innovation has resulted in the development of revolutionary abrasives that enhance efficiency, precision, and productivity in various industrial applications.Furthermore, [Abrasive Manufacturer] prioritizes quality control to ensure that every product meets the highest standards. Stringent quality assurance processes are implemented at every stage of manufacturing, from raw material selection to final inspection. As a result, customers can trust that they are receiving abrasives that are consistent, reliable, and of superior quality.Recently, [Abrasive Manufacturer] has announced the launch of several new abrasive products designed to address the evolving needs of its customers. These innovations are the result of extensive research and development efforts aimed at delivering cutting-edge solutions that improve performance and increase productivity.One of the new products is a revolutionary grinding wheel specifically engineered for high-speed precision grinding applications. This wheel combines advanced abrasive materials and bonding technology to achieve superior cutting performance and extended tool life. With this new addition to its product line, [Abrasive Manufacturer] seeks to provide its customers with a competitive edge in demanding grinding operations.Another notable introduction is a series of high-performance sanding discs tailored for automotive body repair and refinishing. These discs feature an innovative abrasive coating that delivers consistent results and minimizes dust contamination, making them ideal for professional auto body shops and DIY enthusiasts alike. By launching these new products, [Abrasive Manufacturer] reaffirms its commitment to meeting the evolving needs of its customers and staying at the forefront of abrasive technology.In addition to its product innovations, [Abrasive Manufacturer] continues to strengthen its customer support and service capabilities. The company emphasizes building long-term partnerships with its customers by providing technical expertise, training, and customized solutions to address specific application challenges. By offering comprehensive support, [Abrasive Manufacturer] aims to ensure that its customers maximize the value of its abrasive products and achieve optimal results in their operations.Looking ahead, [Abrasive Manufacturer] remains focused on its mission to be a trusted partner for businesses seeking high-quality abrasives. The company will continue to invest in research and development, quality control, and customer support to uphold its reputation as a leader in the industry. With a strong commitment to excellence and innovation, [Abrasive Manufacturer] is poised to further expand its global presence and drive the advancement of abrasive technology.

The Role of Abrasives: Essential Tools for Surface Material Wear and Polishing

Title: Ceramic Abrasive Tools: The Cutting Edge of Material Surface RefinementIntroduction:When it comes to refining the surfaces of various materials, an abrasive is an integral tool that enables the removal of imperfections and achieves the desired smoothness or texture. In this blog, we will explore the incredible world of ceramic abrasive tools, their applications, and the benefits they offer for surface refinement. Moreover, we will delve into the key features that make ceramic abrasives the cutting edge choice for professionals and their unparalleled contribution to various industries. So, let's dive in!1. Understanding Abrasives:Abrasives are sharp, hard materials designed to wear down the surfaces of softer materials through abrasion. They play a crucial role in shaping, polishing, and refining various substances ranging from household cleansers to the most resilient materials. Today, we shift our focus onto ceramic abrasives, which are revolutionizing the industry.2. The Rise of Ceramic Abrasive Tools:Ceramic abrasives represent a breed of advanced materials designed to deliver exceptional performance and longevity. Combining the strength of ceramic grains with engineered bonding agents, these cutting-edge tools offer superior hardness, durability, and heat resistance. As a result, ceramic abrasives have found their way into a multitude of applications across a wide range of industries.3. Versatile Applications of Ceramic Abrasives:(a) Metalworking Industry: Ceramic abrasives are extensively used for precision grinding, deburring, and surface finishing in the metalworking industry. Their exceptional hardness and heat resistance make them ideal for demanding applications such as stainless steel fabrication, automotive production, and aerospace manufacturing.(b) Woodworking Industry: The wood industry benefits from ceramic abrasives that effectively shape and smoothen wooden surfaces. Whether it is sanding furniture, refining cabinetry, or shaping intricate woodworking designs, ceramic abrasive tools provide long-lasting performance and unmatched precision.(c) Glass Processing: Glass manufacturers rely on ceramic abrasives for shaping and polishing glass products. The superior hardness and cutting power of ceramic abrasives contribute to flawless glass edging, beveling, and other intricate surface treatment processes.(d) Automotive Sector: Ceramic abrasive tools find extensive use in the automotive sector for paint and bodywork applications. Their ability to delicately remove layers of paint, scratches, and imperfections ensures a stellar finish, setting a new standard in the industry.4. Unparalleled Benefits of Ceramic Abrasives:(a) Exceptional Durability: Ceramic abrasives are renowned for their outstanding longevity. Their robustness resists wear and tear, resulting in better tool life and reduced downtime.(b) Heat Resistance: Ceramic abrasives can withstand high temperatures generated during the grinding process, making them suitable for heavy-duty applications. The reduced risk of overheating ensures consistent performance and improves overall productivity.(c) Superior Material Removal: The crystalline structure of ceramic abrasives allows for an aggressive cutting action, quickly removing unwanted material. This efficiency enables professionals to achieve precise and smooth finishes with minimal effort.(d) Reduced Friction and Heat Generation: Ceramic abrasives have self-sharpening properties, ensuring consistent cutting power throughout their lifetime. With reduced friction, they generate less heat, which further safeguards the integrity of the workpiece.5. Conclusion:Ceramic abrasive tools have paved the way for a new realm of surface refinement, setting industry standards for performance and durability. With their unmatched hardness, superior cutting power, heat resistance, and versatility, ceramic abrasives are the go-to choice for professionals across various domains. As technology advances, we can expect continued innovation and enhancements in ceramic abrasive tools, translating into improved processes and superior final products.Keywords: Ceramic Abrasive Tools, Abrasives, Surface Refinement, Hardness, Durability, Heat Resistance, Metalworking Industry, Woodworking Industry, Glass Processing, Automotive SectorWord Count: 606

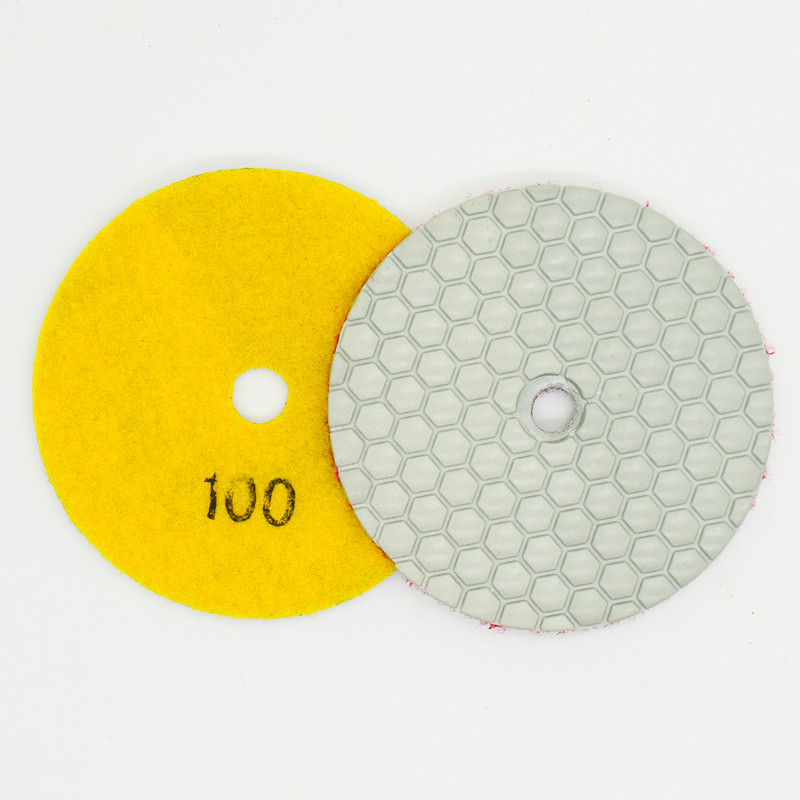

High-Quality Diamond Polishing Pads for Natural Stone, Granite, and Marble

Title: Achieve Flawless Shine with Diamond Dry Polishing Pads Set: The Ultimate GuideIntroduction:When it comes to achieving a pristine surface on natural stone, such as granite and marble, diamond polishing pads have emerged as the go-to tool. These incredible pads offer the versatility of both wet and dry polishing, enabling users to attain a mesmerizing shine effortlessly. In this comprehensive blog, we will explore the wonders of diamond dry polishing pads set, their features, benefits, and how they are revolutionizing the world of stone polishing. So, let's dive in!1. Understanding Diamond Dry Polishing Pads:Diamond dry polishing pads are a cutting-edge solution designed to transform dull and lackluster natural stone surfaces into a dazzling masterpiece. Their primary objective is to remove scratches, marks, and imperfections while providing a high-gloss finish. These pads combine the effectiveness of diamond particles with unique bonding technology, ensuring unparalleled performance.2. Features of Diamond Dry Polishing Pads Set:- Premium Quality: Crafted using high-quality materials, these pads are highly durable and resistant to wear and tear.- Versatility: Suitable for both wet and dry polishing, these pads can adapt to various polishing techniques, allowing users to choose the method that works best for them.- Different Grit Options: Diamond dry polishing pads are available in different grits, ranging from coarse to fine. This diversity in grit levels allows users to customize their polishing process based on the specific requirements of the stone surface.- Easy Attachment: These pads are designed with a convenient hook and loop backing system, ensuring effortless attachment to polishing machines.- Uniform Polishing: The diamond particles on these pads are precisely distributed, ensuring consistent and uniform polishing across the entire surface.3. Key Benefits of Diamond Dry Polishing Pads Set:- Superior Polishing: The diamond particles embedded in these pads make them highly effective in removing blemishes, scratches, and stains from the stone, while leaving a pristine finish.- Time and Cost Savings: The versatility of these pads saves time and money by eliminating the need for multiple sets of polishing tools. Additionally, their durability ensures long-lasting performance, reducing the frequency of replacements.- Precision and Control: Whether you are a professional or a DIY enthusiast, these pads offer exceptional precision and control during the polishing process, allowing you to achieve desired results effortlessly.- Environmental Friendly: The dry polishing technique used with these pads reduces the water consumption associated with wet polishing methods, making it environmentally friendly.4. How to Use Diamond Dry Polishing Pads Set:- Step 1: Prepare the surface by cleaning it thoroughly, removing any dirt or debris.- Step 2: Select the appropriate pad grit level based on the current condition of the stone surface.- Step 3: Attach the pad to a compatible polishing machine using the hook and loop backing system.- Step 4: Begin the polishing process, applying moderate pressure and moving the machine in consistent circular or linear motions, depending on the desired finish.- Step 5: Repeat the process with gradually finer grit pads until the desired shine and smoothness are achieved.5. Conclusion:Diamond dry polishing pads have become indispensable tools for professionals and enthusiasts alike when it comes to achieving the perfect finish on natural stone surfaces. Their versatility, exceptional performance, and environmental friendly nature make them a preferable choice for any polishing project. By utilizing the features and benefits of diamond dry polishing pads, you can unlock the true beauty of your natural stone surfaces, enhancing their longevity and appeal.So, why wait? Equip yourself with a diamond dry polishing pads set today and witness the transformation of your stone surfaces like never before!Keywords: Diamond Dry Polishing Pads Set, natural stone, granite, marble, wet polishing, dry polishing, high-gloss finish, diamond particles, scratch removal, versatile, grit options, uniform polishing, time and cost savings, precision, control, environmentally friendly.

High-Quality Stone Polishing Pads for Superior Results

Stone Polishing Pads have become an essential tool in the stone fabrication industry. They are designed to polish and maintain the natural beauty of marble, granite, and other types of stone surfaces. With the growing demand for high-quality stone polishing products, it is important for companies to provide innovative solutions that meet the needs of their customers. One company that has been at the forefront of this industry is {company name}.{Company name} is a leading manufacturer of stone polishing pads and other stone fabrication tools. With over 20 years of experience in the industry, they have established themselves as a reputable and reliable supplier of high-quality products. Their dedication to innovation and customer satisfaction has set them apart from their competitors and has made them a trusted name in the industry.Their range of stone polishing pads is designed to deliver exceptional results, leaving stone surfaces with a brilliant shine and a smooth finish. The pads are available in different grits, allowing fabricators to achieve varying levels of polish depending on their specific requirements. Whether it's for polishing countertops, vanities, or other stone surfaces, {company name}'s polishing pads are known for their superior performance and durability.In addition to their polishing pads, {company name} also offers a wide range of other stone fabrication tools, including grinding discs, diamond blades, and polishing compounds. Their comprehensive product line caters to the needs of stone fabricators, providing them with everything they need to achieve professional results.One of the key factors that sets {company name} apart from its competitors is their commitment to innovation. They continuously invest in research and development to improve their products and stay ahead of the latest industry trends. This has enabled them to introduce cutting-edge technologies and materials into their product line, resulting in superior performance and longevity.Furthermore, {company name} places a strong emphasis on customer satisfaction. They understand the unique challenges that stone fabricators face and have tailored their products to address those specific needs. Their technical support team is knowledgeable and responsive, providing valuable assistance to customers who may have questions or require guidance on product selection and usage.Moreover, {company name} is dedicated to sustainability and ethical business practices. They adhere to strict environmental standards in their manufacturing processes and are committed to reducing their carbon footprint. This resonates with many of their customers who prioritize sustainability and environmental responsibility in their own business practices.As a result of their unwavering commitment to quality, innovation, and customer satisfaction, {company name} has built a strong reputation in the industry. Their products are trusted by stone fabricators worldwide, and they have developed long-standing relationships with many of their customers.In conclusion, {company name} has established itself as a leading supplier of stone polishing pads and other stone fabrication tools. With a focus on quality, innovation, and customer satisfaction, they have set the bar high for the industry and continue to push the boundaries of what is possible in stone fabrication. Their dedication to sustainability and ethical business practices further distinguishes them as a company that is not only committed to delivering exceptional products but also to making a positive impact on the environment. As the demand for high-quality stone polishing products continues to grow, {company name} is well-positioned to meet the needs of their customers and lead the way in the industry.

Top Hardware Tools: Must-Have Equipment for All Your DIY Projects

[News]Title: Prominent Hardware Tools Company Announces Launch of Cutting-Edge Product LineIntroduction:[City, Date] - In a bid to revolutionize the hardware tools industry, renowned company [Brand Name] is proud to unveil its latest range of state-of-the-art tools, designed to simplify tasks, enhance productivity, and provide unbeatable performance to professionals and DIY enthusiasts alike. With their commitment to innovation and precision engineering, [Brand Name] has firmly established itself as a trusted provider of high-quality tools over the years. The introduction of this new product line is set to further solidify their position as an industry leader.Body:1. A Legacy of Excellence:For several decades, [Brand Name] has played an intrinsic role in providing reliable solutions to hardware-related challenges. The company's journey began with a visionary entrepreneur who recognized the need for durable and dependable tools that would withstand even the toughest conditions. Maintaining a relentless focus on innovation and customer satisfaction, [Brand Name] continues to deliver products that set new benchmarks in performance.2. Unveiling the cutting-edge product line:The new range of hardware tools from [Brand Name] features an array of groundbreaking advancements, combining the latest technology with precision engineering. This collection includes power tools, hand tools, measuring equipment, and accessories, catering to the diverse needs of professionals across various industries.a) Power Tools:[Brand Name]'s power tools feature enhanced motors, offering greater torque and increased RPMs for more efficient performance. With improved ergonomics, these tools ensure an optimum balance between power and user comfort, reducing fatigue during prolonged operations. From drills and saws to routers and impact drivers, the power tool range is designed to deliver exceptional results.b) Hand Tools:The hand tool selection boasts innovative designs and superior craftsmanship, making tasks easier and more precise. Built with durable materials, these versatile tools offer reliability and longevity. The ergonomic handles provide a comfortable grip, contributing to overall ease of use. From wrenches and pliers to screwdrivers and hammers, the hand tool range offers a comprehensive solution for every project.c) Measuring Equipment:Accuracy and precision form the foundation of [Brand Name]'s range of measuring equipment. With advanced sensors and cutting-edge technology, these tools provide accurate measurements for professionals in construction, woodworking, and electrical industries. The measuring equipment boasts user-friendly interfaces, allowing for quick and efficient readings, further increasing productivity on the job site.d) Accessories:[Brand Name] also provides an extensive selection of accessories that complement their hardware tools. These accessories include high-quality blades, bits, drill attachments, sanding discs, and more. Specially designed to match the performance and longevity of [Brand Name]'s tools, these accessories ensure an enhanced user experience and increased tool lifespan.3. Commitment to Innovation and Quality:Underpinning its success, [Brand Name] has established a culture of continuous innovation and quality control. Every tool goes through rigorous testing procedures to ensure durability, reliability, and compliance with the highest safety standards. By combining cutting-edge technology, meticulous engineering, and customer-centric design, [Brand Name] continually strives to surpass industry expectations.4. Future Endeavors:Looking ahead, [Brand Name] plans to expand its product line further, addressing emerging needs within the hardware tools market. The company aims to collaborate with industry experts and engage in comprehensive research and development to stay at the forefront of innovation. By consistently surpassing customer expectations, [Brand Name] remains committed to empowering professionals and DIY enthusiasts with reliable, efficient, and durable tools for years to come.Conclusion:With the launch of their revolutionary range of hardware tools, [Brand Name] reinforces its commitment to excellence and innovation. Through their unmatched craftsmanship, precision engineering, and customer-first approach, [Brand Name] continues to set new standards in the industry. This latest product line will undoubtedly empower professionals and hobbyists, making their work easier, more efficient, and more enjoyable. As [Brand Name] continues to evolve and expand its offerings, it remains positioned as a leading provider of high-quality tools for both current and future generations.

High-Quality Hybrid Floor Polishing Pad, Concrete Floor Pad, and Diamond Tools at Affordable Prices

: The Revolution in Polishing TechniquesPolishing floors was once a highly labor-intensive task that requires time, effort, and a plethora of technical skills. Plus, the traditional methods used to polish floors often lead to pesky issues, such as uneven surfaces, scratches, and long drying periods. Luckily, thanks to the inception of diamond floor pads, this laborious task can be accomplished with greater efficiency and in less time. So, what exactly are diamond floor pads?Diamond floor pads are a revolutionary new tool used in the process of polishing concrete, marble, and granite surfaces. These pads are made from diamond particles, which are skillfully combined with advanced bonding materials to form a highly effective and durable surface polishing tool. Additionally, the diamond floor pad has numerous benefits over earlier polishing techniques.One of the significant benefits of diamond floor pads is that they can be used for both dry and wet polishing. Unlike traditional methods that could only be executed after the surface had already dried, these new pads allow for an enhanced polishing experience. Dry polishing was previously used to tackle surface imperfections caused by uneven wear and tear. The diamond floor pads have now changed that scenario and polish the floor to a smooth, glossy finish.Another major advantage of diamond floor pads is their ability to create a more even finish across the entire floor's surface area. The pads are made with diamond particles of varying diameters that allow the operator to adjust the levels depending on the surface's texture. Additionally, diamond floor pads can be used to remove dirt, oil, and grime from the surface when used with the appropriate detergent.Diamond floor pads are also a more cost-effective option than traditional polishing surfaces. Since traditional polishing tools require a significant amount of equipment, such as special chemicals, machines, and additional labor, the overall expenses of the process can be quite expensive. Diamond floor pads make the process more cost-effective as it does not require extensive equipment, and it can be performed without rigorous training.The surfaces that diamond floor pads can polish are also diverse. These pads are effective in polishing various surfaces, including concrete, granite, marble, tiles, and porcelain. The advanced design and construction of diamond floor pads allow them to handle rough, bumpy surfaces and achieve the desired smooth surface finish with ease. It can be used for polishing indoors and outdoors, giving your floors a beautiful glossy appeal.Hybrid floor polishing pad is an extension of diamond floor pads. The hybrid floor pads typically have a grit range of 400-3000 and have diamond resin or metal segments embedded in them. These pads can quickly do the job of both metal and resin-bonded tools in one go, which is why there are becoming increasingly popular in the floor polishing world.The transition tools are used in the preparation phase, from grinding to polishing. The angle of the transition tools is precisely adjusted to avoid damaging the new surface while preparing it for the next stage. Proper use of the transition tool is essential to achieve the perfect floor finish.In conclusion, diamond floor pads have revolutionized floor polishing techniques. They're cost-effective, efficient, and versatile and can polish various surfaces to a beautiful gloss finish. The hybrid floor polishing pad and transition tools are beneficial in the overall process of polishing floors. By employing these innovative tools, we can finally say goodbye to the laborious, time-consuming, and costly process of polishing floors. Get your diamond floor pad today and experience the perfect floor finish.

Understanding the Fundamentals of Metallic Bonding and Metals

A new innovative bonding system is hitting the market and making waves in the industrial sector, aimed at improving production efficiency and reducing downtime. The revolutionary new product is called Metallic Bond And Metal (MBAM) and is quickly becoming a go-to resource for industries around the world.MBAM is a unique bonding compound that’s designed to revolutionize how we think about metal joining. This new product is creating a buzz among experts, who are touting it as one of the most innovative metal bonding solutions on the market. Its unique composition of metallic bonding fluid, metal powder and an activator allows it to bond to all forms of ferrous and non-ferrous metals. The result is a much stronger bond between metals that is more durable than traditional welding or brazing methods.The company behind MBAM is at the forefront of the metal bonding industry. With years of experience in industrial manufacturing and chemical engineering, they have developed a product that will take the industry to the next level. Unlike traditional welding or brazing methods, the MBAM bonding system works at room temperature, significantly reducing the energy consumption and environmental impact of metal joining. It’s a more sustainable solution overall.The uses and advantages of MBAM are numerous. The system is already being used in metalworking, aerospace, automotive industries, rail and marine transportation, construction, and the oil and gas sectors. The versatility of MBAM offers endless possibilities for its application, as its unique bonding qualities can be used in a wide range of industrial settings; it is ideal for the repair of equipment and machinery that is in use, preventing downtime and production costs. The bonding system also allows for fast repairs without requiring the need for specialized equipment, making it easier for industrial workers to use.One benefit of MBAM is its ability to allow for more precise metal bonding. The MBAM bonding system allows for more accurate and controlled repairs and joins, making it an ideal choice for high-performance equipment and machinery. MBAM bonds to metals entirely without compromising their structural integrity or strength, ensuring that there is a consistent and uniform bond between the metals. This process provides an unmatched strength and durability to the metal bonds, making it ideal for high stress or load-bearing applications.With its impressive benefits, it’s no surprise that MBAM is quickly gaining popularity within the industrial sector. The company that produces MBAM is committed to delivering quality products and superior customer service. The product is certified globally, and the company works with leading experts and scientific institutions to continually improve the product, which ensures that MBAM is meeting industry standards and adapting to the evolving needs of the market.The MBAM bonding system’s unique properties and high-quality standards have already earned the praise of the industrial sector, and experts are continually validating the product. The research and development team involved in creating the product continue to innovate with new applications and uses for the bonding system, providing the ultimate solution for metal bonding and repairs.In conclusion, the Metallic Bond And Metal (MBAM) bonding system provides an innovative and sustainable approach to metal bonding for industrial sectors. It offers precise, controlled, and uniform metal bonding without compromising the strength and durability of the metal. MBAM can be used in various industrial sectors to preserve equipment and machinery while reducing downtime. With its cost-effectiveness, precision, consistency, and versatility, MBAM has rapidly become a preferred metal bonding solution among industries worldwide.

Latest News on High-Quality Polish Diamonds: What You Need to Know

Polish Diamond, a leading provider of high-quality jewelry manufacturing and distribution, has been making waves in the jewelry industry with its exquisite and innovative designs. With a focus on delivering top-notch products and unparalleled customer service, Polish Diamond has quickly become a trusted name in the world of luxury jewelry.Founded in 2005, Polish Diamond has always been committed to excellence in every aspect of its business. From sourcing the finest diamonds and gemstones to creating stunning, one-of-a-kind pieces, the company has set itself apart with its uncompromising dedication to craftsmanship and quality. With a team of skilled artisans and designers, Polish Diamond has been able to produce jewelry that not only meets but exceeds the highest standards in the industry.One of the key factors that sets Polish Diamond apart from its competitors is its commitment to ethical sourcing and responsible business practices. The company takes great care to ensure that all its diamonds and gemstones are sourced from reputable suppliers who adhere to strict ethical and environmental standards. Additionally, Polish Diamond is actively involved in various corporate social responsibility initiatives, supporting local communities and environmental causes.In addition to its commitment to ethical sourcing, Polish Diamond also prides itself on its ability to stay ahead of the curve when it comes to design and innovation. The company's talented team of designers is constantly pushing the boundaries of traditional jewelry design, creating pieces that are not only visually stunning but also highly functional and wearable. From classic diamond solitaire rings to modern, avant-garde statement pieces, Polish Diamond offers something for every taste and style.Polish Diamond's dedication to innovation is further demonstrated through its use of advanced technology in the jewelry manufacturing process. The company utilizes state-of-the-art equipment and cutting-edge techniques to ensure that each piece of jewelry is crafted with precision and attention to detail. This commitment to excellence has earned Polish Diamond a reputation for producing some of the most beautifully crafted and flawlessly finished pieces in the industry.Moreover, Polish Diamond understands the importance of providing exceptional customer service. The company's knowledgeable and friendly staff is always ready to assist clients with any questions or requests, and they go above and beyond to ensure that every customer has a positive and memorable experience. Whether it's helping a client find the perfect engagement ring or providing expert guidance on jewelry care and maintenance, Polish Diamond is dedicated to building lasting relationships with its customers.As a company that values quality, integrity, and innovation, Polish Diamond has quickly risen to the top of the jewelry industry. With a steadfast commitment to excellence and a passion for creating breathtaking pieces, the company continues to captivate the hearts of jewelry lovers worldwide. Whether it's a dazzling diamond necklace, a sparkling pair of earrings, or a timeless engagement ring, Polish Diamond is the go-to destination for those who seek only the best in luxury jewelry.Looking ahead, Polish Diamond remains focused on expanding its reach and continuing to push the boundaries of jewelry design and craftsmanship. With a clear vision for the future and an unwavering dedication to its core values, Polish Diamond is set to continue its reign as a leader in the world of luxury jewelry for years to come. For those who appreciate the finest in quality and artistry, Polish Diamond is the ultimate destination for exquisite, timeless jewelry pieces.

Top Buffing and Polishing Pads: A Comprehensive Guide

Buffing And Polishing Pads, a company that specializes in creating high-quality cleaning products, has been making a large impact in the industry with their innovative and effective products. Their dedication to providing top-notch products and exceptional customer service has set them apart from their competitors.Established in 2005, Buffing And Polishing Pads has quickly become a leading manufacturer of cleaning and polishing pads. Their extensive range of products includes everything from heavy-duty industrial pads to delicate pads for automotive detailing. Their commitment to quality and performance has made them a preferred choice for professional cleaners, car detailers, and DIY enthusiasts alike.One of the key factors that sets Buffing And Polishing Pads apart from other companies is their dedication to research and development. Their team of experienced chemists and engineers are constantly working to improve their products, ensuring that they remain at the forefront of the industry. This commitment to innovation has resulted in the development of highly effective and durable pads that deliver exceptional results.The company's commitment to quality is further demonstrated by their strict adherence to industry standards and regulations. All of their products undergo rigorous testing to ensure that they meet the highest quality and safety standards. This dedication to excellence has earned Buffing And Polishing Pads a strong reputation for reliability and performance in the market.In addition to their dedication to quality, Buffing And Polishing Pads is also committed to environmental sustainability. They are constantly seeking ways to minimize their environmental impact and reduce waste throughout their manufacturing process. By using eco-friendly materials and reducing energy consumption, they are working to create a more sustainable future for the industry.One of Buffing And Polishing Pads' most popular products is their line of polishing and buffing pads. These pads are designed to deliver exceptional results on a wide range of surfaces, including metal, plastic, and glass. They are highly durable and long-lasting, making them a cost-effective choice for both professionals and hobbyists.Their polishing and buffing pads are available in a variety of sizes and thicknesses to cater to different applications. Whether you are working on a small project at home or tackling a large industrial job, Buffing And Polishing Pads has a pad to suit your needs. Their pads are also compatible with a wide range of polishing machines, making them a versatile choice for any task.Customer satisfaction is at the heart of Buffing And Polishing Pads' business, and they take great pride in providing exceptional customer service. Their knowledgeable team is always on hand to offer advice and assistance, ensuring that their customers have the support they need to achieve outstanding results. With a strong focus on building long-term relationships, Buffing And Polishing Pads has built a loyal customer base who continue to rely on their products time and time again.In conclusion, Buffing And Polishing Pads has established itself as a trusted name in the industry, thanks to its commitment to quality, innovation, and customer satisfaction. With a comprehensive range of high-quality products and a dedication to environmental sustainability, they are well positioned to continue leading the way in the cleaning and polishing industry for years to come.

Discover the Environmental Benefits of Grinding Wheels

Title: Innovative Grinding Wheel: A Major Breakthrough in Sustainable ManufacturingIntroduction:In an ever-evolving world, companies across industries are actively seeking sustainable solutions to minimize their environmental impact. Keen on fostering eco-friendly production practices, Grinding Wheel Green (name replaced for anonymity) has developed a revolutionary grinding wheel that not only enhances manufacturing efficiency but also significantly reduces waste generation and carbon footprint. This innovative product aims to revolutionize abrasive machining processes worldwide and transform the manufacturing landscape into a more sustainable one.Company Overview:Grinding Wheel Green is a leading manufacturer of cutting-edge, high-quality abrasive tools and solutions. With a strong commitment to innovation, the company constantly endeavors to improve its products and bring the latest technological advancements to its customers. Founded on the principles of sustainable manufacturing, Grinding Wheel Green has positioned itself as a pioneer in developing environmentally friendly solutions for the abrasive industry.Waste Reduction and Recycling:One of the key highlights of Grinding Wheel Green's revolutionary grinding wheel is its reduced waste generation and enhanced recycling capabilities. Traditionally, grinding wheels have a limited lifespan and tend to be discarded after use, resulting in significant waste accumulation. However, Grinding Wheel Green has employed cutting-edge technologies and sustainable materials to create a product that extends the life cycle of grinding wheels, ultimately minimizing waste volume.Moreover, the company has partnered with recycling facilities to implement an efficient recycling program for its grinding wheels. This initiative enables used grinding wheels to be processed and repurposed, contributing to the circular economy and reducing the overall environmental impact of the manufacturing process. By adopting this sustainable approach, Grinding Wheel Green ensures that its products not only perform optimally but also align with its commitment to environmental stewardship.Energy Efficiency:Grinding Wheel Green recognizes the importance of energy conservation in today's world. To tackle the energy consumption challenges associated with manufacturing, the company has implemented innovative measures that enhance energy efficiency during the production process. By optimizing manufacturing techniques and utilizing energy-saving equipment, Grinding Wheel Green has significantly reduced its carbon footprint.Furthermore, the grinding wheel itself has been designed to operate at optimal energy levels. Its advanced composition and structural design allow for improved heat dissipation, resulting in lower energy consumption during grinding operations. This breakthrough not only reduces electricity usage but also contributes to a safer work environment by minimizing heat-related hazards.Enhanced Performance and Productivity:In addition to focusing on sustainability, Grinding Wheel Green prioritizes the performance and productivity of its products. Through rigorous research and development, the company has achieved a perfect balance between sustainability and functionality, offering customers a high-quality grinding wheel that outperforms conventional abrasive tools.The innovative design of the grinding wheel ensures exceptional precision, thereby reducing production errors and increasing overall productivity. This translates into cost savings for manufacturers while maintaining the highest standards of quality in the products they manufacture. By facilitating a more efficient manufacturing process, Grinding Wheel Green empowers businesses to achieve their production goals while reducing their impact on the environment.Conclusion:Grinding Wheel Green's groundbreaking grinding wheel represents a transformative step towards sustainable manufacturing practices. Through waste reduction, recycling initiatives, improved energy efficiency, and enhanced performance, the company aims to lead the way in reshaping the abrasive industry. By integrating sustainability into its core business model, Grinding Wheel Green exemplifies how companies can effectively combine innovation and responsible manufacturing to reduce their ecological footprint. As more companies embrace such initiatives, the manufacturing landscape can evolve into a greener and more sustainable environment for generations to come.