Powerful Brushless Angle Grinder for Efficient Cutting and Grinding

By:Admin

The Brushless Angle Grinder is the result of extensive research and development efforts by the engineering team at [Company Name]. Equipped with a powerful brushless motor, this angle grinder delivers higher efficiency and longer life compared to traditional brushed motors. The absence of brushes also means less maintenance and a reduction in overall operating costs for users.

One of the key features of the Brushless Angle Grinder is its ergonomic design, which prioritizes user comfort and control. The tool is lightweight and compact, making it easy to handle and maneuver in tight spaces. Additionally, [Company Name] has incorporated advanced vibration reduction technology into the design, ensuring minimal user fatigue during prolonged use.

Safety is a top priority for [Company Name], and the Brushless Angle Grinder is no exception. The tool is equipped with a range of safety features, including a kickback brake system and an electronic clutch, which help to minimize the risk of injury in the event of a sudden stall or kickback. Furthermore, the tool is compliant with all relevant safety standards and regulations, giving users peace of mind while on the job.

In terms of performance, the Brushless Angle Grinder is a versatile tool that can handle a wide range of applications. Whether it's cutting through metal pipes, grinding down welds, or polishing surfaces, this angle grinder is up to the task. The brushless motor delivers consistent power output, ensuring a smooth and precise finish every time.

"We are thrilled to introduce the Brushless Angle Grinder to the market," said [Spokesperson Name], a representative of [Company Name]. "This tool represents the latest in power tool technology and showcases our commitment to delivering high-quality, innovative solutions to our customers. We believe that the Brushless Angle Grinder will be a game-changer for professionals and DIY enthusiasts alike."

The Brushless Angle Grinder is available in a range of configurations to suit different user needs. [Company Name] offers a selection of grinding discs and accessories that complement the tool, allowing users to tackle various tasks with ease. Additionally, the tool is backed by [Company Name]'s renowned customer support and warranty program, providing users with the confidence that their investment is protected.

Feedback from early users of the Brushless Angle Grinder has been overwhelmingly positive, with many praising its performance, ergonomics, and overall durability. Professionals in industries such as construction, metal fabrication, and automotive repair have already adopted the tool into their daily operations, citing its reliability and efficiency.

With the introduction of the Brushless Angle Grinder, [Company Name] continues to solidify its position as a leader in the power tools industry. The company's commitment to innovation, quality, and user satisfaction is evident in this latest offering, and it is poised to make a significant impact in the market.

For more information about the Brushless Angle Grinder and other products from [Company Name], please visit [Company Website] or contact [Company Name] directly.

Company News & Blog

Discover the Best Cut and Polish Pads for Achieving Stunning Results

Cut And Polish Pads Revolutionize the Auto Detailing Industry[Company Introduction]In a ground-breaking development, prominent auto care company [Company Name] has harnessed cutting-edge technology to create the highly anticipated Cut And Polish Pads. This innovative product is poised to revolutionize the auto detailing industry, providing professionals and enthusiasts alike with unprecedented efficiency and performance in the quest for a mirror-like finish.With over X years of experience, [Company Name] has firmly established itself as a leader in the auto care industry. The company's commitment to research, development, and customer satisfaction has allowed it to consistently deliver exceptional products. Now, with the introduction of Cut And Polish Pads, [Company Name] is once again setting new standards within the industry.[Product Description]Designed with meticulous attention to detail and engineered with state-of-the-art materials, Cut And Polish Pads take the art of auto detailing to a whole new level. These pads are specifically formulated to deliver superior results, effortlessly restoring the brilliance and shine of any vehicle's paintwork.The secret behind the unparalleled effectiveness of Cut And Polish Pads lies in their advanced composition. Made from a unique combination of microfibers and innovative abrasives, these pads boast an exceptional cutting capacity while minimizing the risk of swirl marks and scratching. This revolutionary design ensures an efficient and safe restoration process, providing users with the confidence they need to achieve professional-grade results.Furthermore, Cut And Polish Pads are available in a variety of sizes and aggressiveness levels, allowing users to tailor their approach based on the condition of the paintwork. This versatility ensures that both experts and novices can achieve optimal results with ease, offering a truly user-friendly experience.[Industry Impact]The introduction of Cut And Polish Pads is set to create ripples throughout the auto detailing industry. Professionals will now enjoy a significant reduction in time required to restore paintwork, as the cutting power of these pads greatly expedites the correction process. This efficiency translates into increased customer satisfaction and improved profitability for detailing businesses.The DIY auto care market will also benefit greatly from this technological advancement. Enthusiasts who take pride in maintaining their vehicle's appearance will find Cut And Polish Pads indispensable. The ease of use and outstanding results offered by these pads will empower car owners to effortlessly enhance the aesthetic appeal of their vehicles, all within the comfort of their own garages.Moreover, Cut And Polish Pads align perfectly with the industry's growing emphasis on sustainability. By minimizing the need for harsh chemicals and reducing the necessity of multiple passes during the detailing process, these pads contribute to a more eco-friendly approach to auto care.[Widespread Adoption]As word spreads about the remarkable capabilities of Cut And Polish Pads, enthusiasm for this ground-breaking product is rapidly growing. [Company Name] is working closely with distributors worldwide to meet the increasing demand. Additionally, the company is investing in comprehensive training programs to ensure that professionals and enthusiasts alike can utilize these pads to their full potential.In conclusion, the introduction of Cut And Polish Pads marks a significant milestone in the auto detailing industry. This innovative product, developed by [Company Name], promises to transform the way professionals and DIY enthusiasts approach auto care. With its unrivaled cutting power, ease of use, and sustainable nature, Cut And Polish Pads have secured their position as a game-changer in the pursuit of automotive perfection.

Understanding the Basics of Metallic Bond Chemical Bonds

Metallic Bond Chemical Bonds, a leading chemical company specializing in the production of high-quality metallic bonds for various industrial applications, has recently announced the launch of its latest line of advanced metallic bonding agents. These cutting-edge chemical compounds are designed to provide exceptional bonding strength and durability for a wide range of metal-based materials, making them an ideal choice for use in industries such as automotive, aerospace, construction, and manufacturing.With a strong focus on innovation and continuous improvement, Metallic Bond Chemical Bonds has dedicated significant resources to research and development in order to create the most effective and reliable metallic bonding solutions on the market. The company's team of experienced chemists and engineers have worked tirelessly to develop a proprietary formulation that offers superior adhesion and performance, setting a new standard for quality and effectiveness in the industry.One of the key advantages of Metallic Bond Chemical Bonds' latest products is their ability to form strong, long-lasting bonds with a variety of metals, including steel, aluminum, copper, and titanium. This versatility makes them well-suited for a wide range of applications, from bonding metal components in automotive manufacturing to securing structural elements in architectural projects. In addition, these advanced metallic bonding agents are formulated to withstand extreme environmental conditions, including high temperatures, corrosive chemicals, and heavy mechanical loads, ensuring reliable performance in even the most demanding operating environments.In a statement, the company's CEO expressed great enthusiasm for the new product line, noting that the development of these advanced metallic bonding agents represents a significant milestone for Metallic Bond Chemical Bonds. "We are thrilled to introduce our latest line of metallic bonding solutions to the market," said the CEO. "These products are the result of years of dedicated research and development, and we are confident that they will set a new standard for performance and reliability in the industry. We believe that our customers will greatly benefit from the exceptional bonding strength and durability that our products offer."As part of the launch, Metallic Bond Chemical Bonds is offering comprehensive technical support and assistance to help customers integrate the new metallic bonding agents into their manufacturing processes. The company's team of experts is available to provide guidance on product selection, application techniques, and compatibility considerations, ensuring that customers can achieve optimal results with the new products.Furthermore, Metallic Bond Chemical Bonds has also emphasized its commitment to sustainability and environmental responsibility in the development and production of its metallic bonding agents. The company has implemented rigorous quality control processes and environmental management systems to minimize its environmental footprint and ensure that its products adhere to the highest standards of environmental performance.With its latest line of advanced metallic bonding agents, Metallic Bond Chemical Bonds is poised to further strengthen its position as a leading provider of high-performance chemical solutions for industrial applications. The company's unwavering dedication to innovation, quality, and customer satisfaction has earned it a strong reputation in the industry, and the introduction of these new products is expected to further solidify its standing as a trusted partner for businesses seeking advanced metallic bonding solutions.

Ultimate Guide to Wet/Dry Polishing Pads for a Perfect Finish

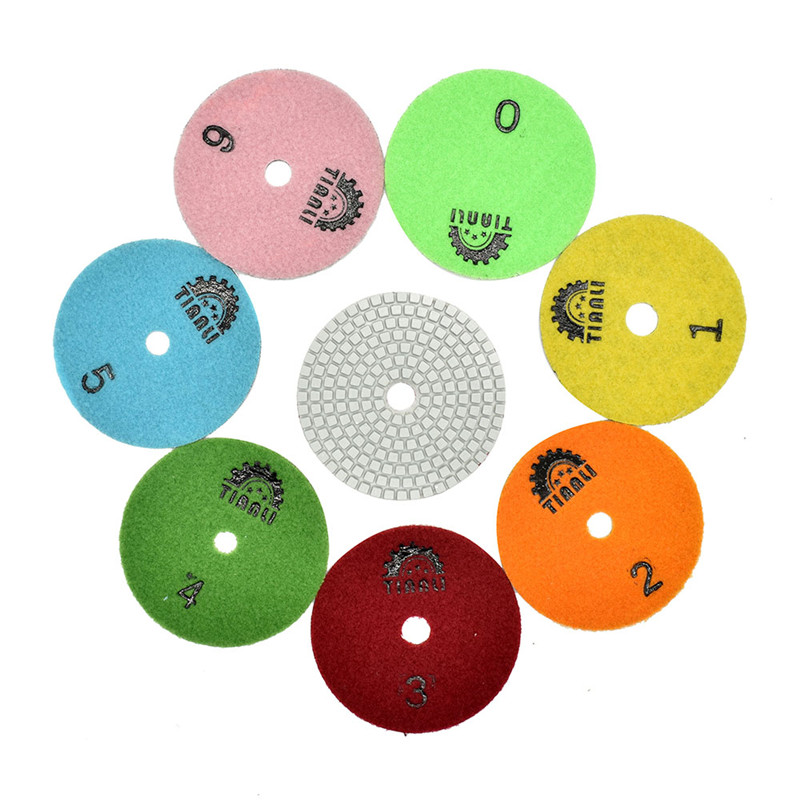

For Immediate ReleaseWet/Dry Polishing Pads Revolutionize Surface Polishing[Company Name], a leading manufacturer of high-quality surface polishing products, has introduced a new line of Wet/Dry Polishing Pads that are set to revolutionize the industry. The innovative design and advanced technology of these pads make them suitable for use on a wide range of surfaces, providing exceptional results with both wet and dry applications.The new Wet/Dry Polishing Pads from [Company Name] are engineered to deliver superior performance and durability, making them ideal for professional contractors, DIY enthusiasts, and anyone else seeking high-quality surface polishing solutions. These pads are designed to be used on various materials, including granite, marble, engineered stone, and concrete, making them versatile and highly efficient for a wide range of polishing projects.One of the key features of the Wet/Dry Polishing Pads is their ability to perform exceptionally well in both wet and dry applications. This versatility allows users to achieve exceptional results without the need for multiple sets of pads, saving both time and money. Whether working on a wet surface or dry, these pads deliver consistent and professional results, making them a valuable addition to any polishing toolkit.The advanced technology used in the manufacturing of these pads ensures exceptional performance and longevity. The diamond particles embedded in the pads are designed to provide maximum abrasion and durability, ensuring that they maintain their performance over extended periods of use. This means that users can rely on these pads to deliver consistent results, project after project, without the need for frequent replacements.In addition to their exceptional performance, the Wet/Dry Polishing Pads from [Company Name] are also designed with user convenience in mind. The Velcro backing on the pads makes them easy to attach and remove from polishing equipment, allowing for quick and efficient pad changes. This convenient feature saves time and effort, allowing users to focus on achieving the best possible results with minimal downtime.Furthermore, the Wet/Dry Polishing Pads are available in a range of grit sizes, allowing users to select the most suitable option for their specific polishing needs. Whether working on a coarse or fine surface, these pads provide the versatility and flexibility needed to achieve outstanding results on a wide range of materials.[Company Name] takes pride in its commitment to delivering high-quality surface polishing products that exceed the expectations of its customers. With the introduction of the Wet/Dry Polishing Pads, the company continues to demonstrate its dedication to innovation and excellence in the industry. The superior performance, durability, and versatility of these pads make them a standout choice for anyone seeking top-quality surface polishing solutions.As a trusted leader in the industry, [Company Name] remains dedicated to providing exceptional products and unparalleled customer service. The introduction of the Wet/Dry Polishing Pads further cements the company's reputation as a go-to source for high-quality surface polishing products, and solidifies its position as a leader in the industry.In conclusion, the new line of Wet/Dry Polishing Pads from [Company Name] represents a significant advancement in surface polishing technology. With their exceptional performance, versatility, and durability, these pads are set to revolutionize the industry and set a new standard for surface polishing products. Whether used by professional contractors or DIY enthusiasts, these pads offer the reliability and quality needed to achieve outstanding results on a wide range of materials. For anyone seeking high-quality surface polishing solutions, the Wet/Dry Polishing Pads from [Company Name] are the ideal choice.

Effective Dry Polishing Pads for Diamond Finishing

Introducing the Revolutionary Diamond Dry Polishing Pads, a game-changing innovation in the field of polishing and finishing services for a wide range of materials. These remarkable pads are designed to provide a superior finish on various surfaces, including granite, marble, concrete, and engineered stone. The remarkable technology behind these pads enables quick and efficient polishing, while also delivering exceptional results.The company behind this groundbreaking product, {Company Name}, is a leading provider of high-quality polishing tools and equipment. With years of experience in the industry, the company has gained a reputation for delivering innovative and reliable solutions for professional contractors, DIY enthusiasts, and commercial operators. Their commitment to excellence and dedication to customer satisfaction have made them a trusted name in the industry.The Diamond Dry Polishing Pads are a testament to the company's dedication to providing high-quality products that deliver outstanding results. These pads are designed to be used with dry polishing techniques, making them exceptionally versatile and easy to use. They are ideal for use in a wide range of applications, including countertop polishing, floor refinishing, and restoration projects.One of the key features of these pads is their diamond-infused design, which allows for superior polishing and finishing capabilities. The diamond particles embedded in the pads ensure a consistent and uniform finish, while also providing exceptional durability and longevity. This means that users can achieve stunning results with minimal effort and time, making the Diamond Dry Polishing Pads a valuable addition to any polishing toolkit.In addition to their superior performance, these pads are also designed with user convenience in mind. The Velcro backing ensures easy and secure attachment to polishing tools, while the flexible design allows for smooth and seamless operation on curved and uneven surfaces. This versatility makes the pads suitable for a wide range of applications, from small-scale projects to large-scale commercial jobs.The Diamond Dry Polishing Pads are available in various grit sizes, allowing for different levels of polishing and finishing. Whether a user requires a coarse finish for heavy grinding or a fine finish for final polishing, these pads can deliver exceptional results every time. Furthermore, the long lifespan of these pads ensures that users can achieve consistent results over an extended period, making them a cost-effective solution for all polishing needs.The company is also dedicated to providing exceptional customer support and service. From product selection to technical assistance, their team of experts is on hand to provide guidance and advice to ensure that customers get the most out of their polishing tools. This commitment to customer satisfaction sets the company apart and makes them the go-to choice for professionals and enthusiasts alike.The Diamond Dry Polishing Pads are revolutionizing the way surfaces are polished and finished. With their exceptional performance, versatility, and durability, these pads are a valuable addition to any polishing toolkit. Whether for commercial or residential use, these pads are designed to deliver exceptional results and provide an unmatched polishing experience. With the backing of a trusted and reputable company, users can have confidence in the quality and reliability of these innovative polishing pads.

Revolutionary Floor Grinders that Mimic Manual Grinding Movements for Optimal Polishing

Title: Diamond Grinding Machine Floor: Revolutionizing Construction with Cutting-Edge TechnologyIntroduction Paragraph:In a bid to enhance efficiency and empower construction professionals, the groundbreaking Diamond Grinding Machine Floor presents a technological marvel that is set to redefine the industry standards. Its novel design effectively mimics the rocking sidetoside movements traditionally made manually by operators, making it a game-changer in the construction arena. Developed by Husqvarna, a globally recognized industry leader in providing construction solutions, the Diamond Grinding Machine Floor encompasses a wide range of machines and diamond tools, enabling professionals to leverage advanced technology for precision grinding and polishing.Body:1. Pioneering Technology for Enhanced Efficiency (100 words)The Diamond Grinding Machine Floor is equipped with cutting-edge technology, providing construction professionals with an unparalleled solution for their grinding and polishing needs. One of its standout features is its capability to seamlessly mimic the traditional sidetoside movements performed manually by operators. This unique feature eliminates the physical strain on operators, reducing fatigue and enhancing overall productivity. By automating this process, the Diamond Grinding Machine Floor ensures consistent and precise results, delivering a level of efficiency that was previously unattainable with traditional grinding machines.2. Three Main Benefits of Diamond Grinding Machine Floor (200 words)The Diamond Grinding Machine Floor offers three primary benefits that are set to revolutionize construction practices:a. Reduced Operator Fatigue: Traditional grinding machines require the operator to perform repetitive sidetoside movements manually. This repetitive motion can lead to fatigue and strain injuries. With the Diamond Grinding Machine Floor, operators can now experience reduced fatigue as the machine mimics the manual rocking movements, eliminating strain and optimizing overall operational efficiency.b. Superior Precision and Consistency: By automating the sidetoside movements, the Diamond Grinding Machine Floor ensures a consistently level and even grinding or polishing surface. This results in superior precision and a flawless finish, a crucial factor in meeting strict industry standards and client expectations.c. Increased Productivity: The automation of the rocking sidetoside movements provides an immense boost to productivity. Construction professionals can now accomplish more in less time, translating into improved profitability and quicker turnaround times for projects.3. The Support and Expertise of Husqvarna (150 words)The Diamond Grinding Machine Floor is an achievement brought to you by Husqvarna, a renowned name in the construction industry. Husqvarna has established itself as a leader in providing innovative solutions, including a diverse range of machines and diamond tools. Backed by decades of experience and a deep-rooted passion for excellence, Husqvarna offers complete support and service to construction professionals, helping them make the most of the Diamond Grinding Machine Floor. From consultation to training and ongoing assistance, Husqvarna stands as an unwavering partner for all construction needs. The company's commitment to delivering top-notch solutions, along with a focus on sustainable practices, has earned it a well-deserved reputation and the trust of professionals worldwide.4. Beyond Diamond Grinding Machine Floor: Husqvarna's Comprehensive Solutions (250 words)Husqvarna caters to a vast array of construction requirements, providing a comprehensive range of machines, diamond tools, and associated services. Their extensive portfolio encompasses cutting, grinding, and drilling equipment, along with advanced technologies for surface preparation and polishing. The company's commitment to pushing boundaries and meeting customer demands drives continuous innovation and elevates the industry standards. Husqvarna's diamond tools are designed to tackle all surfaces and materials, ensuring outstanding performance even in the most demanding conditions. With their relentless focus on research and development, Husqvarna consistently introduces groundbreaking designs, enabling professionals to achieve exceptional results.Additionally, Husqvarna's commitment towards sustainability is evident in their products. The Diamond Grinding Machine Floor, like many other machines, is designed to minimize energy consumption and reduce environmental impact. This environmentally conscious approach aligns with Husqvarna's vision of providing sustainable solutions that not only benefit the construction industry but also contribute to creating a greener future.Conclusion Paragraph:The Diamond Grinding Machine Floor by Husqvarna is a technological wonder that is set to reshape the construction landscape. With its ability to mimic sidetoside movements traditionally made manually, this innovative machine brings a newfound level of efficiency, precision, and productivity to the industry. Backed by Husqvarna's expertise, support, and comprehensive range of machines and diamond tools, construction professionals now have the means to achieve flawless results while reducing fatigue and maximizing their project's profitability. With the Diamond Grinding Machine Floor, Husqvarna continues to spearhead advancements in construction technology, revolutionizing the way professionals approach grinding and polishing tasks.

Effective 3 Step Polishing Pads for High Quality Results

Introducing the Next Level of Polishing Technology: 3 Step Polishing PadsIn the ever-evolving world of automotive detailing and polishing, innovation is key to staying ahead of the competition. With this in mind, [Company Name] is proud to introduce our latest breakthrough in polishing technology - the 3 Step Polishing Pads.These new pads have been meticulously designed and engineered to provide a superior polishing experience, delivering impeccable results with minimal effort. Through extensive research and development, our team has created a product that is set to revolutionize the industry and set a new standard for excellence.The 3 Step Polishing Pads are the result of [Company Name]'s commitment to pushing the boundaries of what is possible in the world of automotive care. With a focus on quality, performance, and user-friendliness, these pads are poised to become an essential tool for professionals and enthusiasts alike.What sets the 3 Step Polishing Pads apart from traditional polishing methods is their unique three-step process. Each pad is specifically designed for a particular stage of the polishing process, allowing for a seamless and efficient workflow. From initial cutting and leveling to refining and finishing, these pads are engineered to deliver unparalleled results with precision and consistency.Furthermore, the 3 Step Polishing Pads are compatible with a wide range of polishing machines, making them a versatile and practical choice for any detailing professional. Whether you are working on paint correction, refinishing, or restoration, these pads are up to the task, delivering a flawless finish every time.In addition to their exceptional performance, the 3 Step Polishing Pads are also designed with durability in mind. Constructed from high-quality materials and engineered to withstand rigorous use, these pads are built to last. This not only ensures a reliable and consistent performance but also makes them a cost-effective choice for professionals looking to maximize their investment.At [Company Name], we take great pride in our commitment to excellence, and the introduction of the 3 Step Polishing Pads is a testament to that commitment. We are dedicated to providing our customers with the highest quality products that not only meet but exceed their expectations. With these new pads, we are confident that our customers will experience a new level of excellence in their polishing endeavors.As part of our dedication to customer satisfaction, we also offer comprehensive support and guidance to ensure that our customers get the most out of their 3 Step Polishing Pads. Whether you are a seasoned professional or a novice enthusiast, our team is ready to provide the knowledge and expertise needed to achieve outstanding results.In conclusion, the introduction of the 3 Step Polishing Pads marks a significant milestone for [Company Name] and the automotive detailing industry as a whole. By combining cutting-edge technology with unparalleled performance, these pads are set to redefine the standard for polishing excellence. Whether you are a detailing professional looking to elevate your craft or an enthusiast seeking to achieve showroom-quality results, the 3 Step Polishing Pads are the ultimate solution.With a relentless pursuit of innovation and a steadfast commitment to quality, [Company Name] is proud to present the 3 Step Polishing Pads as the next evolution in automotive polishing technology. Experience the difference for yourself and discover a new level of perfection with the 3 Step Polishing Pads from [Company Name].

Effective Wet Polishing Pads for Concrete Surfaces

XIAMEN, China - The global leader in manufacturing high-quality stone and concrete products, {Company Name}, is excited to introduce its latest innovation in the field of concrete polishing - the Wet Polishing Pads Concrete. This revolutionary product is set to redefine the standards of concrete polishing in the industry, offering unmatched efficiency and performance.Designed to be used with water, the Wet Polishing Pads Concrete are equipped with advanced technology that allows for smooth and consistent polishing of concrete surfaces. Whether it's for a residential driveway, commercial flooring, or industrial concrete surfaces, these pads are engineered to deliver exceptional results every time. The key to the success of these pads lies in their unique composition, which consists of high-quality diamonds and resins. This combination ensures maximum durability and effectiveness, making them an indispensable tool for professional concrete polishing contractors.One of the standout features of the Wet Polishing Pads Concrete is their ability to reduce the risk of over-heating during the polishing process, thanks to the water lubrication. This not only enhances the longevity of the pads but also contributes to a safer working environment for the operators.Furthermore, these pads are designed to deliver a superior finish on various hardness levels of concrete, from soft to extremely hard surfaces. This versatility makes them a valuable asset for contractors who work on a wide range of concrete projects.In addition to their exceptional performance, the Wet Polishing Pads Concrete are also designed with user convenience in mind. Their easy-to-use nature ensures that even inexperienced operators can achieve professional results, thereby expanding the accessibility of high-quality concrete polishing.The introduction of the Wet Polishing Pads Concrete serves as a testament to {Company Name}'s relentless commitment to innovation and excellence. With a track record of delivering cutting-edge solutions to the stone and concrete industry, the company continues to raise the bar with each new product release.Established in 1993, {Company Name} has consistently been at the forefront of the industry, providing a wide range of products including diamond tools, polishing abrasives, and machinery for stone and concrete processing. With a focus on research and development, the company has invested heavily in state-of-the-art manufacturing facilities and a team of experienced engineers and technicians.Moreover, {Company Name} takes pride in its commitment to environmental sustainability. The company's manufacturing processes adhere to strict environmental standards, ensuring that its products are not only high-performing but also eco-friendly.In addition to its technological prowess, {Company Name} places a strong emphasis on customer satisfaction. The company's global distribution network and prompt customer support have earned it a reputation for reliability and trustworthiness among its diverse clientele.Looking ahead, {Company Name} is poised to continue its legacy of driving innovation in the stone and concrete industry, with a keen focus on developing products that cater to the evolving needs of its customers.The launch of the Wet Polishing Pads Concrete is a significant milestone for {Company Name}, marking yet another step forward in its mission to empower contractors with the tools they need to achieve unparalleled results in concrete polishing. As the product makes its way to markets worldwide, it is poised to set a new standard for efficiency and excellence in the field of concrete polishing.

Suppliers of Abrasives and Welding Equipment: Reviews and Product Info

Title: Enhancing Metal Finishing Processes with High-Quality AbrasivesIntroduction (approx. 100 words):When it comes to achieving stellar results in metal finishing processes, using top-notch abrasives is crucial. From sandpapers and grinding wheels to polishing compounds, these abrasive materials play a significant role in refining metal surfaces, removing imperfections, and ensuring a smooth end result. In this blog, we will delve into the world of abrasives, shedding light on the importance of choosing reputable suppliers and the benefits of utilizing high-quality metal abrasives. Join us as we explore the key factors to consider when selecting abrasives and learn how they can elevate your metal finishing processes to new heights.1. Understanding the Role of Abrasives in Metal Finishing (approx. 200 words):Metal finishing encompasses a wide range of processes, such as abrasive blasting, grinding, sanding, and polishing. These techniques aim to improve the appearance, functionality, and longevity of metal surfaces. At the core of each process lies the abrasive materials, which streamline the entire metal finishing journey.Abrasives serve as the key agents of change in metal finishing by removing unwanted material layers, leveling imperfections, and ensuring a uniform surface. They can be categorized based on their composition, size, and intended purpose. From natural abrasive minerals like garnet and diamond to synthetic options like aluminum oxide and silicon carbide, suppliers offer an extensive range of metal abrasives suitable for various applications.2. The Importance of Reliable Abrasive Suppliers (approx. 250 words):When selecting a supplier for your metal abrasives, it is crucial to prioritize reliability, quality, and customer service. Choosing the wrong supplier can lead to subpar products, delays, and overall dissatisfaction. Therefore, thorough research and consideration are necessary to make an informed decision.Reliable suppliers boast impeccable track records and positive customer reviews. These indicators of customer satisfaction are a testament to the supplier's commitment to quality. By collaborating with established suppliers, you gain access to a wide range of high-quality metal abrasives that will enhance your metal finishing processes.Additionally, reputable suppliers often provide ample product and service information, empowering customers to make well-informed purchasing decisions. Detailed profiles of suppliers allow you to understand their expertise, experience, and capabilities, enabling you to choose a partner that aligns with your specific needs.3. Benefits of High-Quality Metal Abrasives (approx. 250 words):Investing in high-quality metal abrasives can transform your metal finishing processes and yield remarkable results. Here are some key benefits of using premium abrasives:- Enhanced Efficiency: High-quality abrasives exhibit superior cutting, grinding, and polishing capabilities, allowing you to accomplish tasks more efficiently, saving both time and resources.- Superior Surface Finish: Premium abrasives enable you to achieve impeccable surface finishes by removing imperfections, scratches, and roughness efficiently, resulting in aesthetically pleasing and durable metal surfaces.- Extended Abrasive Lifespan: Top-notch metal abrasives often boast increased durability and longevity, reducing the need for frequent replacements and leading to cost savings in the long run.- Consistency and Precision: Reliable suppliers ensure consistent quality across their abrasive products, promoting precise performance and predictable outcomes in your metal finishing processes.Conclusion (approx. 150 words):Choosing the right supplier for your metal abrasive needs is paramount to achieve exceptional results in metal finishing processes. By selecting reputable suppliers and investing in high-quality metal abrasives, you can enhance efficiency, improve surface finishes, extend abrasives' lifespan, and achieve consistent and precise outcomes. Take advantage of the wide array of metal abrasives available in the market and revolutionize your metal finishing processes today.

Ultimate Guide to Diamond Grinding Drum Wheel: What You Need to Know

Diamond Grinding Drum Wheel, a revolutionary product by a leading company in the construction industry, has been creating waves in the market with its superior performance and efficiency. This innovative tool has been designed to provide exceptional results in various concrete grinding applications, making it a preferred choice for contractors and professionals.The Diamond Grinding Drum Wheel, which is available in a range of sizes and grits, is manufactured using high-quality diamonds that are bonded to a metal body. This combination ensures exceptional durability and long-lasting performance, making it a cost-effective solution for heavy-duty grinding tasks. The tool is also designed to deliver fast and smooth grinding results, reducing the overall time and effort required for the job.One of the key features of the Diamond Grinding Drum Wheel is its ability to effectively remove coatings, adhesives, and other surface contaminants from concrete, making it an ideal choice for surface preparation work. Its aggressive grinding action and efficient material removal capabilities make it a valuable tool for a wide range of applications, including concrete polishing, concrete leveling, and general surface grinding.The company behind the Diamond Grinding Drum Wheel has a strong reputation for producing high-quality construction tools and equipment. With years of experience in the industry, the company has developed a deep understanding of the needs and requirements of contractors and professionals, allowing them to create products that meet and exceed industry standards.In addition to its commitment to quality, the company also places a strong emphasis on innovation and technology. The Diamond Grinding Drum Wheel is a prime example of this, as it represents a new and advanced approach to concrete grinding that delivers exceptional results. By investing in research and development, the company continues to push the boundaries of what is possible in the construction industry, providing its customers with cutting-edge solutions that improve productivity and performance.Furthermore, the company's dedication to customer satisfaction is evident in its comprehensive support services. From product selection and technical advice to after-sales support, the company ensures that its customers are fully supported throughout their projects. This commitment to service has earned the company a loyal customer base and a solid reputation for reliability and professionalism.The Diamond Grinding Drum Wheel has already garnered a positive response from the market, with contractors and professionals praising its performance and reliability. Many have noted the significant time and cost savings achieved by using this innovative tool, making it a valuable addition to their arsenal of equipment.Looking ahead, the company is set to continue its focus on developing advanced solutions for the construction industry. With a strong emphasis on quality, innovation, and customer satisfaction, the company is well-positioned to lead the way in delivering cutting-edge tools and equipment that meet the evolving needs of the market.In conclusion, the Diamond Grinding Drum Wheel is a game-changer in the field of concrete grinding, offering superior performance, durability, and efficiency. With the backing of a reputable and innovative company, this revolutionary tool is set to make a significant impact on the industry, providing contractors and professionals with a valuable solution for their surface preparation and grinding needs.

New Drill Bit Polishing Pad for Enhanced Tool Performance

The world-renowned company, with decades of experience in the manufacturing and production of high-quality industrial tools and equipment, has recently introduced a revolutionary new product to the market – the Drill Bit Polishing Pad. This innovative and cutting-edge tool is set to change the way that professionals in the drilling and metalworking industries approach their work.The Drill Bit Polishing Pad is a result of years of research and development, drawing on the company’s extensive expertise in the field. It has been designed to address a common challenge faced by professionals in the industry – the need to maintain and restore the sharpness and effectiveness of drill bits. Over time, drill bits can become worn and dull, reducing their efficiency and leading to increased downtime and costs for businesses. The Drill Bit Polishing Pad offers a simple and effective solution to this problem, allowing users to quickly and easily restore the sharpness of their drill bits, thereby extending their lifespan and improving overall productivity.The key to the effectiveness of the Drill Bit Polishing Pad lies in its innovative design and construction. Made from high-quality materials that have been specifically chosen for their durability and performance, the polishing pad is capable of removing burrs, sharpening edges, and restoring the cutting ability of drill bits with ease. Furthermore, its ergonomic design and user-friendly interface make it simple and intuitive to use, allowing professionals of all levels to benefit from its capabilities.In addition to its practical benefits, the Drill Bit Polishing Pad also boasts a number of features that set it apart from other similar products on the market. For instance, it is designed to be compatible with a wide range of drill bits, regardless of their size or material. This means that it offers a versatile solution that can be used across different applications and industries. Furthermore, the polishing pad is also designed to be long-lasting and resistant to wear and tear, ensuring that it will continue to deliver exceptional results over an extended period of time.The introduction of the Drill Bit Polishing Pad represents a significant milestone for the company, further solidifying its reputation as a leader in the industry. With a track record of delivering innovative and reliable products, the company has earned the trust and respect of professionals around the world. The release of the polishing pad serves to reinforce this reputation, demonstrating the company’s ongoing commitment to meeting the needs of its customers and pushing the boundaries of what is possible in the field of industrial tools and equipment.As the drilling and metalworking industries continue to evolve and demand increasingly high levels of performance and efficiency, the introduction of the Drill Bit Polishing Pad comes at a crucial time. By providing professionals with a tool that is capable of enhancing the performance and longevity of their drill bits, the company is empowering them to work more effectively and sustainably. This, in turn, has the potential to drive positive outcomes for businesses across the industry, helping them to streamline their operations and achieve greater levels of success.In conclusion, the introduction of the Drill Bit Polishing Pad represents a significant step forward for the company, as well as a game-changing development for the drilling and metalworking industries as a whole. With its innovative design, practical benefits, and versatile capabilities, the polishing pad has the potential to have a lasting impact on the way that professionals approach their work. As the company continues to push the boundaries of what is possible in the industry, it is clear that they are committed to driving positive change and delivering exceptional solutions to meet the needs of their customers.