Newly Developed Disc Grinding Wheel Offers Superior Performance and Durability

By:Admin

Introduction:

Marching ahead with its commitment to innovation and excellence, [Company Name] has introduced an advanced Disc Grinding Wheel that promises to revolutionize the grinding industry. With its cutting-edge technology and superior design, this state-of-the-art grinding wheel delivers unparalleled precision and efficiency, catering to the diverse needs of multiple industries. In this article, we will delve into the features and benefits of the Disc Grinding Wheel while shedding light on how it is set to transform the landscape of grinding.

Precise and Reliable Performance:

The Disc Grinding Wheel, developed by [Company Name], offers an exceptional level of precision and reliability in grinding applications. Designed with meticulous attention to detail, this product ensures the highest standards of accuracy, making it a top choice for professionals across industries such as automotive, aerospace, metalworking, and more. The grinding wheel's innovative composition allows for consistent and uniform contact with the workpiece, resulting in a smooth finish with minimal tolerances.

Enhanced Efficiency and Productivity:

One of the key advantages of the Disc Grinding Wheel is its ability to enhance efficiency and productivity in grinding operations. Thanks to its advanced abrasive technology, this grinding wheel provides exceptional material removal rates, reducing the time required for grinding tasks. This efficiency not only boosts productivity but also reduces operational costs, making it a cost-effective solution for companies aiming to optimize their manufacturing processes.

Durability and Longevity:

[Company Name]'s Disc Grinding Wheel is built to withstand rigorous usage, ensuring long-lasting performance. Constructed with high-quality abrasives and reinforced materials, this grinding wheel offers exceptional durability even when used in intense grinding environments. Its robust composition minimizes the risk of deformation or breakage, ensuring consistent performance over extended periods of use. This durability translates into reduced downtime for maintenance and replacement, further increasing efficiency and productivity.

Safe and User-Friendly:

Safety is paramount in any industrial setting. Recognizing this, [Company Name] has prioritized the safety aspects of the Disc Grinding Wheel. With carefully engineered designs, this product offers a high level of user-friendliness, reducing the risk of accidents or injuries. Its ergonomic grip and vibration reduction technology ensure optimum control and comfort during operation, minimizing operator fatigue and enhancing overall safety.

Wide Range of Applications:

The versatile nature of the Disc Grinding Wheel allows it to excel in various industrial sectors. From surface grinding and edge rounding to deburring and polishing, this grinding wheel can handle a wide range of applications with exceptional efficiency and precision. Its adaptability and versatility make it suitable for use across diverse industries such as automotive, aerospace, construction, and more, ensuring a cost-effective and reliable solution for grinding needs in different sectors.

Sustainability and Environmental Responsibility:

In line with [Company Name]'s commitment to sustainability and environmental responsibility, the Disc Grinding Wheel adheres to strict eco-friendly manufacturing practices. Constructed with fewer abrasive materials, this grinding wheel minimizes waste generation and reduces environmental impact. Additionally, its longevity and durability further contribute to reducing material consumption and waste generation, positioning it as an environmentally conscious choice.

Conclusion:

With [Company Name]'s introduction of the advanced Disc Grinding Wheel, the grinding industry is poised to experience a significant transformation. Combining precision, efficiency, durability, and sustainability, this state-of-the-art product is set to redefine the standards of grinding performance. By catering to a wide range of industries and applications, it serves as a reliable and cost-effective solution for professionals seeking unparalleled results. [Company Name] continues to innovate and push boundaries, enabling companies to achieve new heights of productivity and quality in their grinding operations.

Company News & Blog

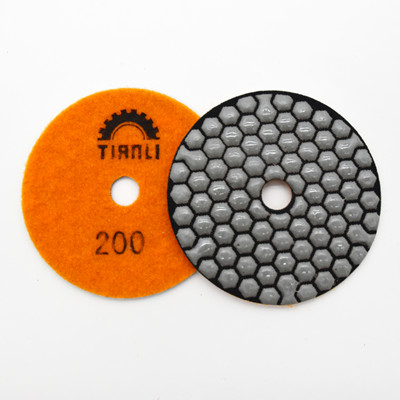

High-Quality Diamond Polishing Pads for Natural Stone, Granite, and Marble

Title: Achieve Flawless Shine with Diamond Dry Polishing Pads Set: The Ultimate GuideIntroduction:When it comes to achieving a pristine surface on natural stone, such as granite and marble, diamond polishing pads have emerged as the go-to tool. These incredible pads offer the versatility of both wet and dry polishing, enabling users to attain a mesmerizing shine effortlessly. In this comprehensive blog, we will explore the wonders of diamond dry polishing pads set, their features, benefits, and how they are revolutionizing the world of stone polishing. So, let's dive in!1. Understanding Diamond Dry Polishing Pads:Diamond dry polishing pads are a cutting-edge solution designed to transform dull and lackluster natural stone surfaces into a dazzling masterpiece. Their primary objective is to remove scratches, marks, and imperfections while providing a high-gloss finish. These pads combine the effectiveness of diamond particles with unique bonding technology, ensuring unparalleled performance.2. Features of Diamond Dry Polishing Pads Set:- Premium Quality: Crafted using high-quality materials, these pads are highly durable and resistant to wear and tear.- Versatility: Suitable for both wet and dry polishing, these pads can adapt to various polishing techniques, allowing users to choose the method that works best for them.- Different Grit Options: Diamond dry polishing pads are available in different grits, ranging from coarse to fine. This diversity in grit levels allows users to customize their polishing process based on the specific requirements of the stone surface.- Easy Attachment: These pads are designed with a convenient hook and loop backing system, ensuring effortless attachment to polishing machines.- Uniform Polishing: The diamond particles on these pads are precisely distributed, ensuring consistent and uniform polishing across the entire surface.3. Key Benefits of Diamond Dry Polishing Pads Set:- Superior Polishing: The diamond particles embedded in these pads make them highly effective in removing blemishes, scratches, and stains from the stone, while leaving a pristine finish.- Time and Cost Savings: The versatility of these pads saves time and money by eliminating the need for multiple sets of polishing tools. Additionally, their durability ensures long-lasting performance, reducing the frequency of replacements.- Precision and Control: Whether you are a professional or a DIY enthusiast, these pads offer exceptional precision and control during the polishing process, allowing you to achieve desired results effortlessly.- Environmental Friendly: The dry polishing technique used with these pads reduces the water consumption associated with wet polishing methods, making it environmentally friendly.4. How to Use Diamond Dry Polishing Pads Set:- Step 1: Prepare the surface by cleaning it thoroughly, removing any dirt or debris.- Step 2: Select the appropriate pad grit level based on the current condition of the stone surface.- Step 3: Attach the pad to a compatible polishing machine using the hook and loop backing system.- Step 4: Begin the polishing process, applying moderate pressure and moving the machine in consistent circular or linear motions, depending on the desired finish.- Step 5: Repeat the process with gradually finer grit pads until the desired shine and smoothness are achieved.5. Conclusion:Diamond dry polishing pads have become indispensable tools for professionals and enthusiasts alike when it comes to achieving the perfect finish on natural stone surfaces. Their versatility, exceptional performance, and environmental friendly nature make them a preferable choice for any polishing project. By utilizing the features and benefits of diamond dry polishing pads, you can unlock the true beauty of your natural stone surfaces, enhancing their longevity and appeal.So, why wait? Equip yourself with a diamond dry polishing pads set today and witness the transformation of your stone surfaces like never before!Keywords: Diamond Dry Polishing Pads Set, natural stone, granite, marble, wet polishing, dry polishing, high-gloss finish, diamond particles, scratch removal, versatile, grit options, uniform polishing, time and cost savings, precision, control, environmentally friendly.

Tips and Tricks for Polishing Marble Floors to Restore Their Shine

Title: Marble Polishing: Tips and Tricks to Restore the Shine of Your Marble FloorsIntroduction:Marble floors are renowned for their elegance and timeless beauty, but over time, they can lose their shine and develop scratches and stains. Using the right marble polishing techniques and tools can help you restore the natural luster of your marble floors. In this blog post, we will guide you through the process of polishing marble, using polishing powder and pads for both dry and wet polishing methods.Keywords: Marble Polishing, Polishing Powder, Polishing Pads, Marble Floors, Restore ShineI. Understanding Marble Polishing:- What is marble polishing?- The importance of regular marble floor maintenance.- Difference between dry and wet marble polishing techniques.- Benefits of using polishing powder and pads for marble restoration.- Marble polishing tools and equipment needed for the job.Keywords: Marble Polishing, Regular Maintenance, Dry Polishing, Wet Polishing, Polishing Powder, Polishing Pads, Marble Restoration, Tools and Equipment.II. Preparing Your Marble Floors for Polishing:- Inspecting and identifying any damages or stains.- Clearing the room and protecting surrounding surfaces.- Removing dust and debris from the marble surface.- Filling any cracks or holes in the marble.Keywords: Damages, Stains, Surface Preparation, Dust Removal, Crack Filling.III. Dry Marble Polishing Method: Steps and Procedures:- Choosing the right polishing powder for dry polishing.- Applying the polishing powder evenly on the marble surface.- Working the powder into the marble using a floor machine and a polishing pad.- Repeating the process until the desired shine is achieved.- Cleaning and buffing the marble surface after dry polishing.Keywords: Dry Polishing Method, Polishing Powder, Even Application, Floor Machine, Polishing Pad, Cleaning, Buffing.IV. Wet Marble Polishing Method: Steps and Procedures:- Preparing a mixture of water and polishing powder for wet polishing.- Applying the mixture onto the marble surface using a sprayer or a sponge.- Working the mixture into the marble with a floor machine and a polishing pad.- Rinsing off any excess powder and residues.- Drying and buffing the marble surface after wet polishing.Keywords: Wet Polishing Method, Water and Polishing Powder Mixture, Application, Sprayer, Sponge, Rinsing, Drying, Buffing.V. Additional Marble Polishing Tips and Tricks:- Regular cleaning and maintenance practices to prolong the shine.- Using pH-neutral cleaners for routine maintenance.- Avoiding abrasive materials or cleaners that may harm the marble surface.- Utilizing a protective sealant to enhance durability and resistance.- Seeking professional help for extensive damages or deep stains.Keywords: Cleaning and Maintenance, pH-Neutral Cleaners, Abrasive Materials, Protective Sealant, Professional Assistance.Conclusion:By following these marble polishing techniques and utilizing the appropriate tools, you can restore the natural shine and appeal of your marble floors. Whether you choose the dry or wet polishing method, remember to prioritize regular cleaning and maintenance to keep your marble floors looking their best.

Quality Preparation Equipment for Sale in QLD and NSW - Visit Us Today!

Title: A Comprehensive Guide to Choosing and Using the Perfect 100mm Grinding WheelIntroduction (70 words):When it comes to preparing surfaces for various tasks, a high-quality grinding wheel is an indispensable tool. In this blog post, we will explore the features, benefits, and application of the 100mm grinding wheel. Whether you are a homeowner, DIY enthusiast, or professional contractor, understanding the nuances of this versatile tool will help you make informed choices and achieve optimum results. So, let's dive into the world of the 100mm grinding wheel!Section 1: Understanding the 100mm Grinding Wheel (150 words)The 100mm grinding wheel, also known as a 4-inch grinding wheel, is a widely used abrasive tool that is designed for various applications. It is typically made from a combination of abrasive particles and bonding agents, offering excellent durability and cutting ability. The size of the wheel allows for precise control and maneuverability, making it suitable for both small and large-scale projects.Section 2: Features and Benefits of the 100mm Grinding Wheel (200 words)- High Performance: The 100mm grinding wheel is specifically engineered to provide exceptional performance and longevity. Its abrasive particles are selected for their hardness and durability, ensuring efficient material removal without compromising the wheel's structural integrity.- Versatility: This grinding wheel is suitable for different materials, including metal, stone, concrete, and more. Its versatility makes it a favorite choice among contractors and DIY enthusiasts for a wide range of applications, such as sharpening, shaping, and smoothing surfaces.- Precise and Controlled Grinding: The 100mm wheel's size allows for precise control and maneuverability, making it ideal for detailed work. Whether you are removing rust, smoothing weld seams, or grinding down surfaces, you can achieve precise results with ease.- Compatibility: The 100mm grinding wheel is designed to fit various grinding tools, such as angle grinders and bench grinders. Its standard size ensures compatibility, making it readily available for both professionals and hobbyists.Section 3: Tips for Choosing the Right 100mm Grinding Wheel (300 words)- Consider the Material: Different grinding wheels are designed for specific materials. Ensure that the 100mm grinding wheel you choose is suitable for the material you intend to work with. For example, a wheel specifically designed for metal grinding may not be as effective for concrete surfaces.- Grit Size: The grit size determines the coarseness or fineness of the wheel. Smaller grit sizes provide smoother finishes, while larger grit sizes are ideal for rougher grinding tasks. Evaluate the desired outcome and choose the appropriate grit size accordingly.- Bonding Agent: The bonding agent holds the abrasive particles together. Opt for a wheel with a bonding agent that suits your application. For instance, a resin-bonded wheel is ideal for general-purpose tasks, while vitrified wheels are more suitable for heavy-duty applications.- Safety Considerations: Always prioritize safety when selecting a grinding wheel. Look for wheels with appropriate safety markings, such as ANSI (American National Standards Institute) or OSHA (Occupational Safety and Health Administration) approval. Additionally, ensure that the wheel has the appropriate speed rating to match your grinder.Conclusion (80 words):In summary, when it comes to surface preparation and grinding tasks, the 100mm grinding wheel is an essential tool in any DIY or professional toolkit. Its versatility, durability, and precise control make it an excellent choice for a range of applications. By understanding the features, benefits, and tips for choosing the right wheel, you can ensure optimal performance and successful outcomes. So, equip yourself with the perfect 100mm grinding wheel and let your projects shine with precision and efficiency.Keywords: 100mm grinding wheel, surface preparation, abrasive tool, precision grinding, versatile, compatibility, grit size, bonding agent, safety

Top-rated Cutting and Grinding Wheels for Precision Cutting

Cutting Edge Tools Introduces Innovative Cutting Wheel and Grinding Wheel for Enhanced PerformanceIn the ever-evolving world of manufacturing and construction, having access to reliable and efficient tools is paramount. Cutting Edge Tools, a leader in innovative cutting and grinding solutions, is proud to announce the launch of their new cutting wheel and grinding wheel, designed to deliver enhanced performance and reliability.With decades of experience in producing high-quality tools, Cutting Edge Tools has been committed to meeting the evolving needs of their customers. The introduction of the cutting wheel and grinding wheel demonstrates their dedication to providing the most efficient and effective options in the market.The newly launched cutting wheel is equipped with state-of-the-art technology that ensures precision and durability. The wheel's design allows for smooth and quick cuts across a variety of materials, including metal, wood, and plastic. The use of premium quality materials guarantees long-lasting performance, reducing the need for frequent replacements.One of the key features of the cutting wheel is its versatility. It offers compatibility with a range of power tools, making it an ideal choice for professionals in various industries. Whether it's for construction, automotive repair, or DIY projects, this cutting wheel proves to be an essential tool for any cutting application.In addition to the cutting wheel, Cutting Edge Tools has also developed a grinding wheel that delivers outstanding results. The grinding wheel is designed to provide a consistent and uniform finish on different surfaces. Its superior abrasive properties allow for efficient material removal, saving both time and effort.The grinding wheel has been engineered with user convenience in mind. It features an ergonomic design for comfortable handling and reduced fatigue during extended use. Additionally, its exceptional heat dissipation properties prevent overheating, ensuring optimal performance even under intense working conditions.The launch of the cutting wheel and grinding wheel marks Cutting Edge Tools' commitment to innovation and customer satisfaction. With extensive research and development, they have successfully created tools that not only meet but exceed industry standards."We are thrilled to introduce our cutting wheel and grinding wheel to the market," said {Company Representative}. "These tools are a testament to our dedication to excellence and provide our customers with efficient and reliable solutions for their cutting and grinding needs. We believe that these products will enhance productivity and assist professionals in achieving high-quality results."As a company, Cutting Edge Tools aims to deliver products of exceptional quality that are also environmentally sustainable. The cutting wheel and grinding wheel are manufactured using eco-friendly materials and production processes, reducing their impact on the environment.To ensure customer satisfaction, Cutting Edge Tools provides prompt customer service support and offers a warranty on all their tools. They are determined to maintain their reputation as a trustworthy and reliable provider of cutting and grinding solutions."Customer satisfaction is at the core of our business values," stated {Company Representative}. "We believe in building long-lasting relationships with our customers by providing them with top-notch products and exceptional service. Our cutting wheel and grinding wheel are a testament to our commitment to their success."Cutting Edge Tools continues to lead the industry with their dedication to innovation and their drive to meet the evolving needs of their customers. The cutting wheel and grinding wheel are just the beginning of a series of groundbreaking products set to revolutionize the cutting and grinding industry.With the launch of these advanced tools, Cutting Edge Tools remains at the forefront of the industry, providing professionals with reliable, efficient, and durable solutions for their cutting and grinding requirements.

Optimize Your Grinding Process with High-Quality Diamond Grinding Wheels

Diamond Grinding Wheels Revolutionize the Cutting and Grinding IndustryDiamond grinding wheels are one of the most innovative and efficient tools in the cutting and grinding industry. These wheels are a powerful alternative to traditional abrasive wheels and offer many benefits, including longer life, faster cutting speeds, and improved performance. The diamond grinding wheel (name removed for privacy) is leading the way in the development of these revolutionary tools.Diamond Grinding Wheels Offer Numerous Advantages Over Traditional Abrasive WheelsDiamond grinding wheels use diamond particles embedded in a metal matrix to cut through hard materials. This technology offers numerous advantages over traditional abrasive wheels. For example, diamond wheels have a longer life, which means they don't need to be replaced as often as their abrasive counterparts. They also have faster cutting speeds and can handle higher temperatures and pressures. Additionally, diamond wheels produce less dust, which translates to less cleaning and maintenance.Diamond grinding wheels have become increasingly popular in numerous industries, including automotive, aerospace, and construction. They are an essential tool for cutting through hard metals, ceramics, and other materials.The company behind the Diamond Grinding Wheel (name removed for privacy) has earned a reputation for producing high-quality products that meet the needs of various industries. The company has been at the forefront of developing and improving diamond grinding wheel technology.Quicker Cutting Speeds and Greater EfficiencyOne of the most significant advantages of diamond grinding wheels is their quicker cutting speed. This feature translates to greater efficiency in cutting and grinding tasks, as it reduces the amount of time needed to complete a job. Diamond grinding wheels can be used to cut through materials like carbide, ceramic, glass, and stone. They are also an ideal tool for precision grinding and have applications in the food, chemical, and pharmaceutical industries.Furthermore, diamond wheels have greater durability than traditional abrasive wheels. They can withstand high temperatures and pressures without losing their cutting ability or shape. This durability translates to a longer product life and fewer replacements, which saves time and money.The company behind the Diamond Grinding Wheel (name removed for privacy) is committed to creating innovative diamond grinding wheels that provide exceptional performance, durability, and value to customers. The company prides itself on its extensive research and development program, which focuses on the latest technology and customer needs.Improved Surface Finish and AccuracyDiamond grinding wheels are also known for their ability to improve surface finish and accuracy. This feature is critical in applications where precision is required, such as in the medical and aerospace industries. Diamond wheels remove material uniformly, leaving a smooth and even finish that reduces the need for further processing.Another benefit of diamond grinding wheels is that they produce less heat during use. This characteristic is highly desirable when working with heat-sensitive materials like plastic, rubber, and delicate metal alloys. The cooler temperatures help prevent thermal damage to the material, which can result in cracking or warping.The Diamond Grinding Wheel (name removed for privacy) is continually investing in the latest technology and equipment, ensuring that they can meet the ever-changing needs of their customers. They are dedicated to providing high-quality diamond grinding wheels that will improve efficiency and accuracy in the cutting and grinding industry.In conclusion, the Diamond Grinding Wheel (name removed for privacy) is leading the way in the development of innovative diamond grinding wheels for various industries. These wheels provide numerous benefits over traditional abrasive wheels, including quicker cutting speeds, greater durability, and improved surface finish and accuracy. As technology continues to improve, diamond grinding wheels will undoubtedly become even more prevalent in the cutting and grinding industry. The company behind the Diamond Grinding Wheel (name removed for privacy) is committed to meeting this demand by investing in research, development, and the latest technology.

Shop high-quality polishing and buffing pads for car detailing

: Tips and Tricks for Effective Auto DetailingAuto detailing enthusiasts know that one of the most important tools in their arsenal is a good set of polishing pads. These small but mighty accessories can help you achieve the perfect shine on your car's exterior, and can make a big difference in your overall detailing results. But with so many types of polishing pads on the market, how do you know which ones to choose? And once you have your pads, how do you use them effectively? In this blog post, we'll explore some tips and tricks for cleaning car polishing pads, as well as how to select the best pads for your specific detailing needs.Types of Polishing PadsBefore we dive into the specifics of polishing pad maintenance and use, let's take a quick look at the different types of pads available on the market. Some of the most common types include:- Foam pads: These pads are made of foam and are available in a variety of colors and densities. The softer the foam, the gentler the pad will be on your car's paint. Some foam pads are designed for cutting or heavy polishing, while others are better suited for finishing work.- Microfiber pads: These pads are made of small fibers that can help to buff out scratches and swirls. They are often used in conjunction with a polishing compound to remove light imperfections in the paint.- Wool pads: These pads are made from natural or synthetic wool fibers. They are typically used for heavy polishing or compounding, as their abrasive nature can remove deep scratches or other defects in the paint.When selecting polishing pads for your detailing kit, consider the type of work you will be performing. If you're just looking to do some light polishing and finishing work, a soft foam or microfiber pad is likely your best bet. For more intensive work, such as removing deep scratches or heavy oxidation, a wool pad may be necessary.Cleaning Car Polishing PadsOnce you have your polishing pads, it's important to keep them clean and free of debris. Over time, polishing pads can become clogged with excess polish or dirt, which can reduce their effectiveness. To clean your pads, follow these simple steps:- Rinse the pad with cool water to remove any loose debris.- Apply a small amount of pad cleaner or degreaser to the pad.- Massage the cleaner into the pad using a soft bristled brush.- Rinse the pad thoroughly with cool water.- Squeeze out any excess water and allow the pad to air dry.Some polishing pad manufacturers also recommend machine washing their pads in a gentle cycle, but be sure to check the manufacturer's instructions before doing so.Tips for Effective Polishing Pad UseNow that your polishing pads are clean and free of debris, it's time to put them to use. Here are some tips for effective polishing pad usage:- Use the right pad for the job: As we mentioned earlier, different types of pads are better suited for different types of detailing work. Make sure you select the appropriate pad for the task at hand.- Use the right amount of product: Too much polish or compound can clog your pad and reduce its effectiveness. Use small amounts of product and build up as needed.- Keep your pad level: When using your buffer, be sure to keep your pad level to the surface of your car. Tilting the pad can cause uneven results and potentially damage your paint.- Work in small sections: Focus on one small section at a time, working the polish into the paint until the scratches or defects are removed.- Clean your pad frequently: As you work, your polishing pad will accumulate debris and excess product. Clean it frequently to prevent clogging and maintain optimal performance.By following these tips and tricks, you can effectively use and maintain your polishing pads for optimal auto detailing results. Happy buffing!

Top-Quality Wet Polishing Pads: Essential for Polishing Various Stones

Wet Polishing Pads - The Ultimate Solution for Stone PolishingAre you tired of the dull, lifeless look of your stone surfaces? Do you want a perfect solution to restore their shine and beauty? Look no further than wet polishing pads! These pads are an incredible invention that has revolutionized the stone polishing industry. With their exceptional polishing power and versatility, flexible diamond polishing pads have become a go-to tool for all types of stone polishing.Wet polishing pads are designed to polish all types of stones, including marble, granite, and concrete. They can make your stone surfaces look brand new with just a few applications. The pads are designed to be used with water, which makes them ideal for polishing sensitive stones like marble. They allow for a smooth and even finish without any damage to the surface.Flexible diamond polishing pads come in various grits and sizes. The grit refers to the coarseness of the pad. The lower the number of grit, the coarser the pad, and the higher the number, the finer the pad. Choose the grit according to the level of polishing needed. The pads also come in different sizes to suit different polishing tools and surfaces.Flexibility is an essential feature of wet polishing pads. They are highly flexible, which enables them to mold to the surface of the stone easily. The flexibility ensures even polishing, even on curved or uneven surfaces. The diamond particles on the pads are also highly concentrated, which ensures a fast and efficient polishing process.An essential factor to consider while using wet polishing pads is the amount of water used. The pads require water for effective use, but too much water can cause the polishing process to slow down. On the other hand, insufficient water can lead to the pad's clogging, making it less efficient. It's essential always to have a steady flow of water while using the pads to ensure optimal results.In conclusion, flexible diamond polishing pads are a must-have tool for any stone polishing job. Wet polishing pads offer an efficient, cost-effective, and reliable solution to restore the natural beauty of stone surfaces. Besides, they are easy to use, durable, and versatile. Whether it's granite polishing, marble polishing, or concrete polishing, flexible diamond polishing pads are the ultimate solution for excellent results. Purchase a set today and see the difference in your stone surfaces!

Top Replacement Pads for Auto Spa Polishers: Enhance Your Vehicle's Shine

Auto Spa is a leading name in the automotive industry, renowned for producing high-quality car cleaning and maintenance products. With an unmatched commitment to innovation and customer satisfaction, Auto Spa has recently announced the launch of its newest product – the Polisher Replacement Pads.With its state-of-the-art manufacturing facility and team of dedicated professionals, Auto Spa has established itself as a global leader in the automotive industry. The company offers a wide range of cleaning and maintenance solutions, including car wash accessories, tire care products, and interior cleaning supplies, among others.Recognizing the need for efficient and reliable car polishers, Auto Spa has invested significant time and resources in developing the Polisher Replacement Pads. This new addition to their product line is designed to enhance the performance and longevity of their existing range of polishers.The Polisher Replacement Pads are manufactured using premium-quality materials to ensure durability and effectiveness. The pads are specifically engineered to provide a smooth, swirl-free polishing experience that delivers stunning results every time. With their innovative design, these replacement pads significantly reduce the risk of damaging the vehicle's paint surface, ensuring a flawless, showroom-quality finish.Auto Spa understands the importance of variety and versatility in the automotive industry. Hence, the Polisher Replacement Pads come in different sizes and densities, catering to various polishing requirements. Whether it's removing minor scratches, restoring dull paint, or creating a mirror-like shine, these pads offer the perfect solution for all car enthusiasts and professionals alike.One of the key features of the Auto Spa Polisher Replacement Pads is their ease of use. Designed for both beginners and seasoned professionals, these pads can be easily attached and detached from the polishers, making the polishing process hassle-free and time-efficient. The pads also feature a Velcro backing that ensures a secure and stable connection, enabling precise control and maneuverability during the polishing process.Another noteworthy aspect of the Auto Spa Polisher Replacement Pads is their durability. Crafted to withstand intense pressure and frequent use, these pads are built to last. The high-quality materials used in their construction ensure that they maintain their shape and performance even after prolonged and rigorous use.Additionally, Auto Spa prioritizes environmental consciousness and sustainability. The Polisher Replacement Pads are designed to be reusable, reducing waste and contributing to a greener planet. By minimizing the need for constant replacement, these pads not only save customers money but also make a positive impact on the environment.In conclusion, Auto Spa's latest offering, the Polisher Replacement Pads, exemplifies the company's commitment to excellence and innovation in the automotive industry. With their dedication to customer satisfaction, Auto Spa has introduced a versatile and high-performing solution for car enthusiasts and professionals alike. These pads, with their superior quality, ease of use, and durability, are set to revolutionize the car polishing experience, providing an unparalleled level of convenience and effectiveness. As Auto Spa continues to expand its product range, customers can expect nothing short of exceptional quality and groundbreaking innovation from this industry-leading brand.

Marble Polishing: How to Restore the Shine of Your Marble Floors

Marble Polishing: How to Polish Marble Floors & Restore the ShineMarble floors are a timeless and elegant choice for any home or business. However, over time and through wear and tear, the shine on your marble floors can begin to fade and become dull. That's where marble polishing comes in.Polishing your marble floors can restore the shine and luster that they once had. In this article, we'll share some marble floor polishing tips and tricks to help you achieve beautiful, shiny floors.Dry Polishing vs. Wet PolishingThere are two main methods of polishing marble floors: dry polishing and wet polishing. Both methods have their advantages and it really depends on your personal preference and the condition of your floors.Dry polishing involves using a polishing powder and special dry diamond polishing pads to buff the surface of the marble. Wet polishing, as the name suggests, involves using water and a wet polishing pad. Wet polishing is generally considered to be more effective than dry polishing as it produces a smoother and shinier finish.If you decide to go with wet polishing, it's important to use a high-quality wet diamond polishing pad for marble. One such pad is the Dry Diamond Polishing Pads for Marble by [remove brand name]. These pads are designed for use on marble, travertine, and limestone and are engineered to provide excellent results on both polished and unpolished surfaces.Tips for Marble Floor PolishingHere are some tips for polishing your marble floors to restore their shine and protect them from further damage.1. Clean the floor thoroughly: Before you start polishing, it's important to clean your floors thoroughly to remove any dirt or grime. Use a mild detergent and warm water to clean the floors.2. Repair any cracks or chips: If your floors have any cracks or chips, it's important to repair them before polishing. This will prevent further damage to the floors and ensure a smooth and even surface for polishing.3. Use the right polishing pad: As mentioned earlier, it's important to use a high-quality polishing pad that is designed for use on marble floors. The Dry Diamond Polishing Pads for Marble by [remove brand name] are a great choice for achieving a shiny and smooth finish.4. Start with a coarser pad: When using a diamond polishing pad, it's best to start with a coarser pad and work your way up to a finer pad. This will help to remove any scratches or imperfections on the surface of the marble.5. Use water: If you're using a wet polishing pad, make sure to keep the surface of the marble wet while you're polishing. This will help to prevent the pad from overheating and damaging the marble.6. Be patient: Polishing marble floors takes time and patience. Take your time and don't rush the process. You'll be rewarded with beautiful, shiny floors that will last for years to come.In conclusion, marble floor polishing is a great way to restore the shine and luster to your marble floors. With the right tools and techniques, you can achieve beautiful and long-lasting results. Remember to clean your floors thoroughly before polishing, use a high-quality polishing pad designed for use on marble, and be patient. Happy polishing!

Revolutionize Your Concrete Grinding with Diamond Tools

Concrete Diamond Grinding Tools Boost Efficiency and Maximize ProductivityConcrete grinders are some of the most essential tools in the construction and renovation industries. With a concrete grinder, contractors and builders can effectively remove any old coatings and debris from floors and walls. However, not all concrete grinding tools are created equal. There are those that are efficient and result-oriented, and then there are those that waste time and resources. One of the most effective concrete grinding tools in the market today is the diamond grinding tool, which enables faster, more accurate, and more efficient results. Diamond grinding tools are made from diamond grains that have been coated on the grinding surface of the tool. The diamond grains are natural or synthetic and have been treated with extreme heat and pressure to make them hard and durable. These tools are an effective way to polish concrete or grind down uneven surfaces on floors and walls. One of the companies that have mastered the art of creating diamond grinding tools is a leading manufacturer based in China. The company’s range of diamond grinding tools is designed to meet the specific needs of professionals in the construction industry. The company has an array of diamond grinding tools that are used to grind concrete surfaces and achieve a smooth, level finish. The tools are highly versatile and can be used on a wide range of surfaces, including concrete floors, walls, and ceilings.One of the key features of the diamond grinding tools is their longevity. The diamond particles used in the grinding surface are highly resistant to wear and tear, making them ideal for use in high-intensity grinding applications. This means that the tools will maintain their effectiveness over a long period of time, thereby delivering maximum productivity and cost savings.Another advantage of diamond grinding tools is that they provide a high-quality finish in a short amount of time. The diamond grains used in the tools are designed to wear evenly, which means that they will maintain their shape and sharpness throughout the grinding process. As a result, the tools can be used to grind down large areas of concrete quickly and efficiently, without compromising on the quality of the finish.Furthermore, diamond grinding tools enable contractors and builders to work on a variety of surfaces with ease. The tools are designed to be highly versatile and can be used on surfaces of different hardness levels. This means that they can be used to grind down hard concrete surfaces as well as softer materials such as marble and stone.The company behind these diamond grinding tools has over 20 years of experience in manufacturing high-quality diamond tools. The company has invested heavily in research and development to ensure that their diamond tools are of the highest possible quality. They use the latest technology and cutting-edge techniques to produce diamond grinding tools that are both durable and efficient.The company has a commitment to customer satisfaction, and this is reflected in their dedication to producing high-quality products. They work closely with their clients to ensure that the diamond grinding tools they produce meet their specific needs and requirements. They provide a wide range of tools that cater to the different needs of their clients, including those involved in the construction, renovation, and maintenance of concrete surfaces.In conclusion, diamond grinding tools are an essential aspect of the construction industry. They are highly versatile, durable, and efficient, providing contractors and builders with a cost-effective way to grind down concrete surfaces quickly and easily. The company behind these diamond grinding tools has a proven track record of producing high-quality tools that are designed to meet the specific needs of their clients. Their commitment to customer satisfaction and quality assurance has earned them a reputation as a leading manufacturer of diamond tools in the industry.