How Metal Bond Technology is Revolutionizing Industrial Applications

By:Admin

Metal Bond has been a key player in the industrial bonding industry for over two decades, and its expertise and experience have made it a trusted name among businesses and manufacturers worldwide. The company's mission is to deliver innovative and reliable bonding solutions that meet the unique needs of its customers, and its latest product is a testament to this commitment.

The new product, which has been developed after years of research and development, is designed to offer superior bonding performance in the most demanding industrial environments. The product's advanced formulation and unique properties make it suitable for a wide range of applications, including metal-to-metal bonding, metal-to-plastic bonding, and other challenging bonding requirements.

Metal Bond's new product also boasts exceptional durability and resistance to harsh conditions, making it an ideal choice for industries such as aerospace, automotive, construction, and manufacturing. Its high-strength bonding capabilities ensure that the bonded materials remain securely in place, even under extreme pressure and temperature fluctuations.

In addition to its superior performance, the new product also stands out for its ease of use and versatility. Its user-friendly application process and compatibility with various substrates make it suitable for a wide range of bonding applications, providing businesses with a cost-effective and efficient solution for their bonding needs.

"We are thrilled to introduce our latest product to the market," said [spokesperson's name], [position] at Metal Bond. "Our team has worked tirelessly to develop a product that not only meets but exceeds the expectations of our customers. We are confident that this new product will set a new standard for industrial bonding solutions and provide our customers with the reliability and performance they need to succeed in their respective industries."

Metal Bond's commitment to quality and innovation has earned the company a reputation as a leader in the industrial bonding industry. Its products are trusted by businesses around the world, and its dedication to customer satisfaction has made it a preferred partner for many manufacturers and industrial companies.

The launch of Metal Bond's latest product is set to further solidify the company's position as a frontrunner in the industry. With its unrivaled performance, durability, and versatility, the new product is expected to raise the bar for industrial bonding solutions and address the ever-evolving needs of the market.

As Metal Bond continues to push the boundaries of industrial bonding technology, businesses and manufacturers can expect more cutting-edge solutions that will enhance their processes and drive their success. With its relentless pursuit of excellence, Metal Bond is poised to shape the future of industrial bonding and set new benchmarks for quality and performance in the industry.

Company News & Blog

Different Types of Grinding Wheel Dressers: A Comprehensive Guide

Grinding Wheel Dresser Types: Enhancing Efficiency and Precision in ManufacturingIn today's rapidly advancing manufacturing industry, efficiency and precision are of paramount importance. One of the key tools used for achieving these goals is the grinding wheel dresser. A grinding wheel dresser is a vital device used to shape and clean abrasive wheels in order to maintain their optimal performance. With various types of grinding wheel dressers available in the market, companies are constantly seeking the most appropriate type to enhance productivity and quality. Grinding wheel dressers come in different forms and serve unique purposes. One popular type is the diamond dresser. Incorporating diamond grains on its surface, this dresser offers unparalleled hardness and durability. Diamonds are known for their exceptional strength in cutting, shaping, and cleaning abrasive materials, making them the ideal choice for grinding wheel dressers. By utilizing diamonds, the dresser is able to maintain its sharpness even after extensive use, resulting in consistent and precise grinding.Another commonly used grinding wheel dresser is the star dresser. This type features multiple hardened steel discs with raised points in a star-like pattern. These points, often made from either high-speed steel or carbide, are crucial for truing and straightening the grinding wheel. The star dresser works by cutting into the wheel surface, creating grooves and channels, which ultimately improve its cutting efficiency and provide a smoother grinding action. This type of dresser is highly effective for removing excess material on the grinding wheel and achieving the desired shape.Yet another important type of grinding wheel dresser is the dressing stick or block. This dresser is made of abrasive grains, typically silicon carbide or aluminum oxide, adhered together with a bonding agent. The dressing stick is primarily used for cleaning and reshaping the grinding wheel by removing any debris or unevenness. It is especially useful in removing built-up metal shavings, known as glazing, which can significantly decrease the wheel's effectiveness. The dressing stick is an economical option that ensures the grinding wheel remains in optimal condition for prolonged usage.In light of these various grinding wheel dresser types, manufacturers are constantly seeking the most suitable option for their specific needs. This is where the company {}, a renowned leader in manufacturing solutions, comes into play. With a wealth of experience and expertise in the field, {} offers a wide range of grinding wheel dressers that cater to diverse industrial requirements.For instance, {} specializes in producing diamond dressers that are not only highly durable but also available in different sizes and shapes to accommodate various grinding wheel specifications. With their diamond dressers, customers can expect improved grinding efficiency, reduced dressing times, and increased precision in their manufacturing processes. By adopting diamond dressers from {}, manufacturers can achieve higher productivity, prolonged tool life, and enhanced overall quality.Furthermore, {} also offers an extensive selection of star dressers that can effectively dress a wide range of abrasive wheels, including vitrified, resin-bonded, and diamond grinding wheels. The company's star dressers are made from premium-quality materials, ensuring long-lasting performance and excellent truing capabilities. By utilizing {}'s star dressers, manufacturers can achieve optimal wheel conditions, resulting in enhanced surface finishes and reduced cycle times in their operations.Additionally, {} provides a comprehensive range of dressing sticks that are tailor-made for different grinding wheel materials and applications. Through their selection of dressing sticks, manufacturers can maintain the sharpness and efficiency of their grinding wheels, leading to consistent and precise results. {}'s dressing sticks are known for their durability and cost-effectiveness, making them a reliable solution in the grinding industry.In conclusion, grinding wheel dressers play a crucial role in maintaining the effectiveness and precision of abrasive grinding wheels. With a variety of types available, ranging from diamond dressers to star dressers and dressing sticks, manufacturers have multiple options to choose from based on their specific needs. By utilizing high-quality grinding wheel dressers from {}, companies can significantly enhance their manufacturing efficiency, improve product quality, and stay at the forefront of the rapidly evolving industry.

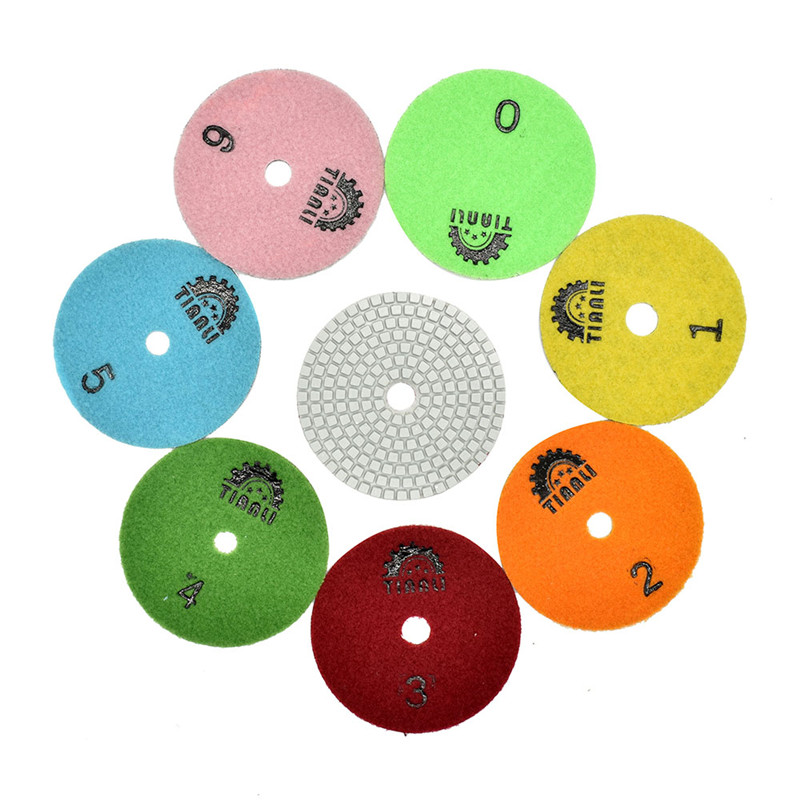

High-quality Stone Polishing Pads for Wet Grinding - A Complete Guide

Wet Stone Polishing Pads have revolutionized the way professionals and DIY enthusiasts polish and maintain natural stone surfaces. Whether it's granite, marble, or any other natural stone, these innovative polishing pads are designed to deliver exceptional results with minimal effort.These high-quality pads, developed by a leading manufacturer in the industry, are known for their durability, efficiency, and versatility. With a wide range of grits available, they are suitable for all stages of the polishing process, from initial grinding to final polishing. This makes them a must-have tool for contractors, stone fabricators, and anyone else working with natural stone.The company behind these exceptional products has been a major player in the stone fabrication industry for over a decade. Their commitment to quality, innovation, and customer satisfaction has earned them a reputation as a trusted supplier of stone fabrication tools and accessories. With a focus on research and development, they have continuously improved their products to meet the evolving needs of the industry.One of the key features of these Wet Stone Polishing Pads is their superior performance on both wet and dry surfaces. This versatility allows users to achieve outstanding results in various working conditions, making the pads ideal for a wide range of applications. Whether it's a small residential project or a large-scale commercial job, these pads deliver consistent and impressive results every time.In addition to their impressive performance, these pads are also designed for maximum durability. Their long lifespan ensures that users can rely on them for multiple projects, making them a cost-effective choice for professionals and DIYers alike. The company's dedication to producing long-lasting, high-quality products is evident in every aspect of the pads' design and construction.Furthermore, these pads are engineered for user convenience and safety. With an easy-to-use design, they allow for smooth and efficient operation, reducing fatigue and increasing productivity. Additionally, the company has incorporated advanced safety features into the pads, providing users with peace of mind during use.The company also takes pride in its commitment to sustainability. By using efficient manufacturing processes and environmentally friendly materials, they strive to minimize the environmental impact of their products. This dedication to sustainability aligns with the growing demand for eco-friendly solutions in the stone fabrication industry.The exceptional performance, durability, and user-friendly design of these Wet Stone Polishing Pads have made them a popular choice among professionals and DIY enthusiasts. With a strong commitment to quality and innovation, the company continues to set industry standards and exceed customer expectations.In conclusion, Wet Stone Polishing Pads have become an indispensable tool for anyone working with natural stone. Their exceptional performance, durability, and user-friendly design make them a top choice for professionals and DIYers alike. With a trusted and reputable company behind them, these pads are sure to remain a staple in the stone fabrication industry for years to come.

Understanding the Chemistry of Metallic Bonds and Their Properties

Metallic Bonds Chemistry: A Breakthrough in Material ScienceThe field of material science has been revolutionized with the development of metallic bonds chemistry, a groundbreaking innovation that has potential applications across a wide range of industries. This new technology, developed by a team of researchers at {}, promises to unlock new possibilities in the creation of advanced materials with exceptional strength, flexibility, and conductivity.Metallic bonds are a type of chemical bond that occurs between atoms of metallic elements. Unlike other types of chemical bonds, such as covalent or ionic bonds, metallic bonds are unique in that the electrons are not tied to any specific atoms and are instead free to move throughout the structure. This gives metallic materials their characteristic properties, such as high electrical and thermal conductivity, malleability, and luster.The development of metallic bonds chemistry has been a focus of research and development at {} for several years. The company, a leading innovator in the field of material science, has dedicated substantial resources to understanding the fundamental principles of metallic bonding and harnessing this knowledge to create new materials with superior performance characteristics.One of the key advantages of metallic bonds chemistry is the ability to tailor the properties of materials by controlling the arrangement of atoms and the nature of the bonding interactions. By manipulating these factors, researchers can design materials with specific attributes, such as enhanced strength, improved corrosion resistance, or optimized electrical conductivity. This level of control over material properties opens up a myriad of possibilities for the creation of innovative products across various industries, from electronics and aerospace to automotive and construction.The potential applications of metallic bonds chemistry are vast and far-reaching. For instance, in the electronics industry, materials with superior electrical conductivity and thermal stability are in high demand for the development of high-performance electronic devices and components. Metallic bonds chemistry offers a pathway to create such materials, paving the way for more efficient and durable electronic products.Similarly, the aerospace and automotive industries stand to benefit from the use of advanced materials derived from metallic bonds chemistry. The unparalleled strength and lightweight nature of these materials make them ideal for use in the construction of aircraft, spacecraft, and automobiles, where the demand for high-performance, durable materials is paramount.The construction industry is also poised to benefit from the advancements in metallic bonds chemistry. The development of materials with enhanced structural integrity and corrosion resistance can lead to the creation of more resilient and long-lasting infrastructure, ranging from bridges and buildings to pipelines and offshore structures.In addition to its applications in various industries, metallic bonds chemistry also holds promise for enabling sustainable and environmentally friendly solutions. By developing materials with improved durability and longevity, the need for frequent replacements and repairs can be reduced, leading to significant cost savings and minimizing the environmental impact associated with the production and disposal of materials.The emergence of metallic bonds chemistry as a leading technology in material science exemplifies the commitment of {} to pushing the boundaries of innovation and driving positive change across industries. The company's dedication to research and development, combined with its expertise in material science, positions it at the forefront of this cutting-edge technology, poised to deliver groundbreaking solutions that have the potential to reshape the future of materials and manufacturing.As the applications of metallic bonds chemistry continue to expand, it is clear that this innovative technology will play a crucial role in advancing the capabilities of materials and driving progress across diverse sectors. With its far-reaching implications and transformative potential, metallic bonds chemistry stands as a testament to the power of scientific innovation and the ability to create a brighter, more sustainable future through the development of advanced materials.

Dry Polishing Pads: Achieve Diamond-like Results with this Revolutionary Technique

Title: Revolutionizing Stone Polishing: Diamond Dry Polishing Pads Deliver Superior ResultsIntroduction:In the competitive field of stone polishing, a breakthrough has been achieved with the development of the innovative Diamond Dry Polishing Pads. These pads, specifically designed for stone polishing tasks, have quickly gained recognition for their exceptional performance and ability to deliver superior results. Pioneered by a leading industry player specializing in diamond tool manufacturing, this revolutionary product has the potential to transform the stone polishing industry for professionals and enthusiasts alike.Company Introduction: [Company Name]With over two decades of industry experience, [Company Name] has emerged as a leading entity in the field of diamond tool manufacturing. The company prides itself on its extensive research and development to create cutting-edge products that cater to the requirements of various industries. Utilizing state-of-the-art technology and a highly skilled team, [Company Name] consistently delivers innovative solutions that are at the forefront of the industry.Article Body:The quest for a precise and effective stone polishing method has led [Company Name] to develop Diamond Dry Polishing Pads, a game-changer in the field. By honing the perfect combination of advanced materials and groundbreaking manufacturing techniques, these pads have managed to set a new benchmark for stone polishing.The unique composition of Diamond Dry Polishing Pads ensures exceptional durability and longevity. The pads are crafted using high-quality diamond particles that are meticulously embedded into a resin matrix, enabling them to withstand the most demanding polishing applications. This design promotes consistent performance throughout the polishing process, resulting in a flawlessly polished stone surface every time.One of the standout features of the Diamond Dry Polishing Pads is their ability to function without the need for water or any other lubricating agent. This characteristic significantly expedites the polishing process, eliminates the mess associated with traditional methods, and reduces water consumption. The eco-friendly nature of these pads aligns perfectly with the growing demand for sustainable practices within various industries.Compatibility across an extensive range of stone types is another noteworthy advantage of Diamond Dry Polishing Pads. Whether it's marble, granite, quartz, or even engineered stone, these pads deliver exceptional results on any surface. This versatility has made them a favorite among professionals in the stonework industry, ensuring that each project is executed with precision and efficiency.Furthermore, Diamond Dry Polishing Pads are designed to operate at optimal speeds, reducing the overall polishing time without compromising on the quality of the finish. The superior heat dissipation of these pads not only enhances efficiency but also extends their lifespan, ultimately providing cost-effective solutions for businesses in the stone polishing sector.In addition to their remarkable polishing capabilities, Diamond Dry Polishing Pads also boast an innovative design that guarantees ease of use. The flexible and lightweight construction ensures comfortable handling, thereby reducing operator fatigue and enhancing overall productivity. The gripping technology incorporated within the pads minimizes slippage and ensures stable control, allowing for smooth and consistent polishing motions.Recognizing the industry's changing dynamics and the need for continuous improvement, [Company Name] remains committed to further enhancing the performance of their Diamond Dry Polishing Pads. The team is constantly investing in research and development, exploring new advancements in materials and manufacturing techniques to stay at the forefront of an ever-evolving industry.Conclusion:In conclusion, the introduction of Diamond Dry Polishing Pads by [Company Name] has marked a significant milestone in the stone polishing industry. Achieving unparalleled results, these innovative pads have revolutionized stone polishing techniques with their durability, compatibility, eco-friendliness, and exceptional performance. With the constant pursuit of perfection, [Company Name] continues to redefine industry standards, cementing its position as a leading player in the diamond tool manufacturing sector.

How to Use a Dry Polishing Pads Kit for Granite Countertops

Introducing a New Innovation in Granite Polishing: Dry Polishing Pads Kit Brings Unmatched Quality and Efficiency to Stone FabricationAs the demand for high-quality granite and stone fabrication continues to soar, the need for advanced and efficient polishing solutions has never been more critical. In response to this demand, the team at [Company Name] is delighted to unveil the Dry Polishing Pads Kit, a groundbreaking product that promises to revolutionize the way granite and stone surfaces are polished.Designed to meet the evolving needs of stone fabricators and installers, the Dry Polishing Pads Kit represents the culmination of years of industry experience and a relentless dedication to innovation and excellence. With a focus on unparalleled quality, efficiency, and ease of use, this exciting new product is poised to set a new standard for granite polishing.The Dry Polishing Pads Kit is the result of exhaustive research and development, combined with the latest advancements in polishing technology. By harnessing the power of advanced abrasives and cutting-edge bonding materials, this innovative product delivers a level of performance that is simply unmatched in the industry.One of the key features of the Dry Polishing Pads Kit is its ability to eliminate the need for water during the polishing process. This not only streamlines the fabrication and installation process but also minimizes the mess and clean-up associated with traditional wet polishing methods. With this new dry polishing solution, fabricators can achieve exceptional results with unprecedented speed and precision, all while maintaining a clean and organized work environment.In addition to its superior performance, the Dry Polishing Pads Kit is also incredibly versatile, making it suitable for a wide range of applications. Whether it's polishing granite, marble, or other types of stone, this innovative product delivers exceptional results across the board. From intricate details to large surface areas, the Dry Polishing Pads Kit is capable of meeting the diverse needs of stone fabricators with ease.At [Company Name], our commitment to excellence goes beyond our products. We take great pride in providing our customers with the highest level of service and support, ensuring that they have everything they need to succeed. With the introduction of the Dry Polishing Pads Kit, we are furthering our mission to empower our customers with the tools and resources they need to thrive in a competitive industry.In addition to offering superior quality and performance, the Dry Polishing Pads Kit also represents exceptional value. By streamlining the polishing process and minimizing the need for water and additional supplies, fabricators can enjoy significant cost savings without sacrificing results. This makes the Dry Polishing Pads Kit a smart investment for any stone fabrication business looking to enhance its efficiency and profitability.As we look to the future, the team at [Company Name] is excited to continue pushing the boundaries of innovation in the stone fabrication industry. The Dry Polishing Pads Kit is just the latest example of our unwavering commitment to delivering cutting-edge solutions that meet the evolving needs of our customers. We are confident that this groundbreaking product will make a meaningful impact on the industry and help our customers achieve new levels of success.In conclusion, the introduction of the Dry Polishing Pads Kit represents a significant milestone for [Company Name] and a game-changer for the stone fabrication industry as a whole. With its unmatched quality, efficiency, and versatility, this innovative product is poised to redefine the standard for granite polishing and set a new benchmark for excellence. We are thrilled to bring this groundbreaking solution to our customers and look forward to the positive impact it will have on their businesses.

Diamond Polishing Pad with Snail Lock Edge for Superior Surface Finishing

The demand for high-quality and long-lasting polishing pads in the construction and manufacturing industries has been on the rise. In response to this demand, a leading company in the field of diamond tools and equipment has introduced a new and innovative product to the market – the Snail Lock Edge Diamond Polishing Pad. This new polishing pad is designed to provide exceptional performance and durability, making it the go-to choice for professionals in the industry.With years of experience and expertise in manufacturing diamond tools and equipment, the company has established itself as a trusted name in the industry. They have a strong commitment to producing top-of-the-line products that meet the needs and expectations of their customers. The introduction of the Snail Lock Edge Diamond Polishing Pad is yet another example of their dedication to innovation and excellence.The Snail Lock Edge Diamond Polishing Pad is a game-changer in the industry, thanks to its unique and advanced features. The snail lock edge design ensures a secure and tight fit, preventing the pad from slipping or moving during use. This feature provides stability and precision, allowing professionals to achieve smooth and even results in their polishing applications.Furthermore, the diamond abrasives used in the construction of the polishing pad are of the highest quality, ensuring exceptional performance and long-lasting durability. The pad is designed to withstand the rigorous demands of heavy-duty use, making it a cost-effective investment for professionals in the industry. Whether it is for polishing concrete, marble, granite, or other types of stone surfaces, the Snail Lock Edge Diamond Polishing Pad delivers outstanding results that exceed expectations.One of the key advantages of the Snail Lock Edge Diamond Polishing Pad is its versatility. It is suitable for use with a wide range of equipment, including floor polishers and grinders, making it a practical and flexible choice for professionals in the industry. This versatility, combined with its exceptional performance, has made the polishing pad a popular and sought-after product in the market.The company's commitment to quality and innovation is further exemplified by their rigorous testing and quality control processes. Each Snail Lock Edge Diamond Polishing Pad undergoes thorough testing to ensure that it meets the company's high standards for performance and durability. This dedication to quality assurance has earned the company a reputation for reliability and trustworthiness among its customers.In addition to the superior performance of the Snail Lock Edge Diamond Polishing Pad, the company also prides itself on providing excellent customer service and support. They understand the diverse needs of their customers and are dedicated to offering personalized solutions and expert advice. Whether it is assistance with product selection, technical support, or after-sales service, customers can rely on the company's knowledgeable and professional team for assistance.As the demand for high-quality polishing pads continues to grow in the construction and manufacturing industries, the introduction of the Snail Lock Edge Diamond Polishing Pad comes as a timely and valuable addition to the market. Its exceptional performance, durability, and versatility make it a standout choice for professionals seeking top-tier diamond tools and equipment.In conclusion, the Snail Lock Edge Diamond Polishing Pad from the company is a groundbreaking product that raises the bar for performance and reliability in the industry. With its innovative design, high-quality materials, and versatile application, it has quickly become a preferred choice for professionals in the field. As the company continues to lead the way in diamond tools and equipment, customers can expect to see more cutting-edge products that deliver exceptional results and value.

Understanding the Different Types of Metal Bonds for Industrial Applications

Metal Bonds Type Introduces Innovative Solution for Industrial ApplicationsMetal Bonds Type, a leading provider of industrial solutions, is proud to introduce their innovative metal bonding technology. This cutting-edge process offers a wide range of benefits for industrial applications, including increased strength, durability, and performance.The metal bonding technology developed by Metal Bonds Type utilizes advanced techniques to create a strong and reliable bond between metal surfaces. This is achieved through a combination of high-quality materials and precision engineering, resulting in a bond that is capable of withstanding even the most demanding industrial environments.One of the key advantages of Metal Bonds Type's metal bonding technology is its ability to improve the overall performance of industrial equipment. By enhancing the strength and durability of metal components, this technology can help to reduce the risk of failure and ensure that equipment continues to operate at peak efficiency.In addition to its performance benefits, Metal Bonds Type's metal bonding technology also offers significant cost savings for industrial applications. By extending the lifespan of equipment and reducing the need for frequent repairs or replacements, this technology can help to lower maintenance costs and improve overall operational efficiency.Metal Bonds Type is dedicated to providing the highest quality metal bonding solutions to their customers. With a commitment to excellence and a focus on innovation, the company continues to push the boundaries of what is possible in the field of industrial bonding technology."We are thrilled to introduce our new metal bonding technology to the market," said a spokesperson for Metal Bonds Type. "This innovative solution has the potential to revolutionize industrial applications, offering unmatched performance and durability for a wide range of equipment and machinery."The introduction of Metal Bonds Type's metal bonding technology comes at a time when the demand for advanced industrial solutions is higher than ever. As industries continue to evolve and grow, the need for reliable and efficient equipment becomes increasingly important. With this in mind, Metal Bonds Type is proud to offer a solution that meets the needs of modern industrial applications.With its unrivaled strength, durability, and performance, Metal Bonds Type's metal bonding technology is poised to make a significant impact on the industrial sector. As more businesses and organizations recognize the benefits of this innovative solution, it is expected to become an essential component of a wide range of industrial applications.In conclusion, Metal Bonds Type's metal bonding technology represents a major advancement in the field of industrial bonding solutions. With its ability to enhance the performance and durability of equipment, while also providing significant cost savings, this technology is well-positioned to become a cornerstone of modern industrial applications.As Metal Bonds Type continues to lead the way in developing cutting-edge industrial solutions, it is clear that their metal bonding technology will play a key role in shaping the future of the industrial sector. Businesses and organizations that are looking to improve the performance and reliability of their equipment would be wise to consider the benefits of Metal Bonds Type's innovative metal bonding technology.

Understanding the Different Types of Metal Bonds: A Comprehensive Guide

Metal Type of Bonds: A New Player in the Industrial WorldInnovation has never ceased to amaze us. Today, we have access to various tools and machines that make our lives easier. The industrial sector has particularly thrived in recent years, thanks to the numerous advancements that have been made. In this regard, Metal Type of Bonds is one of the latest inventions to hit the market, and it has the potential to revolutionize the industrial world.What is Metal Type of Bonds?Metal Type of Bonds is a type of metal bonding process that has been developed by one of the leading metal manufacturers in the country. The key feature of this process is its ability to bond various metals, which was not possible using traditional welding methods. Metal Type of Bonds utilizes a unique combination of heat and pressure to bond metals of different types and thicknesses, without adding any filler metal.The process involves placing two metal surfaces in contact with each other, then using a high-pressure spindle to apply heat and pressure at the same time. This process creates a strong and secure bond between the two metals, resulting in a joint that is as strong as the base metals themselves. Unlike traditional welding methods, this process does not require the use of any additional materials, which makes it more cost-effective and efficient.Why use Metal Type of Bonds?The use of Metal Type of Bonds comes with various benefits. Some of the advantages include:1. Enhanced structural integrity: Metal Type of Bonds creates a bond that is stronger than traditional welding methods, which means that the joint is more reliable and durable.2. Cost-effective: The process eliminates the need for filler metal, which reduces the cost of production significantly.3. Versatility: Metal Type of Bonds can bond various metals, which means that it can be used in numerous applications, including electrical equipment, automotive parts, aerospace, and many more.4. Environment-friendly: The bonding process does not generate any fumes or waste, which makes it a more eco-friendly option compared to traditional welding methods.Who can benefit from Metal Type of Bonds?The Metal Type of Bonds technology has numerous applications across various industries. Some of the industries that can benefit from this technology include:1. Automotive: Metal Type of Bonds can be used to bond auto parts together, eliminating the need for rivets or screws. This results in a more streamlined and lightweight design, which can improve the car's performance and fuel efficiency.2. Aerospace: Metal Type of Bonds can be applied to various components in aircraft, including wings, frames, and engines. The metal bonding process creates a joint that is stronger than the base metals, ensuring safety and reliability.3. Electrical equipment: Metal Type of Bonds can be used in electrical equipment manufacturing, including transformers, motors, and generators. Since the bonding process does not interfere with the electrical conductivity of the metals, it is an ideal solution for these applications.4. Medical devices: Metal Type of Bonds can be applied to medical devices and equipment, ensuring that they are safe and reliable. The process eliminates the need for soldering or welding, which can prevent bacterial growth and contamination.ConclusionThe Metal Type of Bonds technology is a game-changer in the industrial world. Its ability to bond various metals of different thicknesses and types has many advantages, making it a preferred option for various industries. Its cost-effectiveness, strength, and versatility are some of the features that make it stand out. The technology can be applied to numerous applications, including automotive, aerospace, electrical equipment, and medical devices, among others. Metal Type of Bonds has set a new benchmark in the metal bonding industry, and it will be interesting to see how it develops in the future.

Different Types of Grinding Wheel for Various Applications

Grinding Wheel Types and Their ApplicationsGrinding wheels are essential tools in the manufacturing and metalworking industries, used for shaping and finishing metals and other materials. They are available in a variety of types, each designed for specific applications and materials. Understanding the different types of grinding wheels can help manufacturers and metalworkers choose the right tool for their needs.A leading player in the manufacturing industry, {company name} is a renowned provider of grinding wheels and other abrasive products. With a strong emphasis on quality and innovation, {company name}'s extensive range of grinding wheels caters to various industries and applications.{company name} offers a diverse selection of grinding wheel types, each tailored to meet the needs of different materials and applications. The following are some of the most commonly used grinding wheel types and their respective applications:1. Straight Grinding Wheels: These are the most common type of grinding wheel, featuring a simple, flat design. They are used for surface grinding, cylindrical grinding, and tool sharpening.2. Cylinder Wheels: These wheels have a long, cylindrical shape, making them suitable for grinding long, narrow surfaces.3. Tapered Grinding Wheels: As the name suggests, these wheels have a tapered shape, making them ideal for grinding threads and gear teeth.4. Dish Grinding Wheels: These wheels have a slightly concave shape, making them suitable for grinding tools and cutters.5. Diamond Wheels: Diamond grinding wheels are made with synthetic diamonds, making them extremely durable and suitable for grinding hard materials such as carbides, ceramics, and glass.6. CBN Wheels: Cubic Boron Nitride (CBN) wheels are designed for grinding ferrous materials such as steel and cast iron, offering high thermal conductivity and chemical stability.7. Segmented Grinding Wheels: These wheels are made up of multiple segments, allowing for aggressive material removal and improved cooling during grinding.8. Mounted Points: These small, specialized grinding wheels are used for precision grinding in hard-to-reach areas.{company name} is committed to delivering high-quality grinding wheels that meet the diverse needs of its customers. With a focus on innovation and technological advancement, {company name} continuously develops new grinding wheel types and formulations to address the evolving needs of the industry.In addition to offering a wide range of grinding wheel types, {company name} provides expert guidance and technical support to help customers choose the right wheel for their specific applications. Through its extensive industry experience and technical expertise, {company name} ensures that its customers achieve optimal grinding results and maximize productivity.The use of high-quality grinding wheels is essential for achieving precision and efficiency in metalworking and manufacturing processes. {company name} is dedicated to providing solutions that enable its customers to enhance their productivity, reduce operating costs, and improve the quality of their finished products.As a leading provider of grinding wheels and abrasive products, {company name} has built a strong reputation for its commitment to quality, innovation, and customer satisfaction. With a comprehensive range of grinding wheel types and a dedication to technical excellence, {company name} continues to be at the forefront of the abrasive industry.In conclusion, choosing the right grinding wheel is crucial for achieving optimal results in metalworking and manufacturing processes. With its extensive range of grinding wheel types and a focus on quality and innovation, {company name} is the preferred choice for customers seeking high-performance abrasive solutions. Whether it's surface grinding, cylindrical grinding, or precision grinding, {company name} has the right grinding wheel for every application.

Ultimate Guide to Wet/Dry Polishing Pads for a Perfect Finish

For Immediate ReleaseWet/Dry Polishing Pads Revolutionize Surface Polishing[Company Name], a leading manufacturer of high-quality surface polishing products, has introduced a new line of Wet/Dry Polishing Pads that are set to revolutionize the industry. The innovative design and advanced technology of these pads make them suitable for use on a wide range of surfaces, providing exceptional results with both wet and dry applications.The new Wet/Dry Polishing Pads from [Company Name] are engineered to deliver superior performance and durability, making them ideal for professional contractors, DIY enthusiasts, and anyone else seeking high-quality surface polishing solutions. These pads are designed to be used on various materials, including granite, marble, engineered stone, and concrete, making them versatile and highly efficient for a wide range of polishing projects.One of the key features of the Wet/Dry Polishing Pads is their ability to perform exceptionally well in both wet and dry applications. This versatility allows users to achieve exceptional results without the need for multiple sets of pads, saving both time and money. Whether working on a wet surface or dry, these pads deliver consistent and professional results, making them a valuable addition to any polishing toolkit.The advanced technology used in the manufacturing of these pads ensures exceptional performance and longevity. The diamond particles embedded in the pads are designed to provide maximum abrasion and durability, ensuring that they maintain their performance over extended periods of use. This means that users can rely on these pads to deliver consistent results, project after project, without the need for frequent replacements.In addition to their exceptional performance, the Wet/Dry Polishing Pads from [Company Name] are also designed with user convenience in mind. The Velcro backing on the pads makes them easy to attach and remove from polishing equipment, allowing for quick and efficient pad changes. This convenient feature saves time and effort, allowing users to focus on achieving the best possible results with minimal downtime.Furthermore, the Wet/Dry Polishing Pads are available in a range of grit sizes, allowing users to select the most suitable option for their specific polishing needs. Whether working on a coarse or fine surface, these pads provide the versatility and flexibility needed to achieve outstanding results on a wide range of materials.[Company Name] takes pride in its commitment to delivering high-quality surface polishing products that exceed the expectations of its customers. With the introduction of the Wet/Dry Polishing Pads, the company continues to demonstrate its dedication to innovation and excellence in the industry. The superior performance, durability, and versatility of these pads make them a standout choice for anyone seeking top-quality surface polishing solutions.As a trusted leader in the industry, [Company Name] remains dedicated to providing exceptional products and unparalleled customer service. The introduction of the Wet/Dry Polishing Pads further cements the company's reputation as a go-to source for high-quality surface polishing products, and solidifies its position as a leader in the industry.In conclusion, the new line of Wet/Dry Polishing Pads from [Company Name] represents a significant advancement in surface polishing technology. With their exceptional performance, versatility, and durability, these pads are set to revolutionize the industry and set a new standard for surface polishing products. Whether used by professional contractors or DIY enthusiasts, these pads offer the reliability and quality needed to achieve outstanding results on a wide range of materials. For anyone seeking high-quality surface polishing solutions, the Wet/Dry Polishing Pads from [Company Name] are the ideal choice.