High-Performance Diamond Impregnated Concrete Floor Pads: What You Need to Know

By:Admin

The {Company Name} is proud to introduce their latest line of Diamond Impregnated Concrete Floor Pads, which are engineered to deliver exceptional performance and long-lasting results. With a focus on quality and innovation, {Company Name} has established itself as a leader in the industry, providing high-quality concrete flooring solutions to meet the needs of their diverse clientele.

The Diamond Impregnated Concrete Floor Pads offered by {Company Name} are manufactured using advanced technology and premium-grade materials, ensuring superior performance and reliability. These pads are designed to withstand heavy-duty use, making them suitable for a wide range of flooring projects, from warehouses and manufacturing facilities to retail spaces and office buildings.

One of the key benefits of Diamond Impregnated Concrete Floor Pads is their ability to provide a smooth and high-gloss finish to concrete surfaces, enhancing their overall appearance and durability. This makes them an ideal choice for businesses and property owners looking to maintain and enhance the aesthetic appeal of their concrete floors.

In addition to their superior performance, Diamond Impregnated Concrete Floor Pads also offer cost-effective benefits, as they are designed to reduce the need for frequent maintenance and repairs. This not only helps businesses save time and money but also ensures that their concrete floors remain in pristine condition for years to come.

{Company Name} takes pride in offering a comprehensive range of Diamond Impregnated Concrete Floor Pads, catering to the specific needs and preferences of their clients. Whether it's a large-scale industrial flooring project or a small commercial space, {Company Name} has the expertise and resources to deliver tailored solutions that exceed expectations.

Furthermore, {Company Name} is committed to sustainability and environmental responsibility, and their Diamond Impregnated Concrete Floor Pads are designed with this in mind. The pads are engineered to minimize waste and reduce the environmental impact of concrete floor maintenance, making them a sustainable choice for businesses looking to go green.

With a team of experienced professionals and a dedication to customer satisfaction, {Company Name} is well-positioned to meet the evolving needs of the flooring industry. Their Diamond Impregnated Concrete Floor Pads are a testament to their commitment to excellence and innovation, offering a reliable and efficient solution for maintaining and enhancing concrete floors.

In conclusion, the introduction of Diamond Impregnated Concrete Floor Pads by {Company Name} represents a significant advancement in the flooring industry, offering a superior solution for concrete floor maintenance and polishing. With their exceptional performance, cost-effective benefits, and sustainable design, these pads are set to revolutionize the way concrete surfaces are treated, setting a new standard for quality and durability in the industry. Businesses and property owners can now turn to {Company Name} for cutting-edge concrete flooring solutions that deliver outstanding results.

Company News & Blog

How to Choose the Best Polishing Pads for Your Granite Surfaces

(title): Revolutionary Granite Polishing Technology Set to Redefine Stone Restoration(subtitle): [Company Name] Launches Groundbreaking Granite Polishing Pads for Unmatched Performance and Shine[date][Location]In a game-changing move for the stone restoration industry, [Company Name], a pioneering leader in stone care solutions, has unveiled its revolutionary Granite Polishing Pads. Setting a new standard for granite surface restoration, these pads are poised to redefine the way professionals bring back the natural luster and shine of granite countertops, flooring, and other surfaces.With over two decades of experience and a relentless commitment to innovation, [Company Name] has developed this breakthrough technology to address the longstanding challenges faced by stone restoration experts. The lack of effective and durable solutions had hindered their ability to deliver consistent and superior results – until now.By leveraging cutting-edge research and advancements in material engineering, the Granite Polishing Pads from [Company Name] offer an unparalleled level of performance and shine. These pads are specially designed with a combination of advanced abrasive technology and a unique bonding system, ensuring maximum efficiency and durability.One of the key highlights of these pads is their versatility. Developed to cater to a wide range of granite types, they adapt to the specific needs of each surface. No longer will professionals have to search for multiple polishing tools to accommodate different granite finishes. The Granite Polishing Pads from [Company Name] remove the hassle of trial and error, offering a one-stop solution for an array of granite surfaces.Furthermore, these pads are specifically engineered to address common issues faced during the polishing process. Scratches, unevenness, and dullness are expertly tackled by the advanced abrasive particles embedded within the pad's structure. This results in a flawless and uniform finish, elevating the beauty and elegance of every granite surface.Unlike conventional polishing pads, the Granite Polishing Pads from [Company Name] boast exceptional durability and longevity. This groundbreaking attribute significantly reduces downtime and ensures a high return on investment for stone restoration professionals. Laboratories have rigorously tested these pads under rigorous conditions, confirming their ability to withstand prolonged and repeated use without losing their effectiveness."Continuous innovation is at the heart of our company," stated [Company Spokesperson]. "We understand the challenges faced by professionals in the stone restoration industry, and we are committed to providing them with cutting-edge solutions. Our Granite Polishing Pads are a testament to this commitment, and we firmly believe they will revolutionize the way people restore and care for granite surfaces."The launch of these Granite Polishing Pads marks a significant milestone for [Company Name] and the stone restoration industry as a whole. This new technology not only enhances the efficiency and effectiveness of granite restoration but also empowers professionals to deliver unmatched results, surpassing their clients' expectations.As [Company Name] continues to push the boundaries of innovation, they remain committed to delivering superior stone care solutions and setting new industry standards. With the Granite Polishing Pads, stone restoration professionals can now harness the power of advanced technology to transform any granite surface into a work of art.About [Company Name]:[Company Name] is a pioneering leader in stone care solutions, specializing in the development and distribution of innovative products for stone restoration, maintenance, and protection. With over two decades of industry experience, [Company Name] is committed to delivering superior results and revolutionizing the stone care industry through continuous innovation and exceptional customer service.

Rare Gem: Polish Diamond Unearthed in New Discovery

Bartosz Kurek, the Polish professional volleyball player, has recently become the new brand ambassador for a renowned diamond company. This exciting partnership aims to promote the beauty and sophistication of diamond jewelry, as well as to raise awareness about the company's commitment to ethical sourcing and sustainable practices.As one of the most prominent figures in the world of sports, Bartosz Kurek brings with him a strong sense of integrity and passion for excellence, making him an ideal representative for the brand. His dedication to his craft and his unwavering commitment to success mirror the company's values of quality, authenticity, and innovation.Bartosz Kurek's impressive career in volleyball has earned him numerous accolades and recognition from fans and peers alike. With his stellar performance on the court and his charismatic personality off the court, he has captured the hearts of many, making him a perfect fit for the company's mission to celebrate individuality and uniqueness.The partnership between Bartosz Kurek and the diamond company is a testament to their shared vision of inspiring people to find beauty and elegance in every aspect of their lives. Through their collaboration, they hope to showcase the timeless allure of diamond jewelry, as well as the company's unwavering commitment to sustainability and ethical practices.The diamond company, renowned for its exquisite collection of jewelry, has long been dedicated to delivering exceptional craftsmanship and unparalleled beauty to its customers. With a focus on ethically sourced diamonds and sustainable production methods, the company has set itself apart as a leader in the industry, earning the trust and admiration of discerning consumers worldwide.Through its partnership with Bartosz Kurek, the diamond company aims to amplify its message of responsible luxury and environmental stewardship. By aligning with a respected athlete who embodies the values of dedication, integrity, and excellence, the company seeks to reach a broader audience and inspire them to embrace the allure of sustainable, ethically sourced diamond jewelry.In a statement regarding the partnership, Bartosz Kurek expressed his excitement to collaborate with the diamond company, stating, "I am thrilled to join forces with a company that shares my passion for authenticity, integrity, and sustainability. It is an honor to represent a brand that is committed to delivering exceptional quality and beauty, while also prioritizing ethical sourcing and environmental responsibility."Similarly, the diamond company's spokesperson expressed their enthusiasm for the collaboration, emphasizing the importance of partnering with a figure like Bartosz Kurek. "We are thrilled to have Bartosz Kurek as our brand ambassador. His dedication to excellence and his genuine personality perfectly align with our values, and we are confident that his influence will help us showcase the timeless elegance and ethical practices that define our brand."As the partnership between Bartosz Kurek and the diamond company continues to unfold, fans and consumers can expect to witness an array of exciting initiatives and campaigns that celebrate the beauty of diamond jewelry while highlighting the company's dedication to sustainability and ethical sourcing. Together, they aim to inspire individuals to embrace the allure of responsibly sourced, exquisitely crafted diamond jewelry, showcasing how luxury and sustainability can harmoniously coexist in the modern world.

Exploring the Bonding Capabilities of Copper: Unveiling the Strengths of Metal Connections

[Company Introduction]Founded in [year], [Company Name] is a leading manufacturer and supplier in the metal industry, known for its expertise in producing high-quality metal copper bonds. With a commitment to innovation and sustainable practices, [Company Name] has established itself as a trusted partner for various sectors, including electronics, telecommunications, automotive, and renewable energy.By leveraging its state-of-the-art manufacturing facilities and a dedicated team of professionals, the company has consistently delivered copper bonds that meet the highest industry standards. With a wide range of products and customized solutions, [Company Name] caters to the diverse needs of its global clientele while maintaining a strong focus on quality, reliability, and customer satisfaction.[News]Title: [Company Name] Launches Innovative Copper Bond Solution, Revolutionizing the Metal Industry[City, Date] - In a significant breakthrough for the metal industry, [Company Name] has unveiled its latest innovation in metal copper bonds. This groundbreaking solution aims to address various challenges faced by industries using copper bonds, which play a crucial role in the production of electronic devices, telecommunications equipment, and automotive components.The newly developed copper bond technology by [Company Name] promises enhanced durability, superior electrical conductivity, and improved thermal management. By incorporating advanced manufacturing techniques and careful selection of raw materials, the company has achieved a significant breakthrough in metal bonding technology. This innovation is expected to revolutionize various industries, offering higher performance and efficiency.One of the key features of this advanced copper bond solution is its exceptional reliability. With an optimized bonding process, [Company Name] ensures a strong and stable connection that can withstand harsh conditions, enabling longer product lifecycles and improved performance. This breakthrough is set to drive innovation in industries such as telecommunications, renewable energy, and automotive manufacturing.Moreover, the newly developed copper bond product by [Company Name] combines excellent electrical conductivity with superior thermal management. This unique combination allows for efficient heat dissipation and promotes the overall reliability and longevity of electronic components. The improved thermal management capability of the copper bonds reduces the risk of overheating, leading to enhanced product safety and stability.Speaking on the occasion, [Company Name]'s CEO expressed his excitement about the launch, saying, "We are extremely proud to introduce our latest copper bond technology to the market. This innovation showcases our commitment to continuous improvement and addressing the evolving needs of our customers. We are confident that our advanced metal copper bonds will set new benchmarks in the industry, providing unprecedented value to our clients."With a strong focus on sustainability, [Company Name] has also ensured that its copper bonds meet the highest environmental standards. The manufacturing process adheres to strict guidelines, ensuring minimal waste generation and reduced carbon footprint. By implementing eco-friendly practices, [Company Name] aims to contribute to a greener and more sustainable future.As the demand for efficient and reliable electronic components and equipment continues to grow across industries, [Company Name]'s groundbreaking copper bond solution is already gaining traction among key market players. Several leading telecommunications companies and electronics manufacturers have already expressed interest in partnering with [Company Name] to integrate this innovative technology into their products.The introduction of [Company Name]'s advanced metal copper bond solution marks a significant milestone in the metal industry. With its unrivaled durability, exceptional electrical conductivity, and superior thermal management capabilities, this innovative product is poised to become the standard in various sectors, further solidifying [Company Name]'s reputation as a global leader in metal manufacturing and innovation.[Company Name] remains committed to pushing the boundaries of technological advancements and providing cutting-edge solutions that empower industries worldwide. With its latest copper bond technology, the company aims to redefine industry standards and establish itself as the go-to partner for high-performance metal bonding solutions.

Understanding the Different Types of Metal Bonds: A Comprehensive Guide

Metal Type of Bonds: A New Player in the Industrial WorldInnovation has never ceased to amaze us. Today, we have access to various tools and machines that make our lives easier. The industrial sector has particularly thrived in recent years, thanks to the numerous advancements that have been made. In this regard, Metal Type of Bonds is one of the latest inventions to hit the market, and it has the potential to revolutionize the industrial world.What is Metal Type of Bonds?Metal Type of Bonds is a type of metal bonding process that has been developed by one of the leading metal manufacturers in the country. The key feature of this process is its ability to bond various metals, which was not possible using traditional welding methods. Metal Type of Bonds utilizes a unique combination of heat and pressure to bond metals of different types and thicknesses, without adding any filler metal.The process involves placing two metal surfaces in contact with each other, then using a high-pressure spindle to apply heat and pressure at the same time. This process creates a strong and secure bond between the two metals, resulting in a joint that is as strong as the base metals themselves. Unlike traditional welding methods, this process does not require the use of any additional materials, which makes it more cost-effective and efficient.Why use Metal Type of Bonds?The use of Metal Type of Bonds comes with various benefits. Some of the advantages include:1. Enhanced structural integrity: Metal Type of Bonds creates a bond that is stronger than traditional welding methods, which means that the joint is more reliable and durable.2. Cost-effective: The process eliminates the need for filler metal, which reduces the cost of production significantly.3. Versatility: Metal Type of Bonds can bond various metals, which means that it can be used in numerous applications, including electrical equipment, automotive parts, aerospace, and many more.4. Environment-friendly: The bonding process does not generate any fumes or waste, which makes it a more eco-friendly option compared to traditional welding methods.Who can benefit from Metal Type of Bonds?The Metal Type of Bonds technology has numerous applications across various industries. Some of the industries that can benefit from this technology include:1. Automotive: Metal Type of Bonds can be used to bond auto parts together, eliminating the need for rivets or screws. This results in a more streamlined and lightweight design, which can improve the car's performance and fuel efficiency.2. Aerospace: Metal Type of Bonds can be applied to various components in aircraft, including wings, frames, and engines. The metal bonding process creates a joint that is stronger than the base metals, ensuring safety and reliability.3. Electrical equipment: Metal Type of Bonds can be used in electrical equipment manufacturing, including transformers, motors, and generators. Since the bonding process does not interfere with the electrical conductivity of the metals, it is an ideal solution for these applications.4. Medical devices: Metal Type of Bonds can be applied to medical devices and equipment, ensuring that they are safe and reliable. The process eliminates the need for soldering or welding, which can prevent bacterial growth and contamination.ConclusionThe Metal Type of Bonds technology is a game-changer in the industrial world. Its ability to bond various metals of different thicknesses and types has many advantages, making it a preferred option for various industries. Its cost-effectiveness, strength, and versatility are some of the features that make it stand out. The technology can be applied to numerous applications, including automotive, aerospace, electrical equipment, and medical devices, among others. Metal Type of Bonds has set a new benchmark in the metal bonding industry, and it will be interesting to see how it develops in the future.

Understanding Nonmetal Bonds in the Market: Everything You Need to Know

Nonmetal Bonds Celebrates Innovation in Chemical IndustryNonmetal Bonds, a leading supplier of innovative chemical solutions, is proud to celebrate their latest breakthrough in the field of nonmetal bonding technology. With a rich history of providing high-quality products and exceptional customer service, Nonmetal Bonds continues to lead the way in the chemical industry.The company is known for its commitment to research and development, and their latest innovation in nonmetal bonding technology is a testament to their dedication to excellence. By combining their expertise in chemistry with cutting-edge technologies, Nonmetal Bonds has created a revolutionary new product that has the potential to transform the industry.Nonmetal bonding is a process that involves the formation of chemical bonds between nonmetal elements. This technology has a wide range of applications, including in the production of advanced materials, electronics, and pharmaceuticals. The development of new nonmetal bonding solutions has the potential to drive innovation and create new opportunities for a wide range of industries.The team at Nonmetal Bonds is thrilled to introduce their latest nonmetal bonding technology to the market. This breakthrough has been the result of years of intensive research and development, and the company is proud to see their hard work come to fruition. With this new product, Nonmetal Bonds aims to provide their customers with a competitive edge in their respective industries.Nonmetal Bonds has a long history of providing high-quality chemical solutions to their customers. The company was founded on the principles of innovation, quality, and service, and these values continue to guide their operations today. With a team of highly skilled and experienced chemists, engineers, and technical experts, Nonmetal Bonds is committed to pushing the boundaries of what is possible in the world of chemical technology.In addition to their expertise in nonmetal bonding, Nonmetal Bonds also offers a wide range of other chemical products and solutions. Their portfolio includes adhesives, coatings, and specialty chemicals, all of which are designed to meet the needs of their diverse customer base. Nonmetal Bonds prides itself on providing personalized service and tailor-made solutions for their clients, ensuring that they are able to achieve their specific goals and objectives.Nonmetal Bonds is dedicated to sustainability and environmental responsibility, and they are constantly seeking ways to minimize their environmental impact. The company is committed to complying with all relevant regulations and standards, and they prioritize the safe and responsible use of chemicals in all of their operations. Nonmetal Bonds takes their role as a responsible corporate citizen seriously and is always looking for ways to improve their sustainability practices.As Nonmetal Bonds celebrates their latest innovation in nonmetal bonding technology, they are excited about the potential impact it could have on the industry. With this new product, the company hopes to open up new possibilities for their customers and drive further innovation in the field of nonmetal bonding. Nonmetal Bonds looks forward to continuing to serve as a trusted partner to their customers and to deliver exceptional chemical solutions that meet their evolving needs.In conclusion, Nonmetal Bonds' latest breakthrough in nonmetal bonding technology is a testament to their commitment to excellence and innovation. By combining their expertise in chemistry with cutting-edge technologies, the company has developed a revolutionary new product that has the potential to transform the industry. Nonmetal Bonds looks forward to bringing this new technology to the market and to seeing the positive impact it will have on their customers and the wider chemical industry.

High-Quality and Affordable Diamond Polishing Pads for Various Applications

- Importance of Diamond Polishing Pads for Stone RestorationStone restoration is a process that is becoming increasingly popular as people are realizing the benefits of restoring old and damaged stone surfaces. However, the process of stone restoration requires the use of specialized tools and equipment, including diamond polishing pads. These pads are specifically designed to restore stone surfaces to their original beauty and shine. In this blog post, we will discuss the importance of diamond polishing pads in stone restoration.Diamond polishing pads are designed to work with a wide variety of stone surfaces, including marble, granite, and other natural stone materials. They come in different sizes and grits to suit different types of stone surfaces and specific restoration needs. These pads are typically made of diamond-impregnated resin or metal-bonded diamond, which allows them to grind away the surface imperfections and smooth out the stone.The use of diamond polishing pads is an essential part of the stone restoration process. They are used to remove surface scratches, stains, and blemishes, as well as to bring out the natural beauty and shine of the stone. Diamond pads are also used to flatten uneven surfaces, smooth out rough edges, and to achieve a high-gloss finish.When selecting a diamond polishing pad for a stone restoration project, it is important to consider the type of stone surface being restored and the level of damage. The pads come in different grits, ranging from coarse to fine, and each grit is designed for a specific purpose. Coarse grit pads are used for heavy grinding and removing deep scratches and stains. Medium grit pads are used for smoothing out surface imperfections, and fine grit pads are used for achieving a high-gloss finish.In addition to using the appropriate grit, it is important to use the proper technique when using diamond polishing pads. Proper technique involves using a consistent amount of pressure and controlling the speed of the rotary tool. It is also important to use water or a special lubricating fluid to cool the pad and prevent it from overheating.In conclusion, the use of diamond polishing pads is crucial for restoring stone surfaces to their original beauty and shine. With the proper selection of grit, technique, and equipment, diamond pads can be used to remove scratches, stains, and imperfections, as well as to achieve a high-gloss finish. If you are considering a stone restoration project, be sure to work with a professional who understands the importance of using diamond polishing pads for the best results.

Borazon Grinding Wheels: A Comprehensive GuideWhen it comes to high-performance grinding, it's essential to use the right tools for the job. That's where Borazon grinding wheels come in. These wheels are made from cubic boron nitride (CBN), a material that is second only to diamond in terms of hardness. In this blog, we'll explore everything you need to know about Borazon grinding wheels, including their advantages, applications, and how to choose the right one for your needs.Advantages of Borazon Grinding WheelsThe main advantage of Borazon grinding wheels is their exceptional hardness. This makes them ideal for grinding hard materials that are difficult to process with traditional grinding wheels. Borazon wheels also have high abrasive resistance, which means they last longer and require less frequent replacement. Other advantages of these wheels include:• Excellent heat resistance: Borazon wheels can withstand high temperatures without cracking or degrading, making them ideal for applications that generate a lot of heat.• Superior surface finish: Borazon wheels create a smooth, precise surface finish that is free from burrs and other imperfections.• Versatile applications: Borazon wheels can be used to grind a wide range of materials, including hardened steels, cast iron, and superalloys.Applications of Borazon Grinding WheelsBorazon grinding wheels are used in a variety of applications, including:• Aerospace: Borazon wheels are used to grind turbine blades, engine parts, and other components used in the aerospace industry.• Automotive: These wheels are also used in the automotive industry to grind crankshafts, camshafts, and other engine components.• Medical: Borazon wheels are used to grind medical implants, such as hip replacements and dental implants, to ensure a precise fit.• Tool and die: These wheels can be used to grind cutting tools, such as drill bits, taps, and end mills, as well as dies and molds.Choosing the Right Borazon Grinding WheelChoosing the right Borazon grinding wheel depends on several factors, including the material you're grinding, the desired finish, and the type of machine you're using. Here are some tips to help you choose the right wheel:• Determine the hardness of the material you're grinding: Borazon wheels are best suited for grinding hard materials, so if you're grinding a soft material, you may want to consider a different type of wheel.• Consider the grit size: Borazon wheels come in a range of grit sizes, which determine how coarse or fine the abrasive particles are. Choose a finer grit for a smoother finish and a coarser grit for a more aggressive cut.• Check the compatibility with your machine: Make sure that the wheel you choose is compatible with your grinding machine. This includes checking the wheel diameter, arbor size, and maximum RPM.• Consult with a supplier: If you're unsure which wheel to choose, consult with a supplier who specializes in Borazon grinding wheels. They can help you determine the best option based on your specific needs.ConclusionBorazon grinding wheels are an essential tool for grinding hard materials to a precise finish. With their exceptional hardness, heat resistance, and abrasive resistance, these wheels offer many advantages over traditional grinding wheels. When choosing a Borazon wheel, consider the material you're grinding, the desired finish, and the compatibility with your machine. With the right wheel, you can achieve superior results and increase productivity in your grinding operations.

Durable and high-performance grinding wheels for industrial use

The global market for borazon grinding wheels is expected to witness significant growth over the forecast period. Borazon grinding wheels are known for their superior performance in precision grinding applications, making them a preferred choice in industries such as automotive, aerospace, and tool manufacturing.One of the leading providers of borazon grinding wheels is [Company Name], a company that has been at the forefront of innovation in the abrasives industry for over two decades. Their commitment to quality, performance, and customer satisfaction has earned them a solid reputation among their clients.[Company Name] has continually invested in research and development to improve their products and meet the evolving needs of their customers. They have a team of skilled engineers and technicians who are dedicated to developing cutting-edge solutions for the most demanding grinding applications. This dedication to innovation has enabled [Company Name] to stay ahead of the competition and maintain their position as a market leader in the abrasives industry.The borazon grinding wheels offered by [Company Name] are designed to deliver exceptional performance and long service life. They are manufactured using high-quality materials and advanced manufacturing processes to ensure consistency and reliability. These wheels are capable of grinding a wide range of materials, including hardened steels, superalloys, and ceramics, with precision and efficiency.In addition to their standard product offerings, [Company Name] also provides custom grinding wheel solutions to meet the specific requirements of their customers. Whether it's a unique shape, size, or composition, their team is capable of designing and producing customized borazon grinding wheels that deliver exceptional results.Furthermore, [Company Name] is committed to providing outstanding customer service and technical support. They work closely with their clients to understand their needs and provide expert guidance on selecting the right grinding wheel for their applications. With a global distribution network, they are able to deliver their products to customers around the world in a timely and efficient manner.The demand for borazon grinding wheels is driven by the growing need for high-precision grinding in various industries. As manufacturers strive to achieve tighter tolerances and superior surface finishes, the demand for advanced grinding solutions continues to rise. Borazon grinding wheels offer high material removal rates, improved wheel life, and reduced cycle times, making them an ideal choice for manufacturers looking to improve their grinding processes.With their extensive experience and expertise in the abrasives industry, [Company Name] is well-positioned to capitalize on the growing demand for borazon grinding wheels. They continue to invest in research and development to further enhance their product offerings and remain at the forefront of innovation in the industry.In conclusion, the global market for borazon grinding wheels is poised for significant growth, driven by the increasing demand for high-precision grinding solutions. [Company Name] stands out as a leading provider of borazon grinding wheels, with a proven track record of delivering high-quality products and exceptional customer service. With their dedication to innovation and commitment to excellence, they are well-equipped to meet the evolving needs of their customers and maintain their position as a leader in the abrasives industry.

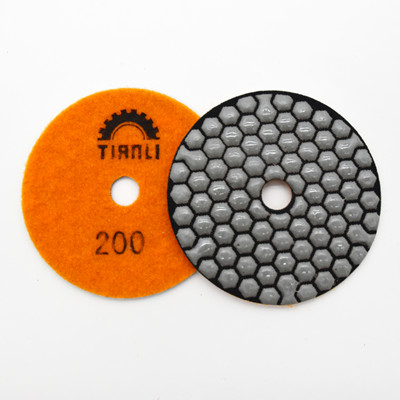

On-Site Dry Polishing Pads for Marble, Granite and Natural Stones

Title: Dry Polishing Pads: Revolutionizing On-Site Stone Polishing for Enhanced ResultsIntroduction:In the ever-evolving world of stone polishing, a breakthrough technology has emerged - Dry Polishing Pads. These innovative pads have ushered in a new era of on-site stone polishing, offering unparalleled convenience, efficiency, and outstanding results. Developed specifically for marble, granite, and other natural stones, as well as concrete floors and countertops, Dry Polishing Pads have quickly gained popularity among professionals in the stone industry. This article delves into the features, benefits, and applications of Dry Polishing Pads, further highlighting their potential to revolutionize the art of stone polishing.Unleashing the Power of Dry Polishing Pads:Traditional wet polishing methods often pose challenges such as extended drying times, hazardous working environments, and inconsistent outcomes. Moreover, the cumbersome process of setting up water sources and managing excess runoff further adds to the complexity and time required to complete polishing projects. However, with Dry Polishing Pads, these obstacles are decisively overcome.Utilizing advanced diamond-impregnated technology, Dry Polishing Pads demonstrate exceptional grit and superior polishing capabilities. The specially formulated resins ensure maximum durability, giving the pads a prolonged lifespan and allowing professionals to complete projects with utmost precision and consistency. Renowned for their ability to produce stunning mirror finishes, these pads provide a seamless, high-gloss appearance to a variety of stone surfaces.Benefits for Professionals:1. Unparalleled Convenience: The absence of water eliminates the need for setup and containment measures, streamlining the polishing process. Professionals can now effortlessly perform on-site repairs, touch-ups, or full-scale polishing with ease.2. Enhanced Efficiency: Dry Polishing Pads significantly reduce project completion time, enabling professionals to cater to multiple clients and projects effectively. The elimination of drying time accelerates productivity and eliminates the risk of water damage to surrounding areas.3. Superior Control: Dry Polishing Pads offer enhanced control, allowing professionals to maintain a consistent finish. The absence of water mitigates the risk of slippage, improving safety and reducing the potential for accidents.Applications:1. Natural Stone Polishing: Dry Polishing Pads have been specially designed to cater to a wide range of natural stones, including marble, granite, quartzite, and limestone. Their versatility ensures consistent and outstanding results on various stone surfaces.2. Concrete Floor Refinishing: Dry Polishing Pads offer exceptional results when used for concrete floor polishing. From industrial surfaces to residential spaces, these pads efficiently restore the natural shine, eliminating imperfections and transforming dull, lifeless floors into visually stunning ones.3. Countertop Restoration: Dry Polishing Pads are the ultimate solution for countertop restoration projects. They effortlessly remove scratches, stains, and blemishes, revitalizing the surface to its original luster.Conclusion:Dry Polishing Pads have heralded a new era in on-site stone polishing, revolutionizing the industry with their efficiency, versatility, and remarkable results. Professionals can now execute projects to the highest standards, saving time and resources while delivering flawless finishes to their clients. With their advanced technology and exceptional performance on various natural stone surfaces and concrete, Dry Polishing Pads have firmly established themselves as an indispensable tool for the modern stone industry.

High-Quality Wet Polishing Pads for Superior Surface Finishing

Wet Polishing Pad is a revolutionary product that has been gaining popularity in the construction and renovation industry. This innovative polishing pad is designed to be used with water to achieve a smooth and shiny finish on various surfaces, including natural stone, concrete, and terrazzo.The Wet Polishing Pad is manufactured by a reputable company that specializes in producing high-quality tools and equipment for the construction and renovation industry. With years of experience and expertise in the field, the company has established itself as a trusted and reliable source for professional-grade products.The Wet Polishing Pad is made with premium quality materials, ensuring durability and long-lasting performance. Its unique design and composition allow for effective and efficient polishing, resulting in a flawless finish. The use of water during the polishing process not only enhances the performance of the pad but also reduces dust and debris, creating a cleaner and safer work environment.One of the key advantages of the Wet Polishing Pad is its versatility. It can be used with a wide range of polishing machines, making it suitable for various projects and applications. Whether it's polishing marble countertops, concrete floors, or terrazzo surfaces, this innovative pad delivers exceptional results, saving time and effort for contractors and professionals.In addition to its outstanding performance, the Wet Polishing Pad is also designed for user convenience. Its easy-to-use design ensures a smooth and hassle-free polishing process, allowing users to achieve professional-quality results with minimal effort. This user-friendly approach makes the pad suitable for both experienced professionals and DIY enthusiasts.Furthermore, the company behind the Wet Polishing Pad is committed to sustainability and environmental responsibility. The pad is designed to minimize water consumption during the polishing process, promoting eco-friendly practices without compromising performance. This aligns with the company's dedication to producing sustainable and environmentally conscious products for the construction industry.The Wet Polishing Pad is backed by the company's dedication to customer satisfaction and support. With a strong focus on quality and reliability, the company ensures that its products meet the highest standards and exceed customer expectations. Additionally, the company provides comprehensive support and assistance, ensuring that customers have access to the information and resources they need to make the most of the Wet Polishing Pad.As the construction and renovation industry continues to evolve, the demand for innovative and efficient tools and equipment remains high. The Wet Polishing Pad offers a solution that addresses the need for a versatile, high-performance polishing pad that delivers exceptional results. With its reliable quality, user-friendly design, and commitment to sustainability, the Wet Polishing Pad has quickly become a go-to choice for professionals in the industry.In conclusion, the Wet Polishing Pad represents a significant advancement in the field of surface polishing, offering a combination of performance, versatility, and sustainability. With the backing of a reputable and experienced company, this innovative product is poised to make a lasting impact on the construction and renovation industry. Whether it's enhancing the appearance of natural stone countertops or polishing concrete floors, the Wet Polishing Pad is a valuable tool that professionals can rely on for outstanding results.