Durable Nylon Wheel Brush for Effective Cleaning and Scrubbing

By:Admin

In today's fast-paced world, keeping our living and working spaces clean and well-maintained is of utmost importance. From homes to commercial establishments, ensuring that every nook and cranny is free from dirt, grime, and debris is a significant factor in maintaining a healthy and conducive environment.

This is where the Nylon Wheel Brush comes into play. With its innovative design and superior functionality, this product has been gaining attention for its ability to effectively clean and maintain various surfaces, particularly those that are hard to reach or have intricate designs such as wheel rims, grilles, and other automotive parts.

The Nylon Wheel Brush is developed and manufactured by a renowned company that has been a leading player in the industry for several years. With a commitment to delivering top-quality products that meet the ever-evolving needs of consumers, the company has established itself as a trusted name in the market.

One of the key features of the Nylon Wheel Brush is its durable nylon bristles, which are designed to effectively remove tough dirt and grime without causing any damage to the surface being cleaned. This is especially crucial when it comes to delicate materials such as aluminum, chrome, or painted surfaces, where using the wrong type of brush can result in scratches or other forms of damage.

Furthermore, the design of the brush includes a sturdy handle that provides a comfortable and secure grip, allowing users to exert just the right amount of pressure during cleaning. This not only ensures a thorough cleaning process but also minimizes the risk of hand fatigue, making it easier to tackle even the most challenging cleaning tasks.

In addition to its effectiveness, the Nylon Wheel Brush is also known for its versatility. It can be used for a wide range of applications, including automotive detailing, household cleaning, and even industrial maintenance. This makes it a valuable tool for individuals and professionals alike, providing a cost-effective solution that delivers exceptional results.

What sets this product apart from other similar brushes on the market is the company's unwavering commitment to quality and innovation. Every aspect of the Nylon Wheel Brush, from its materials to its design, has been carefully considered and tested to ensure that it meets the highest standards of performance and durability.

Moreover, the company's dedication to customer satisfaction is evident in its support and service offerings. Whether it's providing insightful tips on how to get the most out of the Nylon Wheel Brush or addressing any concerns or inquiries, the company is committed to delivering a seamless and enjoyable experience for its customers.

As the demand for effective and reliable cleaning tools continues to grow, the Nylon Wheel Brush stands out as a product that delivers on its promises. By combining cutting-edge design, durable materials, and a commitment to excellence, this product has become a go-to choice for individuals and businesses looking to maintain clean and pristine surfaces with ease.

In conclusion, the Nylon Wheel Brush is a testament to the company's dedication to providing innovative solutions that make a real difference in people's lives. With its exceptional performance, versatility, and unwavering commitment to quality, this product has rightfully earned its place as a must-have cleaning tool for anyone who values cleanliness and maintenance.

Company News & Blog

Find Reputed Polishing Pad Suppliers and Manufacturers - Import Easily from All Countries at buyindustrialtools.com

Polishing Pad: A Great Tool for Achieving a Mirror-Like FinishA polishing pad is an essential tool in the field of metalworking, woodworking, and automotive repair. It is used to achieve a mirror-like finish on surfaces of different materials, including metal, wood, and plastics. Polishing pads are available in different sizes, shapes, and materials, each designed for specific applications. In this blog post, we will talk about polishing pads, their benefits, and how to choose the right one.What is a Polishing Pad?A polishing pad is a circular tool that attaches to an angle grinder, rotary tool, or drill. It consists of a foam or wool backing that holds the abrasive material. The foam or wool backing is essential for distributing and absorbing the pressure, preventing swirls, scratches, and gouges from forming on the surface being polished. The abrasive material can be diamond, aluminum oxide, or silicon carbide, depending on the hardness and thickness of the material being polished.Benefits of Using a Polishing PadUsing a polishing pad has several benefits, including:1. Smooth and Uniform Finish: A polishing pad can achieve a smooth and uniform finish on any surface, removing scratches, swirls, and blemishes.2. Time and Labor-Saving: Polishing pads are quick and efficient, saving time and labor costs. They can remove imperfections, stains, and oxidation quickly without damaging the surface.3. Versatility: Polishing pads can be used on various materials, including metal, wood, plastics, and painted surfaces, making them versatile tools for a range of applications.4. Consistent Results: Polishing pads produce consistent results, ensuring that the surface achieved is the same every time, which is essential for projects that require a uniform finish.Choosing the Right Polishing PadChoosing the right polishing pad is essential for achieving the desired results. Here are some factors to consider when selecting the right polishing pad for your project.1. Material being polished - Different materials require different types of polishing pads. For instance, a soft foam pad is ideal for polishing paint, while a wool pad is perfect for metal surfaces.2. Grit - The grit size determines the level of abrasiveness of the polishing pad. A fine grit of 800-1000 is ideal for achieving a mirror-like finish.3. Size - The size of the polishing pad should match the size of the surface being polished. A larger pad is ideal for polishing large surfaces, while a smaller pad is suitable for intricate details.4. Speed - The speed at which the polishing pad spins is essential for achieving the desired results. A higher speed produces a more aggressive cut, while a slower speed produces a finer finish.ConclusionA polishing pad is an essential tool for achieving a mirror-like finish on a range of materials. They are quick, efficient, and versatile, saving time and labor costs while producing consistent results. When choosing a polishing pad, consider factors such as the material being polished, the grit, size, and speed. Investing in a quality polishing pad is a sound investment that will provide excellent results for years to come. So, if you're looking to achieve a flawless finish, consider investing in a 100mm polishing pad. It is the perfect size for most applications and will produce a mirror-like shine on any surface.

How to Cut and Polish Pads for Optimal Results

Leading Polishing Pad Manufacturer Introduces Cutting-edge Technology for a Flawless FinishWith a commitment to excellence and a passion for innovation, [Company Name] continues to revolutionize the polishing pad industry with their cutting-edge technology. As a leading manufacturer in the industry, [Company Name] has been dedicated to providing high-quality products and unparalleled customer service since its inception.The introduction of their latest product, the Cutting Polishing Pad, has set a new benchmark in the industry. The revolutionary technology incorporated into these pads has been designed to deliver a flawless finish, making them a game-changer for professionals and enthusiasts alike. By combining their years of experience with advanced research and development, [Company Name] has once again raised the bar for polishing pad performance.The Cutting Polishing Pads are engineered to deliver exceptional results when used with a variety of materials, including metal, glass, stone, and composite materials. Their unique design and advanced materials ensure a longer lifespan and superior performance compared to traditional pads. This innovation is a testament to [Company Name]'s unwavering commitment to pushing the boundaries of what is possible in the industry.The key features of the Cutting Polishing Pads include:1. Enhanced Durability: The advanced materials used in the manufacturing process ensure increased durability and longer pad life, reducing the need for frequent replacements and saving time and money for users.2. Superior Finish: The innovative design of the pads delivers a flawless finish, with reduced swirl marks and improved clarity, leaving a professional-grade shine on any surface.3. Versatility: The Cutting Polishing Pads are designed to be compatible with a wide range of materials, making them a versatile and effective tool for professionals in various industries.In addition to the technological advancements of the Cutting Polishing Pads, [Company Name] prides itself on its commitment to sustainability and environmental responsibility. As part of their ongoing efforts to reduce their carbon footprint, [Company Name] has implemented eco-friendly manufacturing practices and materials in the production of their products.Furthermore, [Company Name] is dedicated to providing exceptional customer service and support. Their team of experts is always available to offer guidance and assistance to customers, ensuring that they have the best possible experience with their products.In line with their dedication to continuous improvement and innovation, [Company Name] is constantly investing in research and development to explore new possibilities for enhancing their product range and staying ahead of industry trends. The introduction of the Cutting Polishing Pads is just one example of [Company Name]'s ongoing efforts to lead the way in the polishing pad market.As a company that has built a reputation for excellence, [Company Name] is proud to introduce the Cutting Polishing Pads as the latest addition to their product lineup. With their unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] remains a trusted name in the industry and continues to set the standard for polishing pad performance.In conclusion, the introduction of the Cutting Polishing Pads by [Company Name] marks a significant milestone in the industry, showcasing their dedication to innovation and excellence. With their advanced technology, superior performance, and commitment to sustainability, [Company Name] continues to lead the way in providing high-quality polishing solutions for professionals and enthusiasts around the world.

The Role of Abrasives: Essential Tools for Surface Material Wear and Polishing

Title: Ceramic Abrasive Tools: The Cutting Edge of Material Surface RefinementIntroduction:When it comes to refining the surfaces of various materials, an abrasive is an integral tool that enables the removal of imperfections and achieves the desired smoothness or texture. In this blog, we will explore the incredible world of ceramic abrasive tools, their applications, and the benefits they offer for surface refinement. Moreover, we will delve into the key features that make ceramic abrasives the cutting edge choice for professionals and their unparalleled contribution to various industries. So, let's dive in!1. Understanding Abrasives:Abrasives are sharp, hard materials designed to wear down the surfaces of softer materials through abrasion. They play a crucial role in shaping, polishing, and refining various substances ranging from household cleansers to the most resilient materials. Today, we shift our focus onto ceramic abrasives, which are revolutionizing the industry.2. The Rise of Ceramic Abrasive Tools:Ceramic abrasives represent a breed of advanced materials designed to deliver exceptional performance and longevity. Combining the strength of ceramic grains with engineered bonding agents, these cutting-edge tools offer superior hardness, durability, and heat resistance. As a result, ceramic abrasives have found their way into a multitude of applications across a wide range of industries.3. Versatile Applications of Ceramic Abrasives:(a) Metalworking Industry: Ceramic abrasives are extensively used for precision grinding, deburring, and surface finishing in the metalworking industry. Their exceptional hardness and heat resistance make them ideal for demanding applications such as stainless steel fabrication, automotive production, and aerospace manufacturing.(b) Woodworking Industry: The wood industry benefits from ceramic abrasives that effectively shape and smoothen wooden surfaces. Whether it is sanding furniture, refining cabinetry, or shaping intricate woodworking designs, ceramic abrasive tools provide long-lasting performance and unmatched precision.(c) Glass Processing: Glass manufacturers rely on ceramic abrasives for shaping and polishing glass products. The superior hardness and cutting power of ceramic abrasives contribute to flawless glass edging, beveling, and other intricate surface treatment processes.(d) Automotive Sector: Ceramic abrasive tools find extensive use in the automotive sector for paint and bodywork applications. Their ability to delicately remove layers of paint, scratches, and imperfections ensures a stellar finish, setting a new standard in the industry.4. Unparalleled Benefits of Ceramic Abrasives:(a) Exceptional Durability: Ceramic abrasives are renowned for their outstanding longevity. Their robustness resists wear and tear, resulting in better tool life and reduced downtime.(b) Heat Resistance: Ceramic abrasives can withstand high temperatures generated during the grinding process, making them suitable for heavy-duty applications. The reduced risk of overheating ensures consistent performance and improves overall productivity.(c) Superior Material Removal: The crystalline structure of ceramic abrasives allows for an aggressive cutting action, quickly removing unwanted material. This efficiency enables professionals to achieve precise and smooth finishes with minimal effort.(d) Reduced Friction and Heat Generation: Ceramic abrasives have self-sharpening properties, ensuring consistent cutting power throughout their lifetime. With reduced friction, they generate less heat, which further safeguards the integrity of the workpiece.5. Conclusion:Ceramic abrasive tools have paved the way for a new realm of surface refinement, setting industry standards for performance and durability. With their unmatched hardness, superior cutting power, heat resistance, and versatility, ceramic abrasives are the go-to choice for professionals across various domains. As technology advances, we can expect continued innovation and enhancements in ceramic abrasive tools, translating into improved processes and superior final products.Keywords: Ceramic Abrasive Tools, Abrasives, Surface Refinement, Hardness, Durability, Heat Resistance, Metalworking Industry, Woodworking Industry, Glass Processing, Automotive SectorWord Count: 606

Different Types of Grinding Wheel for Various Applications

Grinding Wheel Types and Their ApplicationsGrinding wheels are essential tools in the manufacturing and metalworking industries, used for shaping and finishing metals and other materials. They are available in a variety of types, each designed for specific applications and materials. Understanding the different types of grinding wheels can help manufacturers and metalworkers choose the right tool for their needs.A leading player in the manufacturing industry, {company name} is a renowned provider of grinding wheels and other abrasive products. With a strong emphasis on quality and innovation, {company name}'s extensive range of grinding wheels caters to various industries and applications.{company name} offers a diverse selection of grinding wheel types, each tailored to meet the needs of different materials and applications. The following are some of the most commonly used grinding wheel types and their respective applications:1. Straight Grinding Wheels: These are the most common type of grinding wheel, featuring a simple, flat design. They are used for surface grinding, cylindrical grinding, and tool sharpening.2. Cylinder Wheels: These wheels have a long, cylindrical shape, making them suitable for grinding long, narrow surfaces.3. Tapered Grinding Wheels: As the name suggests, these wheels have a tapered shape, making them ideal for grinding threads and gear teeth.4. Dish Grinding Wheels: These wheels have a slightly concave shape, making them suitable for grinding tools and cutters.5. Diamond Wheels: Diamond grinding wheels are made with synthetic diamonds, making them extremely durable and suitable for grinding hard materials such as carbides, ceramics, and glass.6. CBN Wheels: Cubic Boron Nitride (CBN) wheels are designed for grinding ferrous materials such as steel and cast iron, offering high thermal conductivity and chemical stability.7. Segmented Grinding Wheels: These wheels are made up of multiple segments, allowing for aggressive material removal and improved cooling during grinding.8. Mounted Points: These small, specialized grinding wheels are used for precision grinding in hard-to-reach areas.{company name} is committed to delivering high-quality grinding wheels that meet the diverse needs of its customers. With a focus on innovation and technological advancement, {company name} continuously develops new grinding wheel types and formulations to address the evolving needs of the industry.In addition to offering a wide range of grinding wheel types, {company name} provides expert guidance and technical support to help customers choose the right wheel for their specific applications. Through its extensive industry experience and technical expertise, {company name} ensures that its customers achieve optimal grinding results and maximize productivity.The use of high-quality grinding wheels is essential for achieving precision and efficiency in metalworking and manufacturing processes. {company name} is dedicated to providing solutions that enable its customers to enhance their productivity, reduce operating costs, and improve the quality of their finished products.As a leading provider of grinding wheels and abrasive products, {company name} has built a strong reputation for its commitment to quality, innovation, and customer satisfaction. With a comprehensive range of grinding wheel types and a dedication to technical excellence, {company name} continues to be at the forefront of the abrasive industry.In conclusion, choosing the right grinding wheel is crucial for achieving optimal results in metalworking and manufacturing processes. With its extensive range of grinding wheel types and a focus on quality and innovation, {company name} is the preferred choice for customers seeking high-performance abrasive solutions. Whether it's surface grinding, cylindrical grinding, or precision grinding, {company name} has the right grinding wheel for every application.

Get the Best Cup Wire Brush for Angle Grinders and Improve Your Metalworking Projects

The {Company name} is proud to announce the release of its latest product, the Cup Wire Brush for Angle Grinder. This innovative tool is designed to make grinding, deburring, and cleaning metal surfaces easier and more efficient than ever before. With its durable construction and high-quality materials, this cup wire brush is built to last and provide outstanding performance in a wide range of applications.The Cup Wire Brush for Angle Grinder is designed for use on angle grinders with a maximum rpm of 12,000. Its unique design allows for smooth and effortless operation, making it ideal for professionals and DIY enthusiasts alike. The brush is constructed with high-quality wire filaments that are designed to withstand heavy-duty use and provide excellent abrasion and wear resistance. This ensures that the brush will maintain its performance and longevity even when used in the most demanding applications.One of the key features of the Cup Wire Brush for Angle Grinder is its innovative cup shape, which allows for increased surface contact and more effective material removal. This design helps to minimize the risk of surface damage, making it an ideal choice for cleaning and preparing metal surfaces prior to painting, coating, or welding. Additionally, the brush is suitable for removing rust, scale, and corrosion from metal surfaces, making it an indispensable tool for anyone working with metal materials.In addition to its outstanding performance, the Cup Wire Brush for Angle Grinder is also designed with user safety and comfort in mind. The brush is equipped with a secure mounting system that ensures stability and reduces the risk of accidents during operation. It also features a comfortable grip that allows for precise control and reduced hand fatigue, enabling users to work for extended periods without discomfort.The Cup Wire Brush for Angle Grinder is just one of many high-quality products offered by {Company name}. With a strong commitment to innovation and excellence, the company has earned a reputation for delivering top-of-the-line tools and equipment to professionals and enthusiasts in a wide range of industries. By combining cutting-edge technology with premium materials and expert craftsmanship, {Company name} continues to set the standard for performance and reliability in the industry.With the release of the Cup Wire Brush for Angle Grinder, {Company name} once again demonstrates its dedication to meeting the needs of its customers and providing them with the tools they need to succeed. Whether you are a professional metalworker or a hobbyist, this versatile and reliable brush is sure to become an essential part of your toolkit. For more information about the Cup Wire Brush for Angle Grinder and other high-quality products from {Company name}, visit their website or contact their customer service team.

Top 10 Hand Polishing Tools for a Professional Finish

Hand Polishing Tools Combine Precision and Quality CraftsmanshipIn the world of woodworking and craftmanship, the quality of hand polishing tools can make all the difference. When it comes to achieving a smooth and flawless finish, precision and quality craftsmanship are crucial. This is where [Company Name], a leading manufacturer of hand polishing tools, excels.With a rich history dating back to 1975, [Company Name] has been dedicated to providing high-quality hand polishing tools to professionals and hobbyists alike. Their commitment to precision and quality craftsmanship has established them as a trusted name in the industry.The [Company Name] hand polishing tools are designed with the needs of their customers in mind. The company offers a wide range of hand polishing tools, including sanding blocks, polishing sticks, and finishing pads, all of which are meticulously crafted to deliver exceptional results. These tools are made from high-quality materials, ensuring durability and longevity.What sets [Company Name] hand polishing tools apart is their attention to detail. Each tool is carefully inspected to ensure that it meets the company's high standards for quality. This commitment to excellence has earned [Company Name] a reputation for producing hand polishing tools that deliver consistent and reliable performance.One of the key advantages of [Company Name] hand polishing tools is their versatility. Whether it's smoothing out rough edges or achieving a glass-like finish, these tools are designed to handle a wide range of tasks with ease. This makes them a valuable addition to any craftsman's toolbox.In addition to their commitment to quality, [Company Name] also places a strong emphasis on customer satisfaction. The company strives to provide exceptional customer service, ensuring that their clients receive the support and assistance they need. This dedication to their customers has helped [Company Name] build long-lasting relationships in the industry.As part of their ongoing commitment to innovation, [Company Name] continues to develop new hand polishing tools that meet the evolving needs of their customers. By staying at the forefront of technology and design, the company ensures that their products remain relevant and competitive in the market.In conclusion, the combination of precision and quality craftsmanship sets [Company Name] hand polishing tools apart from the competition. With a legacy of excellence spanning over four decades, the company has proven itself as a leader in the industry. Whether it's for professional use or personal projects, craftsmen can trust [Company Name] to deliver hand polishing tools that meet their exacting standards. With a focus on quality, versatility, and customer satisfaction, [Company Name] continues to set the standard for hand polishing tools in the woodworking and craftsmanship industry.

Discover the Benefits of Metal and Nonmetal Bonds for Your Application

Metal And Nonmetal Bond, a leading manufacturer of bonding solutions for industrial applications, has recently introduced a new range of bonding products that are designed to provide strong and durable bonds between metal and nonmetal materials. This new range of products is set to revolutionize the bonding industry, offering a solution to the challenges of bonding metal and nonmetal surfaces together.The company, {}, has been a key player in the bonding industry for over 20 years, with a strong reputation for providing high-quality bonding solutions for a wide range of industrial applications. With a focus on innovation and customer satisfaction, Metal And Nonmetal Bond has consistently been at the forefront of developing new and improved bonding products to meet the ever-evolving needs of its customers.The new range of bonding products from Metal And Nonmetal Bond is a result of years of research and development, and is a testament to the company's commitment to continuous improvement. These products are designed to provide superior adhesion and bonding strength, while also offering excellent resistance to heat, moisture, and chemicals. This makes them ideal for use in a variety of industries, including automotive, aerospace, construction, and manufacturing.One of the key features of the new range of bonding products is their versatility. Whether it's bonding metal to plastic, metal to glass, or metal to composite materials, Metal And Nonmetal Bond's products are able to provide strong and reliable bonds in a wide range of applications. This versatility makes the products ideal for use in a variety of industries, where bonding different materials together is a common requirement.Another important aspect of the new range of bonding products is their ease of use. Metal And Nonmetal Bond has always prioritized customer convenience, and these new products are no exception. With easy application and fast curing times, these products are designed to streamline the bonding process, saving time and effort for industrial users.In addition to their superior bonding strength and ease of use, the new range of bonding products from Metal And Nonmetal Bond also offer excellent durability. These products are designed to withstand harsh environmental conditions and heavy-duty usage, making them suitable for even the most demanding industrial applications."Metal And Nonmetal Bond is proud to introduce our new range of bonding products, which are set to raise the bar for bonding solutions in the industry," said [company spokesperson]. "We have put a lot of effort into developing these products, and we are confident that they will provide our customers with the high-quality, reliable bonding solutions they have come to expect from us."As industry demands continue to evolve, Metal And Nonmetal Bond remains committed to staying ahead of the curve by offering innovative and reliable bonding solutions. With the introduction of the new range of bonding products, the company is set to maintain its position as a leader in the bonding industry, and to continue meeting the diverse needs of its customers across various industrial sectors.

Polishing Concrete Floors: Tips and Equipment to Consider

Title: Transforming Concrete Surfaces with Advanced Concrete Polishing PadsIntroduction:In recent years, there has been a growing trend of using concrete as a sleek and stylish flooring option for commercial and residential spaces. With advancements in technology and the availability of specialized tools, concrete floor polishing has emerged as a highly effective method to enhance the appearance and durability of concrete surfaces. One essential element of the process is the use of concrete polishing pads, specifically designed for floor buffer machines. These pads play a crucial role in achieving a flawless and glossy finish on polished concrete floors.The Importance of Concrete Polishing Pads:Concrete polishing pads are specifically engineered to remove imperfections from concrete surfaces and gradually refine them to a smooth and vibrant finish. These pads are made from high-quality materials and are available in various grits, enabling professionals to fine-tune the polishing process as per the unique needs of the project.Key Considerations for Achieving Polished Concrete Floors:1. Grinding and Cost: Before embarking on a concrete floor polishing project, it is essential to consider the grinding process and associated costs. Grinding aids in removing unevenness, stains, and blemishes from the surface, creating a perfect canvas for polishing. The use of appropriate concrete polishing pads for floor machines ensures efficient grinding, leading to cost-effective results.2. Equipment and Supplies: Investing in top-notch concrete polishing equipment is vital to achieving excellent results. The use of high-quality concrete floor polishing machines, along with advanced concrete polishing pads, ensures optimal performance and durability. Additionally, reliable suppliers offer a range of concrete polishing supplies, ensuring seamless execution of the project.3. Professional Services: While DIY concrete floor polishing may seem tempting, seeking professional services is often recommended for flawless and long-lasting results. Experienced professionals possess the necessary knowledge, skills, and expertise to handle complex polishing tasks efficiently. Moreover, their access to premium concrete polishing pads and equipment ensures superior outcomes.4. Epoxy vs. Polished Concrete: When considering concrete flooring options, it's important to understand the difference between epoxy flooring and polished concrete. Epoxy provides a seamless and durable finish, suitable for high-traffic areas. On the other hand, polished concrete offers a unique aesthetic appeal, showcasing the natural beauty of the concrete. Understanding the pros and cons of each option ensures making an informed decision.Benefits of Polished Concrete Floors:1. Aesthetics: Polished concrete floors add a touch of elegance and modernity to any space. The glossy finish accentuates the natural patterns, colors, and texture of the concrete, creating a visually appealing environment.2. Durability: Polished concrete surfaces are extremely durable and resistant to scratches, stains, and wear. This makes them an ideal choice for heavy foot traffic areas, such as retail stores, warehouses, and restaurants.3. Maintenance: Polished concrete floors are easy to clean and maintain. Unlike other flooring options, they do not require waxing or additional coatings, reducing maintenance costs and efforts significantly.4. Sustainable Choice: Concrete is a sustainable material, and by choosing polished concrete floors, one contributes to a greener environment. Reduced maintenance requirements and a longer lifespan further enhance its eco-friendly characteristics.Conclusion:Concrete floor polishing has revolutionized the flooring industry, presenting a cost-effective and visually appealing alternative to traditional options. Key to achieving impeccable results is the use of high-quality concrete polishing pads, specifically designed for floor buffer machines. Professionals well-versed in the process, coupled with advanced equipment and supplies, ensure that concrete surfaces are transformed into durable, elegant, and sustainable flooring solutions.

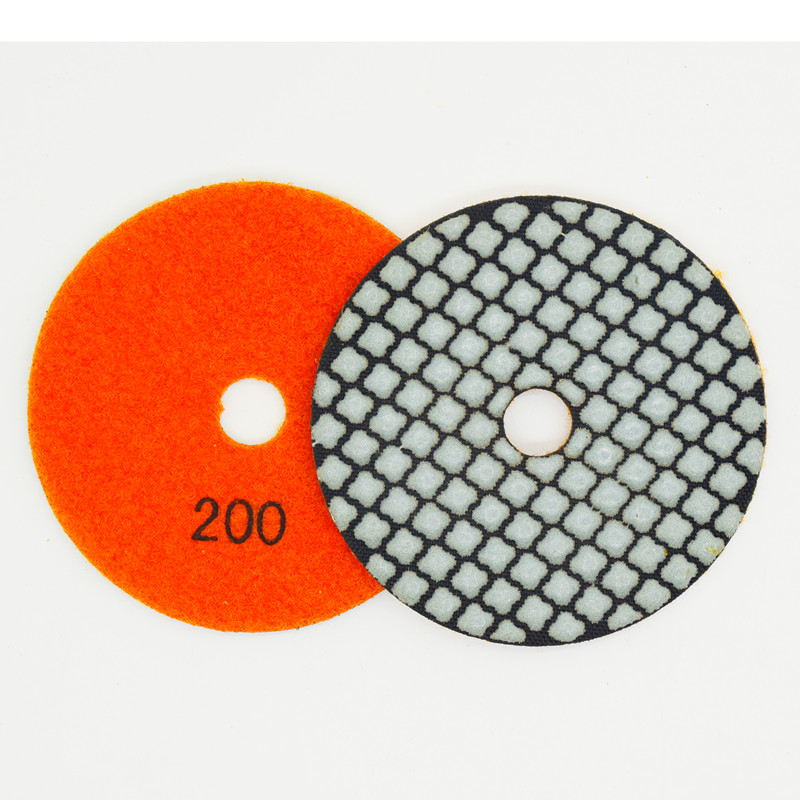

6-1/2" x 7/8" Hook & Loop Standard Duty Orbital (SDO) Polishing Pad for Orange Polishing

Title: LK SDO-22650 Orange Polishing Pad: The Ultimate Standard Duty Hook & Loop Polishing SolutionIntroduction:Established in [year], [Company Name] has become a trusted name in the automotive detailing industry, known for its high-quality products and innovative solutions. As a frontrunner in providing cutting-edge polishing accessories, [Company Name] is proud to introduce the all-new LK SDO-22650 Orange Polishing Pad. This revolutionary 6-1/2" x 7/8" Hook & Loop SDO Pad is designed to redefine the standard duty polishing experience. With a focus on eliminating imperfections and enhancing the overall aesthetic appeal of any surface, the LK SDO-22650 Orange Polishing Pad is set to become an indispensable tool for automotive enthusiasts and professionals alike.Unleashing Advanced Technology:The LK SDO-22650 Orange Polishing Pad utilizes state-of-the-art Hook & Loop technology, providing effortless attachment and removal on compatible orbital polishers. This advanced technology ensures a secure grip, enabling users to tackle even the most demanding polishing tasks with ease.Superior Foam Construction:Built to surpass industry standards, the LK SDO-22650 Orange Polishing Pad incorporates high-quality foam that guarantees exceptional performance. The pad boasts the same superior foam found in the highly acclaimed HDO line but without the dual-layer construction. This innovative design allows for an optimal balance of flexibility and firmness, facilitating efficient polishing while minimizing the risk of introducing new defects to the surface.Unmatched Versatility:The LK SDO-22650 Orange Polishing Pad is engineered to excel in various polishing applications. Whether restoring faded paintwork, removing light scratches, or enhancing the gloss and depth of a surface, this pad delivers unparalleled results. Its unique cell structure ensures a controlled distribution of polishing agents, preventing product wastage while maximizing efficiency. Furthermore, the pad's shape and size make it ideal for tackling both flat and contoured surfaces, ensuring consistent and uniform results across the entire work area.Effective Defect Removal:The orange foam featured in the LK SDO-22650 Polishing Pad is specifically designed for moderate defect removal. It excels at eliminating light to medium swirl marks, oxidation, holograms, and other imperfections, leaving surfaces flawlessly refined. By harnessing the excellent cutting ability of this pad, automotive professionals can achieve a high level of perfection in their work, taking the pride of ownership to a whole new level.Ease of Use:One of the key benefits of the LK SDO-22650 Orange Polishing Pad is its ease of use. The Hook & Loop attachment system allows for quick pad changes, minimizing downtime and increasing productivity. The pad's ergonomic design and optimal weight distribution enable users to maintain excellent control and maneuverability during the polishing process. Additionally, the pad's compatibility with a wide range of automotive polishing compounds ensures that users can effortlessly achieve their desired results, whether using heavy-cutting, all-in-one, or finishing products.Longevity and Durability:The LK SDO-22650 Orange Polishing Pad is designed to withstand rigorous and extended usage, reflecting the company's commitment to delivering products built to last. By utilizing high-quality materials, this pad offers superb heat resistance, reducing the risk of foam disintegration and prolonging its lifespan. Whether used by detailing enthusiasts or professionals during frequent or occasional use, the LK SDO-22650 Orange Polishing Pad will retain its performance and integrity, providing exceptional value for money.Conclusion:With the introduction of the LK SDO-22650 Orange Polishing Pad, [Company Name] continues to demonstrate its commitment to revolutionizing the automotive detailing industry. The combination of the cutting-edge Hook & Loop technology and its superior foam construction makes this pad a game-changer in the standard duty polishing category. Providing outstanding defect removal capabilities, ease of use, and durability, the LK SDO-22650 Orange Polishing Pad is set to become an indispensable tool for enthusiasts and professionals alike. Explore the versatility and precision of the LK SDO-22650 Orange Polishing Pad and elevate your detailing experience to new heights.

New Innovation in Polishing Pads: Hook Loop Polishing Pad

Hook Loop Polishing Pad[Company Name] is proud to introduce our latest innovation in the field of car care products – the Hook Loop Polishing Pad. This state-of-the-art polishing pad is designed to provide a high-quality finish on all types of automotive surfaces, making it the perfect tool for car enthusiasts and professional detailers alike.The Hook Loop Polishing Pad is made with premium materials to ensure durability and long-lasting performance. The hook and loop design allows for easy and secure attachment to polishing machines, making the pad easy to use and versatile for a variety of polishing applications. The pad also features a unique foam composition that provides an even distribution of polish and wax, resulting in a smooth and flawless finish with every use.One of the key features of the Hook Loop Polishing Pad is its versatility. Whether you are polishing paint, chrome, glass, or plastic, this pad is designed to deliver outstanding results on any surface. This makes it an ideal choice for anyone looking to achieve professional-quality results on their vehicle.In addition to its superior performance, the Hook Loop Polishing Pad is also designed with user convenience in mind. The pad is machine washable, allowing for easy cleaning and maintenance after each use. This not only prolongs the life of the pad but also ensures that it maintains its effectiveness over time.[Company Name] is dedicated to providing high-quality car care products that meet the needs of our customers. The development of the Hook Loop Polishing Pad is a result of our commitment to innovation and excellence in the automotive industry. We understand the importance of maintaining the appearance of a vehicle, and our products are designed to make the car care process both effective and enjoyable.The Hook Loop Polishing Pad is now available for purchase and is already receiving positive feedback from car enthusiasts and professionals in the industry. Users have praised the pad for its ease of use, exceptional results, and long-lasting performance. With the introduction of this innovative product, [Company Name] continues to solidify its position as a leader in the car care industry.As [Company Name] continues to grow and expand its product offerings, customers can expect more innovative and high-quality solutions for their car care needs. The Hook Loop Polishing Pad is just the beginning of what [Company Name] has to offer, and we are committed to developing products that exceed the expectations of our customers.In conclusion, the introduction of the Hook Loop Polishing Pad marks a significant milestone for [Company Name] and reinforces our commitment to providing superior car care products. With its advanced design, exceptional performance, and user-friendly features, this pad is set to become a must-have tool for anyone looking to achieve professional-quality results in car detailing. As [Company Name] continues to lead the way in innovation, customers can look forward to more game-changing products that set new standards in the car care industry.