Durable Nylon Cup Brush for Angle Grinder - A Must-Have Tool

By:Admin

In the world of industrial equipment and tools, the importance of having the right accessories cannot be overstated. From cutting and grinding to polishing and finishing, having the right attachments for your machinery can make all the difference in the efficiency and quality of your work. One such essential accessory is the Nylon Cup Brush for Angle Grinder, an innovative and versatile tool designed for a wide range of industrial applications.

Manufactured by a leading company in the industry, the Nylon Cup Brush for Angle Grinder is a high-quality attachment that is designed to deliver exceptional performance and durability. The company has been at the forefront of producing top-notch industrial tools and equipment for several years, and their commitment to excellence is reflected in the design and functionality of this nylon cup brush.

The nylon cup brush is specifically designed for use with angle grinders, making it a flexible and adaptable tool that can be used for a variety of applications. It is ideal for removing rust, paint, and corrosion from metal surfaces, as well as for cleaning welds and preparing surfaces for painting or coating. Additionally, the nylon bristles are gentle enough to use on wood and other delicate materials, making this brush a versatile addition to any workshop or industrial setting.

One of the key features of the Nylon Cup Brush for Angle Grinder is its durability. The nylon bristles are designed to withstand heavy-duty use, making it a reliable tool for demanding industrial applications. Whether used for surface preparation, cleaning, or finishing, this brush is built to last and can withstand the rigors of industrial use.

Moreover, the design of the nylon cup brush allows for efficient and effective operation. The brush is easy to attach to an angle grinder, and its ergonomic design ensures comfortable and precise maneuverability. This enables users to achieve consistent and professional results with minimal effort, making it an invaluable tool for any industrial setting.

The nylon cup brush is also a safer alternative to wire brushes, as it eliminates the risk of metal bristles breaking off and causing injury or damage to the workpiece. The soft and flexible nylon bristles are also less likely to scratch or gouge the surface being worked on, making it a reliable and safe option for a wide range of applications.

In addition to its practical and functional benefits, the Nylon Cup Brush for Angle Grinder is also a cost-effective tool that offers excellent value for money. Its long-lasting performance and versatility make it a wise investment for any workshop or industrial facility, helping to improve efficiency and productivity while delivering high-quality results.

Overall, the Nylon Cup Brush for Angle Grinder is a versatile and effective tool that is well-suited for a wide range of industrial applications. With its durable construction, efficient operation, and cost-effective nature, this brush is an essential accessory for anyone looking to enhance the performance and versatility of their angle grinder.

For more information about the Nylon Cup Brush for Angle Grinder and other innovative industrial tools and equipment, please visit {company website} or contact {company name} directly.

Company News & Blog

The Role of Abrasives: Essential Tools for Surface Material Wear and Polishing

Title: Ceramic Abrasive Tools: The Cutting Edge of Material Surface RefinementIntroduction:When it comes to refining the surfaces of various materials, an abrasive is an integral tool that enables the removal of imperfections and achieves the desired smoothness or texture. In this blog, we will explore the incredible world of ceramic abrasive tools, their applications, and the benefits they offer for surface refinement. Moreover, we will delve into the key features that make ceramic abrasives the cutting edge choice for professionals and their unparalleled contribution to various industries. So, let's dive in!1. Understanding Abrasives:Abrasives are sharp, hard materials designed to wear down the surfaces of softer materials through abrasion. They play a crucial role in shaping, polishing, and refining various substances ranging from household cleansers to the most resilient materials. Today, we shift our focus onto ceramic abrasives, which are revolutionizing the industry.2. The Rise of Ceramic Abrasive Tools:Ceramic abrasives represent a breed of advanced materials designed to deliver exceptional performance and longevity. Combining the strength of ceramic grains with engineered bonding agents, these cutting-edge tools offer superior hardness, durability, and heat resistance. As a result, ceramic abrasives have found their way into a multitude of applications across a wide range of industries.3. Versatile Applications of Ceramic Abrasives:(a) Metalworking Industry: Ceramic abrasives are extensively used for precision grinding, deburring, and surface finishing in the metalworking industry. Their exceptional hardness and heat resistance make them ideal for demanding applications such as stainless steel fabrication, automotive production, and aerospace manufacturing.(b) Woodworking Industry: The wood industry benefits from ceramic abrasives that effectively shape and smoothen wooden surfaces. Whether it is sanding furniture, refining cabinetry, or shaping intricate woodworking designs, ceramic abrasive tools provide long-lasting performance and unmatched precision.(c) Glass Processing: Glass manufacturers rely on ceramic abrasives for shaping and polishing glass products. The superior hardness and cutting power of ceramic abrasives contribute to flawless glass edging, beveling, and other intricate surface treatment processes.(d) Automotive Sector: Ceramic abrasive tools find extensive use in the automotive sector for paint and bodywork applications. Their ability to delicately remove layers of paint, scratches, and imperfections ensures a stellar finish, setting a new standard in the industry.4. Unparalleled Benefits of Ceramic Abrasives:(a) Exceptional Durability: Ceramic abrasives are renowned for their outstanding longevity. Their robustness resists wear and tear, resulting in better tool life and reduced downtime.(b) Heat Resistance: Ceramic abrasives can withstand high temperatures generated during the grinding process, making them suitable for heavy-duty applications. The reduced risk of overheating ensures consistent performance and improves overall productivity.(c) Superior Material Removal: The crystalline structure of ceramic abrasives allows for an aggressive cutting action, quickly removing unwanted material. This efficiency enables professionals to achieve precise and smooth finishes with minimal effort.(d) Reduced Friction and Heat Generation: Ceramic abrasives have self-sharpening properties, ensuring consistent cutting power throughout their lifetime. With reduced friction, they generate less heat, which further safeguards the integrity of the workpiece.5. Conclusion:Ceramic abrasive tools have paved the way for a new realm of surface refinement, setting industry standards for performance and durability. With their unmatched hardness, superior cutting power, heat resistance, and versatility, ceramic abrasives are the go-to choice for professionals across various domains. As technology advances, we can expect continued innovation and enhancements in ceramic abrasive tools, translating into improved processes and superior final products.Keywords: Ceramic Abrasive Tools, Abrasives, Surface Refinement, Hardness, Durability, Heat Resistance, Metalworking Industry, Woodworking Industry, Glass Processing, Automotive SectorWord Count: 606

Understanding the Difference Between Nonmetal and Metal Bonds

Nonmetal and Metal Bonds: Revolutionizing the Aerospace IndustryAs technology continues to advance, the aerospace industry is constantly seeking innovative materials and methods to improve the performance of their products. One such advancement is the development of nonmetal and metal bonds, which has the potential to revolutionize the way aircraft components are manufactured and utilized.The use of nonmetal and metal bonds has been gaining traction in the aerospace industry due to their unique combination of properties, including high strength, light weight, and durability. These bonds are created through a process that involves the bonding of nonmetal materials, such as carbon fiber or ceramics, with metal alloys, resulting in a material that offers the best of both worlds.One company that has been at the forefront of this technology is {}. With a strong focus on research and development, {} has been able to create a range of nonmetal and metal bonded materials that are tailored to the specific needs of the aerospace industry. These materials have been met with enthusiasm from industry professionals and are expected to play a significant role in the future of aircraft manufacturing.The use of nonmetal and metal bonds has the potential to significantly reduce the weight of aircraft components, resulting in improved fuel efficiency and reduced carbon emissions. In addition, these materials offer greater strength and durability compared to traditional materials, which can contribute to increased safety and longevity of aircraft.Furthermore, nonmetal and metal bonded materials are also more resistant to corrosion and fatigue, reducing the need for frequent maintenance and repair. This can lead to cost savings for airlines and contribute to improved operational efficiency.{} has been working closely with aerospace manufacturers to integrate their nonmetal and metal bonded materials into various components of aircraft, including wings, fuselage, and engine parts. The company’s expertise in material science and engineering has allowed them to create tailored solutions that meet the stringent requirements of the aerospace industry.The development of nonmetal and metal bonded materials also aligns with the industry’s efforts to adopt more sustainable and environmentally friendly practices. By utilizing lightweight materials that improve fuel efficiency, aerospace companies can reduce their overall carbon footprint and contribute to a greener future for air travel.In addition to the benefits for aircraft manufacturing, nonmetal and metal bonded materials also have the potential to be utilized in other industries, such as automotive, construction, and renewable energy. This versatility makes them a valuable asset for companies like {} as they continue to explore new opportunities for their innovative materials.As the aerospace industry continues to evolve, the adoption of nonmetal and metal bonded materials is poised to become a transformative trend. With their numerous benefits and potential applications, these materials are set to play a crucial role in the development of next-generation aircraft and pave the way for a more sustainable and efficient future for air travel.With their expertise and dedication to innovation, {} is well-positioned to lead the charge in bringing nonmetal and metal bonded materials to the forefront of the aerospace industry. Their commitment to pushing the boundaries of material science and engineering will undoubtedly have a lasting impact on the industry and the way aircraft are designed and manufactured.

Cup Wheel Grinding Discs: Enhancing Precision and Efficiency in Grinding Tasks

Cup Wheel Grinding Discs are among the most popular and versatile tools in the grinding and cutting industry. These discs are used for a wide range of applications including shaping, grinding, and polishing various surfaces. The grinding disc is primarily designed for use on concrete surfaces, but it is also effective on other surfaces such as stone, masonry, and metal.Leading manufacturers of grinding discs produce high-quality products that cater to the needs of professionals in diverse industries, which means that the company behind it is critical to ensure that you are investing in the right product. One of the top manufacturers and suppliers of Cup Wheel Grinding Discs in the market is {}, a leading company in the abrasives industry.Beginnings of {}{} was founded in 1999 with a mission to provide quality abrasives for the machinery industry. {} has since established itself as a leading supplier of abrasives and industrial tools in the market. The company focuses on delivering the highest quality product to their customers. They invest heavily in research and development to ensure that their products are the best in the market.{} has a team of skilled engineers who work closely with the research and development team to ensure that their products meet the highest standards of quality. The company operates in modern facilities equipped with advanced machinery and tools. This ensures that they meet established industry regulations and are always one step ahead of their competitors.In addition to its manufacturing capabilities, {} has an efficient distribution network that ensures its products are readily available to customers worldwide. The company has established strong partnerships with various distributors globally who work closely with them to serve their customers and meet their needs efficiently.Product RangeThe company produces a variety of grinding discs, but the Cup Wheel Grinding Discs are one of their most popular products. The Cup Wheel Grinding Disc is available in different materials and sizes, and it comes with different grit levels depending on the needs of the user.The diamond cup wheel grinding disc is designed for heavy-duty applications such as grinding concrete, granite, and marble surfaces. The diamond cup wheel grinding disc is fitted with a diamond impregnated section that can cut through the toughest surfaces, making it the perfect tool for professionals in the concrete and stone cutting fields.Moreover, the diamond cup wheel grinding disc is available in different shapes such as the single row, double row, and turbo style cup wheel, giving professionals the freedom to choose the one that suits their specific needs.Another popular product is the silicon carbide cup wheel grinding disc, which is perfect for use on stone surfaces such as marble and granite. The silicon carbide cup wheel grinding disc is a versatile tool that is known for its fast cutting performance and durability.ConclusionAs a professional in any field, investing in quality tools is critical to ensuring that your work is not only efficient but also of the highest quality. The Cup Wheel Grinding Disc from {} is a must-have in your arsenal. By investing in the Cup Wheel Grinding Disc, you are assured of a tool that is made to the highest standards of quality and performance.

Understanding the Basics of Metallic Bond Chemical Bonds

Metallic Bond Chemical Bonds, a leading chemical company in the industry, is making significant strides in the field of metallic bonding. With a mission to innovate and develop high-quality products, Metallic Bond Chemical Bonds has been a frontrunner in the market for several years.Metallic bonding is a type of chemical bonding that occurs between atoms of metallic elements. In this type of bonding, the valence electrons are delocalized and free to move throughout the structure, giving metals their unique properties such as conductivity and malleability.One of the key areas of focus for Metallic Bond Chemical Bonds has been to develop new and advanced materials with improved metallic bonding properties. By leveraging their expertise in chemical engineering and materials science, the company has been able to create innovative products that offer superior performance and durability.One of the latest advancements from Metallic Bond Chemical Bonds is the development of a new line of metallic bonding agents that are set to revolutionize various industries. These agents have been designed to enhance the strength and conductivity of metallic materials, making them ideal for use in electrical and automotive applications.In addition to their groundbreaking products, Metallic Bond Chemical Bonds is also committed to sustainability and environmental responsibility. The company has implemented cutting-edge technologies and processes to reduce its environmental footprint and minimize waste in its manufacturing operations.Furthermore, Metallic Bond Chemical Bonds is dedicated to fostering a culture of innovation and collaboration. The company actively collaborates with academic institutions and research organizations to stay at the forefront of technological advancements and contribute to the scientific community.With a strong focus on research and development, Metallic Bond Chemical Bonds has built a reputation for producing high-quality products that meet the needs of various industries. Whether it is in the automotive, aerospace, or electronics sector, the company's products have been instrumental in driving innovation and progress.Moreover, Metallic Bond Chemical Bonds has a global presence, with a network of distributors and partners around the world. This allows the company to reach a wide range of customers and deliver its cutting-edge products to various markets.Looking ahead, Metallic Bond Chemical Bonds is set to continue its trajectory of success and innovation. With a dedicated team of researchers and engineers, the company is well-positioned to introduce even more advanced products and solutions that will shape the future of metallic bonding.In conclusion, Metallic Bond Chemical Bonds is a pioneering force in the field of metallic bonding, leading the way with its innovative products and commitment to excellence. With a focus on sustainability and collaboration, the company is poised to make a lasting impact on the industry and drive progress for years to come.

Ultimate Guide to Ceramic Abrasive Tools: What You Need to Know

Ceramic Abrasive Tools has been making waves in the industry with its innovative and high-quality products that have been gaining popularity among professionals and DIY enthusiasts alike. The company, which was established in 2005, has quickly grown to become a leading provider of ceramic abrasive tools that are known for their exceptional performance and durability.The company's products are designed to meet the needs of a wide range of applications, including metalworking, woodworking, and surface preparation. With a focus on quality and innovation, Ceramic Abrasive Tools has developed a reputation for delivering cutting-edge solutions that help users achieve superior results in their work.One of the key factors that sets Ceramic Abrasive Tools apart from its competitors is its use of advanced ceramic technology. The company's abrasive tools are made from high-quality ceramic grains that are engineered to deliver outstanding cutting performance and longer product life. This has made Ceramic Abrasive Tools a preferred choice for professionals who demand the best in their tools.In addition to its focus on performance, Ceramic Abrasive Tools also takes pride in its commitment to sustainability and environmental responsibility. The company's products are designed to minimize waste and reduce energy consumption, making them an eco-friendly choice for conscientious users.Another important aspect of Ceramic Abrasive Tools' success is its dedication to customer satisfaction. The company understands the importance of delivering reliable and effective tools, and it goes the extra mile to ensure that its customers receive the support and guidance they need to make the most of their products. This customer-centric approach has earned Ceramic Abrasive Tools a loyal following and a strong reputation for excellence.Recently, Ceramic Abrasive Tools introduced a new line of products that have been generating a lot of excitement in the industry. These new tools build on the company's legacy of quality and innovation, offering even better performance and versatility for a wide range of applications. With these new products, Ceramic Abrasive Tools continues to demonstrate its leadership and commitment to driving the industry forward.The new line of products includes a variety of abrasive tools that are designed to meet the diverse needs of professionals and hobbyists. Whether it's grinding, cutting, or polishing, these tools are engineered to deliver exceptional results with precision and efficiency. As with all of Ceramic Abrasive Tools' products, these new tools are made with the highest standards of quality and performance in mind.One of the standout features of the new line of products is their enhanced durability. Ceramic Abrasive Tools has incorporated advanced materials and engineering techniques to make these tools even more rugged and long-lasting, ensuring that they can stand up to the rigors of demanding applications. This durability not only helps users achieve better results, but it also reduces the need for frequent replacements, saving time and money in the long run.Ceramic Abrasive Tools' new products have also been designed with user convenience in mind. The company has paid close attention to ergonomic design and ease of use, making these tools comfortable and efficient to operate. This thoughtful approach to user experience sets Ceramic Abrasive Tools apart and makes its products a pleasure to work with.With the introduction of these new products, Ceramic Abrasive Tools is once again proving why it is a leader in the industry. By combining cutting-edge technology, superior performance, and a customer-centric approach, the company continues to set the standard for excellence in the abrasive tools market. As professionals and enthusiasts alike seek the best tools for their work, Ceramic Abrasive Tools remains the go-to choice for those who demand the highest quality and performance.

Highly Popular Glass Polishing Kit with 8 Wool Buffing Pads - Effective Household Cleaning Solution

Title: Revitalize your Glass Surfaces with the Great Interest Glass Polishing Kit 8pcsIntroductionGlass is a key component of modern architecture and interior design. Its sleek and transparent appearance adds elegance and sophistication to any space. However, over time, glass surfaces can become dull, scratched, or stained, diminishing their overall aesthetic appeal. Fortunately, there is a solution – the Great Interest Glass Polishing Kit 8pcs. In this blog post, we will explore how this innovative kit, featuring Wool Buffing Pads and Polishing Pads, can transform the health and hygiene of your household’s glass surfaces. Furthermore, we will dive into the benefits of using a Solar Buffing Pad, to ensure you achieve the best possible results.Chapter 1: Unleash the Power of the Great Interest Glass Polishing Kit1.1 Introducing the Great Interest Glass Polishing KitThe Great Interest Glass Polishing Kit is a comprehensive solution for restoring the sparkle and shine to your glass surfaces. This kit includes eight different Wool Buffing Pads and Polishing Pads, each with a specific purpose. These pads are designed to remove scratches, stains, water marks, and other imperfections, bringing your glass surfaces back to their original glory.1.2 Understanding the BenefitsThe Glass Polishing Kit is not limited to glass surfaces alone. It is also effective on various materials like acrylic, ceramic, and even metal surfaces, making it a versatile tool for your household cleaning needs. The kit is designed to be used with a polishing machine, providing consistent and effortless results.Chapter 2: The Key Components of the Great Interest Glass Polishing Kit2.1 Wool Buffing Pads – Why They MatterThe Wool Buffing Pads are the heart of the Great Interest Glass Polishing Kit. Made from high-quality wool fibers, these pads effectively remove minor scratches, swirl marks, and oxidation from your glass surfaces. Their soft and delicate nature ensures that they do not damage the surface while providing a thorough clean. With the Wool Buffing Pads, you can say goodbye to dull and lifeless glass.2.2 Polishing Pads – Enhancing the ShineTo achieve that extra level of shine, the Polishing Pads play a crucial role. These pads are made from a combination of wool and microfiber materials, providing a gentle but effective polishing action. They remove fine imperfections, restore clarity, and bring out the brilliance of your glass. The Polishing Pads are the perfect finishing touch to your glass cleaning process.Chapter 3: Taking it a Step Further with Solar Buffing Pad3.1 Unveiling the Solar Buffing PadTo maximize the effectiveness of the Great Interest Glass Polishing Kit, the Solar Buffing Pad is the perfect addition. This pad harnesses the energy of the sun, allowing for the removal of stubborn stains and marks that regular pads cannot reach. The Solar Buffing Pad utilizes innovative technology to deliver outstanding results, effortlessly.3.2 The Benefits of Solar Buffing PadThe Solar Buffing Pad is eco-friendly, as it reduces the need for electricity while utilizing solar energy. It is also extremely simple to use – just place it under direct sunlight for a few minutes and it's ready to go. This pad can even be used for outdoor glass surfaces, such as windows, glass patio furniture, and solar panels. Its versatility and convenience offer endless possibilities for maintaining the sparkle of your glass.ConclusionWith the Great Interest Glass Polishing Kit 8pcs, consisting of Wool Buffing Pads, Polishing Pads, and the Solar Buffing Pad, you can easily restore the beauty of your glass surfaces. Its innovative design, combined with high-quality materials, ensures efficient cleaning and impressive results. By using these products, you can transform your household cleaning routine while also promoting environmental sustainability. Say goodbye to dull and stained glass, and let the Great Interest Glass Polishing Kit illuminate your home with sparkling brilliance.Keywords: Glass Polishing Kit, Wool Buffing Pad, Polishing Pad, Solar Buffing Pad, household cleaning, household supplies, glass polish, shiny glass, glass maintenance, glass cleaning tools.

Understanding the Different Types of Metal Bonds for Industrial Applications

Metal Bonds Type Introduces Innovative Solution for Industrial ApplicationsMetal Bonds Type, a leading provider of industrial solutions, is proud to introduce their innovative metal bonding technology. This cutting-edge process offers a wide range of benefits for industrial applications, including increased strength, durability, and performance.The metal bonding technology developed by Metal Bonds Type utilizes advanced techniques to create a strong and reliable bond between metal surfaces. This is achieved through a combination of high-quality materials and precision engineering, resulting in a bond that is capable of withstanding even the most demanding industrial environments.One of the key advantages of Metal Bonds Type's metal bonding technology is its ability to improve the overall performance of industrial equipment. By enhancing the strength and durability of metal components, this technology can help to reduce the risk of failure and ensure that equipment continues to operate at peak efficiency.In addition to its performance benefits, Metal Bonds Type's metal bonding technology also offers significant cost savings for industrial applications. By extending the lifespan of equipment and reducing the need for frequent repairs or replacements, this technology can help to lower maintenance costs and improve overall operational efficiency.Metal Bonds Type is dedicated to providing the highest quality metal bonding solutions to their customers. With a commitment to excellence and a focus on innovation, the company continues to push the boundaries of what is possible in the field of industrial bonding technology."We are thrilled to introduce our new metal bonding technology to the market," said a spokesperson for Metal Bonds Type. "This innovative solution has the potential to revolutionize industrial applications, offering unmatched performance and durability for a wide range of equipment and machinery."The introduction of Metal Bonds Type's metal bonding technology comes at a time when the demand for advanced industrial solutions is higher than ever. As industries continue to evolve and grow, the need for reliable and efficient equipment becomes increasingly important. With this in mind, Metal Bonds Type is proud to offer a solution that meets the needs of modern industrial applications.With its unrivaled strength, durability, and performance, Metal Bonds Type's metal bonding technology is poised to make a significant impact on the industrial sector. As more businesses and organizations recognize the benefits of this innovative solution, it is expected to become an essential component of a wide range of industrial applications.In conclusion, Metal Bonds Type's metal bonding technology represents a major advancement in the field of industrial bonding solutions. With its ability to enhance the performance and durability of equipment, while also providing significant cost savings, this technology is well-positioned to become a cornerstone of modern industrial applications.As Metal Bonds Type continues to lead the way in developing cutting-edge industrial solutions, it is clear that their metal bonding technology will play a key role in shaping the future of the industrial sector. Businesses and organizations that are looking to improve the performance and reliability of their equipment would be wise to consider the benefits of Metal Bonds Type's innovative metal bonding technology.

Durable Aluminum Backer Pad for Polishing and Grinding applications

Aluminum Backer Pad is a leading manufacturer and supplier of top-quality diamond tools and accessories for the stone and construction industry. With a strong focus on innovation and quality, the company has established a solid reputation for providing professional-grade products that meet the needs of their customers.The company's Aluminum Backer Pad is a key component in the stone fabrication process, as it is designed to provide a stable and secure backing for diamond polishing pads. Made from high-quality aluminum, the backer pad is durable and long-lasting, ensuring that it can withstand the rigors of heavy-duty use. Its superior construction also allows for maximum flexibility and balance, making it ideal for polishing and grinding uneven surfaces.One of the key features of the Aluminum Backer Pad is its unique hook and loop design, which allows for quick and easy attachment and removal of diamond polishing pads. This innovative system makes it easy for fabricators to change out pads as needed, saving time and increasing efficiency in the work process. The backer pad's smooth and consistent performance also ensures a high-quality finish on the stone surface, delivering professional results with every use.In addition to its superior performance, the Aluminum Backer Pad is also designed with user comfort in mind. Its lightweight and ergonomic design minimizes operator fatigue, allowing for extended periods of use without strain or discomfort. This is particularly important in the stone fabrication industry, where precision and attention to detail are essential for achieving the desired finish on a wide range of materials.The company's commitment to quality and innovation is reflected in the Aluminum Backer Pad, which has quickly become a preferred choice among stone fabricators and construction professionals. Its reliability and durability make it a valuable asset in any tool collection, providing consistent performance and long-term cost savings for users.With a strong emphasis on customer satisfaction, Aluminum Backer Pad is dedicated to providing exceptional service and support to its clients. The company's team of knowledgeable and experienced professionals is always available to offer personalized guidance and assistance, ensuring that customers have access to the information and resources they need to get the most out of their products.In addition to its flagship Aluminum Backer Pad, the company offers a comprehensive range of diamond tools and accessories, including polishing pads, diamond blades, core bits, and more. Each product is carefully engineered to meet the highest standards of quality and performance, making Aluminum Backer Pad a trusted partner for professionals in the stone and construction industry.As the demand for high-quality diamond tools continues to grow, Aluminum Backer Pad remains at the forefront of the industry, constantly striving to develop new and innovative solutions that meet the evolving needs of its customers. With its unwavering commitment to excellence, the company is well-positioned to continue its success and maintain its status as a leading provider of diamond tools and accessories for years to come.In conclusion, Aluminum Backer Pad is a name synonymous with quality and reliability in the stone and construction industry. Its Aluminum Backer Pad is a testament to the company's commitment to innovation and excellence, providing professionals with a superior tool for achieving exceptional results. With a focus on customer satisfaction and continuous improvement, Aluminum Backer Pad is poised to remain a trusted partner for professionals in the industry.

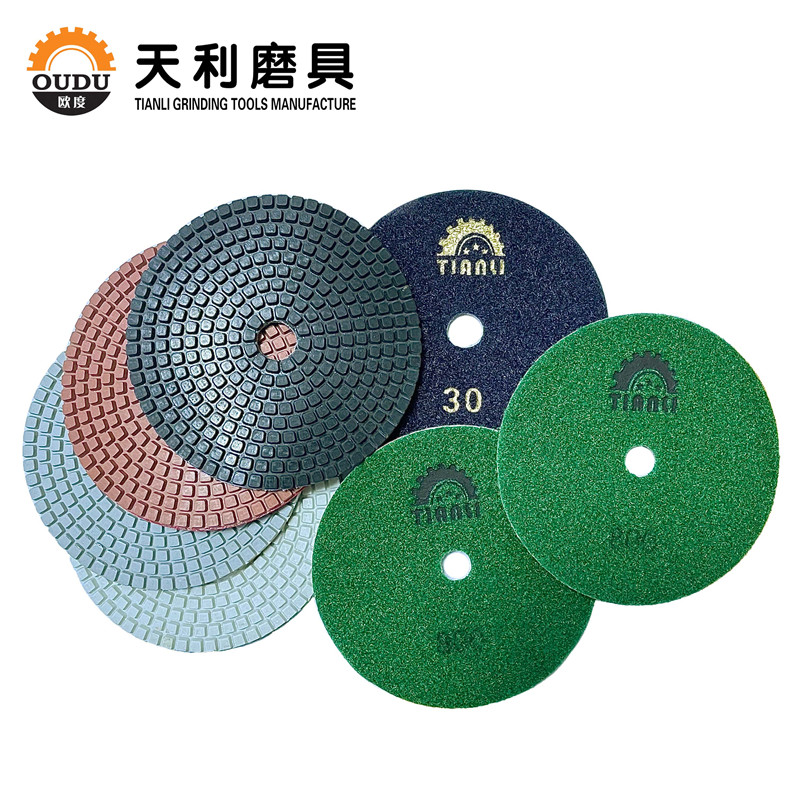

Versatile Diamond Polishing Pads for Granite, Marble, Stone, and More

Diamond Resin Dry Polishing Pads: Perfecting the Art of Stone PolishingDiamond polishing pads have become an indispensable tool in the field of stone polishing. With their ability to enhance the appearance of various types of surfaces such as granite, marble, engineered and natural stone, concrete, terrazzo, countertops, and floors, these pads have revolutionized the way we finish and beautify these materials. Among the many options available, Diamond Resin Dry Polishing Pads stand out as one of the best choices for achieving impeccable results. In this blog, we will explore the features, benefits, and applications of these remarkable pads that have taken the industry by storm.The first thing that sets Diamond Resin Dry Polishing Pads apart is their composition. Crafted using the finest quality of diamonds and resin, these pads are designed to deliver exceptional polishing performance. The diamonds embedded in the resin matrix provide the necessary cutting power, while the resin acts as a bonding agent, ensuring durability and longevity.One of the primary advantages of using Diamond Resin Dry Polishing Pads is their versatility. They can be used on a variety of surfaces, ranging from granite to marble, engineered and natural stone, concrete, terrazzo, countertops, and floors. This gives contractors and polishing professionals the flexibility to work on different projects without the need for multiple sets of pads. Whether you are polishing a kitchen countertop or a luxurious marble floor, Diamond Resin Dry Polishing Pads are your go-to solution.Another remarkable feature of these pads is their ability to perform effectively in dry polishing applications. Traditionally, wet polishing has been the preferred method due to its cooling effect, dust suppression, and easier debris removal. However, dry polishing offers its own set of advantages, such as convenience, versatility, and cost-effectiveness. Diamond Resin Dry Polishing Pads excel in this area, providing a superior dry polishing experience by delivering exceptional results without the need for water or slurry.Additionally, Diamond Resin Dry Polishing Pads offer enhanced flexibility and adaptability. Their design allows them to conform to the shape and contours of the surface being polished, ensuring even distribution of pressure and an immaculate finish. This makes them an ideal choice for intricate designs and curved surfaces, where achieving a perfect polish can be quite challenging.When it comes to achieving a high-gloss shine, Diamond Resin Dry Polishing Pads are second to none. The combination of diamond and resin creates a synergy that not only removes scratches and imperfections but also imparts a lustrous and reflective finish to the surface. This property is particularly significant in applications where aesthetics play a crucial role, such as luxury hotels, high-end residential properties, and commercial spaces.In terms of performance, Diamond Resin Dry Polishing Pads offer exceptional efficiency and endurance. The diamonds embedded in the pads ensure consistent cutting power, allowing for faster material removal and uniform polishing. This, coupled with their exceptional durability, makes them a cost-effective investment that can withstand rigorous use and produce superior results over an extended period.In conclusion, Diamond Resin Dry Polishing Pads have become a game-changer in the world of stone polishing. Their ability to polish various surfaces, adapt to different shapes, and deliver impeccable results without the need for water or slurry make them an essential tool for contractors and polishing professionals. Whether you are looking to enhance the beauty of your granite countertop, transform your marble floors, or revamp your terrazzo surfaces, Diamond Resin Dry Polishing Pads are your trusted companion. Invest in these pads and elevate your stone polishing projects to new heights of perfection.

Durable Tool Holder Options for Your Needs - Find the Best Solution Here

Diamond Tool Holder Revolutionizes Cutting Efficiency in Manufacturing IndustryIn the ever-evolving world of manufacturing, efficiency is key. Companies are constantly seeking new technologies and tools to improve their productivity and ultimately their bottom line. One company leading the charge in this endeavor is (company name). With their revolutionary Diamond Tool Holder, they are changing the game when it comes to cutting efficiency in the manufacturing industry.The Diamond Tool Holder, as the name suggests, is a cutting-edge tool holder that utilizes diamond technology to improve cutting efficiency and performance. This innovative tool is designed to provide a longer tool life, improved surface finish, and increased productivity for a wide range of manufacturing applications.The (company name) is a leading manufacturer of high-precision tools and tooling systems, with a strong focus on innovation and technology. Their team of expert engineers and designers are dedicated to developing cutting-edge solutions that meet the ever-growing demands of the manufacturing industry. With a commitment to quality and performance, they have earned a reputation as a trusted partner for companies looking to improve their manufacturing processes.The Diamond Tool Holder is the latest addition to their impressive portfolio of products. It is designed to address the common challenges faced by manufacturers when it comes to cutting tools, such as tool wear, chip control, and surface finish. By using diamond technology, the tool holder is able to provide a superior cutting experience that delivers exceptional results.One of the key advantages of the Diamond Tool Holder is its extended tool life. The use of diamond technology significantly reduces tool wear, allowing for longer-lasting performance and fewer tool changes. This not only saves time but also reduces the overall cost of tooling for manufacturers. Additionally, the improved surface finish achieved with the Diamond Tool Holder helps to enhance the quality of the end product, providing a competitive edge in the market.Moreover, the Diamond Tool Holder offers increased productivity by delivering faster cutting speeds and improved chip control. This allows manufacturers to complete jobs more efficiently, ultimately leading to a higher output and a more streamlined production process.The Diamond Tool Holder is suitable for a wide range of materials, including metals, composites, and ceramics. Its versatility makes it an ideal choice for various industries, including aerospace, automotive, medical, and general manufacturing. Whether it's milling, turning, or drilling, the Diamond Tool Holder delivers exceptional performance across the board.In addition to its cutting-edge technology, the Diamond Tool Holder is also designed with user-friendly features that make it easy to install and use. Its ergonomic design and simple operation ensure that manufacturers can seamlessly integrate it into their existing processes without any hassle.As the manufacturing industry continues to evolve, the demand for advanced cutting tools that can keep up with the pace is only going to grow. With the Diamond Tool Holder, (company name) is at the forefront of this change, providing a solution that not only meets the current needs of manufacturers but also sets the stage for future advancements in cutting technology.The Diamond Tool Holder is a testament to (company name)'s commitment to innovation and excellence. By leveraging the power of diamond technology, they have created a tool that is set to revolutionize cutting efficiency in the manufacturing industry. As companies strive to stay ahead of the competition, the Diamond Tool Holder offers a clear advantage, delivering superior performance, extended tool life, and increased productivity. With this breakthrough tool, (company name) continues to solidify its position as a leader in the world of high-precision tools and tooling systems.