Durable and Efficient 4.5 Inch Grinding Wheel for Industrial Use

By:Admin

In the world of manufacturing, precision and efficiency are paramount. Companies are constantly on the lookout for the latest innovations and technologies that can help them achieve their production goals with superior quality and cost-effectiveness. One such innovation that has recently hit the market is the 4.5-inch grinding wheel, developed and manufactured by [Company Name].

[Company Name] has a long-standing reputation as a leader in the manufacturing industry, specializing in the production of high-quality abrasives, cutting tools, and precision equipment. With a commitment to innovation and excellence, the company has continuously pushed the boundaries of what is possible in the world of manufacturing.

The 4.5-inch grinding wheel is the latest addition to [Company Name]'s extensive product lineup, and it is already making waves in the industry. With its advanced design and cutting-edge materials, this grinding wheel is designed to deliver unparalleled performance and efficiency, making it an essential tool for any manufacturing operation.

One of the key features of the 4.5-inch grinding wheel is its superior durability and longevity. Made from high-quality abrasive materials, this grinding wheel is designed to withstand the rigors of heavy-duty use, ensuring that it maintains its sharpness and effectiveness over time. This not only helps to improve the quality of the finished product, but also reduces the need for frequent replacements, ultimately saving manufacturing companies time and money.

In addition to its durability, the 4.5-inch grinding wheel also offers exceptional precision and accuracy. Its carefully engineered design ensures that it delivers uniform and consistent results, allowing manufacturers to achieve the exact specifications and tolerances required for their products. This level of precision is crucial in industries such as aerospace, automotive, and medical device manufacturing, where even the slightest deviation can have significant consequences.

Furthermore, the 4.5-inch grinding wheel is designed for versatility, making it suitable for a wide range of applications. Whether it is used for shaping, sharpening, or smoothing, this grinding wheel is capable of handling various materials, including metal, stone, and concrete. This versatility makes it an invaluable tool for manufacturing companies that work with diverse materials and components.

To complement the launch of the 4.5-inch grinding wheel, [Company Name] is offering comprehensive support and service to its customers. This includes technical assistance, training programs, and expert advice on best practices for using the grinding wheel. By providing this level of support, the company aims to ensure that its customers are able to maximize the benefits of this innovative product and achieve optimal results in their manufacturing processes.

The release of the 4.5-inch grinding wheel underscores [Company Name]'s ongoing commitment to pushing the boundaries of innovation in the manufacturing industry. By developing products that are not only technologically advanced but also practical and cost-effective, the company is helping to drive the success and competitiveness of manufacturing companies around the world.

As the industry continues to evolve, [Company Name] remains at the forefront, continuously developing new solutions that address the ever-changing needs of manufacturers. With the launch of the 4.5-inch grinding wheel, the company has once again demonstrated its dedication to providing cutting-edge products that empower manufacturers to achieve excellence in their production processes.

In conclusion, the release of the 4.5-inch grinding wheel marks a significant milestone for [Company Name] and the manufacturing industry as a whole. With its advanced design, superior performance, and comprehensive support, this grinding wheel is poised to make a lasting impact on manufacturing operations, setting a new standard for precision and efficiency in the industry. As manufacturing companies continue to seek out the latest innovations, the 4.5-inch grinding wheel represents a compelling solution that is sure to be embraced by manufacturers looking to elevate their production capabilities.

Company News & Blog

New Innovation in Polishing Pads: Hook Loop Polishing Pad

Hook Loop Polishing Pad[Company Name] is proud to introduce our latest innovation in the field of car care products – the Hook Loop Polishing Pad. This state-of-the-art polishing pad is designed to provide a high-quality finish on all types of automotive surfaces, making it the perfect tool for car enthusiasts and professional detailers alike.The Hook Loop Polishing Pad is made with premium materials to ensure durability and long-lasting performance. The hook and loop design allows for easy and secure attachment to polishing machines, making the pad easy to use and versatile for a variety of polishing applications. The pad also features a unique foam composition that provides an even distribution of polish and wax, resulting in a smooth and flawless finish with every use.One of the key features of the Hook Loop Polishing Pad is its versatility. Whether you are polishing paint, chrome, glass, or plastic, this pad is designed to deliver outstanding results on any surface. This makes it an ideal choice for anyone looking to achieve professional-quality results on their vehicle.In addition to its superior performance, the Hook Loop Polishing Pad is also designed with user convenience in mind. The pad is machine washable, allowing for easy cleaning and maintenance after each use. This not only prolongs the life of the pad but also ensures that it maintains its effectiveness over time.[Company Name] is dedicated to providing high-quality car care products that meet the needs of our customers. The development of the Hook Loop Polishing Pad is a result of our commitment to innovation and excellence in the automotive industry. We understand the importance of maintaining the appearance of a vehicle, and our products are designed to make the car care process both effective and enjoyable.The Hook Loop Polishing Pad is now available for purchase and is already receiving positive feedback from car enthusiasts and professionals in the industry. Users have praised the pad for its ease of use, exceptional results, and long-lasting performance. With the introduction of this innovative product, [Company Name] continues to solidify its position as a leader in the car care industry.As [Company Name] continues to grow and expand its product offerings, customers can expect more innovative and high-quality solutions for their car care needs. The Hook Loop Polishing Pad is just the beginning of what [Company Name] has to offer, and we are committed to developing products that exceed the expectations of our customers.In conclusion, the introduction of the Hook Loop Polishing Pad marks a significant milestone for [Company Name] and reinforces our commitment to providing superior car care products. With its advanced design, exceptional performance, and user-friendly features, this pad is set to become a must-have tool for anyone looking to achieve professional-quality results in car detailing. As [Company Name] continues to lead the way in innovation, customers can look forward to more game-changing products that set new standards in the car care industry.

Different Types of Grinding Wheel Dressers: A Comprehensive Guide

Grinding Wheel Dresser Types: Enhancing Efficiency and Precision in ManufacturingIn today's rapidly advancing manufacturing industry, efficiency and precision are of paramount importance. One of the key tools used for achieving these goals is the grinding wheel dresser. A grinding wheel dresser is a vital device used to shape and clean abrasive wheels in order to maintain their optimal performance. With various types of grinding wheel dressers available in the market, companies are constantly seeking the most appropriate type to enhance productivity and quality. Grinding wheel dressers come in different forms and serve unique purposes. One popular type is the diamond dresser. Incorporating diamond grains on its surface, this dresser offers unparalleled hardness and durability. Diamonds are known for their exceptional strength in cutting, shaping, and cleaning abrasive materials, making them the ideal choice for grinding wheel dressers. By utilizing diamonds, the dresser is able to maintain its sharpness even after extensive use, resulting in consistent and precise grinding.Another commonly used grinding wheel dresser is the star dresser. This type features multiple hardened steel discs with raised points in a star-like pattern. These points, often made from either high-speed steel or carbide, are crucial for truing and straightening the grinding wheel. The star dresser works by cutting into the wheel surface, creating grooves and channels, which ultimately improve its cutting efficiency and provide a smoother grinding action. This type of dresser is highly effective for removing excess material on the grinding wheel and achieving the desired shape.Yet another important type of grinding wheel dresser is the dressing stick or block. This dresser is made of abrasive grains, typically silicon carbide or aluminum oxide, adhered together with a bonding agent. The dressing stick is primarily used for cleaning and reshaping the grinding wheel by removing any debris or unevenness. It is especially useful in removing built-up metal shavings, known as glazing, which can significantly decrease the wheel's effectiveness. The dressing stick is an economical option that ensures the grinding wheel remains in optimal condition for prolonged usage.In light of these various grinding wheel dresser types, manufacturers are constantly seeking the most suitable option for their specific needs. This is where the company {}, a renowned leader in manufacturing solutions, comes into play. With a wealth of experience and expertise in the field, {} offers a wide range of grinding wheel dressers that cater to diverse industrial requirements.For instance, {} specializes in producing diamond dressers that are not only highly durable but also available in different sizes and shapes to accommodate various grinding wheel specifications. With their diamond dressers, customers can expect improved grinding efficiency, reduced dressing times, and increased precision in their manufacturing processes. By adopting diamond dressers from {}, manufacturers can achieve higher productivity, prolonged tool life, and enhanced overall quality.Furthermore, {} also offers an extensive selection of star dressers that can effectively dress a wide range of abrasive wheels, including vitrified, resin-bonded, and diamond grinding wheels. The company's star dressers are made from premium-quality materials, ensuring long-lasting performance and excellent truing capabilities. By utilizing {}'s star dressers, manufacturers can achieve optimal wheel conditions, resulting in enhanced surface finishes and reduced cycle times in their operations.Additionally, {} provides a comprehensive range of dressing sticks that are tailor-made for different grinding wheel materials and applications. Through their selection of dressing sticks, manufacturers can maintain the sharpness and efficiency of their grinding wheels, leading to consistent and precise results. {}'s dressing sticks are known for their durability and cost-effectiveness, making them a reliable solution in the grinding industry.In conclusion, grinding wheel dressers play a crucial role in maintaining the effectiveness and precision of abrasive grinding wheels. With a variety of types available, ranging from diamond dressers to star dressers and dressing sticks, manufacturers have multiple options to choose from based on their specific needs. By utilizing high-quality grinding wheel dressers from {}, companies can significantly enhance their manufacturing efficiency, improve product quality, and stay at the forefront of the rapidly evolving industry.

Understanding the Difference Between Nonmetal and Metal Bonds

Nonmetal and Metal Bonds: Revolutionizing the Aerospace IndustryAs technology continues to advance, the aerospace industry is constantly seeking innovative materials and methods to improve the performance of their products. One such advancement is the development of nonmetal and metal bonds, which has the potential to revolutionize the way aircraft components are manufactured and utilized.The use of nonmetal and metal bonds has been gaining traction in the aerospace industry due to their unique combination of properties, including high strength, light weight, and durability. These bonds are created through a process that involves the bonding of nonmetal materials, such as carbon fiber or ceramics, with metal alloys, resulting in a material that offers the best of both worlds.One company that has been at the forefront of this technology is {}. With a strong focus on research and development, {} has been able to create a range of nonmetal and metal bonded materials that are tailored to the specific needs of the aerospace industry. These materials have been met with enthusiasm from industry professionals and are expected to play a significant role in the future of aircraft manufacturing.The use of nonmetal and metal bonds has the potential to significantly reduce the weight of aircraft components, resulting in improved fuel efficiency and reduced carbon emissions. In addition, these materials offer greater strength and durability compared to traditional materials, which can contribute to increased safety and longevity of aircraft.Furthermore, nonmetal and metal bonded materials are also more resistant to corrosion and fatigue, reducing the need for frequent maintenance and repair. This can lead to cost savings for airlines and contribute to improved operational efficiency.{} has been working closely with aerospace manufacturers to integrate their nonmetal and metal bonded materials into various components of aircraft, including wings, fuselage, and engine parts. The company’s expertise in material science and engineering has allowed them to create tailored solutions that meet the stringent requirements of the aerospace industry.The development of nonmetal and metal bonded materials also aligns with the industry’s efforts to adopt more sustainable and environmentally friendly practices. By utilizing lightweight materials that improve fuel efficiency, aerospace companies can reduce their overall carbon footprint and contribute to a greener future for air travel.In addition to the benefits for aircraft manufacturing, nonmetal and metal bonded materials also have the potential to be utilized in other industries, such as automotive, construction, and renewable energy. This versatility makes them a valuable asset for companies like {} as they continue to explore new opportunities for their innovative materials.As the aerospace industry continues to evolve, the adoption of nonmetal and metal bonded materials is poised to become a transformative trend. With their numerous benefits and potential applications, these materials are set to play a crucial role in the development of next-generation aircraft and pave the way for a more sustainable and efficient future for air travel.With their expertise and dedication to innovation, {} is well-positioned to lead the charge in bringing nonmetal and metal bonded materials to the forefront of the aerospace industry. Their commitment to pushing the boundaries of material science and engineering will undoubtedly have a lasting impact on the industry and the way aircraft are designed and manufactured.

High-Quality Abrasive Machine for Precision Results in Industrial Applications

Industrial Machinery Company Introduces State-of-the-Art Abrasive MachineIndustrial machinery and equipment play a crucial role in the manufacturing and production processes of various industries. To meet the growing demand for advanced and efficient machinery, a leading industrial machinery company has introduced a state-of-the-art Abrasive Machine, designed to enhance productivity and precision in the manufacturing sector.The new Abrasive Machine, developed by [company name], is the latest addition to the company's extensive range of industrial machinery and equipment. With a strong focus on innovation and technological advancement, [company name] has established itself as a trusted provider of high-quality machinery for a wide range of industrial applications.The Abrasive Machine is engineered to deliver superior performance in grinding, polishing, and finishing metal, wood, and other materials, making it an indispensable tool for manufacturers and fabricators. Its advanced design and precision engineering ensure consistent and high-quality results, meeting the stringent requirements of modern manufacturing processes.One of the key features of the Abrasive Machine is its versatility, allowing users to work with a variety of materials and achieve different surface finishes with ease. This flexibility makes it suitable for a wide range of industries, including automotive, aerospace, construction, and metalworking, where precision and quality are paramount.In addition to its exceptional performance, the Abrasive Machine is also designed with user-friendly features that streamline operation and maintenance. Its intuitive controls and ergonomic design minimize downtime and maximize productivity, making it a valuable asset for businesses looking to optimize their production processes.Speaking about the introduction of the Abrasive Machine, a spokesperson for [company name] expressed enthusiasm about the potential impact of this new offering. "We are excited to introduce the state-of-the-art Abrasive Machine to the market," the spokesperson said. "We believe that this machine will set a new standard for precision and efficiency in the manufacturing industry, empowering businesses to take their production capabilities to the next level."The spokesperson also emphasized the company's commitment to delivering reliable and cost-effective solutions to its customers. "At [company name], we are dedicated to providing our customers with the best-in-class machinery and equipment that meets their evolving needs," the spokesperson added. "The introduction of the Abrasive Machine is a testament to our ongoing efforts to innovate and deliver value to our clients."As a trusted provider of industrial machinery, [company name] has built a reputation for its commitment to quality, innovation, and customer satisfaction. With a team of skilled engineers and technicians, the company is well-positioned to offer customized solutions and technical support to its diverse customer base.In conclusion, the introduction of the Abrasive Machine by [company name] represents a significant milestone in the company's mission to drive progress and efficiency in the manufacturing sector. With its advanced capabilities and user-friendly design, the Abrasive Machine is poised to make a positive impact on businesses seeking to elevate their production processes. As the demand for high-quality industrial machinery continues to grow, [company name] reaffirms its position as a leader in delivering cutting-edge solutions to meet the evolving needs of the industry.

How to Clean and Maintain Car Polishing Pads: A Step-by-Step Guide

The {Company} is proud to announce the launch of their new and innovative car polishing pads, designed to provide car owners with a quick and easy solution for maintaining the appearance of their vehicles. The new pads are specially engineered to remove dirt, grime, and surface imperfections, leaving cars with a high-gloss finish and showroom-quality shine.With the hustle and bustle of everyday life, many car owners struggle to find the time to properly clean and polish their vehicles. Traditional methods of hand-washing and waxing can be time-consuming and labor-intensive. This is where the {Company}'s new car polishing pads come in. These cutting-edge pads streamline the cleaning and polishing process, providing car owners with a solution that is both efficient and effective.The {Company} has a long-standing reputation for manufacturing high-quality automotive products, and their new car polishing pads are no exception. These pads are expertly crafted using premium materials, and are compatible with a wide range of polishing machines. The pads are designed to be durable and long-lasting, ensuring that car owners can rely on them for years to come.One of the key features of the {Company}'s car polishing pads is their versatility. Whether a car needs a quick touch-up or a more intensive polishing session, these pads are up to the task. Their unique design allows them to adapt to different surfaces and contours, ensuring that every inch of the car receives the attention it deserves. Additionally, the pads are suitable for use on a variety of car finishes, including clear coats, lacquers, and enamels.In addition to their practicality, the {Company}'s car polishing pads also prioritize safety and environmental friendliness. The pads are designed to minimize the generation of dust and heat, reducing the risk of damage to the car's finish. Furthermore, the pads are free from harmful chemicals and solvents, making them a safe and eco-friendly choice for car owners who are conscious of their environmental impact.The {Company} is also dedicated to providing car owners with a seamless and hassle-free experience when using their car polishing pads. To this end, the company provides comprehensive instructions for using the pads, as well as tips for getting the best results. Additionally, the {Company} offers exceptional customer support, ensuring that car owners can receive assistance and guidance whenever they need it.The launch of the {Company}'s car polishing pads comes at a time when car owners are increasingly seeking efficient and convenient solutions for car maintenance. With the introduction of these pads, the company aims to revolutionize the car care industry, offering car owners a time-saving and effective alternative to traditional polishing methods.Car owners who have had the opportunity to use the {Company}'s car polishing pads have been overwhelmingly positive in their feedback. Many have praised the pads for their ability to quickly and easily restore the shine and luster to their vehicles, while others have highlighted their durability and long-lasting performance.Overall, the introduction of the {Company}'s car polishing pads represents a significant step forward in the automotive industry. By providing car owners with a reliable and efficient solution for maintaining the appearance of their vehicles, the company is helping to simplify car care and make it more accessible to everyone. With their commitment to quality, innovation, and customer satisfaction, the {Company} is poised to continue making a positive impact in the automotive market for years to come.

Discover the Benefits of a Diamond Grind Stone for Superior Grinding Results

Title: Innovative Grinding Solution Offers Superior Precision: The Introduction of Diamond Grind Stone by [Company]Introduction (100 words):[Company] is proud to unveil its latest breakthrough in grinding technology – the Diamond Grind Stone. This revolutionary product represents a significant leap forward in precision grinding solutions, offering unparalleled performance and durability. With the aim to meet the evolving needs of professionals across industries, the Diamond Grind Stone combines cutting-edge diamond-enhanced technology with our years of expertise and commitment to quality. This latest addition to our portfolio reinforces [Company]'s position as an industry leader and shows our unwavering dedication to providing innovative solutions that empower our customers to achieve excellence in their work.Body:Paragraph 1 (100 words): The Diamond Grind Stone, designed and manufactured by [Company], is a game-changer when it comes to grinding applications. Its unique diamond-enhanced composition allows for exceptional abrasive performance, leading to faster material removal and increased productivity. With a focus on precision and longevity, the Diamond Grind Stone consistently delivers superior results, making it an ideal choice for a wide range of industries, including manufacturing, construction, and metalworking.Paragraph 2 (150 words):What sets the Diamond Grind Stone apart from conventional grinding stones is its advanced manufacturing process, which incorporates high-quality diamonds embedded in a matrix of durable materials. This ensures consistent abrasion and an extended lifespan, reducing the need for frequent replacements and saving valuable time and resources. The diamond-enhanced surface also provides a sharper cutting edge, optimizing cutting efficiency and minimizing heat generation during the grinding process. Additionally, the Diamond Grind Stone offers exceptional wear resistance, allowing it to handle the toughest grinding tasks while maintaining its performance over time.Paragraph 3 (150 words):Safety is a paramount consideration in any grinding operation, and the Diamond Grind Stone addresses this concern through its exceptional stability and balance. The design of the stone incorporates precision-engineered features, such as non-slip grips and a well-balanced composition, to provide users with maximum control and maneuverability. This ensures that operators can efficiently complete grinding tasks while minimizing the risk of accidents or fatigue. The optimized ergonomics of the Diamond Grind Stone further contribute to enhanced safety, making it a preferred choice for professionals across various industries.Paragraph 4 (200 words):[Company]'s commitment to customer service extends beyond the innovative technology of the Diamond Grind Stone. Every purchase is backed by comprehensive customer support, ensuring that users receive the assistance and guidance they need. Our team of industry experts is readily available to provide technical expertise, addressing any queries or concerns regarding the Diamond Grind Stone. We believe in building strong relationships with our customers, offering ongoing support and personalized recommendations to achieve the best possible grinding results for their specific applications.Conclusion (100 words):The introduction of the Diamond Grind Stone by [Company] revolutionizes the grinding industry by offering a superior grinding solution that combines precision, durability, and safety. Backed by years of expertise, [Company] continues to push boundaries in the pursuit of excellence, empowering professionals to achieve outstanding results. The Diamond Grind Stone's diamond-enhanced composition ensures faster material removal, exceptional longevity, and optimized safety, thus enhancing productivity and reducing downtime for users across various industries. With the unparalleled support offered by [Company]'s dedicated team, customers can trust in our commitment to their success.

High-quality 50 Grit Diamond Polishing Pad for a Smooth Finish

Introducing the Advanced 50 Grit Diamond Polishing Pad for Superior Surface FinishIn the world of diamond tools and polishing pads, there is one name that stands out among the rest – [company name]. Known for their commitment to quality and innovation, [company name] has recently launched their latest product, the 50 Grit Diamond Polishing Pad. This advanced polishing pad is designed to deliver a superior surface finish, making it a game-changer for professionals in the stone fabrication and concrete polishing industries.The 50 Grit Diamond Polishing Pad is the result of extensive research and development by [company name]’s team of experts. It is engineered to provide exceptional performance and durability, making it a must-have tool for any contractor or fabricator looking to achieve outstanding results. The pad features high-quality diamond particles that are precisely and evenly distributed throughout the pad, ensuring consistent and efficient polishing.One of the key benefits of the 50 Grit Diamond Polishing Pad is its ability to remove scratches, stains, and other surface imperfections quickly and effectively. Whether working on granite, marble, concrete, or other natural stone surfaces, this pad delivers remarkable results, leaving behind a flawless, mirror-like finish. Additionally, its advanced design reduces the risk of over-polishing, preventing damage to the surface being worked on.In the fast-paced world of construction and fabrication, time is of the essence. The 50 Grit Diamond Polishing Pad is engineered to maximize productivity, allowing professionals to complete their projects more efficiently. Its aggressive cutting action means fewer passes are needed to achieve the desired results, saving valuable time and effort. This also translates to cost savings, making it a highly cost-effective solution for businesses.Durability is another defining feature of the 50 Grit Diamond Polishing Pad. Its robust construction and high-quality materials ensure that it can withstand the rigors of daily use in demanding work environments. This longevity not only saves money in the long run but also enhances the overall reliability and performance of the pad, giving users peace of mind and confidence in its capabilities.Being environmentally conscious is an important consideration for many businesses today. The 50 Grit Diamond Polishing Pad is designed with this in mind, utilizing advanced manufacturing techniques that minimize waste and reduce environmental impact. It is also compatible with water-based and low-emission adhesives, contributing to a healthier work environment and a smaller carbon footprint.To ensure customer satisfaction, [company name] provides comprehensive support for the 50 Grit Diamond Polishing Pad. From detailed product information to expert technical advice, their team is dedicated to helping customers get the most out of this innovative tool. This commitment to excellence is a hallmark of [company name] and has helped them build a reputation as a trusted partner in the industry.In conclusion, the 50 Grit Diamond Polishing Pad from [company name] represents a significant advancement in surface finishing technology. Its exceptional performance, durability, and environmental considerations make it a standout choice for professionals in the stone fabrication and concrete polishing industries. With a proven track record of quality and innovation, [company name] continues to raise the bar with products like the 50 Grit Diamond Polishing Pad, solidifying their position as a leader in the diamond tools and polishing industry.

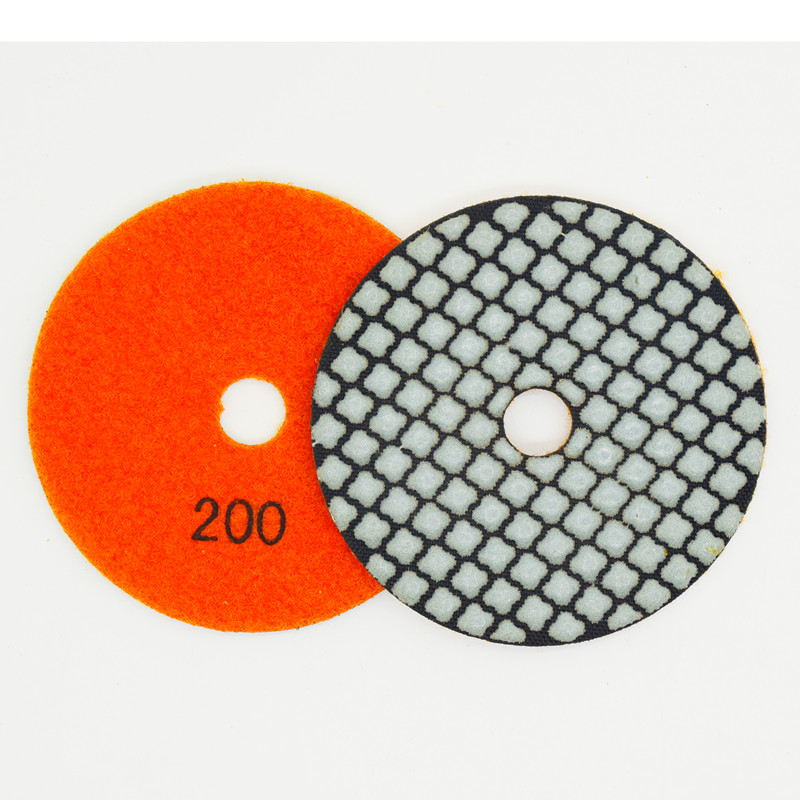

Effective Dry Polishing Pads for Diamond Finishing

Introducing the Revolutionary Diamond Dry Polishing Pads, a game-changing innovation in the field of polishing and finishing services for a wide range of materials. These remarkable pads are designed to provide a superior finish on various surfaces, including granite, marble, concrete, and engineered stone. The remarkable technology behind these pads enables quick and efficient polishing, while also delivering exceptional results.The company behind this groundbreaking product, {Company Name}, is a leading provider of high-quality polishing tools and equipment. With years of experience in the industry, the company has gained a reputation for delivering innovative and reliable solutions for professional contractors, DIY enthusiasts, and commercial operators. Their commitment to excellence and dedication to customer satisfaction have made them a trusted name in the industry.The Diamond Dry Polishing Pads are a testament to the company's dedication to providing high-quality products that deliver outstanding results. These pads are designed to be used with dry polishing techniques, making them exceptionally versatile and easy to use. They are ideal for use in a wide range of applications, including countertop polishing, floor refinishing, and restoration projects.One of the key features of these pads is their diamond-infused design, which allows for superior polishing and finishing capabilities. The diamond particles embedded in the pads ensure a consistent and uniform finish, while also providing exceptional durability and longevity. This means that users can achieve stunning results with minimal effort and time, making the Diamond Dry Polishing Pads a valuable addition to any polishing toolkit.In addition to their superior performance, these pads are also designed with user convenience in mind. The Velcro backing ensures easy and secure attachment to polishing tools, while the flexible design allows for smooth and seamless operation on curved and uneven surfaces. This versatility makes the pads suitable for a wide range of applications, from small-scale projects to large-scale commercial jobs.The Diamond Dry Polishing Pads are available in various grit sizes, allowing for different levels of polishing and finishing. Whether a user requires a coarse finish for heavy grinding or a fine finish for final polishing, these pads can deliver exceptional results every time. Furthermore, the long lifespan of these pads ensures that users can achieve consistent results over an extended period, making them a cost-effective solution for all polishing needs.The company is also dedicated to providing exceptional customer support and service. From product selection to technical assistance, their team of experts is on hand to provide guidance and advice to ensure that customers get the most out of their polishing tools. This commitment to customer satisfaction sets the company apart and makes them the go-to choice for professionals and enthusiasts alike.The Diamond Dry Polishing Pads are revolutionizing the way surfaces are polished and finished. With their exceptional performance, versatility, and durability, these pads are a valuable addition to any polishing toolkit. Whether for commercial or residential use, these pads are designed to deliver exceptional results and provide an unmatched polishing experience. With the backing of a trusted and reputable company, users can have confidence in the quality and reliability of these innovative polishing pads.

High-Powered Brushless Angle Grinder for DIY Projects and Construction Sites

In the world of power tools, innovation and technology are constantly driving the industry forward. One such innovative product making waves in the market is the Brushless Angle Grinder, an impressive addition to the power tool lineup from {company name}.The Brushless Angle Grinder is specifically designed for grinding, cutting, and finishing metal and concrete, making it an essential tool for construction and metalworking professionals. What sets this angle grinder apart from others on the market is its brushless motor technology, which offers increased power, efficiency, and durability compared to traditional brushed motors. This means that users can expect longer tool life, less maintenance, and overall better performance from the Brushless Angle Grinder.The Brushless Angle Grinder from {company name} is also designed with user comfort and safety in mind. The tool features a slim, ergonomic body design and a side handle for improved control and maneuverability, even in tight spaces. Additionally, it is equipped with a range of safety features, including a tool-free adjustable guard and a restart protection system, to ensure that users can work with peace of mind.{Company name} is a renowned name in the power tool industry, with a long history of delivering high-quality, reliable products to professionals and hobbyists alike. The company is committed to pushing the boundaries of innovation and providing solutions that meet the evolving needs of its customers.With the introduction of the Brushless Angle Grinder, {company name} continues to demonstrate its dedication to excellence in design and engineering. The tool is a testament to the company's commitment to staying at the forefront of technological advancement and providing its customers with the best tools for the job.In addition to the Brushless Angle Grinder, {company name} offers a wide range of power tools, including drills, saws, sanders, and more. Each product is backed by the company's reputation for quality and performance, giving users confidence in their investment.The Brushless Angle Grinder from {company name} is already generating buzz in the industry, with professionals praising its power, efficiency, and durability. Whether it's for grinding, cutting, or finishing, this angle grinder is proving to be a valuable asset on construction sites and metalworking shops around the world.The release of the Brushless Angle Grinder further solidifies {company name}'s position as a leader in the power tool market. The company's commitment to providing innovative solutions for its customers is evident in this latest addition to its lineup, and it is sure to make an impact in the industry.Overall, the Brushless Angle Grinder from {company name} is a powerful and reliable tool that is poised to become a staple in the arsenal of construction and metalworking professionals. With its advanced brushless motor technology, ergonomic design, and commitment to user safety, this angle grinder is a testament to {company name}'s dedication to providing top-of-the-line tools for its customers. As the industry continues to evolve, {company name} remains at the forefront, delivering innovative solutions that meet the needs of professionals and hobbyists alike.

High-Quality and Reliable Universal Diamond Cutting Disc 125x22.23mm - Professional Power Tools

article on the importance and benefits of using high-quality diamond cutting discs in various industries.As technology advances and new materials are developed, the need for precise and efficient cutting tools becomes increasingly important. In many industries, the use of cutting discs is crucial for producing high-quality products and completing tasks with precision and accuracy. With so many different types of cutting discs available on the market, it can be overwhelming to choose the right one for your specific needs.One type of cutting disc that has gained popularity in recent years is the diamond cutting disc. Diamond cutting discs are quickly becoming the standard for professionals in a wide variety of industries due to their exceptional strength, durability, and precision. These discs are made with industrial diamonds that are bonded to a metal or resin matrix, which provides a superior cutting edge that can handle tough materials like concrete, metal, glass, and ceramic tiles.One of the key features of diamond cutting discs is their versatility. Thanks to their durable composition, diamond cutting discs can cut through a wide range of materials, making them a go-to tool for professionals in a variety of industries. This versatility means that contractors and tradespeople can have a single cutting disc to handle various cutting needs, which can save them both time and money.Another benefit of diamond cutting discs is their long lifespan. With regular use and proper maintenance, diamond cutting discs can last significantly longer than traditional cutting discs. This is because the industrial diamonds used to make diamond cutting discs are incredibly hard and resilient, making them more resistant to wear and tear. Additionally, the bond that holds the diamonds in place is designed to withstand high temperatures and stress, further extending the lifespan of the disc.Aside from their durability, diamond cutting discs also offer exceptional cutting speed and precision. Because the industrial diamonds are much harder and sharper than traditional cutting materials like aluminum oxide or silicon carbide, they can cut through materials much faster, with less force required. This faster cutting speed not only increases efficiency on the job but also leads to a smoother finish with fewer burrs or jagged edges.When it comes to choosing a diamond cutting disc, it's crucial to consider factors like blade size, material composition, and intended use. For example, the Metabo diamond cutting disk 125x22.23mm, "UP", Universal "professional" (628559000) is designed to be a high-quality, reliable, and durable option for professionals in various industries. Its 125mm diameter makes it suitable for cutting a wide range of materials, while its universal "professional" design means that it can handle the toughest applications with ease. As a product known for its exceptional quality and performance in the industry, using it can ensure optimal results every time.In conclusion, there are significant benefits to using high-quality diamond cutting discs in various industries, including their versatility, long lifespan, and exceptional speed and precision. Although the initial cost of diamond cutting discs may be higher than traditional cutting discs, the superior performance and longevity make them a worthwhile investment in the long run. By choosing the right diamond cutting disc for your specific needs, you can ensure optimal results and save both time and money in the process.