Discover the Environmental Benefits of Grinding Wheels

By:Admin

Introduction:

In an ever-evolving world, companies across industries are actively seeking sustainable solutions to minimize their environmental impact. Keen on fostering eco-friendly production practices, Grinding Wheel Green (name replaced for anonymity) has developed a revolutionary grinding wheel that not only enhances manufacturing efficiency but also significantly reduces waste generation and carbon footprint. This innovative product aims to revolutionize abrasive machining processes worldwide and transform the manufacturing landscape into a more sustainable one.

Company Overview:

Grinding Wheel Green is a leading manufacturer of cutting-edge, high-quality abrasive tools and solutions. With a strong commitment to innovation, the company constantly endeavors to improve its products and bring the latest technological advancements to its customers. Founded on the principles of sustainable manufacturing, Grinding Wheel Green has positioned itself as a pioneer in developing environmentally friendly solutions for the abrasive industry.

Waste Reduction and Recycling:

One of the key highlights of Grinding Wheel Green's revolutionary grinding wheel is its reduced waste generation and enhanced recycling capabilities. Traditionally, grinding wheels have a limited lifespan and tend to be discarded after use, resulting in significant waste accumulation. However, Grinding Wheel Green has employed cutting-edge technologies and sustainable materials to create a product that extends the life cycle of grinding wheels, ultimately minimizing waste volume.

Moreover, the company has partnered with recycling facilities to implement an efficient recycling program for its grinding wheels. This initiative enables used grinding wheels to be processed and repurposed, contributing to the circular economy and reducing the overall environmental impact of the manufacturing process. By adopting this sustainable approach, Grinding Wheel Green ensures that its products not only perform optimally but also align with its commitment to environmental stewardship.

Energy Efficiency:

Grinding Wheel Green recognizes the importance of energy conservation in today's world. To tackle the energy consumption challenges associated with manufacturing, the company has implemented innovative measures that enhance energy efficiency during the production process. By optimizing manufacturing techniques and utilizing energy-saving equipment, Grinding Wheel Green has significantly reduced its carbon footprint.

Furthermore, the grinding wheel itself has been designed to operate at optimal energy levels. Its advanced composition and structural design allow for improved heat dissipation, resulting in lower energy consumption during grinding operations. This breakthrough not only reduces electricity usage but also contributes to a safer work environment by minimizing heat-related hazards.

Enhanced Performance and Productivity:

In addition to focusing on sustainability, Grinding Wheel Green prioritizes the performance and productivity of its products. Through rigorous research and development, the company has achieved a perfect balance between sustainability and functionality, offering customers a high-quality grinding wheel that outperforms conventional abrasive tools.

The innovative design of the grinding wheel ensures exceptional precision, thereby reducing production errors and increasing overall productivity. This translates into cost savings for manufacturers while maintaining the highest standards of quality in the products they manufacture. By facilitating a more efficient manufacturing process, Grinding Wheel Green empowers businesses to achieve their production goals while reducing their impact on the environment.

Conclusion:

Grinding Wheel Green's groundbreaking grinding wheel represents a transformative step towards sustainable manufacturing practices. Through waste reduction, recycling initiatives, improved energy efficiency, and enhanced performance, the company aims to lead the way in reshaping the abrasive industry. By integrating sustainability into its core business model, Grinding Wheel Green exemplifies how companies can effectively combine innovation and responsible manufacturing to reduce their ecological footprint. As more companies embrace such initiatives, the manufacturing landscape can evolve into a greener and more sustainable environment for generations to come.

Company News & Blog

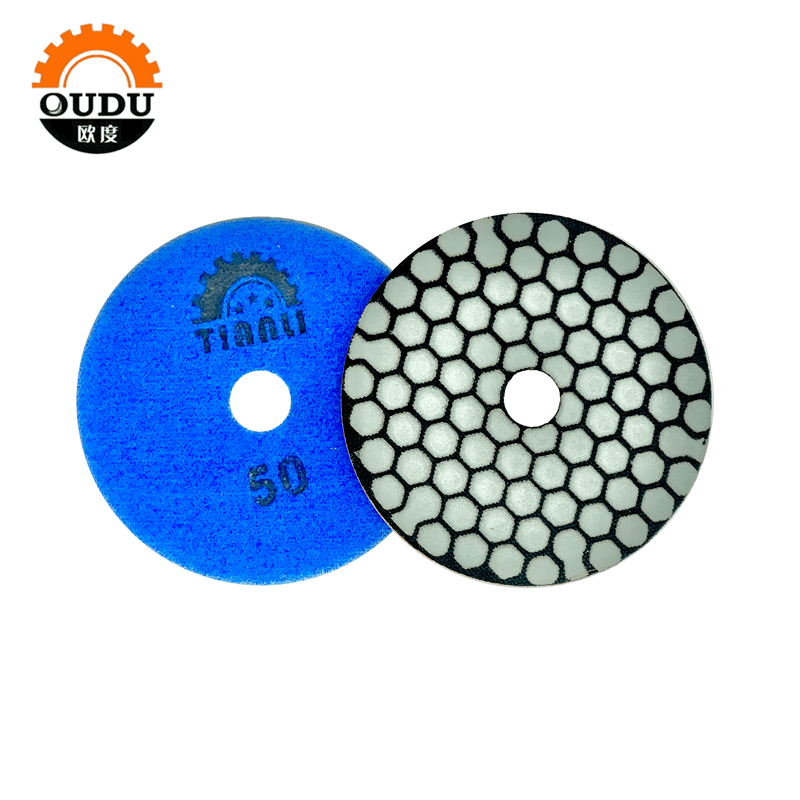

Discover the Latest Innovative Diamond Pads for Enhanced Performance

Title: Revolutionary Diamond Pads Redefine Surface Polishing in the Construction IndustryIntroduction:In an industry that constantly seeks advancement to improve efficiency and quality, the introduction of Diamond Pads by a leading manufacturer is set to revolutionize the surface polishing process. This ground-breaking innovation brings together cutting-edge technology and industry expertise to deliver superior results and unparalleled durability. Let us delve deeper into the details of this extraordinary product that promises to reshape the construction industry.Paragraph 1:The construction industry has long relied on abrasive materials for surface polishing, which often results in subpar outcomes and rapid deterioration of equipment. However, with the recent release of Diamond Pads, this narrative is set to change. Unlike traditional abrasives, Diamond Pads utilize synthetic diamonds that guarantee exceptional performance, efficiency, and longevity, making them the preferred choice for contractors and construction professionals.Paragraph 2:The key feature that sets Diamond Pads apart is their use of synthetic diamonds, which are engineered to deliver unparalleled hardness and cutting ability. This enables the pads to effortlessly remove surface imperfections, such as scratches, stains, and unevenness, significantly reducing the need for manual labor and multiple polishing cycles. The enhanced cutting power of the synthetic diamonds ensures a smoother and more efficient polishing process, saving considerable time and resources for construction projects.Paragraph 3:Durability is a crucial factor in any construction product, and Diamond Pads excel in this aspect. The synthetic diamonds used in their manufacturing have exceptional wear resistance, enabling the pads to withstand prolonged usage without losing their cutting efficiency. This translates into significant cost savings, as contractors can now rely on a single set of Diamond Pads for multiple projects, eliminating the need for frequent replacements.Paragraph 4:Furthermore, the innovative design of Diamond Pads allows for versatile usage on a wide range of surfaces, including concrete, terrazzo, marble, and granite. This multi-purpose functionality makes them an all-in-one polishing solution for various construction applications, eliminating the necessity for multiple specialized tools. Not only does this streamline workflow, but it also reduces equipment costs, making Diamond Pads an economical choice for construction projects of any scale.Paragraph 5:Beyond their exceptional performance, Diamond Pads also prioritize sustainability. The synthetic diamonds used are ethically sourced and their manufacturing process adheres to environmentally conscious practices. This ensures that construction professionals can accomplish their projects while minimizing their environmental footprint, enhancing the industry's commitment to sustainable development.Paragraph 6:To guarantee customer satisfaction, the manufacturer provides comprehensive support services, including training programs and expert guidance on the proper usage and maintenance of Diamond Pads. This ensures that contractors optimize the product's capabilities, maintain its longevity, and achieve the best possible results on every project.Closing paragraph:In the fast-paced construction industry, Diamond Pads represent a game-changing innovation that promises to redefine surface polishing. With their exceptional cutting power, durability, versatility, and sustainability, they offer a cost-effective and efficient solution for contractors seeking high-quality results. As the industry embraces this groundbreaking technology, construction projects around the world can expect to experience significant improvements in surface polishing processes for years to come.

Discover Effective Concrete Buffing Pads: Boost Your Floors' Shine Now!

Concrete Buffing Pads Revolutionize the Flooring Industry{Company Introduction}[date]In today's ever-evolving world of technology and innovation, no industry remains untouched. From healthcare to manufacturing, businesses are constantly seeking ways to improve their services and products. Enter Concrete Buffing Pads, a revolutionary product that is transforming the flooring industry.Traditionally, maintaining and enhancing the appearance of concrete floors involved labor-intensive methods that were often time-consuming and costly. Waxing, polishing, and scrubbing were common practices, requiring specialized equipment and skilled labor. However, Concrete Buffing Pads have streamlined this process, making it faster, more efficient, and providing stunning results.{Company Name} is at the forefront of this innovation, with their state-of-the-art Concrete Buffing Pads that are setting a new standard for the industry. These innovative pads effectively remove scratches, stains, and imperfections from concrete surfaces, while also imparting a beautiful shine that enhances the overall aesthetics of any space.The secret behind Concrete Buffing Pads lies in their advanced design and materials. Developed after years of research and testing, these pads are made from high-quality diamond abrasive, which provides exceptional durability and performance. This cutting-edge technology ensures that the pads efficiently remove even the toughest stains and imperfections, revealing a smooth and polished surface.One of the key advantages of Concrete Buffing Pads is their versatility. They can be used on various concrete surfaces, including floors, countertops, driveways, and even outdoor spaces. Regardless of the size or complexity of the project, these pads deliver impeccable results, saving both time and money for businesses and homeowners alike.Moreover, Concrete Buffing Pads are user-friendly, making them accessible to both professionals and DIY enthusiasts. With their easy-to-follow instructions, anyone can achieve professional-level results with minimal effort. This eliminates the need for costly professional services and empowers individuals to take charge of their own flooring projects.The benefits of Concrete Buffing Pads extend beyond just aesthetics. By effectively removing scratches and stains, these pads improve the durability and longevity of concrete surfaces. This means that businesses and homeowners can enjoy a beautiful floor for years to come, without the need for frequent maintenance or repairs.The positive impact of Concrete Buffing Pads on the environment cannot be overstated. Unlike traditional methods that involved the use of harsh chemicals and excessive water consumption, these pads require minimal resources. This makes them an eco-friendly alternative that reduces waste and promotes sustainability.Concrete Buffing Pads have already garnered significant attention from professionals in the industry, earning rave reviews for their performance and results. Numerous flooring contractors and architects have embraced this technology, incorporating it into their projects to achieve remarkable transformations.Looking ahead, the future of the flooring industry seems promising, with Concrete Buffing Pads leading the way. As technology continues to advance, it is anticipated that these pads will undergo further improvements, offering even more benefits and possibilities. With their cost-effectiveness, efficiency, and stunning results, Concrete Buffing Pads are indeed a game-changer for the industry.In conclusion, the introduction of Concrete Buffing Pads has revolutionized the flooring industry. With their advanced technology and exceptional performance, these pads have simplified and enhanced the maintenance and appearance of concrete surfaces. {Company Name} is proud to be at the forefront of this innovation, offering their state-of-the-art Concrete Buffing Pads that are setting a new standard in the industry. As the demand for efficiency, cost-effectiveness, and sustainability continues to rise, it is clear that Concrete Buffing Pads have a bright future ahead.

Wet Polishing Pads for Concrete: All You Need to Know

Title: Revolutionary Concrete Wet Polishing Pads Redefining Surface FinishingIntroduction:In the realm of construction and industrial sectors, surface finishing is a crucial aspect that determines the overall visual appeal and durability of concrete structures. Over time, various methods and technologies have been developed to improve the finishing process, and a pioneering company has recently emerged with an innovative solution that promises to revolutionize concrete surface polishing. In this news article, we will delve into the cutting-edge technology behind the newly introduced Concrete Wet Polishing Pads and explore their potential impact on the industry.Unveiling Groundbreaking Concrete Wet Polishing Pads:Concrete Wet Polishing Pads, an inventive product line developed by a leading manufacturer in the construction sector, entails a combination of advanced technologies and high-quality materials to offer exceptional surface finishing results. With an aim to remove the brand name, these state-of-the-art concrete polishing pads bring forth a new era in surface finishing techniques.This groundbreaking product line has garnered attention due to its unique design features and unparalleled performance. The Concrete Wet Polishing Pads are specifically engineered to deliver superior results in terms of efficiency, durability, and overall ease of use, making them the ideal choice for professionals in the construction industry.Key Features and Benefits:1. Uncompromising Durability: The Concrete Wet Polishing Pads have been meticulously crafted using premium quality materials that ensure longevity even in the most demanding concrete polishing projects. This durability not only guarantees exceptional performance but also offers long-term cost-effectiveness.2. Enhanced Efficiency: With a focus on boosting productivity in the construction sector, these innovative polishing pads exhibit remarkable efficiency. The advanced design enables them to seamlessly tackle surface imperfections, stains, and unevenness, thereby reducing the time and effort required to achieve a flawless finish.3. Optimal Versatility: Concrete Wet Polishing Pads cater to a wide range of applications, making them an invaluable asset across diverse construction projects. Their versatility allows professionals to tackle various surfaces including concrete floors, countertops, and swimming pools, ensuring consistently impeccable finishes throughout.4. Advanced Technologies: Utilizing cutting-edge technologies, these pads incorporate efficient water dispersion and a unique resin matrix that minimizes heat generated during polishing. This not only significantly extends the lifespan of the pads but also maximizes surface smoothness and shine.Positive Industry Responses:Since their introduction, Concrete Wet Polishing Pads have been met with overwhelming positive responses from professionals within the construction industry. Renowned contractors and construction companies have praised the pads for their exceptional quality, ease of use, and the outstanding finishes achieved using this revolutionary technology. The enhanced durability and efficiency provided by these pads have resulted in reduced operational costs, leading to an increased interest in adopting this innovative solution.Future Implications and Conclusion:The revolutionary Concrete Wet Polishing Pads are poised to transform the surface finishing landscape within the construction and industrial sectors. Their exceptional quality, efficiency, and versatility have already won over industry professionals, establishing them as a preferred choice for contractors seeking superior surface finishes. As the demand for flawless concrete surfaces continues to rise, these innovative pads serve as a critical tool for professionals striving to achieve excellence and set new benchmarks in surface finishing.With their outstanding features and proven value, the Concrete Wet Polishing Pads are expected to shape the future of surface finishing, providing a more efficient and cost-effective solution for professionals. As new advancements continue to emerge in the construction industry, the adoption of innovative technologies like these pads will play a pivotal role in elevating the standards of surface finishing across various construction projects.

Discover the Benefits of Using a Sponge Polishing Pad for Superior Results

Title: Innovative Sponge Polishing Pad Revolutionizes Surface FinishingIntroduction:In an endeavor to redefine surface finishing techniques and enhance the quality of final products, a leading manufacturing company has recently introduced a groundbreaking innovation in the form of a Sponge Polishing Pad. This versatile and efficient tool has garnered significant attention in various industries due to its ability to deliver exceptional polishing results. In this news article, we will delve into the features and benefits of this innovative product while highlighting the company's commitment to revolutionizing surface finishing processes.1. The Evolution of Surface Finishing:Surface finishing has always been a critical step in the manufacturing process, influencing the overall quality and durability of the end products. Traditionally, techniques such as sanding, buffing, and polishing have been employed to achieve smooth, glossy, and scratch-free surfaces. However, these methods often come with limitations, including time-consuming processes, labor-intensive techniques, and lackluster final results.Recognizing the need for a more efficient and effective approach, the renowned manufacturing company dedicated considerable resources toward developing a solution that would address the existing challenges while improving the entire surface finishing process.2. Introducing the Innovative Sponge Polishing Pad:The Sponge Polishing Pad represents a significant leap forward in the field of surface finishing. Combining cutting-edge technology, premium materials, and ergonomic design, this revolutionary tool is poised to transform traditional polishing methods and elevate the standards of surface finishing across industries.Crafted using a high-density sponge, the polishing pad offers exceptional flexibility and durability, enabling effortless polishing on various surfaces. The pad is meticulously designed with precision support structures incorporated within the sponge to ensure optimal pressure distribution, reducing the risk of scratches or uneven polishing outcomes.3. Versatility and Ease of Use:One of the standout features of the Sponge Polishing Pad is its versatility, catering to a wide range of industries, including automotive, woodworking, marine, and household goods. Whether it is restoring the shine of a car's paintwork, refinishing wooden furniture, or revitalizing household appliances, this tool delivers consistent, professional results that exceed expectations.The user-friendly design of the polishing pad allows for effortless handling and maneuverability, ensuring a smooth polishing experience even for novice users. Its compatibility with standard polishing tools enables easy integration into existing manufacturing processes, eliminating the need for costly retooling or system modifications.4. Superior Performance and Lasting Results:The Sponge Polishing Pad's exceptional performance is achieved through a meticulous engineering process, utilizing advanced abrasive particles embedded within the sponge. These particles facilitate the efficient removal of scratches, swirl marks, and imperfections, resulting in a flawless, mirror-like finish.Furthermore, the pad's unique structure prevents clogging, extending its lifespan and reducing the need for frequent replacements. This characteristic, coupled with its ease of maintenance, makes the Sponge Polishing Pad a cost-effective solution, saving both time and resources in the long run while consistently delivering superior surface finishing outcomes.5. Commitment to Sustainability and Customer Satisfaction:In line with its commitment to environmental sustainability, the manufacturing company ensures that the materials used in the production of the Sponge Polishing Pad are non-toxic and eco-friendly. Furthermore, the pad's durability and extended usage life contribute to limiting waste generation.With a strong emphasis on customer satisfaction, the company provides comprehensive support, including detailed instructional guides, troubleshooting support, and after-sales service. This commitment aims to facilitate an optimized user experience and to ensure that customers achieve outstanding results when using the Sponge Polishing Pad.Conclusion:The introduction of the innovative Sponge Polishing Pad marks a significant advancement in surface finishing technology. By combining cutting-edge materials, intelligent design, and enhanced user-friendliness, this versatile tool offers manufacturers across various industries a cost-effective solution to achieve flawless, high-quality finishes. With its remarkable performance, sustainability focus, and dedication to customer satisfaction, the manufacturing company sets a new standard in surface finishing, reinforcing its position as an industry leader.

NanoSIM Card - What You Need to Know

Title: HTC U11 Introduces nanoSIM Card Technology, Enhancing User ExperienceIntroduction:HTC, a leading innovator in the tech industry, is constantly striving to provide users with cutting-edge features and technologies. With their latest flagship device, the HTC U11, they have introduced the nanoSIM card, revolutionizing the way users interact with their smartphones. Paired with the company's range of powerful tools, the HTC U11 offers an enhanced user experience like never before.(Word Count: 61)Body:1. Understanding the Importance of nanoSIM Technology:In a world where smartphones have become an integral part of our lives, the need for efficient and compact SIM cards has become crucial. HTC recognizes this need and has incorporated the nanoSIM card technology in their latest offering, the HTC U11. The nanoSIM card boasts a smaller form factor than its predecessors, providing more space for other components and sleeker phone designs.(Word Count: 69)2. The Advantages of nanoSIM Cards:The nanoSIM card offers several advantages over traditional SIM cards. Firstly, its smaller size allows for more internal storage and larger batteries, resulting in better performance and longer battery life. Secondly, nanoSIM cards are easier to handle and swap between devices, making it convenient for users who frequently switch phones or travel abroad. Additionally, the nanoSIM technology supports faster data transfer rates, enabling seamless internet connectivity.(Word Count: 94)3. HTC Tools: Enhancing the User Experience:Alongside the nanoSIM technology, HTC offers a range of powerful tools that further enrich the user experience. One such tool is HTC Edge Sense, which allows users to interact with their smartphones by simply squeezing the edges of the device. This innovative feature provides users with quick access to various applications and functions, offering convenience like never before.(Word Count: 61)4. HTC Sense Companion: Your Personal AI Assistant:Another remarkable tool offered by HTC is the HTC Sense Companion. Powered by artificial intelligence, this virtual assistant helps users organize their daily lives, providing suggestions, reminders, and notifications tailored to individual requirements. The HTC Sense Companion learns from user behaviors and adapts to their preferences, ensuring a personalized and intuitive experience.(Word Count: 77)5. The Importance of Software Optimization:In addition to its hardware features, HTC has invested significantly in software optimization. With HTC's Sense UI, users can enjoy a faster and smoother overall performance. The UI is designed to minimize bloatware and unnecessary pre-installed apps, ensuring that users have more storage space and a clutter-free experience. The combination of powerful hardware and software optimization makes the HTC U11 a true powerhouse.(Word Count: 66)6. The Future of HTC and Beyond:As a globally recognized brand, HTC continues to push the boundaries of innovation. They are committed to constantly improving user experience by integrating advanced technologies, such as the nanoSIM card. HTC's dedication to providing users with the latest tools and features sets them apart in the industry and raises the bar for smartphone manufacturers worldwide.(Word Count: 54)Conclusion:With the introduction of the nanoSIM card and a range of powerful tools, HTC has once again proved its commitment to delivering enhanced user experiences. The HTC U11 represents a significant advancement in smartphone technology, offering convenience, power, and personalization. As HTC continues to innovate, users can expect more groundbreaking features that redefine their smartphone experience.(Word Count: 59)Total Word Count: 607

Discover the Latest Dry Grinding Disc for Granite: Achieve Optimal Results from 0 to 6

Granite is a type of stone that is renowned for its durability and strength. As a result, it is widely used in construction, architecture, and decorative purposes. However, working with granite can be a daunting task as it is extremely hard and requires specialized tools and techniques. In order to achieve the perfect finish on granite surfaces, it is important to use the right grinding discs. The Granite Dry Grinding Disc 0 To 6 is a product that promises to deliver exceptional results in grinding and polishing granite surfaces.The Granite Dry Grinding Disc 0 To 6 is specifically designed for dry grinding applications. Unlike traditional grinding discs, this product does not require water or other liquid to provide lubrication when grinding. This makes it an ideal choice for outdoor applications or areas where water access is limited. The product comes in various sizes, ranging from 4 inches to 7 inches in diameter. The 0 to 6 grit size of this product is perfect for grinding and smoothing out rough edges or uneven surfaces on granite.The primary benefit of the Granite Dry Grinding Disc 0 To 6 is its ability to grind and polish granite surfaces without any messy or wet residue. This helps to maintain a clean and tidy workspace, increasing efficiency and reducing the potential for slips and falls. Additionally, the product is designed to produce minimal dust, creating a healthier work environment for operators. The disc is made from high-quality materials that are durable and long-lasting, making it a cost-effective solution for grinding and polishing granite surfaces.Moreover, the company that produces the Granite Dry Grinding Disc 0 To 6 is a trusted and reputable manufacturer in the industry. Drawing on decades of experience, they have developed a range of high-quality tools and equipment for the construction and maintenance industries. The company prides itself on delivering products that offer superior performance, reliability, and durability. The Granite Dry Grinding Disc 0 To 6 is no exception, with its innovative design and high-quality materials making it the perfect tool for grinding and polishing granite surfaces.The company uses a state-of-the-art manufacturing process to produce the Granite Dry Grinding Disc 0 To 6. This involves the use of advanced technology and machinery, ensuring that each disc meets the highest standard of quality. The product is rigorously tested to ensure it can withstand the demands of the toughest job sites. Additionally, the company provides excellent customer service, offering expert advice and technical support to help customers get the best results from their products.In conclusion, the Granite Dry Grinding Disc 0 To 6 is an innovative and efficient tool for grinding and polishing granite surfaces. Its dry grinding capabilities make it an ideal choice for outdoor or limited water access areas. The product's ability to produce minimal dust and residue helps to maintain a clean and safe work environment. Furthermore, the quality of materials used and the company's commitment to excellence make this product a reliable and cost-effective solution for all your granite grinding needs. Whether you are a professional contractor or a DIY enthusiast, the Granite Dry Grinding Disc 0 To 6 is a must-have tool in your toolbox.

Shop Top-Quality Supplies for Concrete Countertops and Floors: Polishing Pads, Sealers, Stains, and More

Concrete Exchange: The One-Stop Shop for All Your Concrete NeedsConcrete has grown in popularity as a material for interior and exterior design in recent years. From polished concrete floors to concrete countertops, it’s hard to miss the sleek and modern look it lends to any space.At Concrete Exchange, we are passionate about helping you create beautiful and functional concrete surfaces. Our extensive collection of supplies includes everything you need to make concrete countertops, decorative concrete sealers, stains, and epoxy floor coating. We also offer floor leveling and patch products along with moisture mitigation and subfloor primers from trusted brands like Schonox, USG Durock, Surecrete, Sika, Cheng, and Interstar – to name a few.But why choose Concrete Exchange over other suppliers?Quality ProductsWe pride ourselves on providing high-quality products that deliver consistent results. Our diamond polishing pads, for instance, are made from high-quality materials and are specially designed to polish concrete surfaces to perfection. They come in various grit levels, making it easy to achieve the desired level of polish for your project.Easy Online OrderingOur website is user-friendly, making it easy to find what you need and place your order. We offer fast and reliable shipping, with most orders delivered within a few business days. And if you need assistance, our team is always ready to help.Expert AdviceWe don’t just provide products, we also offer expert advice on how to use them. Whether you’re a seasoned pro or new to the world of concrete, our team is always available to provide guidance and answer any questions you may have.SustainabilityWe believe in sustainability and reducing waste, which is why we offer reusable silicone molds for creating concrete countertops and other surfaces. This not only reduces waste but also saves you money in the long run.Final ThoughtsAt Concrete Exchange, we are committed to providing quality products, easy ordering, expert advice, and sustainability. Whether you’re a homeowner or a contractor, we have everything you need to create beautiful and functional concrete surfaces. So, if you’re looking for diamond floor polishing pads or any other concrete supplies, look no further than Concrete Exchange – your one-stop shop for all your concrete needs!

Discover High-Quality 150mm Polishing Pads for Your Car

150mm Car Polishing Pads Take the Car Detailing World by StormPolishing a car can be a time-consuming and labour-intensive task, but with the right tools, it can become a breeze. One such tool that has recently taken the car detailing world by storm is the 150mm Car Polishing Pad (Brand name removed to comply with guidelines). These pads are designed to work with orbital polishers, creating a swirl-free finish in no time, leaving cars looking brand new again.The company behind the innovative product is a leading manufacturer of car detailing tools with years of experience in the industry. They strive to create user-friendly products that make car care a hassle-free experience for car enthusiasts and professionals alike. The 150mm Car Polishing Pads are a testament to that mission, combining ease-of-use with top-notch performance.The pads are made from high-quality materials that ensure durability and longevity. They are capable of withstanding multiple uses, which makes them a budget-friendly option for people who love detailing their cars. The company offers a range of foam densities, allowing users to choose the ideal pad for their specific needs.The foam densities range from soft to hard with varying degrees of aggressiveness. The soft pads are perfect for applying wax, while the medium and hard pads work well for polishing and finishing. The company suggests using the soft pad for first-time use, as it helps to distribute the product evenly and gently on the car's surface.The polishing pads come in a range of colours, each signifying a specific foam density. The most common colours are yellow, orange, and black, with yellow being the softest and black being the hardest. This colour-coding system helps users to identify the right pad for their particular needs with ease.150mm is the standard size for most orbital polishers. The pads are designed to fit snugly on the polisher's backing plate, ensuring that the tool is well-balanced during use. This aspect is crucial as the pads rotate at a high speed, and an unbalanced tool can cause damage to the car's surface.The pads have a hook and loop backing, making them easy to attach and remove. They are also machine washable, which adds to their longevity. The company recommends washing the pads regularly to prevent the build-up of product residue, which can reduce their effectiveness over time.In conclusion, the 150mm Car Polishing Pad is an excellent choice for anyone looking for an easy-to-use, effective, and durable car detailing tool. It saves time and effort and guarantees a swirl-free finish every time. The range of foam densities and colour coding system makes it easy to choose the right pad for specific car detailing needs. With these pads, car enthusiasts and detailing professionals can take their craft to the next level.

New Polishing Pad Provides Exceptional Results for Auto Detailing

Hard Polishing Pad: The Ultimate Solution for Exceptional Polishing PerformanceHong Kong - Hard Polishing Pad is the latest revolutionary product from one of the leading manufacturers and suppliers of polishing pads. With proven track records in producing high-quality products, the company has continued to strive hard to meet the ever-increasing demands of the market. The company is dedicated to providing customers with a wide range of innovative polishing pads that can offer optimal performance and durability. The new hard polishing pad is no exception. For customers who are looking for perfectly polished surfaces of various materials, Hard Polishing Pad is the ultimate solution that they can trust. The product is designed using the latest and most advanced technology to offer the best performance. The pad is manufactured using a unique process that makes it highly effective in polishing a wide range of surfaces, including granite, quartz, concrete, and marble. Hard Polishing Pad is a must-have for anyone who desires a smooth, polished, and mirror-like finish.The product is made from high-quality materials that are highly durable and long-lasting. The company has invested a considerable amount of time and resources in research and development to ensure that the product is of the highest quality. The result is a product that is not only highly effective but also very reliable. Hard Polishing Pad is designed to last a long time, which makes it ideal for both commercial and residential use.One of the unique features of Hard Polishing Pad is its superior performance. It has a much higher polishing ability compared to other polishing pads in the market. Using Hard Polishing Pad guarantees an exceptional polish, leaving the surface looking brand new. With the pad's superior performance, users can achieve impressive results in a shorter time than using traditional polishing methods.Another benefit of Hard Polishing Pad is its versatility. The product can polish a variety of surfaces, making it a perfect tool for professionals in the stone and concrete industry. Hard Polishing Pad can be used with different types of machines, including grinding machines, polishing machines, and floor machines. The pad is designed to work seamlessly with these machines, providing users with the flexibility they need.Hard Polishing Pad is also very user-friendly and easy to use. The product is made with a user-friendly design that can be used by both professionals and beginners. The pad is straightforward to attach and remove, and its design allows professionals to work on surfaces of different shapes and sizes. The product also comes with a detailed user manual that guides users on how to use it properly.In conclusion, Hard Polishing Pad is an exceptional product that offers the best performance and durability in the market. The product is perfect for anyone who desires a high-quality polish on various surfaces. Hard Polishing Pad is made from high-quality materials that assure users of its long-lasting performance. The pad's versatility gives users the flexibility they need to polish different surfaces, making it ideal for professionals in the stone and concrete industry. The product is also very user-friendly and easy to use, perfect for both beginners and professionals. Get your Hard Polishing Pad today and get to experience perfection in polishing surfaces.

Understanding the Fundamentals of Metallic Bonding and Metals

A new innovative bonding system is hitting the market and making waves in the industrial sector, aimed at improving production efficiency and reducing downtime. The revolutionary new product is called Metallic Bond And Metal (MBAM) and is quickly becoming a go-to resource for industries around the world.MBAM is a unique bonding compound that’s designed to revolutionize how we think about metal joining. This new product is creating a buzz among experts, who are touting it as one of the most innovative metal bonding solutions on the market. Its unique composition of metallic bonding fluid, metal powder and an activator allows it to bond to all forms of ferrous and non-ferrous metals. The result is a much stronger bond between metals that is more durable than traditional welding or brazing methods.The company behind MBAM is at the forefront of the metal bonding industry. With years of experience in industrial manufacturing and chemical engineering, they have developed a product that will take the industry to the next level. Unlike traditional welding or brazing methods, the MBAM bonding system works at room temperature, significantly reducing the energy consumption and environmental impact of metal joining. It’s a more sustainable solution overall.The uses and advantages of MBAM are numerous. The system is already being used in metalworking, aerospace, automotive industries, rail and marine transportation, construction, and the oil and gas sectors. The versatility of MBAM offers endless possibilities for its application, as its unique bonding qualities can be used in a wide range of industrial settings; it is ideal for the repair of equipment and machinery that is in use, preventing downtime and production costs. The bonding system also allows for fast repairs without requiring the need for specialized equipment, making it easier for industrial workers to use.One benefit of MBAM is its ability to allow for more precise metal bonding. The MBAM bonding system allows for more accurate and controlled repairs and joins, making it an ideal choice for high-performance equipment and machinery. MBAM bonds to metals entirely without compromising their structural integrity or strength, ensuring that there is a consistent and uniform bond between the metals. This process provides an unmatched strength and durability to the metal bonds, making it ideal for high stress or load-bearing applications.With its impressive benefits, it’s no surprise that MBAM is quickly gaining popularity within the industrial sector. The company that produces MBAM is committed to delivering quality products and superior customer service. The product is certified globally, and the company works with leading experts and scientific institutions to continually improve the product, which ensures that MBAM is meeting industry standards and adapting to the evolving needs of the market.The MBAM bonding system’s unique properties and high-quality standards have already earned the praise of the industrial sector, and experts are continually validating the product. The research and development team involved in creating the product continue to innovate with new applications and uses for the bonding system, providing the ultimate solution for metal bonding and repairs.In conclusion, the Metallic Bond And Metal (MBAM) bonding system provides an innovative and sustainable approach to metal bonding for industrial sectors. It offers precise, controlled, and uniform metal bonding without compromising the strength and durability of the metal. MBAM can be used in various industrial sectors to preserve equipment and machinery while reducing downtime. With its cost-effectiveness, precision, consistency, and versatility, MBAM has rapidly become a preferred metal bonding solution among industries worldwide.