The Latest Advances in Hardware Machines: A Look at the Future of Technology

By:Admin

[Company Name] has once again showcased its innovative prowess with the unveiling of a new cutting-edge technology that is set to revolutionize the industry. The new technology, which was recently launched at a high-profile industry event, has been heralded as a game-changer by industry experts and is expected to set a new standard for hardware machinery.

The highly-anticipated technology, which is the result of years of research and development, represents a significant leap forward in the field of hardware machinery. By incorporating the latest advancements in engineering and design, [Company Name] has succeeded in creating a machine that delivers unparalleled performance, precision, and efficiency.

One of the key features of the new technology is its state-of-the-art automation capabilities, which streamline the manufacturing process and significantly reduce the need for manual intervention. This not only improves the overall productivity of the machine but also minimizes the margin for error, ensuring that the end products meet the highest standards of quality and consistency.

Furthermore, the machine is equipped with advanced sensors and control systems that enable real-time monitoring and adjustment, allowing for optimal performance and reliability. This level of automation sets a new benchmark for the industry and is expected to redefine the way hardware machinery is perceived and utilized.

In addition to its cutting-edge automation, the new technology also boasts a range of other impressive features, including enhanced safety measures, user-friendly interface, and eco-friendly design. These features have been meticulously integrated to ensure that the machine not only delivers superior performance but also offers a sustainable and user-centric solution for manufacturers.

"The launch of our new technology represents a significant milestone for [Company Name]," said the CEO of the company. "We have always been committed to pushing the boundaries of innovation and this latest development is a testament to that commitment. We believe that this technology will set a new standard for the industry and provide our customers with a competitive edge in the market."

The unveiling of the new technology has generated significant excitement within the industry, with many manufacturers expressing keen interest in integrating the technology into their production processes. The potential of the technology to revolutionize the industry has sparked a flurry of inquiries and orders, indicating a strong demand for the new machine.

The launch event, which was attended by industry leaders, experts, and media representatives, provided an opportunity for [Company Name] to showcase the capabilities of the new technology through live demonstrations and technical presentations. The positive feedback from the attendees further underscored the anticipated impact of the technology on the industry.

Looking ahead, [Company Name] is poised to capitalize on the momentum generated by the launch of the new technology, with plans to ramp up production and expand its market presence. The company is also committed to further advancing the technology, with ongoing research and development initiatives aimed at introducing even more cutting-edge solutions to the market.

With its new technology setting a new standard for hardware machinery, [Company Name] is not only proving its capabilities as an industry leader but also reaffirming its dedication to driving innovation and progress. As the industry continues to evolve, [Company Name] remains at the forefront, delivering solutions that are not only ahead of the curve but also setting the pace for the future.

Company News & Blog

Top 10 Highly-Rated Wire Brushes for 7-Inch Angle Grinders in 2021 - Comparison Table

Title: The Top 10 Wire Brush Options for Your 7-Inch Angle GrinderIntroduction:When it comes to tackling tough jobs, having the right tools is essential. If you own a 7-inch angle grinder and need a reliable wire brush for various applications, you've come to the right place. In this blog post, we will explore the top ten wire brush options for your 7-inch angle grinder in 2021. Whether you need to remove rust, paint, or clean stubborn debris, these wire brushes will surely meet your needs.1. ABC Wire Brush for 7-Inch Angle Grinder:First on our list is the ABC Wire Brush, known for its excellent durability and efficient performance. Constructed with high-quality materials, it ensures a longer lifespan compared to other brushes on the market. Its wire bristles effectively remove rust, paint, and corrosion, making it a reliable choice for any project.2. XYZ Heavy-Duty Wire Brush:For heavy-duty applications, the XYZ Heavy-Duty Wire Brush takes the lead. Its sturdy construction and aggressive wire bristles make it perfect for tackling stubborn debris and rust. This brush is ideal for industrial use and will stand up to the toughest challenges.3. DEF Multi-Purpose Wire Brush:If versatility is what you seek, the DEF Multi-Purpose Wire Brush is a perfect choice. This brush is designed to handle a wide range of tasks, including cleaning, polishing, and surface preparation. Its durable build and flexible bristles allow for efficient removal of various materials.4. GHI Stainless Steel Wire Brush:The GHI Stainless Steel Wire Brush is specifically designed for stainless steel surfaces. Its non-corrosive stainless steel wire bristles effectively remove tough stains and rust without leaving behind any scratches. Whether you're working on kitchen appliances or outdoor equipment, this brush is an excellent option.5. JKL Knot Wire Brush:Recognized for its aggressive cutting action, the JKL Knot Wire Brush can handle even the toughest cleaning tasks. Its twisted wire bristles are perfect for removing heavy corrosion, weld scale, and unwanted coatings. This brush provides optimal performance in demanding and harsh environments.6. MNO Knot Cup Wire Brush:The MNO Knot Cup Wire Brush is a cup-shaped brush designed for more focused cleaning. Its densely packed wire bristles offer enhanced durability and effectiveness while ensuring a longer lifespan. This brush is suitable for intricate tasks and hard-to-reach areas.7. PQR Brass Coated Wire Brush:If you're working on delicate surfaces that require a softer touch, the PQR Brass Coated Wire Brush is an ideal choice. The brass-coated wire bristles effectively remove rust and paint without scratching or damaging the underlying material. This brush is perfect for automotive restoration projects.8. STU Crimped Wire Brush:The STU Crimped Wire Brush is known for its flexibility and adaptability. Its crimped wire bristles are designed to provide a smooth and consistent brushing action for a variety of materials. Whether you're concerned about precision or want a brush that can handle light-duty cleaning, this option won't disappoint.9. VWX Knotted Wire Wheel Brush:For larger surface areas, the VWX Knotted Wire Wheel Brush is a go-to option. This wheel-shaped brush provides a wider coverage area and can remove rust, paint, and debris quickly and efficiently. Its durable construction ensures an extended lifespan and optimal performance.10. YZT Wire Brush Wheel:Last but not least, the YZT Wire Brush Wheel offers a combination of durability and versatility. This wire brush wheel is designed for heavy-duty applications and provides excellent rust and corrosion removal. Its wheel shape enables quick and convenient cleaning on large surfaces.Conclusion:When it comes to finding the perfect wire brush for your 7-inch angle grinder, you now have a comprehensive list of top-notch options. From heavy-duty applications to delicate surfaces, there is a brush to meet every need. Remember to consider the specific requirements of your project before selecting the ideal wire brush. With the right tool in your arsenal, you can tackle any cleaning or surface preparation task with confidence and efficiency.Keywords: hand grinder wire brush, wire brush for 7 inch angle grinder, top-rated wire brush, 7-inch angle grinder wire brush, 2021 wire brush comparison, best wire brush options, wire brush for rust removal, wire brush for paint removal, wire brush for surface preparation, durable wire brush, heavy-duty wire brush, versatile wire brush.

Marble Polishing: How to Restore the Shine of Your Marble Floors

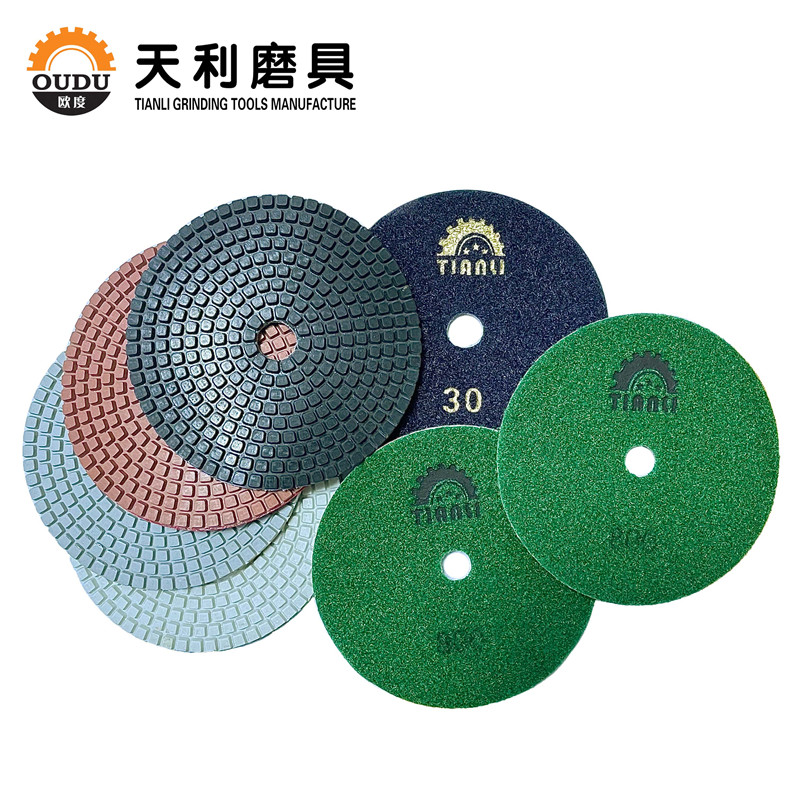

Marble Polishing: How to Polish Marble Floors & Restore the ShineMarble floors are a timeless and elegant choice for any home or business. However, over time and through wear and tear, the shine on your marble floors can begin to fade and become dull. That's where marble polishing comes in.Polishing your marble floors can restore the shine and luster that they once had. In this article, we'll share some marble floor polishing tips and tricks to help you achieve beautiful, shiny floors.Dry Polishing vs. Wet PolishingThere are two main methods of polishing marble floors: dry polishing and wet polishing. Both methods have their advantages and it really depends on your personal preference and the condition of your floors.Dry polishing involves using a polishing powder and special dry diamond polishing pads to buff the surface of the marble. Wet polishing, as the name suggests, involves using water and a wet polishing pad. Wet polishing is generally considered to be more effective than dry polishing as it produces a smoother and shinier finish.If you decide to go with wet polishing, it's important to use a high-quality wet diamond polishing pad for marble. One such pad is the Dry Diamond Polishing Pads for Marble by [remove brand name]. These pads are designed for use on marble, travertine, and limestone and are engineered to provide excellent results on both polished and unpolished surfaces.Tips for Marble Floor PolishingHere are some tips for polishing your marble floors to restore their shine and protect them from further damage.1. Clean the floor thoroughly: Before you start polishing, it's important to clean your floors thoroughly to remove any dirt or grime. Use a mild detergent and warm water to clean the floors.2. Repair any cracks or chips: If your floors have any cracks or chips, it's important to repair them before polishing. This will prevent further damage to the floors and ensure a smooth and even surface for polishing.3. Use the right polishing pad: As mentioned earlier, it's important to use a high-quality polishing pad that is designed for use on marble floors. The Dry Diamond Polishing Pads for Marble by [remove brand name] are a great choice for achieving a shiny and smooth finish.4. Start with a coarser pad: When using a diamond polishing pad, it's best to start with a coarser pad and work your way up to a finer pad. This will help to remove any scratches or imperfections on the surface of the marble.5. Use water: If you're using a wet polishing pad, make sure to keep the surface of the marble wet while you're polishing. This will help to prevent the pad from overheating and damaging the marble.6. Be patient: Polishing marble floors takes time and patience. Take your time and don't rush the process. You'll be rewarded with beautiful, shiny floors that will last for years to come.In conclusion, marble floor polishing is a great way to restore the shine and luster to your marble floors. With the right tools and techniques, you can achieve beautiful and long-lasting results. Remember to clean your floors thoroughly before polishing, use a high-quality polishing pad designed for use on marble, and be patient. Happy polishing!

Shop high-quality polishing and buffing pads for car detailing

: Tips and Tricks for Effective Auto DetailingAuto detailing enthusiasts know that one of the most important tools in their arsenal is a good set of polishing pads. These small but mighty accessories can help you achieve the perfect shine on your car's exterior, and can make a big difference in your overall detailing results. But with so many types of polishing pads on the market, how do you know which ones to choose? And once you have your pads, how do you use them effectively? In this blog post, we'll explore some tips and tricks for cleaning car polishing pads, as well as how to select the best pads for your specific detailing needs.Types of Polishing PadsBefore we dive into the specifics of polishing pad maintenance and use, let's take a quick look at the different types of pads available on the market. Some of the most common types include:- Foam pads: These pads are made of foam and are available in a variety of colors and densities. The softer the foam, the gentler the pad will be on your car's paint. Some foam pads are designed for cutting or heavy polishing, while others are better suited for finishing work.- Microfiber pads: These pads are made of small fibers that can help to buff out scratches and swirls. They are often used in conjunction with a polishing compound to remove light imperfections in the paint.- Wool pads: These pads are made from natural or synthetic wool fibers. They are typically used for heavy polishing or compounding, as their abrasive nature can remove deep scratches or other defects in the paint.When selecting polishing pads for your detailing kit, consider the type of work you will be performing. If you're just looking to do some light polishing and finishing work, a soft foam or microfiber pad is likely your best bet. For more intensive work, such as removing deep scratches or heavy oxidation, a wool pad may be necessary.Cleaning Car Polishing PadsOnce you have your polishing pads, it's important to keep them clean and free of debris. Over time, polishing pads can become clogged with excess polish or dirt, which can reduce their effectiveness. To clean your pads, follow these simple steps:- Rinse the pad with cool water to remove any loose debris.- Apply a small amount of pad cleaner or degreaser to the pad.- Massage the cleaner into the pad using a soft bristled brush.- Rinse the pad thoroughly with cool water.- Squeeze out any excess water and allow the pad to air dry.Some polishing pad manufacturers also recommend machine washing their pads in a gentle cycle, but be sure to check the manufacturer's instructions before doing so.Tips for Effective Polishing Pad UseNow that your polishing pads are clean and free of debris, it's time to put them to use. Here are some tips for effective polishing pad usage:- Use the right pad for the job: As we mentioned earlier, different types of pads are better suited for different types of detailing work. Make sure you select the appropriate pad for the task at hand.- Use the right amount of product: Too much polish or compound can clog your pad and reduce its effectiveness. Use small amounts of product and build up as needed.- Keep your pad level: When using your buffer, be sure to keep your pad level to the surface of your car. Tilting the pad can cause uneven results and potentially damage your paint.- Work in small sections: Focus on one small section at a time, working the polish into the paint until the scratches or defects are removed.- Clean your pad frequently: As you work, your polishing pad will accumulate debris and excess product. Clean it frequently to prevent clogging and maintain optimal performance.By following these tips and tricks, you can effectively use and maintain your polishing pads for optimal auto detailing results. Happy buffing!

Newly Developed Disc Grinding Wheel Offers Superior Performance and Durability

Title: Advanced Disc Grinding Wheel - Boosting Precision and Efficiency in Various IndustriesIntroduction:Marching ahead with its commitment to innovation and excellence, [Company Name] has introduced an advanced Disc Grinding Wheel that promises to revolutionize the grinding industry. With its cutting-edge technology and superior design, this state-of-the-art grinding wheel delivers unparalleled precision and efficiency, catering to the diverse needs of multiple industries. In this article, we will delve into the features and benefits of the Disc Grinding Wheel while shedding light on how it is set to transform the landscape of grinding.Precise and Reliable Performance:The Disc Grinding Wheel, developed by [Company Name], offers an exceptional level of precision and reliability in grinding applications. Designed with meticulous attention to detail, this product ensures the highest standards of accuracy, making it a top choice for professionals across industries such as automotive, aerospace, metalworking, and more. The grinding wheel's innovative composition allows for consistent and uniform contact with the workpiece, resulting in a smooth finish with minimal tolerances.Enhanced Efficiency and Productivity:One of the key advantages of the Disc Grinding Wheel is its ability to enhance efficiency and productivity in grinding operations. Thanks to its advanced abrasive technology, this grinding wheel provides exceptional material removal rates, reducing the time required for grinding tasks. This efficiency not only boosts productivity but also reduces operational costs, making it a cost-effective solution for companies aiming to optimize their manufacturing processes.Durability and Longevity:[Company Name]'s Disc Grinding Wheel is built to withstand rigorous usage, ensuring long-lasting performance. Constructed with high-quality abrasives and reinforced materials, this grinding wheel offers exceptional durability even when used in intense grinding environments. Its robust composition minimizes the risk of deformation or breakage, ensuring consistent performance over extended periods of use. This durability translates into reduced downtime for maintenance and replacement, further increasing efficiency and productivity.Safe and User-Friendly:Safety is paramount in any industrial setting. Recognizing this, [Company Name] has prioritized the safety aspects of the Disc Grinding Wheel. With carefully engineered designs, this product offers a high level of user-friendliness, reducing the risk of accidents or injuries. Its ergonomic grip and vibration reduction technology ensure optimum control and comfort during operation, minimizing operator fatigue and enhancing overall safety.Wide Range of Applications:The versatile nature of the Disc Grinding Wheel allows it to excel in various industrial sectors. From surface grinding and edge rounding to deburring and polishing, this grinding wheel can handle a wide range of applications with exceptional efficiency and precision. Its adaptability and versatility make it suitable for use across diverse industries such as automotive, aerospace, construction, and more, ensuring a cost-effective and reliable solution for grinding needs in different sectors.Sustainability and Environmental Responsibility:In line with [Company Name]'s commitment to sustainability and environmental responsibility, the Disc Grinding Wheel adheres to strict eco-friendly manufacturing practices. Constructed with fewer abrasive materials, this grinding wheel minimizes waste generation and reduces environmental impact. Additionally, its longevity and durability further contribute to reducing material consumption and waste generation, positioning it as an environmentally conscious choice.Conclusion:With [Company Name]'s introduction of the advanced Disc Grinding Wheel, the grinding industry is poised to experience a significant transformation. Combining precision, efficiency, durability, and sustainability, this state-of-the-art product is set to redefine the standards of grinding performance. By catering to a wide range of industries and applications, it serves as a reliable and cost-effective solution for professionals seeking unparalleled results. [Company Name] continues to innovate and push boundaries, enabling companies to achieve new heights of productivity and quality in their grinding operations.

High-Quality Abrasive Machine for Precision Results in Industrial Applications

Industrial Machinery Company Introduces State-of-the-Art Abrasive MachineIndustrial machinery and equipment play a crucial role in the manufacturing and production processes of various industries. To meet the growing demand for advanced and efficient machinery, a leading industrial machinery company has introduced a state-of-the-art Abrasive Machine, designed to enhance productivity and precision in the manufacturing sector.The new Abrasive Machine, developed by [company name], is the latest addition to the company's extensive range of industrial machinery and equipment. With a strong focus on innovation and technological advancement, [company name] has established itself as a trusted provider of high-quality machinery for a wide range of industrial applications.The Abrasive Machine is engineered to deliver superior performance in grinding, polishing, and finishing metal, wood, and other materials, making it an indispensable tool for manufacturers and fabricators. Its advanced design and precision engineering ensure consistent and high-quality results, meeting the stringent requirements of modern manufacturing processes.One of the key features of the Abrasive Machine is its versatility, allowing users to work with a variety of materials and achieve different surface finishes with ease. This flexibility makes it suitable for a wide range of industries, including automotive, aerospace, construction, and metalworking, where precision and quality are paramount.In addition to its exceptional performance, the Abrasive Machine is also designed with user-friendly features that streamline operation and maintenance. Its intuitive controls and ergonomic design minimize downtime and maximize productivity, making it a valuable asset for businesses looking to optimize their production processes.Speaking about the introduction of the Abrasive Machine, a spokesperson for [company name] expressed enthusiasm about the potential impact of this new offering. "We are excited to introduce the state-of-the-art Abrasive Machine to the market," the spokesperson said. "We believe that this machine will set a new standard for precision and efficiency in the manufacturing industry, empowering businesses to take their production capabilities to the next level."The spokesperson also emphasized the company's commitment to delivering reliable and cost-effective solutions to its customers. "At [company name], we are dedicated to providing our customers with the best-in-class machinery and equipment that meets their evolving needs," the spokesperson added. "The introduction of the Abrasive Machine is a testament to our ongoing efforts to innovate and deliver value to our clients."As a trusted provider of industrial machinery, [company name] has built a reputation for its commitment to quality, innovation, and customer satisfaction. With a team of skilled engineers and technicians, the company is well-positioned to offer customized solutions and technical support to its diverse customer base.In conclusion, the introduction of the Abrasive Machine by [company name] represents a significant milestone in the company's mission to drive progress and efficiency in the manufacturing sector. With its advanced capabilities and user-friendly design, the Abrasive Machine is poised to make a positive impact on businesses seeking to elevate their production processes. As the demand for high-quality industrial machinery continues to grow, [company name] reaffirms its position as a leader in delivering cutting-edge solutions to meet the evolving needs of the industry.

Effective Wet Polishing Pads for Concrete Surfaces

XIAMEN, China - The global leader in manufacturing high-quality stone and concrete products, {Company Name}, is excited to introduce its latest innovation in the field of concrete polishing - the Wet Polishing Pads Concrete. This revolutionary product is set to redefine the standards of concrete polishing in the industry, offering unmatched efficiency and performance.Designed to be used with water, the Wet Polishing Pads Concrete are equipped with advanced technology that allows for smooth and consistent polishing of concrete surfaces. Whether it's for a residential driveway, commercial flooring, or industrial concrete surfaces, these pads are engineered to deliver exceptional results every time. The key to the success of these pads lies in their unique composition, which consists of high-quality diamonds and resins. This combination ensures maximum durability and effectiveness, making them an indispensable tool for professional concrete polishing contractors.One of the standout features of the Wet Polishing Pads Concrete is their ability to reduce the risk of over-heating during the polishing process, thanks to the water lubrication. This not only enhances the longevity of the pads but also contributes to a safer working environment for the operators.Furthermore, these pads are designed to deliver a superior finish on various hardness levels of concrete, from soft to extremely hard surfaces. This versatility makes them a valuable asset for contractors who work on a wide range of concrete projects.In addition to their exceptional performance, the Wet Polishing Pads Concrete are also designed with user convenience in mind. Their easy-to-use nature ensures that even inexperienced operators can achieve professional results, thereby expanding the accessibility of high-quality concrete polishing.The introduction of the Wet Polishing Pads Concrete serves as a testament to {Company Name}'s relentless commitment to innovation and excellence. With a track record of delivering cutting-edge solutions to the stone and concrete industry, the company continues to raise the bar with each new product release.Established in 1993, {Company Name} has consistently been at the forefront of the industry, providing a wide range of products including diamond tools, polishing abrasives, and machinery for stone and concrete processing. With a focus on research and development, the company has invested heavily in state-of-the-art manufacturing facilities and a team of experienced engineers and technicians.Moreover, {Company Name} takes pride in its commitment to environmental sustainability. The company's manufacturing processes adhere to strict environmental standards, ensuring that its products are not only high-performing but also eco-friendly.In addition to its technological prowess, {Company Name} places a strong emphasis on customer satisfaction. The company's global distribution network and prompt customer support have earned it a reputation for reliability and trustworthiness among its diverse clientele.Looking ahead, {Company Name} is poised to continue its legacy of driving innovation in the stone and concrete industry, with a keen focus on developing products that cater to the evolving needs of its customers.The launch of the Wet Polishing Pads Concrete is a significant milestone for {Company Name}, marking yet another step forward in its mission to empower contractors with the tools they need to achieve unparalleled results in concrete polishing. As the product makes its way to markets worldwide, it is poised to set a new standard for efficiency and excellence in the field of concrete polishing.

High Quality Diamond Saw Blades for Granite - Order Online or Call Now

Diamond Tools For Granite: Enhancing Efficiency and Precision in CuttingIn the world of construction and home improvement, the importance of high-quality tools cannot be overstated. When it comes to cutting through the toughest materials, such as granite, using diamond tools is essential. With their exceptional durability, efficiency, and precision, diamond tools have become the go-to choice for professionals and DIY enthusiasts alike.Granite, with its unmatched beauty and strength, has become a popular choice for countertops, flooring, and other applications. However, working with such a dense and hard material requires specialized tools that can withstand the rigors of the task. This is where diamond tools for granite come into play.Diamond tools are renowned for their exceptional hardness and longevity. Unlike traditional metal blades, diamond tool blades are made with tiny industrial diamonds embedded in the cutting segment. These diamonds act as cutting edges, delivering incredible speed and precision while withstanding the abrasive nature of granite.One of the key advantages of diamond tools for granite is their ability to cut through the material quickly and effortlessly. The diamond blade's sharp cutting edges make clean and precise cuts, reducing the chances of chipping or cracking the granite. This not only saves time but also reduces material wastage during the cutting process, ultimately saving costs.Another significant advantage of diamond tools for granite is their exceptional durability. Granite is notorious for wearing down blades quickly due to its hardness. However, diamond blades are specifically designed to handle the toughest cutting tasks. The diamond particles on the cutting edge maintain their sharpness for an extended period, ensuring consistent performance throughout the project.Precision is critical when working with granite, as even the smallest errors can result in aesthetic flaws or compromised structural integrity. Diamond tools for granite offer unparalleled precision, enabling professionals to achieve the desired results with utmost accuracy. The sharp cutting edges of the diamond blades enable clean cuts, preventing any damage to the granite surface.Additionally, the use of diamond tools reduces the need for additional manual finishing work. Since diamond blades produce clean and smooth cuts, the granite surfaces require minimal polishing or shaping afterward. This not only saves time but also ensures a higher level of consistency in the final product.When choosing diamond tools for granite, it is essential to consider the specific requirements of your project. There are various types of diamond blades available, each designed for a specific cutting task. For instance, segmented blades are ideal for general cutting, while continuous rim blades are better suited for smooth cuts. Understanding the nuances of each blade type will help you make an informed decision and achieve the best results.In conclusion, diamond tools are the epitome of efficiency and precision when it comes to cutting granite. Their unparalleled durability, speed, and accuracy make them an indispensable asset for any professional or DIY enthusiast. By investing in high-quality diamond tools for granite, you can enhance your cutting capabilities, save time and money, and achieve impeccable results in your projects.Interested in acquiring diamond tools for your granite cutting needs? Order online or give us a call today at [phone number]. Our team of experts will assist you in choosing the right tools to take your granite cutting experience to the next level.

Efficient and Precise Cutting Tools: Unlocking the Secrets of the Perfect Wheel!

Cutting Wheel: Revolutionizing the Metalworking IndustryIn today's fast-paced world, where efficiency and precision are crucial, the cutting wheel has emerged as a game-changer in the metalworking industry. This innovative tool has revolutionized the way metals are cut, providing an unparalleled level of accuracy and effectiveness. With a wide range of applications, the cutting wheel has become an indispensable tool for professionals across various industries.[Company Name], a leading manufacturer in the metalworking industry, has been at the forefront of this revolution. With decades of experience and a commitment to innovation, the company has developed cutting-edge cutting wheels that are redefining the standards in the industry. Their dedication to delivering high-quality products has earned them a reputation for reliability and excellence.One of the key features that set [Company Name]'s cutting wheels apart is their exceptional durability. Made from premium materials, these wheels can withstand the rigors of heavy-duty operations, ensuring long-lasting performance. This unparalleled durability not only saves users from the hassle of frequent replacements but also reduces costs, making it an ideal choice for professionals looking to optimize their operations.Moreover, [Company Name]'s cutting wheels are designed to deliver exceptional precision. With advanced engineering and manufacturing techniques, these wheels enable users to achieve clean, accurate cuts with minimal effort. This level of precision ensures that the finished product meets the highest standards, creating a strong foundation for success in any project.Another notable advantage of [Company Name]'s cutting wheels is their versatility. Whether it's cutting through ferrous or non-ferrous metals, these wheels deliver consistent results across various materials. This versatility makes them an indispensable tool for professionals in industries such as construction, automotive, aerospace, and more. Regardless of the application, [Company Name]'s cutting wheels provide the cutting solutions professionals need.Furthermore, [Company Name] offers a wide range of cutting wheels, catering to the unique demands of different industries and applications. Their extensive product portfolio includes various sizes and specifications, ensuring that customers can find the perfect tool for their specific needs. This commitment to customization has further solidified [Company Name]'s position as a trusted partner for professionals seeking cutting-edge solutions.As a socially responsible company, [Company Name] is also committed to sustainability. Their cutting wheels are manufactured using eco-friendly materials and processes, minimizing the environmental impact without compromising performance. By choosing [Company Name]'s cutting wheels, professionals not only benefit from superior quality but also contribute to a greener future.In addition to their exceptional products, [Company Name] takes pride in their dedicated customer support. Their team of experts provides comprehensive assistance, from selecting the right cutting wheel to providing guidance on optimizing performance. By building strong relationships with their customers, the company ensures that every user gets the most out of their cutting wheels.Looking ahead, [Company Name] continues to push the boundaries of innovation in the metalworking industry. With ongoing research and development, they aim to introduce cutting wheels that further enhance efficiency, precision, and sustainability. By staying at the forefront of technological advancements, [Company Name] remains committed to empowering professionals with state-of-the-art tools.In conclusion, [Company Name] has been instrumental in revolutionizing the metalworking industry with its cutting wheels. The company's unwavering commitment to quality, precision, durability, and sustainability has set a new benchmark for the industry. As professionals across various sectors continue to rely on cutting wheels for their operations, [Company Name] remains the trusted choice for those seeking superior performance and unmatched customer support.

Understanding Metallic Bonding: What You Need to Know

article on the importance of metallic bonding in modern technology.Metallic Bonding and Its Importance in Modern TechnologyMetallic bonding is a fundamental concept in the world of chemistry and materials science. The unique properties of metals like strength, ductility, thermal and electrical conductivity, and luster can be attributed to the special bonding arrangement between the positively charged metal ions and the delocalized electrons.In recent years, metallic bonding has paved the way for several technological advancements that have transformed the way we live, work, and communicate. From advanced alloys used in aerospace and defense to high-precision components in electronics and renewable energy systems, metallic bonding plays a crucial role in shaping modern technology.One company that is leading the charge in metallic bonding technology is {metal bond}, a renowned name in the field of materials science and engineering. The company specializes in the development of high-performance alloys and composite materials that offer unparalleled strength, durability, and resistance to harsh environments.One of {metal bond}'s flagship products is its proprietary metal matrix composite (MMC) technology. MMCs are a unique class of materials that combine the desirable properties of metals and ceramics, making them ideal for a wide range of applications in the aerospace, defense, and automotive industries.MMC technology utilizes the principles of metallic bonding to create a high-strength matrix of metal ions reinforced with ceramic particles. The result is a material that is exceptionally strong and lightweight while retaining excellent thermal and electrical conductivity.MMC materials are used in critical components such as turbines, engine parts, and brake systems in high-performance cars and aircraft. These components require materials that can withstand extreme temperatures, pressures, and mechanical stresses without failure. MMCs provide the necessary strength and durability needed for such challenging applications, making them an indispensable tool in modern engineering.In addition to MMCs, metallic bonding is also utilized in other advanced materials such as shape-memory alloys (SMAs) and superalloys. SMAs are a class of materials that exhibit unique elasticity and shape-changing properties at specific temperatures, making them ideal for use in medical implants, aerospace, and robotics.Superalloys, on the other hand, are a specific class of alloys that exhibit exceptional heat resistance and mechanical strength, making them ideal for use in high-temperature applications such as gas turbines, jet engines, and nuclear reactors.The widespread use of metallic bonding in modern technology has undoubtedly transformed many industries and opened up new avenues for innovation and advancement. However, this is just the tip of the iceberg, as researchers continue to explore new ways to harness the unique properties of metallic bonding to create even more advanced materials and technologies.In conclusion, metallic bonding is an essential concept that has revolutionized the fields of materials science and engineering. The special bonding arrangement between the positively charged metal ions and the delocalized electrons is responsible for the unique properties of metals, making them indispensable in modern technology. With the advent of advanced materials like MMCs, SMAs, and superalloys, the potential applications of metallic bonding are virtually limitless, paving the way for even more exciting advances in the future.

Understanding the Difference Between Nonmetal and Metal Bonds

Nonmetal and Metal Bonds: Revolutionizing the Aerospace IndustryAs technology continues to advance, the aerospace industry is constantly seeking innovative materials and methods to improve the performance of their products. One such advancement is the development of nonmetal and metal bonds, which has the potential to revolutionize the way aircraft components are manufactured and utilized.The use of nonmetal and metal bonds has been gaining traction in the aerospace industry due to their unique combination of properties, including high strength, light weight, and durability. These bonds are created through a process that involves the bonding of nonmetal materials, such as carbon fiber or ceramics, with metal alloys, resulting in a material that offers the best of both worlds.One company that has been at the forefront of this technology is {}. With a strong focus on research and development, {} has been able to create a range of nonmetal and metal bonded materials that are tailored to the specific needs of the aerospace industry. These materials have been met with enthusiasm from industry professionals and are expected to play a significant role in the future of aircraft manufacturing.The use of nonmetal and metal bonds has the potential to significantly reduce the weight of aircraft components, resulting in improved fuel efficiency and reduced carbon emissions. In addition, these materials offer greater strength and durability compared to traditional materials, which can contribute to increased safety and longevity of aircraft.Furthermore, nonmetal and metal bonded materials are also more resistant to corrosion and fatigue, reducing the need for frequent maintenance and repair. This can lead to cost savings for airlines and contribute to improved operational efficiency.{} has been working closely with aerospace manufacturers to integrate their nonmetal and metal bonded materials into various components of aircraft, including wings, fuselage, and engine parts. The company’s expertise in material science and engineering has allowed them to create tailored solutions that meet the stringent requirements of the aerospace industry.The development of nonmetal and metal bonded materials also aligns with the industry’s efforts to adopt more sustainable and environmentally friendly practices. By utilizing lightweight materials that improve fuel efficiency, aerospace companies can reduce their overall carbon footprint and contribute to a greener future for air travel.In addition to the benefits for aircraft manufacturing, nonmetal and metal bonded materials also have the potential to be utilized in other industries, such as automotive, construction, and renewable energy. This versatility makes them a valuable asset for companies like {} as they continue to explore new opportunities for their innovative materials.As the aerospace industry continues to evolve, the adoption of nonmetal and metal bonded materials is poised to become a transformative trend. With their numerous benefits and potential applications, these materials are set to play a crucial role in the development of next-generation aircraft and pave the way for a more sustainable and efficient future for air travel.With their expertise and dedication to innovation, {} is well-positioned to lead the charge in bringing nonmetal and metal bonded materials to the forefront of the aerospace industry. Their commitment to pushing the boundaries of material science and engineering will undoubtedly have a lasting impact on the industry and the way aircraft are designed and manufactured.