New Drill Bit Polishing Pad for Enhanced Tool Performance

By:Admin

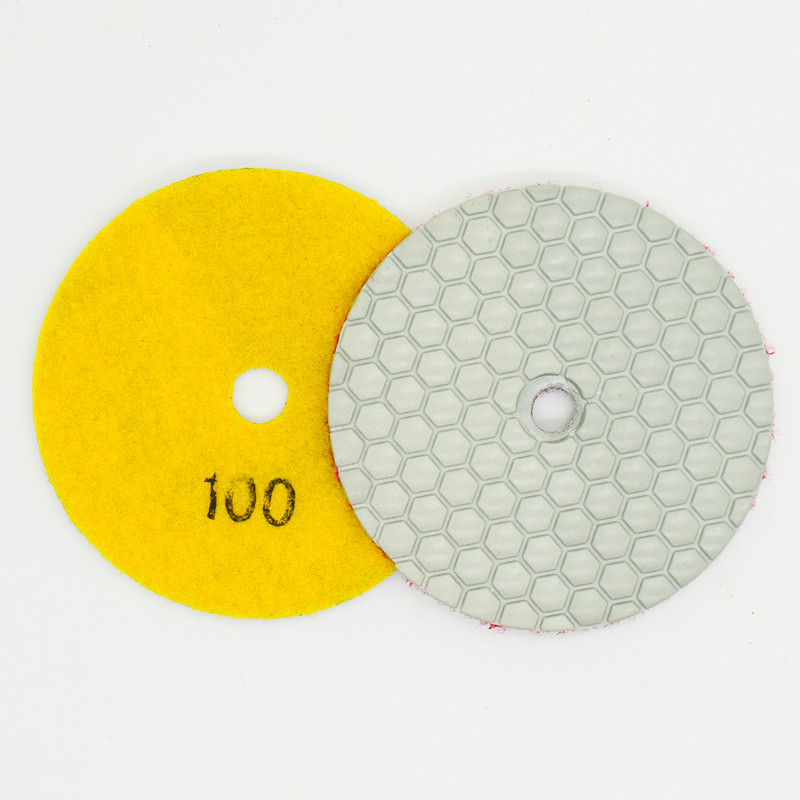

The Drill Bit Polishing Pad is a result of years of research and development, drawing on the company’s extensive expertise in the field. It has been designed to address a common challenge faced by professionals in the industry – the need to maintain and restore the sharpness and effectiveness of drill bits. Over time, drill bits can become worn and dull, reducing their efficiency and leading to increased downtime and costs for businesses. The Drill Bit Polishing Pad offers a simple and effective solution to this problem, allowing users to quickly and easily restore the sharpness of their drill bits, thereby extending their lifespan and improving overall productivity.

The key to the effectiveness of the Drill Bit Polishing Pad lies in its innovative design and construction. Made from high-quality materials that have been specifically chosen for their durability and performance, the polishing pad is capable of removing burrs, sharpening edges, and restoring the cutting ability of drill bits with ease. Furthermore, its ergonomic design and user-friendly interface make it simple and intuitive to use, allowing professionals of all levels to benefit from its capabilities.

In addition to its practical benefits, the Drill Bit Polishing Pad also boasts a number of features that set it apart from other similar products on the market. For instance, it is designed to be compatible with a wide range of drill bits, regardless of their size or material. This means that it offers a versatile solution that can be used across different applications and industries. Furthermore, the polishing pad is also designed to be long-lasting and resistant to wear and tear, ensuring that it will continue to deliver exceptional results over an extended period of time.

The introduction of the Drill Bit Polishing Pad represents a significant milestone for the company, further solidifying its reputation as a leader in the industry. With a track record of delivering innovative and reliable products, the company has earned the trust and respect of professionals around the world. The release of the polishing pad serves to reinforce this reputation, demonstrating the company’s ongoing commitment to meeting the needs of its customers and pushing the boundaries of what is possible in the field of industrial tools and equipment.

As the drilling and metalworking industries continue to evolve and demand increasingly high levels of performance and efficiency, the introduction of the Drill Bit Polishing Pad comes at a crucial time. By providing professionals with a tool that is capable of enhancing the performance and longevity of their drill bits, the company is empowering them to work more effectively and sustainably. This, in turn, has the potential to drive positive outcomes for businesses across the industry, helping them to streamline their operations and achieve greater levels of success.

In conclusion, the introduction of the Drill Bit Polishing Pad represents a significant step forward for the company, as well as a game-changing development for the drilling and metalworking industries as a whole. With its innovative design, practical benefits, and versatile capabilities, the polishing pad has the potential to have a lasting impact on the way that professionals approach their work. As the company continues to push the boundaries of what is possible in the industry, it is clear that they are committed to driving positive change and delivering exceptional solutions to meet the needs of their customers.

Company News & Blog

Discover the Latest Innovation in Polishing Tools with Diamond Pads

[Brand Name] Launches Revolutionary Diamond Pads - Redefining Floor Care[City], [Date] - [Brand Name], a leading innovator in floor care solutions, has introduced its groundbreaking Diamond Pads. These technologically advanced floor maintenance tools promise to revolutionize the way businesses and homeowners clean and care for their floors.[Brand Name] has built a reputation for creating high-quality products that combine innovation, functionality, and durability. Their latest offering, the Diamond Pads, aims to provide an exceptional cleaning experience while extending the lifespan of floors.The Diamond Pads utilize a unique combination of diamond-embedded pads and cutting-edge design to deliver superior results. Unlike traditional floor-cleaning tools, these pads are specifically engineered to remove tough stains, grime, and scuff marks effectively.With the increased focus on sustainability and eco-friendly practices, [Brand Name] has ensured that its Diamond Pads are environmentally responsible. These pads are crafted using eco-friendly materials, reducing their impact on the environment while providing an efficient cleaning solution.The innovative technology used in the Diamond Pads not only allows for effortless cleaning but also offers impressive durability. The diamond-embedded surface, combined with the high-quality materials, ensures long-lasting performance, saving users time and money in the long run.Furthermore, the Diamond Pads are designed for versatile use across a wide range of flooring types, including hardwood, laminate, vinyl, tile, and more. This flexibility makes them an ideal choice for both residential and commercial spaces.According to [Brand Name]'s CEO, [CEO's Name], "We are thrilled to introduce the Diamond Pads to our customers. Our team has put in countless hours of research and development to create a product that revolutionizes floor care. We believe that the Diamond Pads will truly elevate the cleaning experience for our users."Apart from their exceptional cleaning capabilities, the Diamond Pads are also designed with user comfort in mind. The ergonomic, non-slip handle ensures a secure grip, preventing any accidental slips during the cleaning process.In addition to the pads' outstanding performance, [Brand Name] has also established an extensive network of support services to cater to its customers. The company's team of floor care experts is available to provide guidance and advice on the best practices for using the Diamond Pads to achieve optimal results.To celebrate the launch of the Diamond Pads, [Brand Name] is offering an introductory discount of 20% to all customers who purchase the product within the first month. This limited-time offer presents an excellent opportunity for homeowners and businesses to experience the future of floor care at an affordable price.The introduction of [Brand Name]'s Diamond Pads showcases the company's commitment to innovation and customer satisfaction. With its revolutionary technology, eco-friendly design, and exceptional performance, these pads are set to become the go-to solution for floor maintenance.For more information on the Diamond Pads and to place an order, please visit [Brand Name]'s official website or contact their customer service representatives at [contact information].About [Brand Name]:[Brand Name] is a renowned company specializing in innovative floor care solutions. With a focus on quality, functionality, and customer satisfaction, [Brand Name] continues to lead the industry by providing cutting-edge products that redefine the way we care for our floors.

Ceramic Tile Flooring in Mooresville, NC: Easy Selection & Free Consultation Services | Floor Coverings International

Ceramic Floor Tiles, a leading provider of ceramic tile flooring solutions, is proud to offer its extensive range of products and services to homeowners in Mooresville, NC. With a commitment to quality and customer satisfaction, the company has built a reputation as a trusted provider of beautiful and durable flooring options.Ceramic tile flooring has been a popular choice for homeowners for centuries, thanks to its timeless beauty and durability. These types of tiles are made from natural clay that is fired at high temperatures, creating a durable and versatile material that can be used in a variety of settings. Ceramic tiles are available in a wide range of colors, shapes, sizes, and patterns, making them perfect for any living space.At Ceramic Floor Tiles, we understand that choosing the right flooring for your home can be a daunting task. That's why we offer free in-home consultation services to help you navigate your options and select the perfect ceramic tile flooring solution for your Mooresville home. Our team of flooring experts will work with you to understand your design preferences, budget, and lifestyle needs, so we can recommend the best options for your unique situation.We offer a wide range of ceramic tile flooring options for our Mooresville clients. Our selection includes traditional ceramic tiles, which are made from natural clay and come in a variety of colors and patterns. These tiles are perfect for homeowners who want a classic and timeless look. We also offer porcelain tiles, which are made from a denser type of clay and are more resistant to chips, scratches, and stains. Porcelain tiles are a popular choice for high-traffic areas, such as kitchens and bathrooms.In addition to our extensive variety of ceramic tile options, Ceramic Floor Tiles also offers expert installation services. Our team of skilled technicians will ensure that your new flooring is installed correctly, so it looks beautiful and performs well for years to come. We use high-quality materials and follow industry best practices to ensure a flawless finish every time.At Ceramic Floor Tiles, we're committed to providing our Mooresville clients with exceptional customer service. We understand that selecting new flooring is a significant investment for your home, and we're dedicated to helping you make a decision that you'll be happy with for years to come. Our team is available to answer any questions you may have throughout the flooring selection and installation process.In conclusion, if you're looking for a beautiful and durable flooring solution for your Mooresville home, look no further than Ceramic Floor Tiles. With our extensive variety of ceramic tile options, free in-home consultation services, and expert installation, we're the perfect partner for your flooring needs. Contact us today to schedule your consultation and get started on your flooring project.

Different Types of Grinding Wheels: A Complete Guide

Title: Exploring the Different Types of Grinding Wheels Revolutionizing Industrial ApplicationsIntroduction:In today's industrial revolution, grinding wheels play a fundamental role in various sectors, including manufacturing, construction, automotive, and metalworking. These indispensable tools are crucial for precision cutting, shaping, and finishing, enabling businesses to enhance productivity and achieve superior workpiece quality. This article aims to shed light on the various types of grinding wheels available in the market and their importance in revolutionizing industrial applications.1. Straight Grinding Wheels:Straight grinding wheels, also known as Type 1 wheels, are the most common and straightforward type used for surface grinding. These wheels have a flat outer periphery and deliver precise grinding performance on flat surfaces. Typically made from aluminum oxide or silicon carbide abrasive grains, straight grinding wheels are versatile and suitable for a wide array of materials, including steel, cast iron, brass, and non-ferrous metals.2. Cylinder Wheels:Cylinder wheels, designated as Type 2 wheels, possess a unique shape resembling a straight grinding wheel with a cylindrical face. These wheels are primarily used for grinding cylinders, bearings, and other rounded surfaces. The rounded design allows for easy and efficient grinding with reduced friction, resulting in excellent surface finishes.3. Tapered Grinding Wheels:Tapered grinding wheels, commonly referred to as Type 4 wheels, are specially designed for grinding operations that require precision and control. These wheels have a tapered shape, gradually narrowing towards the arbor hole. The tapering enables the wheel to penetrate the workpiece effectively, making them ideal for intricate grinding tasks such as internal grinding.4. Dish Grinding Wheels:Dish grinding wheels, known as Type 11 wheels, possess a dish-shaped design with a roundish outer rim and a depressed center. These wheels are widely used for contour grinding, grinding complex shapes, and removing excess material from the workpiece. The recessed center allows for a higher degree of flexibility, making them suitable for both large and small-scale applications.5. Diamond Wheels:Diamond grinding wheels are the epitome of grinding wheel technology, offering exceptional hardness, durability, and precision. Utilizing diamond abrasives, these wheels excel in cutting and grinding extremely hard materials such as carbides, ceramics, glass, and stones. Their fine grit allows for a smooth finish and minimal material wastage, making diamond wheels ideal for demanding applications.6. CBN Wheels:Cubic Boron Nitride (CBN) grinding wheels are similar to diamond wheels in terms of their exceptional hardness and longevity. These wheels are specifically formulated for grinding ferrous materials, including hardened steels and cast iron. With their heat resistance and ability to retain sharpness, CBN wheels are perfect for high-speed grinding operations, resulting in improved productivity and reduced downtime.Conclusion:Grinding wheels are indispensable tools in the industrial sector, revolutionizing various applications, from metalworking to automotive and construction. This article explored different types of grinding wheels, highlighting their characteristics and applications. The versatility and precision offered by these wheels allow businesses to improve productivity, achieve superior workpiece quality, and ultimately drive the industrial revolution forward. As technology advances further, we can expect the development of innovative grinding wheel types, continually pushing the boundaries of what can be achieved in industrial grinding.

Discover the Many Benefits of Diamond Tool Granites for Your Projects

[Company Name] Introduces Innovative Diamond Tool Granites Revolutionizing the Industry[date][Location] - [Company Name], a leading name in the granite industry, is proud to announce the introduction of their groundbreaking diamond tool granites. With a commitment to innovation, the company is revolutionizing the industry by offering a new range of exceptional quality diamond tool granites, aimed at meeting the evolving needs of their customers worldwide.[Company Name] is known for its expertise in the granite industry, providing top-of-the-line products to various sectors, including construction, architecture, interior design, and more. They have established a strong reputation for their unwavering commitment to quality and customer satisfaction.The newly introduced diamond tool granites are the result of years of extensive research and development. [Company Name] has combined state-of-the-art technology and unmatched craftsmanship to create a product that delivers superior performance and durability.These diamond tool granites are engineered to provide unmatched precision and efficiency in cutting, grinding, and shaping granite surfaces. With its exceptional hardness and resistance to wear and tear, these tools are designed to last longer and reduce overall maintenance costs.What sets [Company Name]'s diamond tool granites apart from others in the market is their unique composition. The company has developed a proprietary blend of diamond abrasives and bonding agents that ensures exceptional performance and longevity. The granites are meticulously crafted to ensure consistent quality and performance across the entire product range.The innovative design of these diamond tool granites significantly reduces the risk of chipping and breaking, making them ideal for use in various applications. This means that contractors, fabricators, and craftsmen can achieve precise cuts and finishes without compromising on quality or safety.Moreover, [Company Name] understands the importance of sustainability in today's world. Therefore, these new diamond tool granites are manufactured with environmental responsibility in mind. The production process adheres to strict environmental standards, reducing energy consumption and minimizing waste generation.The launch of these diamond tool granites marks an important milestone for [Company Name]. They are confident that these game-changing products will enhance the efficiency and productivity of their customers, while also contributing to the industry's overall progress.To celebrate the launch, [Company Name] is offering a limited-time promotion where customers can enjoy exclusive discounts and offers on the purchase of the diamond tool granites. This promotion showcases their commitment to satisfying their customers' needs while ensuring they receive the best value for their investment.As a trusted industry leader, [Company Name] is continuously investing in research and development to bring cutting-edge solutions to their customers. The introduction of these diamond tool granites reflects their dedication to innovation and elevating industry standards.[Company Name] invites customers, industry professionals, and stakeholders to explore the range of diamond tool granites and experience the unbeatable performance and quality they offer. By investing in these advanced tools, businesses can achieve greater efficiency, superior finishes, and increased profitability.With their groundbreaking diamond tool granites, [Company Name] is set to redefine the granite industry. Their commitment to customer satisfaction, combined with a relentless pursuit of excellence, positions them as a leading force in the market.About [Company Name]:[Company Name] is a renowned provider of high-quality granite products for various sectors, including construction, architecture, and interior design. With a focus on innovation and customer satisfaction, they have established themselves as industry leaders. Their extensive product range and commitment to excellence make them the preferred choice for customers worldwide.For media inquiries or more information, please contact:[Company Name][Phone number][Email][Website]

Polishing Concrete Floors: Tips and Equipment to Consider

Title: Transforming Concrete Surfaces with Advanced Concrete Polishing PadsIntroduction:In recent years, there has been a growing trend of using concrete as a sleek and stylish flooring option for commercial and residential spaces. With advancements in technology and the availability of specialized tools, concrete floor polishing has emerged as a highly effective method to enhance the appearance and durability of concrete surfaces. One essential element of the process is the use of concrete polishing pads, specifically designed for floor buffer machines. These pads play a crucial role in achieving a flawless and glossy finish on polished concrete floors.The Importance of Concrete Polishing Pads:Concrete polishing pads are specifically engineered to remove imperfections from concrete surfaces and gradually refine them to a smooth and vibrant finish. These pads are made from high-quality materials and are available in various grits, enabling professionals to fine-tune the polishing process as per the unique needs of the project.Key Considerations for Achieving Polished Concrete Floors:1. Grinding and Cost: Before embarking on a concrete floor polishing project, it is essential to consider the grinding process and associated costs. Grinding aids in removing unevenness, stains, and blemishes from the surface, creating a perfect canvas for polishing. The use of appropriate concrete polishing pads for floor machines ensures efficient grinding, leading to cost-effective results.2. Equipment and Supplies: Investing in top-notch concrete polishing equipment is vital to achieving excellent results. The use of high-quality concrete floor polishing machines, along with advanced concrete polishing pads, ensures optimal performance and durability. Additionally, reliable suppliers offer a range of concrete polishing supplies, ensuring seamless execution of the project.3. Professional Services: While DIY concrete floor polishing may seem tempting, seeking professional services is often recommended for flawless and long-lasting results. Experienced professionals possess the necessary knowledge, skills, and expertise to handle complex polishing tasks efficiently. Moreover, their access to premium concrete polishing pads and equipment ensures superior outcomes.4. Epoxy vs. Polished Concrete: When considering concrete flooring options, it's important to understand the difference between epoxy flooring and polished concrete. Epoxy provides a seamless and durable finish, suitable for high-traffic areas. On the other hand, polished concrete offers a unique aesthetic appeal, showcasing the natural beauty of the concrete. Understanding the pros and cons of each option ensures making an informed decision.Benefits of Polished Concrete Floors:1. Aesthetics: Polished concrete floors add a touch of elegance and modernity to any space. The glossy finish accentuates the natural patterns, colors, and texture of the concrete, creating a visually appealing environment.2. Durability: Polished concrete surfaces are extremely durable and resistant to scratches, stains, and wear. This makes them an ideal choice for heavy foot traffic areas, such as retail stores, warehouses, and restaurants.3. Maintenance: Polished concrete floors are easy to clean and maintain. Unlike other flooring options, they do not require waxing or additional coatings, reducing maintenance costs and efforts significantly.4. Sustainable Choice: Concrete is a sustainable material, and by choosing polished concrete floors, one contributes to a greener environment. Reduced maintenance requirements and a longer lifespan further enhance its eco-friendly characteristics.Conclusion:Concrete floor polishing has revolutionized the flooring industry, presenting a cost-effective and visually appealing alternative to traditional options. Key to achieving impeccable results is the use of high-quality concrete polishing pads, specifically designed for floor buffer machines. Professionals well-versed in the process, coupled with advanced equipment and supplies, ensure that concrete surfaces are transformed into durable, elegant, and sustainable flooring solutions.

Essential Tools for Achieving a Perfect Granite Finish

Granite Finishing Tools Revolutionize Stone Industry[City, Date] – Granite Finishing Tools, a leading provider of high-quality stone finishing equipment, is transforming the stone industry with its innovative range of products. With a focus on efficiency, precision, and durability, Granite Finishing Tools has emerged as the go-to solution for professionals working with granite and other natural stones.Within a highly competitive market, Granite Finishing Tools has quickly gained recognition for its commitment to delivering top-notch tools that cater to the demanding needs of stone fabricators and craftsmen. The company's dedication to continuous research and development has allowed it to stay at the forefront of technological advancements in the industry.With an extensive product line covering every aspect of stone finishing, Granite Finishing Tools offers a comprehensive solution for all stone fabrication processes. From cutting, grinding, polishing, to edge profiling, the company provides an array of tools designed to enhance productivity while achieving exceptional quality results.One of the standout products in their range is the state-of-the-art diamond cutting blade. Known for its exceptional cutting speed and longevity, this blade transforms the cutting process, saving craftsmen time and effort. Furthermore, its superior performance ensures clean cuts with minimal chipping, resulting in a more efficient fabrication process.Granite Finishing Tools has also revolutionized the polishing stage with its highly specialized line of diamond polishing pads. These pads are engineered to deliver an unmatched level of shine while minimizing heat generation. The company's innovative pad design allows for reduced polishing time, resulting in increased productivity and cost savings for fabricators.Additionally, Granite Finishing Tools places a strong emphasis on safety in its product development. The company's range includes effective dust control systems that efficiently capture and remove harmful dust particles generated during stone processing. These systems not only protect the health of workers but also ensure a cleaner work environment, enhancing overall efficiency.Recognizing the diverse needs of its customers, Granite Finishing Tools offers personalized toolkits tailored to specific requirements. This customer-centric approach allows fabricators to optimize their processes, resulting in improved outcomes and increased customer satisfaction.With a commitment to customer support and satisfaction, Granite Finishing Tools provides comprehensive after-sales services, including technical assistance and training. By partnering with experienced professionals in the stone industry, the company ensures that fabricators can fully harness the potential of their tools and achieve outstanding results.Granite Finishing Tools' dedication to quality is reflected in the materials used for manufacturing its products. With a meticulous selection process, the company sources only premium-grade raw materials, ensuring the durability and longevity of its tools. This commitment to quality is in alignment with the company's mission to provide professionals with reliable equipment that guarantees superior performance and longevity.As Granite Finishing Tools expands its reach domestically and internationally, the company envisions a future where stone fabricators can maximize their efficiency and quality outputs with the aid of advanced tools. With a constant drive for innovation and excellence, Granite Finishing Tools remains at the forefront of the stone industry, empowering craftsmen to turn ordinary stone into remarkable works of art.About Granite Finishing Tools:Granite Finishing Tools is a leading provider of high-quality stone finishing equipment, offering a comprehensive range of tools designed to enhance productivity and deliver exceptional quality results. With a focus on innovation and customer satisfaction, Granite Finishing Tools aims to revolutionize the stone industry through cutting-edge technology and personalized solutions. For more information, please visit [company website].

Cup Wheel Grinding Discs: Enhancing Precision and Efficiency in Grinding Tasks

Cup Wheel Grinding Discs are among the most popular and versatile tools in the grinding and cutting industry. These discs are used for a wide range of applications including shaping, grinding, and polishing various surfaces. The grinding disc is primarily designed for use on concrete surfaces, but it is also effective on other surfaces such as stone, masonry, and metal.Leading manufacturers of grinding discs produce high-quality products that cater to the needs of professionals in diverse industries, which means that the company behind it is critical to ensure that you are investing in the right product. One of the top manufacturers and suppliers of Cup Wheel Grinding Discs in the market is {}, a leading company in the abrasives industry.Beginnings of {}{} was founded in 1999 with a mission to provide quality abrasives for the machinery industry. {} has since established itself as a leading supplier of abrasives and industrial tools in the market. The company focuses on delivering the highest quality product to their customers. They invest heavily in research and development to ensure that their products are the best in the market.{} has a team of skilled engineers who work closely with the research and development team to ensure that their products meet the highest standards of quality. The company operates in modern facilities equipped with advanced machinery and tools. This ensures that they meet established industry regulations and are always one step ahead of their competitors.In addition to its manufacturing capabilities, {} has an efficient distribution network that ensures its products are readily available to customers worldwide. The company has established strong partnerships with various distributors globally who work closely with them to serve their customers and meet their needs efficiently.Product RangeThe company produces a variety of grinding discs, but the Cup Wheel Grinding Discs are one of their most popular products. The Cup Wheel Grinding Disc is available in different materials and sizes, and it comes with different grit levels depending on the needs of the user.The diamond cup wheel grinding disc is designed for heavy-duty applications such as grinding concrete, granite, and marble surfaces. The diamond cup wheel grinding disc is fitted with a diamond impregnated section that can cut through the toughest surfaces, making it the perfect tool for professionals in the concrete and stone cutting fields.Moreover, the diamond cup wheel grinding disc is available in different shapes such as the single row, double row, and turbo style cup wheel, giving professionals the freedom to choose the one that suits their specific needs.Another popular product is the silicon carbide cup wheel grinding disc, which is perfect for use on stone surfaces such as marble and granite. The silicon carbide cup wheel grinding disc is a versatile tool that is known for its fast cutting performance and durability.ConclusionAs a professional in any field, investing in quality tools is critical to ensuring that your work is not only efficient but also of the highest quality. The Cup Wheel Grinding Disc from {} is a must-have in your arsenal. By investing in the Cup Wheel Grinding Disc, you are assured of a tool that is made to the highest standards of quality and performance.

Different Types of Grinding Wheel Dressers: A Comprehensive Guide

Grinding Wheel Dresser Types: Enhancing Efficiency and Precision in ManufacturingIn today's rapidly advancing manufacturing industry, efficiency and precision are of paramount importance. One of the key tools used for achieving these goals is the grinding wheel dresser. A grinding wheel dresser is a vital device used to shape and clean abrasive wheels in order to maintain their optimal performance. With various types of grinding wheel dressers available in the market, companies are constantly seeking the most appropriate type to enhance productivity and quality. Grinding wheel dressers come in different forms and serve unique purposes. One popular type is the diamond dresser. Incorporating diamond grains on its surface, this dresser offers unparalleled hardness and durability. Diamonds are known for their exceptional strength in cutting, shaping, and cleaning abrasive materials, making them the ideal choice for grinding wheel dressers. By utilizing diamonds, the dresser is able to maintain its sharpness even after extensive use, resulting in consistent and precise grinding.Another commonly used grinding wheel dresser is the star dresser. This type features multiple hardened steel discs with raised points in a star-like pattern. These points, often made from either high-speed steel or carbide, are crucial for truing and straightening the grinding wheel. The star dresser works by cutting into the wheel surface, creating grooves and channels, which ultimately improve its cutting efficiency and provide a smoother grinding action. This type of dresser is highly effective for removing excess material on the grinding wheel and achieving the desired shape.Yet another important type of grinding wheel dresser is the dressing stick or block. This dresser is made of abrasive grains, typically silicon carbide or aluminum oxide, adhered together with a bonding agent. The dressing stick is primarily used for cleaning and reshaping the grinding wheel by removing any debris or unevenness. It is especially useful in removing built-up metal shavings, known as glazing, which can significantly decrease the wheel's effectiveness. The dressing stick is an economical option that ensures the grinding wheel remains in optimal condition for prolonged usage.In light of these various grinding wheel dresser types, manufacturers are constantly seeking the most suitable option for their specific needs. This is where the company {}, a renowned leader in manufacturing solutions, comes into play. With a wealth of experience and expertise in the field, {} offers a wide range of grinding wheel dressers that cater to diverse industrial requirements.For instance, {} specializes in producing diamond dressers that are not only highly durable but also available in different sizes and shapes to accommodate various grinding wheel specifications. With their diamond dressers, customers can expect improved grinding efficiency, reduced dressing times, and increased precision in their manufacturing processes. By adopting diamond dressers from {}, manufacturers can achieve higher productivity, prolonged tool life, and enhanced overall quality.Furthermore, {} also offers an extensive selection of star dressers that can effectively dress a wide range of abrasive wheels, including vitrified, resin-bonded, and diamond grinding wheels. The company's star dressers are made from premium-quality materials, ensuring long-lasting performance and excellent truing capabilities. By utilizing {}'s star dressers, manufacturers can achieve optimal wheel conditions, resulting in enhanced surface finishes and reduced cycle times in their operations.Additionally, {} provides a comprehensive range of dressing sticks that are tailor-made for different grinding wheel materials and applications. Through their selection of dressing sticks, manufacturers can maintain the sharpness and efficiency of their grinding wheels, leading to consistent and precise results. {}'s dressing sticks are known for their durability and cost-effectiveness, making them a reliable solution in the grinding industry.In conclusion, grinding wheel dressers play a crucial role in maintaining the effectiveness and precision of abrasive grinding wheels. With a variety of types available, ranging from diamond dressers to star dressers and dressing sticks, manufacturers have multiple options to choose from based on their specific needs. By utilizing high-quality grinding wheel dressers from {}, companies can significantly enhance their manufacturing efficiency, improve product quality, and stay at the forefront of the rapidly evolving industry.

Metallic Diamond Abrasive Pads for Coarse Marble Grinding in UK Market

, Marble Polishing, Diamond Polishing Pads, Marble Abrasives, Diamond Metallic Frankfurt Abrasive PadWhen it comes to marble polishing, there is no denying that you need the right tools to accomplish the job. This is where Frankfurt Diamond Abrasives come in - they are one of the most effective and efficient tools for polishing marble.Frankfurt Diamond Abrasives are specially designed to polish marble, offering a unique abrasive surface that works to remove scuffs, scratches, and other imperfections on the stone's surface. This abrasive tool is manufactured with diamond crystals, which is why it has become such a popular option for those looking to polish marble.Marble Abrasives are specifically designed to work on marble surfaces, providing the perfect texture needed for a clean and polished finish. The use of abrasives in marble polishing is a must-have, as they help to remove any imperfections on the surface of the stone.Diamond Polishing Pads are also crucial for marble polishing, and they come in different grades of coarseness. The lower the grit number, the coarser the pad is, and the higher the grit number, the smoother the pad is. Using the correct grade of polishing pad is important, as it will determine the final look of the marble.One of the newest options for marble polishing comes in the form of Diamond Metallic Frankfurt Abrasive Pads. These pads use a combination of diamond crystal and metallic materials, which helps to achieve a polished and glossy finish easily. This new option has become increasingly popular in the UK market due to its effectiveness and efficiency.In conclusion, the use of Frankfurt Diamond Abrasives, Marble Polishing, Diamond Polishing Pads, Marble Abrasives, and Diamond Metallic Frankfurt Abrasive Pads have become necessary for a great marble polishing job. Using the right tools and techniques helps to achieve a polished and glossy finish on your marble surface, making it look brand new and elegant. When looking for the right tools to use in marble polishing, consider the products mentioned above, as they have proved to be the most effective and popular in the market.

Top Replacement Pads for Auto Spa Polishers: Enhance Your Vehicle's Shine

Auto Spa is a leading name in the automotive industry, renowned for producing high-quality car cleaning and maintenance products. With an unmatched commitment to innovation and customer satisfaction, Auto Spa has recently announced the launch of its newest product – the Polisher Replacement Pads.With its state-of-the-art manufacturing facility and team of dedicated professionals, Auto Spa has established itself as a global leader in the automotive industry. The company offers a wide range of cleaning and maintenance solutions, including car wash accessories, tire care products, and interior cleaning supplies, among others.Recognizing the need for efficient and reliable car polishers, Auto Spa has invested significant time and resources in developing the Polisher Replacement Pads. This new addition to their product line is designed to enhance the performance and longevity of their existing range of polishers.The Polisher Replacement Pads are manufactured using premium-quality materials to ensure durability and effectiveness. The pads are specifically engineered to provide a smooth, swirl-free polishing experience that delivers stunning results every time. With their innovative design, these replacement pads significantly reduce the risk of damaging the vehicle's paint surface, ensuring a flawless, showroom-quality finish.Auto Spa understands the importance of variety and versatility in the automotive industry. Hence, the Polisher Replacement Pads come in different sizes and densities, catering to various polishing requirements. Whether it's removing minor scratches, restoring dull paint, or creating a mirror-like shine, these pads offer the perfect solution for all car enthusiasts and professionals alike.One of the key features of the Auto Spa Polisher Replacement Pads is their ease of use. Designed for both beginners and seasoned professionals, these pads can be easily attached and detached from the polishers, making the polishing process hassle-free and time-efficient. The pads also feature a Velcro backing that ensures a secure and stable connection, enabling precise control and maneuverability during the polishing process.Another noteworthy aspect of the Auto Spa Polisher Replacement Pads is their durability. Crafted to withstand intense pressure and frequent use, these pads are built to last. The high-quality materials used in their construction ensure that they maintain their shape and performance even after prolonged and rigorous use.Additionally, Auto Spa prioritizes environmental consciousness and sustainability. The Polisher Replacement Pads are designed to be reusable, reducing waste and contributing to a greener planet. By minimizing the need for constant replacement, these pads not only save customers money but also make a positive impact on the environment.In conclusion, Auto Spa's latest offering, the Polisher Replacement Pads, exemplifies the company's commitment to excellence and innovation in the automotive industry. With their dedication to customer satisfaction, Auto Spa has introduced a versatile and high-performing solution for car enthusiasts and professionals alike. These pads, with their superior quality, ease of use, and durability, are set to revolutionize the car polishing experience, providing an unparalleled level of convenience and effectiveness. As Auto Spa continues to expand its product range, customers can expect nothing short of exceptional quality and groundbreaking innovation from this industry-leading brand.