How to Cut and Polish Pads for Optimal Results

By:Admin

With a commitment to excellence and a passion for innovation, [Company Name] continues to revolutionize the polishing pad industry with their cutting-edge technology. As a leading manufacturer in the industry, [Company Name] has been dedicated to providing high-quality products and unparalleled customer service since its inception.

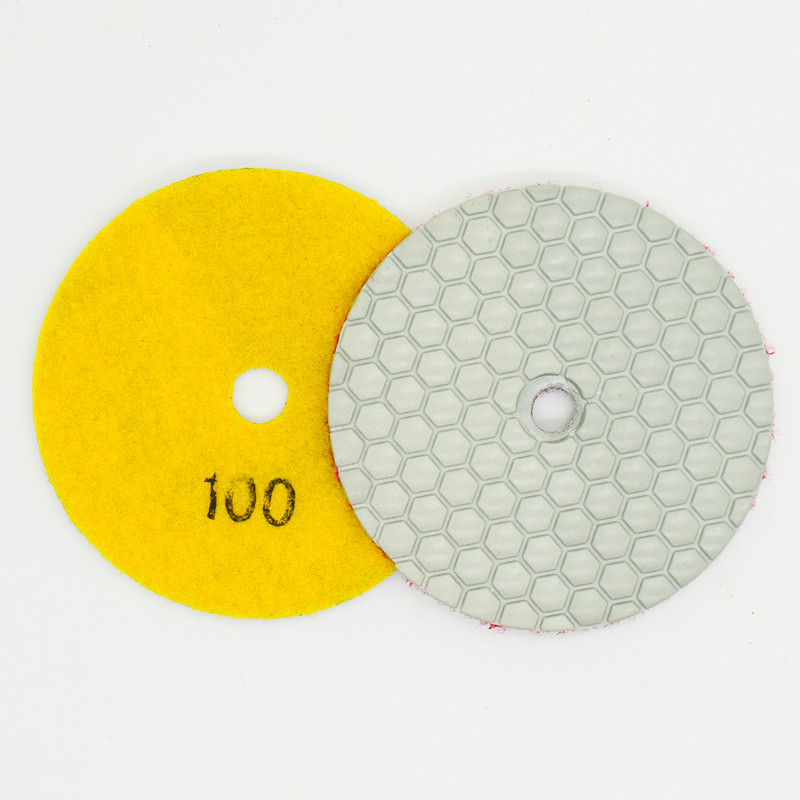

The introduction of their latest product, the Cutting Polishing Pad, has set a new benchmark in the industry. The revolutionary technology incorporated into these pads has been designed to deliver a flawless finish, making them a game-changer for professionals and enthusiasts alike. By combining their years of experience with advanced research and development, [Company Name] has once again raised the bar for polishing pad performance.

The Cutting Polishing Pads are engineered to deliver exceptional results when used with a variety of materials, including metal, glass, stone, and composite materials. Their unique design and advanced materials ensure a longer lifespan and superior performance compared to traditional pads. This innovation is a testament to [Company Name]'s unwavering commitment to pushing the boundaries of what is possible in the industry.

The key features of the Cutting Polishing Pads include:

1. Enhanced Durability: The advanced materials used in the manufacturing process ensure increased durability and longer pad life, reducing the need for frequent replacements and saving time and money for users.

2. Superior Finish: The innovative design of the pads delivers a flawless finish, with reduced swirl marks and improved clarity, leaving a professional-grade shine on any surface.

3. Versatility: The Cutting Polishing Pads are designed to be compatible with a wide range of materials, making them a versatile and effective tool for professionals in various industries.

In addition to the technological advancements of the Cutting Polishing Pads, [Company Name] prides itself on its commitment to sustainability and environmental responsibility. As part of their ongoing efforts to reduce their carbon footprint, [Company Name] has implemented eco-friendly manufacturing practices and materials in the production of their products.

Furthermore, [Company Name] is dedicated to providing exceptional customer service and support. Their team of experts is always available to offer guidance and assistance to customers, ensuring that they have the best possible experience with their products.

In line with their dedication to continuous improvement and innovation, [Company Name] is constantly investing in research and development to explore new possibilities for enhancing their product range and staying ahead of industry trends. The introduction of the Cutting Polishing Pads is just one example of [Company Name]'s ongoing efforts to lead the way in the polishing pad market.

As a company that has built a reputation for excellence, [Company Name] is proud to introduce the Cutting Polishing Pads as the latest addition to their product lineup. With their unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] remains a trusted name in the industry and continues to set the standard for polishing pad performance.

In conclusion, the introduction of the Cutting Polishing Pads by [Company Name] marks a significant milestone in the industry, showcasing their dedication to innovation and excellence. With their advanced technology, superior performance, and commitment to sustainability, [Company Name] continues to lead the way in providing high-quality polishing solutions for professionals and enthusiasts around the world.

Company News & Blog

Powerful Angle Grinder Makes Quick Work of Cutting and Grinding

Angle Grinder Machine Revolutionizes the Industry with Innovation and Precision[City, Date] - Angle Grinder Machine, a cutting-edge product designed by the renowned machinery manufacturer, has successfully revolutionized the industry with its unprecedented innovation and precision. With its versatile features and remarkable performance, this machine has quickly become an essential tool for professionals across various sectors.The Angle Grinder Machine, with its brand's secrecy, offers a unique combination of power, durability, and ease of use. It has been engineered to meet the highest standards of quality and performance, making it the go-to choice for professionals who rely on accuracy and efficiency in their work.One of the distinct features of this Angle Grinder Machine is its powerful motor that delivers impressive speed and torque. This allows users to effortlessly cut through different materials, including metal, concrete, tiles, and more. Whether it's a heavy-duty application or a delicate task, this machine guarantees precise and consistent results every time.Furthermore, the Angle Grinder Machine incorporates advanced safety features, ensuring user protection and preventing accidents. The anti-kickback mechanism and adjustable protective guard provide a secure working environment, reducing the risk of potential injuries. This machine also includes ergonomic features such as a comfortable handle grip, minimizing operator fatigue and improving overall productivity.The versatile nature of the Angle Grinder Machine makes it suitable for a wide range of industries. With its ability to accommodate different cutting discs and accessories, professionals in construction, metalworking, and fabrication find it indispensable for tasks such as cutting, grinding, polishing, and shaping various materials. Its adaptability and performance have made it an invaluable asset for experts in these fields.The company behind the Angle Grinder Machine has a strong reputation for engineering excellence and innovation. With decades of experience in the industry, they have continuously invested in research and development to deliver cutting-edge machinery that meets and exceeds customer expectations.Their commitment to quality is evident in every aspect of the Angle Grinder Machine. Rigorous testing and quality control processes ensure that each machine leaving their production line is of the highest standard. This dedication to precision and reliability has earned the company the trust and loyalty of professionals worldwide.In addition to the outstanding performance of their products, the manufacturer also places great importance on customer satisfaction. They provide comprehensive after-sales support, including training programs and technical assistance, to ensure that users can maximize the benefits of their Angle Grinder Machine. This level of commitment to their customers sets the company apart from its competitors.With its innovative design, exceptional performance, and commitment to customer satisfaction, the Angle Grinder Machine has made a significant impact across various industries. From construction sites to metalworking shops, professionals now rely on this cutting-edge tool to achieve unparalleled efficiency and accuracy in their work.As the industry evolves, the Angle Grinder Machine continues to push boundaries and set new standards. With a strong foundation of quality and innovative design, this revolutionary product is poised to shape the future of the machinery industry. As professionals seek precision and reliability in their work, the Angle Grinder Machine stands proud as the go-to choice for all their cutting and grinding needs.About the CompanyThe manufacturer behind the Angle Grinder Machine is a leading machinery company specializing in the production of high-performance tools. With a rich history of engineering excellence and a strong commitment to innovation, they have become a trusted name in the industry. Their dedication to quality and customer satisfaction has enabled them to revolutionize various sectors with their state-of-the-art machinery.

High-Quality Nylon Wheel Brush for Drills at Affordable Prices

The demand for innovative and efficient cleaning tools has grown significantly in recent years, and one company at the forefront of meeting this demand is [Company Name]. The company has recently introduced a new product to its line of cleaning tools: the Nylon Wheel Brush for Drill.The Nylon Wheel Brush for Drill is designed to be attached to a power drill, transforming it into a powerful cleaning tool. The brush features durable nylon bristles that are tough on dirt and grime, yet gentle on surfaces, making it ideal for a wide range of cleaning applications. Whether it's removing rust and corrosion from metal surfaces, cleaning tires and rims, or scrubbing away stubborn stains from concrete, the Nylon Wheel Brush for Drill is up to the task.One of the key features of the Nylon Wheel Brush for Drill is its versatility. It is compatible with most power drills, making it accessible to a wide range of users. Additionally, the brush is designed to be long-lasting, with the nylon bristles retaining their shape and performance over time. This ensures that users can rely on the brush for consistent and effective cleaning results.[Company Name] is well-known for its commitment to quality and innovation. With a focus on meeting the evolving needs of customers, the company has established itself as a leader in the cleaning tools industry. The introduction of the Nylon Wheel Brush for Drill is a testament to [Company Name]'s dedication to providing cutting-edge solutions for cleaning challenges.In addition to its innovative products, [Company Name] is also recognized for its excellent customer service. The company prides itself on its ability to provide knowledgeable and friendly support to customers, ensuring that they have a positive experience with [Company Name] products. This commitment to customer satisfaction has helped [Company Name] build a loyal and satisfied customer base.The Nylon Wheel Brush for Drill is just the latest example of [Company Name]'s dedication to delivering high-quality, effective cleaning tools. With its durable construction, versatile design, and compatibility with power drills, the brush is set to become a valuable addition to the cleaning arsenal of homeowners, contractors, and maintenance professionals alike."We are excited to introduce the Nylon Wheel Brush for Drill to our customers," said [Spokesperson Name], [Title] at [Company Name]. "This brush represents our ongoing commitment to providing innovative and effective cleaning solutions. We believe that it will make a valuable addition to any cleaning toolkit, and we are confident that our customers will be delighted with its performance."The Nylon Wheel Brush for Drill is now available for purchase through [Company Name]'s website and select retailers. With its arrival on the market, [Company Name] continues to solidify its position as a leading provider of high-quality cleaning tools.For customers who are seeking a reliable and efficient solution for their cleaning needs, the Nylon Wheel Brush for Drill is set to make a significant impact. With [Company Name]'s reputation for excellence and the brush's impressive features, it's clear that this product is poised to become a staple in the world of cleaning tools.

Understanding Metallic Bonding: What You Need to Know

article on the importance of metallic bonding in modern technology.Metallic Bonding and Its Importance in Modern TechnologyMetallic bonding is a fundamental concept in the world of chemistry and materials science. The unique properties of metals like strength, ductility, thermal and electrical conductivity, and luster can be attributed to the special bonding arrangement between the positively charged metal ions and the delocalized electrons.In recent years, metallic bonding has paved the way for several technological advancements that have transformed the way we live, work, and communicate. From advanced alloys used in aerospace and defense to high-precision components in electronics and renewable energy systems, metallic bonding plays a crucial role in shaping modern technology.One company that is leading the charge in metallic bonding technology is {metal bond}, a renowned name in the field of materials science and engineering. The company specializes in the development of high-performance alloys and composite materials that offer unparalleled strength, durability, and resistance to harsh environments.One of {metal bond}'s flagship products is its proprietary metal matrix composite (MMC) technology. MMCs are a unique class of materials that combine the desirable properties of metals and ceramics, making them ideal for a wide range of applications in the aerospace, defense, and automotive industries.MMC technology utilizes the principles of metallic bonding to create a high-strength matrix of metal ions reinforced with ceramic particles. The result is a material that is exceptionally strong and lightweight while retaining excellent thermal and electrical conductivity.MMC materials are used in critical components such as turbines, engine parts, and brake systems in high-performance cars and aircraft. These components require materials that can withstand extreme temperatures, pressures, and mechanical stresses without failure. MMCs provide the necessary strength and durability needed for such challenging applications, making them an indispensable tool in modern engineering.In addition to MMCs, metallic bonding is also utilized in other advanced materials such as shape-memory alloys (SMAs) and superalloys. SMAs are a class of materials that exhibit unique elasticity and shape-changing properties at specific temperatures, making them ideal for use in medical implants, aerospace, and robotics.Superalloys, on the other hand, are a specific class of alloys that exhibit exceptional heat resistance and mechanical strength, making them ideal for use in high-temperature applications such as gas turbines, jet engines, and nuclear reactors.The widespread use of metallic bonding in modern technology has undoubtedly transformed many industries and opened up new avenues for innovation and advancement. However, this is just the tip of the iceberg, as researchers continue to explore new ways to harness the unique properties of metallic bonding to create even more advanced materials and technologies.In conclusion, metallic bonding is an essential concept that has revolutionized the fields of materials science and engineering. The special bonding arrangement between the positively charged metal ions and the delocalized electrons is responsible for the unique properties of metals, making them indispensable in modern technology. With the advent of advanced materials like MMCs, SMAs, and superalloys, the potential applications of metallic bonding are virtually limitless, paving the way for even more exciting advances in the future.

Top Replacement Pads for Auto Spa Polishers: Enhance Your Vehicle's Shine

Auto Spa is a leading name in the automotive industry, renowned for producing high-quality car cleaning and maintenance products. With an unmatched commitment to innovation and customer satisfaction, Auto Spa has recently announced the launch of its newest product – the Polisher Replacement Pads.With its state-of-the-art manufacturing facility and team of dedicated professionals, Auto Spa has established itself as a global leader in the automotive industry. The company offers a wide range of cleaning and maintenance solutions, including car wash accessories, tire care products, and interior cleaning supplies, among others.Recognizing the need for efficient and reliable car polishers, Auto Spa has invested significant time and resources in developing the Polisher Replacement Pads. This new addition to their product line is designed to enhance the performance and longevity of their existing range of polishers.The Polisher Replacement Pads are manufactured using premium-quality materials to ensure durability and effectiveness. The pads are specifically engineered to provide a smooth, swirl-free polishing experience that delivers stunning results every time. With their innovative design, these replacement pads significantly reduce the risk of damaging the vehicle's paint surface, ensuring a flawless, showroom-quality finish.Auto Spa understands the importance of variety and versatility in the automotive industry. Hence, the Polisher Replacement Pads come in different sizes and densities, catering to various polishing requirements. Whether it's removing minor scratches, restoring dull paint, or creating a mirror-like shine, these pads offer the perfect solution for all car enthusiasts and professionals alike.One of the key features of the Auto Spa Polisher Replacement Pads is their ease of use. Designed for both beginners and seasoned professionals, these pads can be easily attached and detached from the polishers, making the polishing process hassle-free and time-efficient. The pads also feature a Velcro backing that ensures a secure and stable connection, enabling precise control and maneuverability during the polishing process.Another noteworthy aspect of the Auto Spa Polisher Replacement Pads is their durability. Crafted to withstand intense pressure and frequent use, these pads are built to last. The high-quality materials used in their construction ensure that they maintain their shape and performance even after prolonged and rigorous use.Additionally, Auto Spa prioritizes environmental consciousness and sustainability. The Polisher Replacement Pads are designed to be reusable, reducing waste and contributing to a greener planet. By minimizing the need for constant replacement, these pads not only save customers money but also make a positive impact on the environment.In conclusion, Auto Spa's latest offering, the Polisher Replacement Pads, exemplifies the company's commitment to excellence and innovation in the automotive industry. With their dedication to customer satisfaction, Auto Spa has introduced a versatile and high-performing solution for car enthusiasts and professionals alike. These pads, with their superior quality, ease of use, and durability, are set to revolutionize the car polishing experience, providing an unparalleled level of convenience and effectiveness. As Auto Spa continues to expand its product range, customers can expect nothing short of exceptional quality and groundbreaking innovation from this industry-leading brand.

Bond Investments: Latest Updates on Corporate Bonds, Government Bonds and Debt Market - The Economic Times

Title: Strongest Metal Bonds: Understanding Corporate and Government BondsIntroduction:In the world of finance, bonds serve as essential investment instruments that enable individuals and organizations to lend money to governments and corporations. These bonds play a crucial role in shaping the global economy, offering investors a means of generating income and diversifying their portfolios. This blog aims to delve into the realm of corporate and government bonds, shedding light on their market dynamics, investment potential, and the concept of metal bonds.Understanding Bonds:Bonds are fixed-income securities with predetermined interest rates, known as coupon rates, and specified maturity dates. They are essentially IOUs issued by entities to gather funds for various purposes, such as project financing, capital expansion, or government spending. By purchasing a bond, investors become creditors to the issuer and receive periodic interest payments until the bond matures.Corporate Bonds:Corporate bonds are debt securities issued by corporations to finance their operations and expansion plans. These bonds offer investors the opportunity to invest in established companies, ranging from tech giants to automotive manufacturers. Attractive coupon rates and the potential for capital appreciation make corporate bonds an appealing choice for risk-averse investors seeking stable income streams. However, the creditworthiness of the issuing company is a crucial consideration as it determines the reliability of interest payments and the timely return of principal.Government Bonds:Government bonds, on the other hand, are issued by national governments to raise funds for public projects and manage the national debt. These bonds are known for their low-risk nature as they are backed by the government's ability to levy taxes and print currency. Countries across the globe issue government bonds, including the US Treasury bills, UK gilts, and Indian government bonds (also known as G-Secs). Government bonds are often considered safe havens during times of economic uncertainty.Indian Debt Market:The Indian debt market plays a significant role in the country's financial ecosystem. It comprises various fixed-income instruments, including corporate bonds, government bonds, debentures, and commercial papers. In recent years, the Indian debt market has witnessed substantial growth, offering investors a range of investment opportunities. The Reserve Bank of India's initiatives to develop the debt market infrastructure have contributed to its increasing depth and liquidity.Bond Interest Rates and Yields:The interest rate on bonds is a crucial factor determining their attractiveness to investors. Higher interest rates generally indicate greater returns; however, they often correspond to higher risks associated with the issuer's creditworthiness. Yield, on the other hand, calculates the effective rate of return on a bond, accounting for its current market price and remaining coupon payments. Investors carefully assess interest rates and yields to determine the potential income and returns of their bond investments.Metal Bonds and Their Strength:Though not directly related to investments, the mention of metal bonds requires some explanation. In a different context, metal bonds are chemical bonds that involve metallic elements. These bonds are known for their strength and durability, giving rise to the concept of "strongest metal bonds." However, it is important to note that metal bonds in this context do not directly relate to the subject matter of bonds in the finance world.Conclusion:Corporate and government bonds play a vital role in the financial markets, offering investors opportunities for income generation, capital appreciation, and portfolio diversification. Corporate bonds cater to those seeking higher returns but with a higher level of risk, while government bonds provide stability and are regarded as safer investments. The Indian debt market continues to grow, fostering a favorable environment for these bond instruments. By understanding the dynamics of bonds and the factors affecting them, investors can make informed decisions to optimize their investment portfolios.

High-Powered Brushless Angle Grinder for DIY Projects and Construction Sites

In the world of power tools, innovation and technology are constantly driving the industry forward. One such innovative product making waves in the market is the Brushless Angle Grinder, an impressive addition to the power tool lineup from {company name}.The Brushless Angle Grinder is specifically designed for grinding, cutting, and finishing metal and concrete, making it an essential tool for construction and metalworking professionals. What sets this angle grinder apart from others on the market is its brushless motor technology, which offers increased power, efficiency, and durability compared to traditional brushed motors. This means that users can expect longer tool life, less maintenance, and overall better performance from the Brushless Angle Grinder.The Brushless Angle Grinder from {company name} is also designed with user comfort and safety in mind. The tool features a slim, ergonomic body design and a side handle for improved control and maneuverability, even in tight spaces. Additionally, it is equipped with a range of safety features, including a tool-free adjustable guard and a restart protection system, to ensure that users can work with peace of mind.{Company name} is a renowned name in the power tool industry, with a long history of delivering high-quality, reliable products to professionals and hobbyists alike. The company is committed to pushing the boundaries of innovation and providing solutions that meet the evolving needs of its customers.With the introduction of the Brushless Angle Grinder, {company name} continues to demonstrate its dedication to excellence in design and engineering. The tool is a testament to the company's commitment to staying at the forefront of technological advancement and providing its customers with the best tools for the job.In addition to the Brushless Angle Grinder, {company name} offers a wide range of power tools, including drills, saws, sanders, and more. Each product is backed by the company's reputation for quality and performance, giving users confidence in their investment.The Brushless Angle Grinder from {company name} is already generating buzz in the industry, with professionals praising its power, efficiency, and durability. Whether it's for grinding, cutting, or finishing, this angle grinder is proving to be a valuable asset on construction sites and metalworking shops around the world.The release of the Brushless Angle Grinder further solidifies {company name}'s position as a leader in the power tool market. The company's commitment to providing innovative solutions for its customers is evident in this latest addition to its lineup, and it is sure to make an impact in the industry.Overall, the Brushless Angle Grinder from {company name} is a powerful and reliable tool that is poised to become a staple in the arsenal of construction and metalworking professionals. With its advanced brushless motor technology, ergonomic design, and commitment to user safety, this angle grinder is a testament to {company name}'s dedication to providing top-of-the-line tools for its customers. As the industry continues to evolve, {company name} remains at the forefront, delivering innovative solutions that meet the needs of professionals and hobbyists alike.

High-Quality and Reliable Universal Diamond Cutting Disc 125x22.23mm - Professional Power Tools

article on the importance and benefits of using high-quality diamond cutting discs in various industries.As technology advances and new materials are developed, the need for precise and efficient cutting tools becomes increasingly important. In many industries, the use of cutting discs is crucial for producing high-quality products and completing tasks with precision and accuracy. With so many different types of cutting discs available on the market, it can be overwhelming to choose the right one for your specific needs.One type of cutting disc that has gained popularity in recent years is the diamond cutting disc. Diamond cutting discs are quickly becoming the standard for professionals in a wide variety of industries due to their exceptional strength, durability, and precision. These discs are made with industrial diamonds that are bonded to a metal or resin matrix, which provides a superior cutting edge that can handle tough materials like concrete, metal, glass, and ceramic tiles.One of the key features of diamond cutting discs is their versatility. Thanks to their durable composition, diamond cutting discs can cut through a wide range of materials, making them a go-to tool for professionals in a variety of industries. This versatility means that contractors and tradespeople can have a single cutting disc to handle various cutting needs, which can save them both time and money.Another benefit of diamond cutting discs is their long lifespan. With regular use and proper maintenance, diamond cutting discs can last significantly longer than traditional cutting discs. This is because the industrial diamonds used to make diamond cutting discs are incredibly hard and resilient, making them more resistant to wear and tear. Additionally, the bond that holds the diamonds in place is designed to withstand high temperatures and stress, further extending the lifespan of the disc.Aside from their durability, diamond cutting discs also offer exceptional cutting speed and precision. Because the industrial diamonds are much harder and sharper than traditional cutting materials like aluminum oxide or silicon carbide, they can cut through materials much faster, with less force required. This faster cutting speed not only increases efficiency on the job but also leads to a smoother finish with fewer burrs or jagged edges.When it comes to choosing a diamond cutting disc, it's crucial to consider factors like blade size, material composition, and intended use. For example, the Metabo diamond cutting disk 125x22.23mm, "UP", Universal "professional" (628559000) is designed to be a high-quality, reliable, and durable option for professionals in various industries. Its 125mm diameter makes it suitable for cutting a wide range of materials, while its universal "professional" design means that it can handle the toughest applications with ease. As a product known for its exceptional quality and performance in the industry, using it can ensure optimal results every time.In conclusion, there are significant benefits to using high-quality diamond cutting discs in various industries, including their versatility, long lifespan, and exceptional speed and precision. Although the initial cost of diamond cutting discs may be higher than traditional cutting discs, the superior performance and longevity make them a worthwhile investment in the long run. By choosing the right diamond cutting disc for your specific needs, you can ensure optimal results and save both time and money in the process.

Ceramic Grinding Disc: A Must-Have for Your Grinding Needs

Norton Abrasives, a leading manufacturer of grinding and cutting products, has recently introduced a new ceramic grinding disc that promises to revolutionize the industry. The latest addition to their extensive product line, the ceramic grinding disc is designed to provide superior performance and durability, making it an ideal choice for a wide range of grinding applications.The new ceramic grinding disc features an innovative design that sets it apart from traditional grinding discs. Made from high-quality ceramic abrasives, the disc offers exceptional material removal and extended service life, delivering outstanding value for users. Its advanced manufacturing process ensures that the disc maintains its sharpness and effectiveness throughout its lifespan, reducing the need for frequent disc changes and increasing productivity.Norton Abrasives has a long-standing reputation for producing high-quality and reliable abrasive products. With over 130 years of experience in the industry, the company has continually set the standard for excellence, providing innovative solutions to meet the evolving needs of their customers. Their commitment to research and development has led to the creation of cutting-edge products that deliver exceptional performance and efficiency, and the new ceramic grinding disc is no exception.The ceramic grinding disc is suitable for use on a variety of materials, including stainless steel, mild steel, and non-ferrous metals, making it a versatile and cost-effective choice for metalworking professionals. Its superior material removal rate and extended lifespan make it an ideal option for heavy-duty grinding applications, such as weld removal, edge grinding, and surface preparation. Additionally, the disc is designed to minimize heat build-up during use, reducing the risk of discoloration and deformation of the workpiece.In addition to its impressive performance, the ceramic grinding disc also offers enhanced safety features, including reinforced fiberglass mesh and a specially formulated bond system that provides added stability and control during operation. These safety enhancements help to prevent the disc from shattering or breaking under high-stress conditions, ensuring the protection of the user and surrounding personnel.Norton Abrasives takes pride in its commitment to sustainability and environmental responsibility. The new ceramic grinding disc is manufactured using eco-friendly processes and materials, reducing the environmental impact of production while still meeting the highest standards for quality and performance. This dedication to sustainability reflects Norton's ongoing efforts to support a greener and more sustainable future for the industry and the planet as a whole.The introduction of the new ceramic grinding disc further solidifies Norton Abrasives' position as a leading provider of cutting-edge abrasive products. With a focus on continuous innovation and customer satisfaction, the company remains at the forefront of the industry, offering solutions that meet the diverse needs of their global customer base. As a trusted partner to professionals in metalworking, manufacturing, and construction, Norton Abrasives continues to set the standard for excellence and reliability in abrasive technology.The new ceramic grinding disc is now available for purchase through Norton Abrasives' extensive network of distributors and authorized retailers. With its exceptional performance, durability, and safety features, the disc is expected to be well-received by professionals seeking a reliable and cost-effective grinding solution for their most demanding applications. As Norton Abrasives continues to drive innovation in the industry, the introduction of the ceramic grinding disc underscores their commitment to providing cutting-edge solutions that empower their customers to achieve optimal results.

Ultimate Guide to Diamond Grinding Wheels: Everything You Need to Know

Title: Advanced Diamond Grinding Wheel Technology Revolutionizes Grinding ProcessesIntroductionLeading-edge technology is transforming industries worldwide, and the realm of grinding and material removal is no exception. One significant development in this field is the revolutionary diamond grinding wheel, designed to enhance grinding efficiencies and optimize output quality. In this article, we explore the exceptional features and benefits of this cutting-edge technology, sans any brand name, along with a brief introduction to the company behind this groundbreaking innovation.I. The Evolution of Grinding WheelsGrinding wheels have long been a crucial tool for numerous industries, enabling precision shaping, finishing, and removing material from a range of surfaces. Over time, advancements in manufacturing techniques and material science have led to the creation of various grinding wheel types. Among them, diamond grinding wheels have emerged as the pinnacle in terms of performance, durability, and versatility.II. Characteristics and Features of Diamond Grinding Wheels1. Exceptional Material Hardness:Diamond grinding wheels are renowned for their exceptional hardness, ensuring extended lifespan and enhanced longevity. Composed of industrial-grade diamond particles, these wheels effectively resist wear, maintaining their sharpness and consistency over prolonged periods.2. Superior Abrasion Resistance:High abrasion resistance is a defining attribute of diamond grinding wheels. This resistance enables them to endure the harsh conditions of various grinding operations, even when subjected to demanding applications that involve the removal of tough materials such as ceramics, composites, and hardened steel.3. Heat Dissipation Capability:One of the key challenges in grinding processes is effectively managing heat generation, as excessive heat can compromise material integrity. Diamond grinding wheels excel in dissipating heat effectively due to the material's exceptional thermal conductivity, minimizing the risk of material distortion or damage during grinding.4. Precision Profiling and Shaping:Diamond grinding wheels offer unparalleled precision for profiling and shaping tasks. The extreme hardness of the diamond abrasive particles allows for precise grinding, enabling exceptional control over the desired surface finish and intricate detailing.5. Minimal Wheel Dressing Requirement:Thanks to the durability and superior abrasive properties, diamond grinding wheels require less frequent dressing to maintain optimal performance. This reduction in downtime for wheel dressing translates into enhanced productivity and cost savings for businesses relying on grinding operations.III. The Company Behind the InnovationThe company leading the charge in revolutionizing grinding processes with diamond grinding wheels is a trailblazer in the field of abrasive tools. With decades of research and development, this company has established itself as a global leader in manufacturing high-quality, cutting-edge grinding wheel systems.Their commitment to innovation, combined with a strong focus on customer needs, has propelled them to the forefront of the industry. They invest substantial resources in continuous product improvement, ensuring their diamond grinding wheels meet and exceed the evolving demands of various industries, including automotive, aerospace, machinery, and more.Furthermore, this visionary company operates under a strict quality control framework, employing rigorous testing procedures to ensure that each grinding wheel leaving their facilities meets the highest standards of performance and reliability. Through collaborations with industry partners and a customer-centric approach, they continue to set new benchmarks for grinding wheel technologies.ConclusionThe advent of diamond grinding wheels has revolutionized grinding processes across industries. The extraordinary characteristics of these wheels, including their hardness, superior abrasion resistance, heat dissipation capabilities, precision profiling and shaping abilities, and reduced dressing requirements, have made them the tool of choice for the most challenging grinding applications.Thanks to the pioneering efforts of the company spearheading this innovation, they have paved the way for enhanced productivity, improved finished product quality, and cost savings for businesses across the globe. As grinding technology continues to evolve, diamond grinding wheels will undoubtedly remain at the forefront, offering efficient and reliable solutions for the material removal needs of countless industries.