How to Choose the Best Edge Polishing Pad and Improve Your Stone Fabrication Business

By:Admin

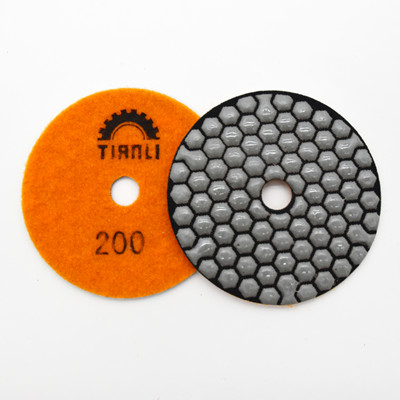

The Edge Polishing Pad is designed to meet the diverse needs of the stone fabrication industry, offering an efficient way to achieve a smooth and glossy finish on all types of stone surfaces. Whether it is granite, marble, or quartz, this polishing pad is engineered to deliver consistent results, making it an ideal choice for both professionals and DIY enthusiasts.

One of the key factors that set this product apart from its competitors is its superior durability. The Edge Polishing Pad is built to withstand the rigors of heavy-duty usage, ensuring that it remains effective and reliable even after prolonged use. This resilience is a testament to the company's commitment to delivering products that not only meet but exceed the expectations of their customers.

In addition to its durability, the Edge Polishing Pad is also known for its versatility. With varying grit levels available, users have the flexibility to choose the right pad for the specific requirements of their project. This adaptability makes it a valuable tool for a wide range of applications, whether it is for smoothing rough edges or putting the finishing touches on intricate designs.

Furthermore, the company behind the Edge Polishing Pad is dedicated to ensuring that their products are not only effective but also environmentally friendly. By utilizing advanced manufacturing processes and materials, they have created a product that minimizes waste and reduces environmental impact without compromising on performance. This sustainability-driven approach reflects the company's commitment to responsible business practices and their dedication to contributing to a cleaner and greener future.

The company's dedication to quality and innovation is further highlighted by their investment in research and development. They continuously strive to improve their products and processes, leveraging the latest technologies and industry trends to stay ahead of the curve. This forward-thinking approach not only enables them to meet the evolving needs of their customers but also positions them as a leader in the industry.

Moreover, the company's commitment to customer satisfaction is evident in their exceptional customer service. They prioritize building strong relationships with their clients, providing extensive support and guidance to ensure that customers are able to maximize the benefits of their products. This personalized approach has earned them a reputation for reliability and trustworthiness, making them a preferred partner for many professionals in the stone fabrication industry.

In conclusion, the Edge Polishing Pad, developed by a forward-thinking and reputable manufacturing company, stands out as a superior solution for stone polishing needs. With its exceptional durability, versatility, and eco-friendly design, it has become a go-to choice for professionals and enthusiasts alike. Coupled with the company's commitment to quality, innovation, and customer satisfaction, it is clear that they are set to continue making a lasting impact in the industry for years to come.

Company News & Blog

Discover the Benefits of a Diamond Grind Stone for Superior Grinding Results

Title: Innovative Grinding Solution Offers Superior Precision: The Introduction of Diamond Grind Stone by [Company]Introduction (100 words):[Company] is proud to unveil its latest breakthrough in grinding technology – the Diamond Grind Stone. This revolutionary product represents a significant leap forward in precision grinding solutions, offering unparalleled performance and durability. With the aim to meet the evolving needs of professionals across industries, the Diamond Grind Stone combines cutting-edge diamond-enhanced technology with our years of expertise and commitment to quality. This latest addition to our portfolio reinforces [Company]'s position as an industry leader and shows our unwavering dedication to providing innovative solutions that empower our customers to achieve excellence in their work.Body:Paragraph 1 (100 words): The Diamond Grind Stone, designed and manufactured by [Company], is a game-changer when it comes to grinding applications. Its unique diamond-enhanced composition allows for exceptional abrasive performance, leading to faster material removal and increased productivity. With a focus on precision and longevity, the Diamond Grind Stone consistently delivers superior results, making it an ideal choice for a wide range of industries, including manufacturing, construction, and metalworking.Paragraph 2 (150 words):What sets the Diamond Grind Stone apart from conventional grinding stones is its advanced manufacturing process, which incorporates high-quality diamonds embedded in a matrix of durable materials. This ensures consistent abrasion and an extended lifespan, reducing the need for frequent replacements and saving valuable time and resources. The diamond-enhanced surface also provides a sharper cutting edge, optimizing cutting efficiency and minimizing heat generation during the grinding process. Additionally, the Diamond Grind Stone offers exceptional wear resistance, allowing it to handle the toughest grinding tasks while maintaining its performance over time.Paragraph 3 (150 words):Safety is a paramount consideration in any grinding operation, and the Diamond Grind Stone addresses this concern through its exceptional stability and balance. The design of the stone incorporates precision-engineered features, such as non-slip grips and a well-balanced composition, to provide users with maximum control and maneuverability. This ensures that operators can efficiently complete grinding tasks while minimizing the risk of accidents or fatigue. The optimized ergonomics of the Diamond Grind Stone further contribute to enhanced safety, making it a preferred choice for professionals across various industries.Paragraph 4 (200 words):[Company]'s commitment to customer service extends beyond the innovative technology of the Diamond Grind Stone. Every purchase is backed by comprehensive customer support, ensuring that users receive the assistance and guidance they need. Our team of industry experts is readily available to provide technical expertise, addressing any queries or concerns regarding the Diamond Grind Stone. We believe in building strong relationships with our customers, offering ongoing support and personalized recommendations to achieve the best possible grinding results for their specific applications.Conclusion (100 words):The introduction of the Diamond Grind Stone by [Company] revolutionizes the grinding industry by offering a superior grinding solution that combines precision, durability, and safety. Backed by years of expertise, [Company] continues to push boundaries in the pursuit of excellence, empowering professionals to achieve outstanding results. The Diamond Grind Stone's diamond-enhanced composition ensures faster material removal, exceptional longevity, and optimized safety, thus enhancing productivity and reducing downtime for users across various industries. With the unparalleled support offered by [Company]'s dedicated team, customers can trust in our commitment to their success.

Environmental group opposes air permit for $340M metal recycling and smelting plant

Augusta Metal Plant Wins Authorization for $760M in BondsAugusta's new metal recycling and secondary smelting facility has received authorization for $760 million in bonds from state authorities. This development marks a significant milestone in the construction of the world-class metal facility, which has been under development in Augusta for many months now.Construction of the plant has been on full swing for a while now, and the project is set to change Augusta's economy. The facility will result in the creation of several new jobs and provide significant economic benefits to the local communities.The Environmental ChallengeThe Savannah Riverkeeper submitted an argument against an air permit for the facility in July 2021. The environmental group fears that the new plant's emissions would cause health hazards to the local community.The permit requested by the plant was to allow it to emit up to 5,000 tons of carbon monoxide annually, which was well above the lower limits proposed by the Savannah Riverkeeper.To resolve these concerns, the facility's authorities agreed to impose stricter regulations for the plant's emissions by keeping the amount of carbon monoxide below 2,500 tons per year.Assuming that the metal recycling and secondary smelting facility will adhere to regulations, it could prove to be a significant asset to the various companies that depend on scrap metal.Benefits of the Metal Recycling and Secondary Smelting FacilityThe new facility will utilize scrap metal and turn it into valuable items- thereby reducing the reliance on non-renewable resources and minimizing the products that end up in landfills.The facility is expected to generate more than 200 well-paying jobs, with a majority going to individuals living in the Augusta area, thus improving the local economy.Moreover, the plant's development will create new trade and supply chain opportunities, meaning that the local market will see an increase in demand, which is expected to cause further economic growth.The authorities have agreed that the facility will be one of the most environmentally sustainable in the world, with a waste-free operation standard. The facility's management team has committed to ensuring that the plant's process is environmentally friendly, and they will monitor it regularly to minimize any environmental impact.Final TakeawayThe authorization of the $760 million in bonds marks a significant step forward for the Augusta facility. The plant is expected to be operational by mid-2022 and will provide a critical infrastructure to Augusta's economy.With all environmental concerns addressed, Augusta's metal recycling and secondary smelting facility has the potential to create a significant economic impact on the local communities while minimizing the facility's footprint on the environment.The metal recycling plant will provide an excellent source of sustainable energy, and with its promise of a waste-free operation, it is expected to set new standards in the metal recycling industry.If Augusta's metal recycling and secondary smelting facility upholds its commitment to sustainable practices, it is bound to grow into a major industry player, providing a diverse range of sustainable solutions. With all these planned developments, it's an exciting time for Augusta, and there is much to look forward to.

The Importance of Polish: How to Achieve a Smooth and Glossy Finish

article highlighting the benefits and applications of these products.Polishes have been around for centuries, helping people to achieve a smooth and glossy finish on different surfaces. Today, there are many different types of polishes available in the market, each designed for specific applications. One of the most popular types of polish is the (brand name) Buff Polish Pad.(Company Name), the manufacturer of Buff Polish Pad, is a leading name in the polishing industry. The company has been providing high-quality polishing products to its customers for over (number) years. Buff Polish Pad is one of their most popular products, used by people all over the world to achieve a high-quality finish on different surfaces.So, what exactly is Buff Polish Pad, and what makes it so special? Buff Polish Pad is an abrasive pad made of high-quality materials that are designed to work with a wide range of surfaces. The pad is made up of tiny abrasive particles that help to remove scratches, stains, and other imperfections from surfaces while also leaving a smooth and glossy finish behind.One of the biggest advantages of using Buff Polish Pad is that it is versatile. It can be used on different types of surfaces, such as wood, metal, plastic, and more. This makes it an excellent choice for professionals and DIY enthusiasts alike.Another advantage of Buff Polish Pad is that it is easy to use. All you need to do is apply the pad to the surface you want to polish and work it in using a circular motion. The pad does the rest of the work for you, leaving behind a smooth and glossy finish.Additionally, Buff Polish Pad is environmentally friendly. It is made from natural and biodegradable materials, which means it is safe for the environment and does not harm the surface being polished.So, what are some of the applications of Buff Polish Pad? The product is widely used by woodworkers, auto mechanics, metalworkers, and others who need to polish different surfaces. Woodworkers use Buff Polish Pad to achieve a smooth and glossy finish on their wooden projects. Auto mechanics use it to polish car bodies and other metal parts. Metalworkers use it to polish metal surfaces to a high luster finish.In conclusion, Buff Polish Pad is an excellent choice for anyone who needs a high-quality polish for their surfaces. Its versatility, ease of use, environmental friendliness, and wide range of applications make it an extremely popular choice in the polishing industry. So, if you need to achieve a smooth and glossy finish on any surface, try Buff Polish Pad today!

Ceramic Tile Flooring in Mooresville, NC: Easy Selection & Free Consultation Services | Floor Coverings International

Ceramic Floor Tiles, a leading provider of ceramic tile flooring solutions, is proud to offer its extensive range of products and services to homeowners in Mooresville, NC. With a commitment to quality and customer satisfaction, the company has built a reputation as a trusted provider of beautiful and durable flooring options.Ceramic tile flooring has been a popular choice for homeowners for centuries, thanks to its timeless beauty and durability. These types of tiles are made from natural clay that is fired at high temperatures, creating a durable and versatile material that can be used in a variety of settings. Ceramic tiles are available in a wide range of colors, shapes, sizes, and patterns, making them perfect for any living space.At Ceramic Floor Tiles, we understand that choosing the right flooring for your home can be a daunting task. That's why we offer free in-home consultation services to help you navigate your options and select the perfect ceramic tile flooring solution for your Mooresville home. Our team of flooring experts will work with you to understand your design preferences, budget, and lifestyle needs, so we can recommend the best options for your unique situation.We offer a wide range of ceramic tile flooring options for our Mooresville clients. Our selection includes traditional ceramic tiles, which are made from natural clay and come in a variety of colors and patterns. These tiles are perfect for homeowners who want a classic and timeless look. We also offer porcelain tiles, which are made from a denser type of clay and are more resistant to chips, scratches, and stains. Porcelain tiles are a popular choice for high-traffic areas, such as kitchens and bathrooms.In addition to our extensive variety of ceramic tile options, Ceramic Floor Tiles also offers expert installation services. Our team of skilled technicians will ensure that your new flooring is installed correctly, so it looks beautiful and performs well for years to come. We use high-quality materials and follow industry best practices to ensure a flawless finish every time.At Ceramic Floor Tiles, we're committed to providing our Mooresville clients with exceptional customer service. We understand that selecting new flooring is a significant investment for your home, and we're dedicated to helping you make a decision that you'll be happy with for years to come. Our team is available to answer any questions you may have throughout the flooring selection and installation process.In conclusion, if you're looking for a beautiful and durable flooring solution for your Mooresville home, look no further than Ceramic Floor Tiles. With our extensive variety of ceramic tile options, free in-home consultation services, and expert installation, we're the perfect partner for your flooring needs. Contact us today to schedule your consultation and get started on your flooring project.

Different Types of Grinding Wheels: A Complete Guide

Title: Exploring the Different Types of Grinding Wheels Revolutionizing Industrial ApplicationsIntroduction:In today's industrial revolution, grinding wheels play a fundamental role in various sectors, including manufacturing, construction, automotive, and metalworking. These indispensable tools are crucial for precision cutting, shaping, and finishing, enabling businesses to enhance productivity and achieve superior workpiece quality. This article aims to shed light on the various types of grinding wheels available in the market and their importance in revolutionizing industrial applications.1. Straight Grinding Wheels:Straight grinding wheels, also known as Type 1 wheels, are the most common and straightforward type used for surface grinding. These wheels have a flat outer periphery and deliver precise grinding performance on flat surfaces. Typically made from aluminum oxide or silicon carbide abrasive grains, straight grinding wheels are versatile and suitable for a wide array of materials, including steel, cast iron, brass, and non-ferrous metals.2. Cylinder Wheels:Cylinder wheels, designated as Type 2 wheels, possess a unique shape resembling a straight grinding wheel with a cylindrical face. These wheels are primarily used for grinding cylinders, bearings, and other rounded surfaces. The rounded design allows for easy and efficient grinding with reduced friction, resulting in excellent surface finishes.3. Tapered Grinding Wheels:Tapered grinding wheels, commonly referred to as Type 4 wheels, are specially designed for grinding operations that require precision and control. These wheels have a tapered shape, gradually narrowing towards the arbor hole. The tapering enables the wheel to penetrate the workpiece effectively, making them ideal for intricate grinding tasks such as internal grinding.4. Dish Grinding Wheels:Dish grinding wheels, known as Type 11 wheels, possess a dish-shaped design with a roundish outer rim and a depressed center. These wheels are widely used for contour grinding, grinding complex shapes, and removing excess material from the workpiece. The recessed center allows for a higher degree of flexibility, making them suitable for both large and small-scale applications.5. Diamond Wheels:Diamond grinding wheels are the epitome of grinding wheel technology, offering exceptional hardness, durability, and precision. Utilizing diamond abrasives, these wheels excel in cutting and grinding extremely hard materials such as carbides, ceramics, glass, and stones. Their fine grit allows for a smooth finish and minimal material wastage, making diamond wheels ideal for demanding applications.6. CBN Wheels:Cubic Boron Nitride (CBN) grinding wheels are similar to diamond wheels in terms of their exceptional hardness and longevity. These wheels are specifically formulated for grinding ferrous materials, including hardened steels and cast iron. With their heat resistance and ability to retain sharpness, CBN wheels are perfect for high-speed grinding operations, resulting in improved productivity and reduced downtime.Conclusion:Grinding wheels are indispensable tools in the industrial sector, revolutionizing various applications, from metalworking to automotive and construction. This article explored different types of grinding wheels, highlighting their characteristics and applications. The versatility and precision offered by these wheels allow businesses to improve productivity, achieve superior workpiece quality, and ultimately drive the industrial revolution forward. As technology advances further, we can expect the development of innovative grinding wheel types, continually pushing the boundaries of what can be achieved in industrial grinding.

Accelerating Growth and Unlocking Potential: Insights from GEM 2011

article with the following headline:"GEM 2011: Accelerating Growth and Unlocking the Potential of Developing Countries"The fourth edition of the Global Entrepreneurship Monitor (GEM) conference was held in[location]on [date], bringing together some of the most influential policy makers, business leaders, development experts and academics from around the world. The conference was focused on discussing new strategies for accelerating growth and unlocking the potential of developing countries.The discussions at the GEM 2011 conference were centered on various topics such as the role of entrepreneurship in the economic development of developing countries, identifying key drivers of success, and overcoming challenges in promoting entrepreneurship in different regions.One of the key highlights of the conference was the presentation by [company introduction] Stone Tools which highlighted its innovative approach towards promoting entrepreneurship in developing countries. The presentation emphasized the crucial role of technology and innovation in promoting entrepreneurial growth in developing countries. Stone Tools also showcased its state-of-the-art digital platform which makes entrepreneurship resources, tools, and insights accessible to entrepreneurs all around the world.The discussion panel at the conference, which included leading experts and entrepreneurs, underlined the importance of creating an enabling environment for entrepreneurship and innovation in developing countries. They stressed upon the need for governments to invest in infrastructure, education, and policies that support entrepreneurship and innovation. The panel also discussed the importance of building strong networks among entrepreneurs, investors, and policymakers to create a vibrant entrepreneurship ecosystem.Another key takeaway from the GEM 2011 conference was the emphasis on the need for a multidisciplinary approach towards entrepreneurship research. The conference highlighted the importance of integrating insights from various fields such as economics, sociology, psychology, and history, to gain a deeper understanding of the complex factors that shape entrepreneurial behavior in different regions.The conference also addressed some of the key challenges faced by entrepreneurs in developing countries such as access to finance, regulatory barriers, cultural and social norms, and limited access to technology and innovation. The experts emphasized upon the need for collaborative efforts between governments, entrepreneurs, and development agencies to overcome these challenges and promote entrepreneurship in developing countries.In conclusion, the GEM 2011 conference provided an excellent platform for discussions on accelerating growth and unlocking the potential of developing countries. The conference showcased some of the latest innovations and insights in the field of entrepreneurship and highlighted the importance of creating a supportive ecosystem for entrepreneurship to thrive in developing countries. The conference also emphasized the need for continued research and collaboration to tackle some of the critical challenges faced by entrepreneurs in the developing world.

High-Quality and Affordable Diamond Polishing Pads for Various Applications

- Importance of Diamond Polishing Pads for Stone RestorationStone restoration is a process that is becoming increasingly popular as people are realizing the benefits of restoring old and damaged stone surfaces. However, the process of stone restoration requires the use of specialized tools and equipment, including diamond polishing pads. These pads are specifically designed to restore stone surfaces to their original beauty and shine. In this blog post, we will discuss the importance of diamond polishing pads in stone restoration.Diamond polishing pads are designed to work with a wide variety of stone surfaces, including marble, granite, and other natural stone materials. They come in different sizes and grits to suit different types of stone surfaces and specific restoration needs. These pads are typically made of diamond-impregnated resin or metal-bonded diamond, which allows them to grind away the surface imperfections and smooth out the stone.The use of diamond polishing pads is an essential part of the stone restoration process. They are used to remove surface scratches, stains, and blemishes, as well as to bring out the natural beauty and shine of the stone. Diamond pads are also used to flatten uneven surfaces, smooth out rough edges, and to achieve a high-gloss finish.When selecting a diamond polishing pad for a stone restoration project, it is important to consider the type of stone surface being restored and the level of damage. The pads come in different grits, ranging from coarse to fine, and each grit is designed for a specific purpose. Coarse grit pads are used for heavy grinding and removing deep scratches and stains. Medium grit pads are used for smoothing out surface imperfections, and fine grit pads are used for achieving a high-gloss finish.In addition to using the appropriate grit, it is important to use the proper technique when using diamond polishing pads. Proper technique involves using a consistent amount of pressure and controlling the speed of the rotary tool. It is also important to use water or a special lubricating fluid to cool the pad and prevent it from overheating.In conclusion, the use of diamond polishing pads is crucial for restoring stone surfaces to their original beauty and shine. With the proper selection of grit, technique, and equipment, diamond pads can be used to remove scratches, stains, and imperfections, as well as to achieve a high-gloss finish. If you are considering a stone restoration project, be sure to work with a professional who understands the importance of using diamond polishing pads for the best results.

High Quality Diamond Saw Blades for Granite - Order Online or Call Now

Diamond Tools For Granite: Enhancing Efficiency and Precision in CuttingIn the world of construction and home improvement, the importance of high-quality tools cannot be overstated. When it comes to cutting through the toughest materials, such as granite, using diamond tools is essential. With their exceptional durability, efficiency, and precision, diamond tools have become the go-to choice for professionals and DIY enthusiasts alike.Granite, with its unmatched beauty and strength, has become a popular choice for countertops, flooring, and other applications. However, working with such a dense and hard material requires specialized tools that can withstand the rigors of the task. This is where diamond tools for granite come into play.Diamond tools are renowned for their exceptional hardness and longevity. Unlike traditional metal blades, diamond tool blades are made with tiny industrial diamonds embedded in the cutting segment. These diamonds act as cutting edges, delivering incredible speed and precision while withstanding the abrasive nature of granite.One of the key advantages of diamond tools for granite is their ability to cut through the material quickly and effortlessly. The diamond blade's sharp cutting edges make clean and precise cuts, reducing the chances of chipping or cracking the granite. This not only saves time but also reduces material wastage during the cutting process, ultimately saving costs.Another significant advantage of diamond tools for granite is their exceptional durability. Granite is notorious for wearing down blades quickly due to its hardness. However, diamond blades are specifically designed to handle the toughest cutting tasks. The diamond particles on the cutting edge maintain their sharpness for an extended period, ensuring consistent performance throughout the project.Precision is critical when working with granite, as even the smallest errors can result in aesthetic flaws or compromised structural integrity. Diamond tools for granite offer unparalleled precision, enabling professionals to achieve the desired results with utmost accuracy. The sharp cutting edges of the diamond blades enable clean cuts, preventing any damage to the granite surface.Additionally, the use of diamond tools reduces the need for additional manual finishing work. Since diamond blades produce clean and smooth cuts, the granite surfaces require minimal polishing or shaping afterward. This not only saves time but also ensures a higher level of consistency in the final product.When choosing diamond tools for granite, it is essential to consider the specific requirements of your project. There are various types of diamond blades available, each designed for a specific cutting task. For instance, segmented blades are ideal for general cutting, while continuous rim blades are better suited for smooth cuts. Understanding the nuances of each blade type will help you make an informed decision and achieve the best results.In conclusion, diamond tools are the epitome of efficiency and precision when it comes to cutting granite. Their unparalleled durability, speed, and accuracy make them an indispensable asset for any professional or DIY enthusiast. By investing in high-quality diamond tools for granite, you can enhance your cutting capabilities, save time and money, and achieve impeccable results in your projects.Interested in acquiring diamond tools for your granite cutting needs? Order online or give us a call today at [phone number]. Our team of experts will assist you in choosing the right tools to take your granite cutting experience to the next level.

Discover the Key Benefits of Diamond Tool Granites for Your Projects

[Company Name] Introduces Innovative Diamond Tool Solution to Revolutionize Granite Industry[City, State]: [Company Name], a leading player in the manufacturing and distribution of advanced cutting and shaping tools, has unveiled its latest groundbreaking product, the Diamond Tool Granites. As the name suggests, this cutting-edge tool offers unprecedented levels of precision and efficiency in the granite industry, positioning [Company Name] as a game-changer in the market.The introduction of Diamond Tool Granites comes at a time when the demand for high-quality granite products is rapidly growing across various industries. With the construction and interior design sectors booming, there is an increased need for tools that can ensure precise and smooth cuts in granite surfaces. Understanding this market demand, [Company Name] has meticulously designed and engineered the Diamond Tool Granites to address these specific needs.The cornerstone of [Company Name]'s success lies in its commitment to innovation and advanced technology. With years of experience in the industry, the company has earned a reputation for consistently delivering cutting-edge solutions tailored to meet the evolving needs of their customers. The introduction of Diamond Tool Granites builds upon this legacy, showcasing the company's dedication to continuous improvement and customer satisfaction.So, what sets Diamond Tool Granites apart from other tools in the market? The answer lies in the revolutionary technology that powers this exceptional tool. Designed with precision and durability in mind, Diamond Tool Granites feature diamond-encrusted cutting blades that guarantee smooth and precise cuts through even the toughest granite surfaces. This innovative design ensures minimal chipping, reducing waste while maintaining the integrity of the granite being worked on.Additionally, the Diamond Tool Granites are engineered to maximize operational efficiency. The tools have been meticulously crafted to increase productivity and reduce downtime. This enables businesses in the granite industry to meet ever-growing customer demands while staying ahead of the competition.Customers who have had the opportunity to work with the Diamond Tool Granites have reported remarkable improvements in their operations. One of the key advantages highlighted by users is the extended lifespan of the tool. Thanks to the usage of advanced materials and cutting-edge technology, the Diamond Tool Granites can withstand the rigors of heavy-duty usage, leading to significant cost savings for businesses in the long run.It is worth noting that [Company Name]'s commitment to quality goes beyond the products they offer. The company places great emphasis on customer support and satisfaction. With a team of knowledgeable and experienced experts, [Company Name] ensures that their customers receive the necessary technical assistance, guidance, and training needed to utilize Diamond Tool Granites to their fullest potential.Looking ahead, [Company Name] plans to further expand its range of innovative products to meet the demands of a diverse customer base. With the introduction of Diamond Tool Granites, the company has firmly established itself as a market leader in the granite industry.As businesses across the globe seek advanced tools and technologies to enhance their operations, [Company Name]'s Diamond Tool Granites are poised to revolutionize the way granite is cut and shaped. Whether it be countertop fabrication, construction projects, or monumental works, these cutting-edge tools ensure unparalleled precision, smoothness, and efficiency, making them an invaluable asset in the granite industry.

High-Quality Hybrid Floor Polishing Pad, Concrete Floor Pad, and Diamond Tools at Affordable Prices

: The Revolution in Polishing TechniquesPolishing floors was once a highly labor-intensive task that requires time, effort, and a plethora of technical skills. Plus, the traditional methods used to polish floors often lead to pesky issues, such as uneven surfaces, scratches, and long drying periods. Luckily, thanks to the inception of diamond floor pads, this laborious task can be accomplished with greater efficiency and in less time. So, what exactly are diamond floor pads?Diamond floor pads are a revolutionary new tool used in the process of polishing concrete, marble, and granite surfaces. These pads are made from diamond particles, which are skillfully combined with advanced bonding materials to form a highly effective and durable surface polishing tool. Additionally, the diamond floor pad has numerous benefits over earlier polishing techniques.One of the significant benefits of diamond floor pads is that they can be used for both dry and wet polishing. Unlike traditional methods that could only be executed after the surface had already dried, these new pads allow for an enhanced polishing experience. Dry polishing was previously used to tackle surface imperfections caused by uneven wear and tear. The diamond floor pads have now changed that scenario and polish the floor to a smooth, glossy finish.Another major advantage of diamond floor pads is their ability to create a more even finish across the entire floor's surface area. The pads are made with diamond particles of varying diameters that allow the operator to adjust the levels depending on the surface's texture. Additionally, diamond floor pads can be used to remove dirt, oil, and grime from the surface when used with the appropriate detergent.Diamond floor pads are also a more cost-effective option than traditional polishing surfaces. Since traditional polishing tools require a significant amount of equipment, such as special chemicals, machines, and additional labor, the overall expenses of the process can be quite expensive. Diamond floor pads make the process more cost-effective as it does not require extensive equipment, and it can be performed without rigorous training.The surfaces that diamond floor pads can polish are also diverse. These pads are effective in polishing various surfaces, including concrete, granite, marble, tiles, and porcelain. The advanced design and construction of diamond floor pads allow them to handle rough, bumpy surfaces and achieve the desired smooth surface finish with ease. It can be used for polishing indoors and outdoors, giving your floors a beautiful glossy appeal.Hybrid floor polishing pad is an extension of diamond floor pads. The hybrid floor pads typically have a grit range of 400-3000 and have diamond resin or metal segments embedded in them. These pads can quickly do the job of both metal and resin-bonded tools in one go, which is why there are becoming increasingly popular in the floor polishing world.The transition tools are used in the preparation phase, from grinding to polishing. The angle of the transition tools is precisely adjusted to avoid damaging the new surface while preparing it for the next stage. Proper use of the transition tool is essential to achieve the perfect floor finish.In conclusion, diamond floor pads have revolutionized floor polishing techniques. They're cost-effective, efficient, and versatile and can polish various surfaces to a beautiful gloss finish. The hybrid floor polishing pad and transition tools are beneficial in the overall process of polishing floors. By employing these innovative tools, we can finally say goodbye to the laborious, time-consuming, and costly process of polishing floors. Get your diamond floor pad today and experience the perfect floor finish.