New Study Reveals the Power of Metallic Sodium Bonds

By:Admin

One company that has been at the forefront of exploring the potential of metallic sodium bonds is {remove brand name}. With a strong focus on research and development, {remove brand name} has been working tirelessly to harness the power of metallic sodium bonds and integrate them into practical applications.

{remove brand name} is a leading chemical company that has made significant strides in the field of materials science and chemistry. The company has a rich history of innovation and has consistently pushed the boundaries of what is possible in the world of chemical engineering. With a team of top-notch scientists and researchers, {remove brand name} has been able to stay ahead of the curve and anticipate the next big breakthrough in the industry.

The discovery of metallic sodium bonds has been a game-changer for {remove brand name}. The company has recognized the potential of this new development and has invested heavily in research and development to explore the various applications of metallic sodium bonds. From creating new materials with enhanced properties to developing advanced energy storage solutions, {remove brand name} has been at the forefront of pioneering groundbreaking innovations using metallic sodium bonds.

One of the key areas where {remove brand name} has been focusing its efforts is in the development of high-performance batteries. Metallic sodium bonds have shown immense potential for improving the efficiency and performance of batteries, making them an ideal candidate for next-generation energy storage solutions. With the global demand for energy storage on the rise, {remove brand name} has been proactive in capitalizing on the opportunities presented by metallic sodium bonds.

In addition to energy storage, {remove brand name} has also been exploring the use of metallic sodium bonds in the field of healthcare. The unique properties of metallic sodium bonds have opened up new possibilities for drug delivery systems and medical devices. By leveraging the power of metallic sodium bonds, {remove brand name} is committed to revolutionizing the healthcare industry and improving the quality of patient care.

Furthermore, {remove brand name} has been collaborating with partners in the manufacturing sector to explore the use of metallic sodium bonds in the development of advanced materials. From lightweight alloys to high-strength composites, metallic sodium bonds have the potential to enhance the performance and durability of various materials used in manufacturing. {remove brand name} has been actively working with industry leaders to bring these innovative materials to the market and drive the next wave of industrial advancement.

As a responsible corporate citizen, {remove brand name} is committed to ensuring the safe and sustainable use of metallic sodium bonds. The company places a strong emphasis on environmental stewardship and is dedicated to developing eco-friendly solutions that leverage the power of metallic sodium bonds without compromising on safety or sustainability. By adhering to rigorous quality and safety standards, {remove brand name} is paving the way for a future where metallic sodium bonds can be used responsibly for the betterment of society.

In conclusion, the discovery of metallic sodium bonds has opened up a world of possibilities for various industries, and {remove brand name} is at the forefront of unlocking the potential of this groundbreaking development. With a strong focus on research and development, {remove brand name} is committed to harnessing the power of metallic sodium bonds and integrating them into practical applications that will shape the future of the chemical and materials science industry. As the world continues to evolve, {remove brand name} is poised to lead the way in driving innovation and advancing the frontiers of science and technology through the power of metallic sodium bonds.

Company News & Blog

Ionic vs. Metal Bonds: Understanding the Key Differences

Ionic And Metal Bonds Combine to Form Innovative New Product LineWith a focus on innovative materials science, {}, a leading chemical company, has recently announced the development of a groundbreaking new product line that combines the unique properties of ionic and metal bonds. This new line of products has the potential to revolutionize various industries, from electronics to pharmaceuticals, with its innovative approach to material design and engineering.Ionic bonds are formed between two atoms when one atom gives up an electron to another. This results in the formation of positively and negatively charged ions which then attract each other, creating a strong bond. On the other hand, metal bonds are formed when metal atoms share their electrons with each other, creating a "sea" of electrons that hold the metal atoms together. By combining these two types of bonds, {} has created a range of materials with unique properties and applications.The new product line, developed by a team of experienced chemists and material scientists at {}, has been designed to offer enhanced conductivity, high tensile strength, and improved corrosion resistance. These properties make the materials ideal for use in electronic components, structural applications, and even medical devices.In the electronics industry, the application of these new materials could lead to the development of faster and more efficient electronic devices. With their enhanced conductivity and durability, the materials could be used to create smaller, more powerful components for smartphones, computers, and other high-tech devices. This could potentially revolutionize the way we use and interact with technology on a daily basis.Furthermore, the high tensile strength and corrosion resistance of these materials make them suitable for a wide range of structural applications. From building materials to aerospace components, these advanced materials have the potential to improve the safety and performance of a variety of products and structures.In the medical industry, the unique properties of the new materials could lead to the development of advanced medical devices with improved biocompatibility and durability. This could have a significant impact on the treatment and management of various medical conditions, leading to better patient outcomes and improved quality of life.The development of this innovative new product line is a testament to {}'s commitment to pushing the boundaries of materials science and engineering. With a focus on research and development, {} has established itself as a leader in the chemical industry, consistently delivering cutting-edge solutions to a diverse range of global challenges.As a company, {} has a long history of innovation and a strong track record of delivering high-quality products to its customers. With a global presence and a commitment to sustainability, {} is well-positioned to drive the adoption of these new materials across various industries, providing sustainable solutions to complex challenges.With the development of this groundbreaking new product line, {} has once again demonstrated its ability to innovate and lead the way in the chemical industry. The potential applications of these new materials are vast, and they have the potential to disrupt and transform a wide range of industries. As the world's demand for advanced materials continues to grow, {}'s new product line could play a significant role in shaping the future of materials science and engineering.

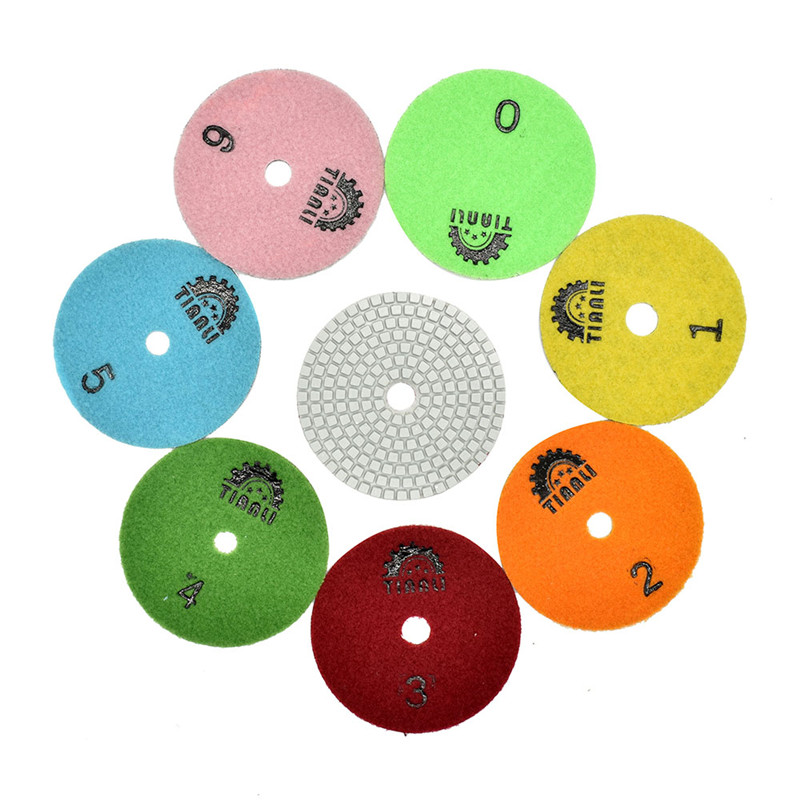

Premium Wet Polishing Pads for Effortless Stone Polishing; Ideal for Marble, Granite, and Concrete Surfaces

Stone Polishing Pads: The Ultimate Guide to Wet Polishing for Marble, Granite, and ConcreteStone polishing is a meticulous process that requires the right tools and techniques to bring out the natural beauty of marble, granite, and concrete. One essential tool in every stone polisher's arsenal is the wet polishing pad. These pads are specially designed to deliver superior results, leaving your surfaces smooth, glossy, and flawless. In this blog post, we will explore the benefits and applications of wet polishing pads, and guide you through the best practices for achieving outstanding results. So, let's dive in!What are Wet Polishing Pads?Wet polishing pads are vital tools used in the stone polishing industry to achieve a mirror-like finish on various types of stones, including marble, granite, and concrete. They are made from high-quality diamond particles that are bonded to a flexible backing material. The diamond particles provide the abrasive qualities needed to grind, shape, and polish the stone surfaces effectively.The wet polishing pads are called so because they are used in conjunction with water or a special polishing lubricant. This water or lubricant serves multiple purposes during the polishing process. Firstly, it acts as a cooling agent, preventing the pads from overheating and causing damage to the stone. Secondly, it helps to eliminate dust and debris, keeping the work area clean. Lastly, the water or lubricant enhances the polishing action, allowing the pad to glide smoothly over the surface, facilitating a faster and more efficient polishing process.Benefits of Wet Polishing Pads:1. Versatility: Wet polishing pads are incredibly versatile tools that can be used on a wide range of stone surfaces. Whether you are working on marble countertops, granite floors, or concrete walls, these pads can effectively deliver exceptional results.2. Superior Polishing Action: Wet polishing pads offer outstanding polishing action, ensuring a high-gloss finish with minimum effort. The diamond particles embedded in the pads provide exceptional grinding power, making it easier to remove scratches, stains, and other imperfections from the stone surfaces.3. Heat Reduction: The use of water or lubricant with wet polishing pads helps to dissipate heat generated during the polishing process. This not only protects the pads from damage but also prevents the stone from cracking or warping due to excessive heat.4. Dust Reduction: Wet polishing pads significantly reduce the generation of dust and debris, ensuring a cleaner and safer work environment. This is particularly important for indoor projects where dust control is crucial.Applications of Wet Polishing Pads:1. Marble Polishing: Marble is a popular choice for countertops, floors, and other decorative elements due to its timeless beauty. Wet polishing pads are highly effective in restoring the luster of marble surfaces, removing etch marks, and bringing out the vibrant colors and natural veining of the stone.2. Granite Polishing: Granite is a durable and elegant stone that is often used in kitchen countertops and high-traffic areas. Wet polishing pads can easily achieve a glossy, mirror-like finish on granite surfaces, enhancing their visual appeal and resistance to staining and wear.3. Concrete Polishing: Concrete is no longer limited to utilitarian purposes; it is now widely used in architectural designs and interior decor. Wet polishing pads can transform plain and dull concrete surfaces into stunning, polished floors, countertops, and walls, adding sophistication and value to any space.Best Practices for Using Wet Polishing Pads:1. Equipment: To achieve optimal results, ensure that you are using the right equipment, including a high-quality variable speed grinder/polisher and the appropriate wet polishing pad designed for the specific stone you are working with.2. Grit Sequence: Wet polishing pads come in varying grit sizes, ranging from coarse to fine. It's important to start with the most aggressive grit pad and gradually work your way up to finer grits to achieve a smooth and glossy finish.3. Pre-Wet: Before using the wet polishing pad, ensure that the pad and stone surface are properly wet. This will prevent the pad from clogging and promote a faster polishing process.4. Proper Technique: Use a consistent and overlapping motion when polishing. This ensures even coverage and minimizes the risk of creating uneven or dull patches on the stone surface.5. Regular Cleaning: Regularly rinse the polishing pad during the process to remove debris and excess residue, maintaining optimal performance.Conclusion:Wet polishing pads are essential tools for achieving exceptional results in stone polishing projects. Their versatility, superior polishing action, heat reduction, and dust control make them the go-to choice for professionals in the industry. Whether you are working with marble, granite, or concrete, wet polishing pads provide the power and precision needed to transform your stone surfaces into stunning works of art. Invest in high-quality wet polishing pads, follow the best practices outlined in this guide, and get ready to witness the transformative results on your next stone polishing endeavor.

High-Quality 100mm Polishing Pads for Professional Detailing

The company, a leading provider of industrial tools, has recently introduced a new line of 100mm Polishing Pads to its wide range of products. These high-quality polishing pads are designed to meet the growing demand for precision and efficiency in the industrial sector.The 100mm Polishing Pads are made with top-grade materials and advanced technology to ensure superior performance and durability. These pads are suitable for use on a variety of surfaces, including metal, concrete, granite, and marble. The company's commitment to quality and innovation is reflected in the design and manufacturing process of these polishing pads, making them an ideal choice for professionals and DIY enthusiasts alike.The company has a long-standing reputation for delivering reliable and efficient industrial tools, and the addition of the 100mm Polishing Pads further solidifies its position as a trusted provider in the industry. With a focus on continuous improvement and customer satisfaction, the company has invested significant resources in research and development to bring cutting-edge products to the market.In addition to their exceptional performance, the 100mm Polishing Pads are also designed for ease of use. The company understands the importance of user-friendly tools in enhancing productivity, and these pads are engineered to provide a smooth and hassle-free polishing experience. Whether for heavy-duty industrial applications or intricate detailing work, these pads deliver consistent results with minimal effort.Furthermore, the 100mm Polishing Pads are part of the company's broader commitment to sustainability. By utilizing eco-friendly materials and energy-efficient manufacturing processes, the company strives to minimize its environmental footprint while delivering products that meet the highest standards of quality and safety.To support the launch of the 100mm Polishing Pads, the company is offering comprehensive customer support and technical assistance. With a team of experienced professionals, customers can rely on the company for expert guidance and assistance in choosing the right polishing pads for their specific requirements. This dedication to customer care is an integral part of the company's philosophy, ensuring that every customer receives the support they need to achieve optimal results.The introduction of the 100mm Polishing Pads is a testament to the company's ongoing commitment to innovation and excellence. By leveraging its expertise and resources, the company continues to expand its product offerings and provide solutions that meet the evolving needs of the industrial sector. With a strong emphasis on quality, performance, and sustainability, these polishing pads are poised to make a significant impact in the market.As the industrial sector continues to evolve, the demand for high-quality tools and equipment remains constant. The release of the 100mm Polishing Pads represents a major milestone for the company and reinforces its position as a leader in the industry. With a focus on innovation and customer satisfaction, the company is well-positioned to meet the diverse needs of its clientele and maintain its reputation as a trusted provider of industrial tools.

Diamond Holder Tool: The Ultimate SEO Title to Optimize Your Strategies

**Title: Revolutionary Diamond Holder Tool Revolutionizes Jewelry Manufacturing****Introduction**Diamond Holder Tool, a revolutionary piece of equipment in the jewelry manufacturing industry, is set to transform the way diamonds are handled and set in jewelry. This innovative tool, developed by a leading jewelry equipment manufacturer, aims to optimize the stone-setting process by improving precision, efficiency, and safety. With its unique design and advanced features, the Diamond Holder Tool promises to streamline manufacturing processes, reduce costs, and elevate the overall quality of diamond-set jewelry. This article delves into the key features and benefits of this groundbreaking tool, emphasizing its potential to revolutionize the jewelry manufacturing industry.**Enhanced Precision and Efficiency**The Diamond Holder Tool's design centers around its ability to securely hold diamonds of various sizes while granting jewelers maximum control and precision during the setting process. Unlike traditional diamond holders, this tool combines a specialized gripping mechanism with state-of-the-art micro-adjustment technology, enabling jewelers to securely position diamonds with unrivaled accuracy. The tool's intuitive design ensures that diamonds remain firmly in place throughout the setting process, eliminating the risk of accidental displacement or damage.This heightened precision not only decreases the possibility of mistakes but also significantly reduces the time and effort required for precise stone placement. With the Diamond Holder Tool, jewelers can execute intricate diamond setting designs with ease, expediting the manufacturing timeline and increasing overall productivity. The tool's efficiency-enhancing features make it an indispensable asset for high-volume jewelry manufacturers, enabling them to meet demanding production deadlines without compromising quality.**Enhanced Safety and Security**Jewelers often grapple with the precarious task of securing diamonds while minimizing the risk of injury. The Diamond Holder Tool incorporates cutting-edge safety features that are designed to protect both the jewelers and the valuable gems they work with. Equipped with a comprehensive locking mechanism, the tool ensures that diamonds remain firmly in place at all times, reducing the risk of accidental slippage or falling. This eliminates the need for jewelers to hold and maneuver the diamonds manually, minimizing the potential for accidental injury.Furthermore, the Diamond Holder Tool's ergonomically designed grip enhances comfort and reduces hand strain during extended work periods. The tool's lightweight construction and optimized handle design contribute to a seamless and effortless user experience, allowing jewelers to maintain focus and attentiveness while working. By prioritizing worker safety, the Diamond Holder Tool establishes itself as a key asset in the pursuit of injury-free, efficient, and productive jewelry manufacturing processes.**Streamlined Manufacturing Process and Cost Reduction**The incorporation of the Diamond Holder Tool into existing jewelry manufacturing workflows can result in significant cost savings. Its innovative design eliminates the need for additional equipment or intricate setups, simplifying the manufacturing process and reducing investment costs. Moreover, the tool's efficiency and precision contribute to a reduction in labor costs, as jewelers can complete stone-setting tasks in a shorter amount of time. This not only accelerates the production cycle but also allows manufacturers to allocate resources more efficiently, boosting profitability.By empowering jewelers to achieve higher levels of precision and efficiency, the Diamond Holder Tool facilitates the production of high-quality diamond-set jewelry at a faster pace. This not only enables manufacturers to meet growing market demands but also provides them with a competitive edge within the industry. Moreover, the tool's user-friendly design requires minimal training, allowing manufacturers to seamlessly integrate it into their existing workflows without significant disruptions or downtime.**Conclusion**The Diamond Holder Tool's introduction into the jewelry manufacturing industry promises to revolutionize the way diamonds are set in jewelry. With its focus on precision, efficiency, safety, and cost reduction, this groundbreaking tool is set to become an essential asset for jewelers and manufacturers worldwide. The Diamond Holder Tool's impact on the industry is expected to be transformative, promoting streamlined manufacturing processes, enhancing worker safety, and ultimately elevating the overall quality of diamond-set jewelry. As the jewelry manufacturing industry continues to evolve, this innovative tool is poised to play an instrumental role in its advancement.

Borazon Grinding Wheels: A Comprehensive GuideWhen it comes to high-performance grinding, it's essential to use the right tools for the job. That's where Borazon grinding wheels come in. These wheels are made from cubic boron nitride (CBN), a material that is second only to diamond in terms of hardness. In this blog, we'll explore everything you need to know about Borazon grinding wheels, including their advantages, applications, and how to choose the right one for your needs.Advantages of Borazon Grinding WheelsThe main advantage of Borazon grinding wheels is their exceptional hardness. This makes them ideal for grinding hard materials that are difficult to process with traditional grinding wheels. Borazon wheels also have high abrasive resistance, which means they last longer and require less frequent replacement. Other advantages of these wheels include:• Excellent heat resistance: Borazon wheels can withstand high temperatures without cracking or degrading, making them ideal for applications that generate a lot of heat.• Superior surface finish: Borazon wheels create a smooth, precise surface finish that is free from burrs and other imperfections.• Versatile applications: Borazon wheels can be used to grind a wide range of materials, including hardened steels, cast iron, and superalloys.Applications of Borazon Grinding WheelsBorazon grinding wheels are used in a variety of applications, including:• Aerospace: Borazon wheels are used to grind turbine blades, engine parts, and other components used in the aerospace industry.• Automotive: These wheels are also used in the automotive industry to grind crankshafts, camshafts, and other engine components.• Medical: Borazon wheels are used to grind medical implants, such as hip replacements and dental implants, to ensure a precise fit.• Tool and die: These wheels can be used to grind cutting tools, such as drill bits, taps, and end mills, as well as dies and molds.Choosing the Right Borazon Grinding WheelChoosing the right Borazon grinding wheel depends on several factors, including the material you're grinding, the desired finish, and the type of machine you're using. Here are some tips to help you choose the right wheel:• Determine the hardness of the material you're grinding: Borazon wheels are best suited for grinding hard materials, so if you're grinding a soft material, you may want to consider a different type of wheel.• Consider the grit size: Borazon wheels come in a range of grit sizes, which determine how coarse or fine the abrasive particles are. Choose a finer grit for a smoother finish and a coarser grit for a more aggressive cut.• Check the compatibility with your machine: Make sure that the wheel you choose is compatible with your grinding machine. This includes checking the wheel diameter, arbor size, and maximum RPM.• Consult with a supplier: If you're unsure which wheel to choose, consult with a supplier who specializes in Borazon grinding wheels. They can help you determine the best option based on your specific needs.ConclusionBorazon grinding wheels are an essential tool for grinding hard materials to a precise finish. With their exceptional hardness, heat resistance, and abrasive resistance, these wheels offer many advantages over traditional grinding wheels. When choosing a Borazon wheel, consider the material you're grinding, the desired finish, and the compatibility with your machine. With the right wheel, you can achieve superior results and increase productivity in your grinding operations.

How to Use a Dry Polishing Pads Kit for Granite Countertops

Introducing a New Innovation in Granite Polishing: Dry Polishing Pads Kit Brings Unmatched Quality and Efficiency to Stone FabricationAs the demand for high-quality granite and stone fabrication continues to soar, the need for advanced and efficient polishing solutions has never been more critical. In response to this demand, the team at [Company Name] is delighted to unveil the Dry Polishing Pads Kit, a groundbreaking product that promises to revolutionize the way granite and stone surfaces are polished.Designed to meet the evolving needs of stone fabricators and installers, the Dry Polishing Pads Kit represents the culmination of years of industry experience and a relentless dedication to innovation and excellence. With a focus on unparalleled quality, efficiency, and ease of use, this exciting new product is poised to set a new standard for granite polishing.The Dry Polishing Pads Kit is the result of exhaustive research and development, combined with the latest advancements in polishing technology. By harnessing the power of advanced abrasives and cutting-edge bonding materials, this innovative product delivers a level of performance that is simply unmatched in the industry.One of the key features of the Dry Polishing Pads Kit is its ability to eliminate the need for water during the polishing process. This not only streamlines the fabrication and installation process but also minimizes the mess and clean-up associated with traditional wet polishing methods. With this new dry polishing solution, fabricators can achieve exceptional results with unprecedented speed and precision, all while maintaining a clean and organized work environment.In addition to its superior performance, the Dry Polishing Pads Kit is also incredibly versatile, making it suitable for a wide range of applications. Whether it's polishing granite, marble, or other types of stone, this innovative product delivers exceptional results across the board. From intricate details to large surface areas, the Dry Polishing Pads Kit is capable of meeting the diverse needs of stone fabricators with ease.At [Company Name], our commitment to excellence goes beyond our products. We take great pride in providing our customers with the highest level of service and support, ensuring that they have everything they need to succeed. With the introduction of the Dry Polishing Pads Kit, we are furthering our mission to empower our customers with the tools and resources they need to thrive in a competitive industry.In addition to offering superior quality and performance, the Dry Polishing Pads Kit also represents exceptional value. By streamlining the polishing process and minimizing the need for water and additional supplies, fabricators can enjoy significant cost savings without sacrificing results. This makes the Dry Polishing Pads Kit a smart investment for any stone fabrication business looking to enhance its efficiency and profitability.As we look to the future, the team at [Company Name] is excited to continue pushing the boundaries of innovation in the stone fabrication industry. The Dry Polishing Pads Kit is just the latest example of our unwavering commitment to delivering cutting-edge solutions that meet the evolving needs of our customers. We are confident that this groundbreaking product will make a meaningful impact on the industry and help our customers achieve new levels of success.In conclusion, the introduction of the Dry Polishing Pads Kit represents a significant milestone for [Company Name] and a game-changer for the stone fabrication industry as a whole. With its unmatched quality, efficiency, and versatility, this innovative product is poised to redefine the standard for granite polishing and set a new benchmark for excellence. We are thrilled to bring this groundbreaking solution to our customers and look forward to the positive impact it will have on their businesses.

Shop Top-Quality Supplies for Concrete Countertops and Floors: Polishing Pads, Sealers, Stains, and More

Concrete Exchange: The One-Stop Shop for All Your Concrete NeedsConcrete has grown in popularity as a material for interior and exterior design in recent years. From polished concrete floors to concrete countertops, it’s hard to miss the sleek and modern look it lends to any space.At Concrete Exchange, we are passionate about helping you create beautiful and functional concrete surfaces. Our extensive collection of supplies includes everything you need to make concrete countertops, decorative concrete sealers, stains, and epoxy floor coating. We also offer floor leveling and patch products along with moisture mitigation and subfloor primers from trusted brands like Schonox, USG Durock, Surecrete, Sika, Cheng, and Interstar – to name a few.But why choose Concrete Exchange over other suppliers?Quality ProductsWe pride ourselves on providing high-quality products that deliver consistent results. Our diamond polishing pads, for instance, are made from high-quality materials and are specially designed to polish concrete surfaces to perfection. They come in various grit levels, making it easy to achieve the desired level of polish for your project.Easy Online OrderingOur website is user-friendly, making it easy to find what you need and place your order. We offer fast and reliable shipping, with most orders delivered within a few business days. And if you need assistance, our team is always ready to help.Expert AdviceWe don’t just provide products, we also offer expert advice on how to use them. Whether you’re a seasoned pro or new to the world of concrete, our team is always available to provide guidance and answer any questions you may have.SustainabilityWe believe in sustainability and reducing waste, which is why we offer reusable silicone molds for creating concrete countertops and other surfaces. This not only reduces waste but also saves you money in the long run.Final ThoughtsAt Concrete Exchange, we are committed to providing quality products, easy ordering, expert advice, and sustainability. Whether you’re a homeowner or a contractor, we have everything you need to create beautiful and functional concrete surfaces. So, if you’re looking for diamond floor polishing pads or any other concrete supplies, look no further than Concrete Exchange – your one-stop shop for all your concrete needs!

High-Quality Wire Brush Grinding Wheel for Precision Grinding Tasks

Wire Brush Grinding Wheel is an essential tool used in various industries for grinding, deburring, and polishing metal surfaces. This type of grinding wheel is known for its efficiency in removing rust, paint, and other surface coatings, making it a highly popular choice among professionals and DIY enthusiasts.With the ever-increasing demand for high-quality wire brush grinding wheels, {Company Name} has emerged as a leading manufacturer and supplier in the industry. Their commitment to excellence and innovation has led to the development of a wide range of wire brush grinding wheels designed to meet the diverse needs of their customers.{Company Name} is dedicated to ensuring that their wire brush grinding wheels are of the highest quality, using only the finest materials and state-of-the-art manufacturing processes. Each wheel is thoroughly tested to ensure durability, performance, and safety, making them a reliable choice for a wide range of applications.One of the key features of {Company Name}'s wire brush grinding wheels is their superior abrasive material, which enables efficient and precise grinding without causing damage to the workpiece. This makes them ideal for applications such as metal fabrication, automotive repair, and general maintenance.In addition to their exceptional performance, {Company Name} also offers a variety of wire brush grinding wheel designs to accommodate different grinding needs. Whether it's a standard wheel for general grinding or a specialized wheel for specific applications, customers can rely on {Company Name} to provide the perfect solution.Moreover, {Company Name} prides itself on its dedication to customer satisfaction, offering personalized service and support to help customers find the right wire brush grinding wheel for their needs. Their team of experienced professionals is always available to provide expert advice and assistance, ensuring that customers can make informed decisions.{Company Name} also places a strong emphasis on sustainability, incorporating eco-friendly practices into their manufacturing process to reduce their environmental impact. This commitment to sustainability is reflected in their use of recyclable materials and energy-efficient production techniques, making their wire brush grinding wheels an environmentally responsible choice.Furthermore, {Company Name} is constantly striving to stay ahead of the curve by investing in research and development to improve their products and introduce new innovative solutions to the market. This dedication to innovation has allowed them to remain at the forefront of the industry, providing customers with cutting-edge wire brush grinding wheel technology.As a testament to their commitment to quality and excellence, {Company Name} has received numerous accolades and certifications for their wire brush grinding wheels, further validating their position as a trusted industry leader. These recognitions serve as a testament to their relentless pursuit of perfection and their unwavering dedication to customer satisfaction.In conclusion, {Company Name} has established itself as a premier manufacturer and supplier of wire brush grinding wheels, offering a comprehensive range of high-quality products designed to meet the diverse needs of their customers. With their unwavering commitment to excellence, innovation, and customer satisfaction, {Company Name} continues to set the standard for wire brush grinding wheels in the industry. Their dedication to quality, sustainability, and customer support makes them a reliable and trusted partner for all grinding needs.

Latest News on High-Quality Polish Diamonds: What You Need to Know

Polish Diamond, a leading provider of high-quality jewelry manufacturing and distribution, has been making waves in the jewelry industry with its exquisite and innovative designs. With a focus on delivering top-notch products and unparalleled customer service, Polish Diamond has quickly become a trusted name in the world of luxury jewelry.Founded in 2005, Polish Diamond has always been committed to excellence in every aspect of its business. From sourcing the finest diamonds and gemstones to creating stunning, one-of-a-kind pieces, the company has set itself apart with its uncompromising dedication to craftsmanship and quality. With a team of skilled artisans and designers, Polish Diamond has been able to produce jewelry that not only meets but exceeds the highest standards in the industry.One of the key factors that sets Polish Diamond apart from its competitors is its commitment to ethical sourcing and responsible business practices. The company takes great care to ensure that all its diamonds and gemstones are sourced from reputable suppliers who adhere to strict ethical and environmental standards. Additionally, Polish Diamond is actively involved in various corporate social responsibility initiatives, supporting local communities and environmental causes.In addition to its commitment to ethical sourcing, Polish Diamond also prides itself on its ability to stay ahead of the curve when it comes to design and innovation. The company's talented team of designers is constantly pushing the boundaries of traditional jewelry design, creating pieces that are not only visually stunning but also highly functional and wearable. From classic diamond solitaire rings to modern, avant-garde statement pieces, Polish Diamond offers something for every taste and style.Polish Diamond's dedication to innovation is further demonstrated through its use of advanced technology in the jewelry manufacturing process. The company utilizes state-of-the-art equipment and cutting-edge techniques to ensure that each piece of jewelry is crafted with precision and attention to detail. This commitment to excellence has earned Polish Diamond a reputation for producing some of the most beautifully crafted and flawlessly finished pieces in the industry.Moreover, Polish Diamond understands the importance of providing exceptional customer service. The company's knowledgeable and friendly staff is always ready to assist clients with any questions or requests, and they go above and beyond to ensure that every customer has a positive and memorable experience. Whether it's helping a client find the perfect engagement ring or providing expert guidance on jewelry care and maintenance, Polish Diamond is dedicated to building lasting relationships with its customers.As a company that values quality, integrity, and innovation, Polish Diamond has quickly risen to the top of the jewelry industry. With a steadfast commitment to excellence and a passion for creating breathtaking pieces, the company continues to captivate the hearts of jewelry lovers worldwide. Whether it's a dazzling diamond necklace, a sparkling pair of earrings, or a timeless engagement ring, Polish Diamond is the go-to destination for those who seek only the best in luxury jewelry.Looking ahead, Polish Diamond remains focused on expanding its reach and continuing to push the boundaries of jewelry design and craftsmanship. With a clear vision for the future and an unwavering dedication to its core values, Polish Diamond is set to continue its reign as a leader in the world of luxury jewelry for years to come. For those who appreciate the finest in quality and artistry, Polish Diamond is the ultimate destination for exquisite, timeless jewelry pieces.

High-Quality Dry Diamond Polishing Pads for Granite

In the world of stone fabrication and restoration, having the right tools and equipment is essential for achieving high-quality results. One essential tool for polishing granite and other natural stone surfaces is the Dry Diamond Polishing Pads. These polishing pads are an indispensable part of the arsenal of any stone fabricator or restoration specialist, providing the ability to achieve a flawless, high-gloss finish on granite and other hard surfaces.The Dry Diamond Polishing Pads are designed to be used with a high-speed angle grinder or polisher, making them a versatile and efficient tool for professionals in the stone fabrication and restoration industry. These pads are engineered to deliver exceptional results while also maximizing efficiency and productivity.One of the key features of the Dry Diamond Polishing Pads is their durability and longevity. These pads are constructed using high-quality diamonds, which are known for their hardness and resistance to wear. As a result, these polishing pads are able to withstand the rigors of the demanding stone fabrication and restoration process, allowing professionals to rely on them for consistent performance and results.In addition to their durability, the Dry Diamond Polishing Pads are also designed for ease of use. The velcro backing on the pads makes them easy to attach and remove from a polishing tool, allowing for quick and efficient pad changes as needed. This feature is particularly important in a fast-paced fabrication or restoration environment, where time is of the essence.The versatility of the Dry Diamond Polishing Pads is another factor that sets them apart from other polishing tools on the market. These pads are suitable for use on a wide range of natural stone surfaces, including granite, marble, and quartz. This means that professionals can rely on these pads for multiple applications, reducing the need for multiple sets of polishing pads for different types of stone.When it comes to achieving a flawless, high-gloss finish on granite and other hard surfaces, the Dry Diamond Polishing Pads are an indispensable tool for professionals in the stone fabrication and restoration industry. With their durability, ease of use, and versatility, these pads have become a go-to choice for professionals who demand the best results for their clients.In addition to the Dry Diamond Polishing Pads, our company, {Company Name}, offers a comprehensive range of tools, equipment, and supplies for the stone fabrication and restoration industry. Our commitment to providing high-quality products and exceptional customer service has made us a trusted partner for professionals in this industry.With a focus on innovation and quality, we continuously strive to bring the latest advancements in stone fabrication and restoration tools to our customers. Our team of experts is dedicated to providing industry-leading solutions that enable our customers to achieve outstanding results for their clients.In conclusion, the Dry Diamond Polishing Pads are an essential tool for professionals in the stone fabrication and restoration industry, offering durability, ease of use, and versatility. When combined with the comprehensive range of tools, equipment, and supplies offered by {Company Name}, professionals have everything they need to achieve exceptional results for their clients. With a commitment to innovation and quality, {Company Name} is the go-to source for professionals in the stone fabrication and restoration industry.