How to Choose the Best Wet Polisher for Granite

By:Admin

[Company Name] is a leading manufacturer of professional-grade tools and equipment for the stone and construction industries. With a commitment to quality and innovation, the company has established itself as a go-to source for reliable and high-performance products. Their range of wet polishers, grinders, and other stone fabrication tools are trusted by professionals around the world for their durability, precision, and efficiency.

The new [Granite Wet Polisher] is a testament to [Company Name]'s dedication to meeting the evolving needs of their customers. Designed to deliver exceptional results on granite surfaces, this wet polisher boasts a range of features that set it apart from the competition. With a powerful motor and adjustable water flow, it ensures smooth and consistent polishing, while reducing the risk of over-heating and prolonging the lifespan of the polishing pads. Additionally, its lightweight and ergonomic design make it easy to handle, resulting in less fatigue and greater control for the operator.

One of the standout features of the [Granite Wet Polisher] is its variable speed control, which allows users to customize the polishing process to suit the specific requirements of the job. Whether working on a delicate edge or a large flat surface, the ability to adjust the speed ensures that the desired finish is achieved with precision and efficiency. This level of versatility is a game-changer for professionals who work with a variety of granite surfaces and need a tool that can adapt to different tasks.

In addition to its performance capabilities, the [Granite Wet Polisher] is also designed with the user's convenience in mind. The tool features a splash guard to minimize water spray and keep the workspace clean, as well as a durable housing that offers protection against dust and debris. Furthermore, it is compatible with a wide range of polishing pads, making it a versatile and cost-effective investment for businesses of all sizes.

To ensure that their customers get the most out of the new [Granite Wet Polisher], [Company Name] also provides comprehensive support and resources. From online tutorials and troubleshooting guides to responsive customer service, they are committed to helping users maximize the potential of their equipment and achieve outstanding results on every project.

The launch of the new [Granite Wet Polisher] has generated significant excitement within the stone fabrication and construction industries. Professionals who have had the opportunity to test the tool have praised its performance, highlighting its efficiency, ease of use, and the quality of the finishes it produces. As word continues to spread, it is expected that the [Granite Wet Polisher] will become a staple in workshops and job sites around the world, further solidifying [Company Name]'s reputation as a leader in the industry.

In conclusion, the introduction of the new and improved [Granite Wet Polisher] by [Company Name] represents a significant advancement in the field of stone fabrication and finishing. With its exceptional performance capabilities, user-friendly design, and comprehensive support, it is poised to become an indispensable tool for professionals working with granite surfaces. As [Company Name] continues to innovate and elevate the standards of quality and efficiency, they are setting a new standard for the industry as a whole.

Company News & Blog

High-Quality Floor Pads for Polishing and Cleaning Diamond Flooring

Diamond Floor Pads: Revolutionizing Floor CleaningIn today's fast-paced world, maintaining cleanliness and hygiene in commercial and residential spaces is more important than ever. Whether it's a restaurant, office building, or home, clean and shiny floors play a crucial role in creating a positive impression on visitors and maintaining a healthy environment.The key to achieving spotless and sparkling floors lies in using the right cleaning tools and techniques. While traditional floor cleaning methods can be labor-intensive and time-consuming, innovations in the cleaning industry have led to the development of advanced products that make the task more efficient and effective.One such groundbreaking product is the Diamond Floor Pad, a revolutionary cleaning tool that is redefining the way floors are maintained and restored. Unlike conventional floor pads, Diamond Floor Pads are embedded with industrial-grade diamonds, which give them unparalleled cleaning and polishing capabilities.These innovative floor pads are the brainchild of {}, a leading provider of high-quality cleaning solutions for commercial and residential use. With a commitment to delivering cutting-edge products that streamline cleaning processes and elevate cleanliness standards, {} has earned a reputation for excellence in the industry.The Diamond Floor Pads offered by {} are designed to deliver exceptional performance on a wide range of floor surfaces, including terrazzo, marble, concrete, and granite. The industrial-grade diamonds embedded in the pads work to effectively remove dirt, grime, and scuff marks, leaving floors with a lustrous shine that enhances the overall appearance of the space.One of the most remarkable features of Diamond Floor Pads is their versatility. Whether it's routine maintenance, deep cleaning, or restoration of worn-out floors, these pads are capable of delivering outstanding results, making them a cost-effective solution for floor care needs.In addition to their superior cleaning and polishing capabilities, Diamond Floor Pads are also engineered for durability and longevity. The industrial-grade diamonds are firmly bonded to the pads, ensuring that they retain their effectiveness over extended periods of use. This durability not only reduces the frequency of pad replacements but also minimizes the environmental impact by reducing waste.Committed to sustainability and eco-friendly practices, {} emphasizes the use of environmentally responsible materials and manufacturing processes in the production of Diamond Floor Pads. This focus on sustainability aligns with the growing demand for green cleaning solutions in the industry and underscores {}'s dedication to meeting the evolving needs of its customers.To further maximize the benefits of Diamond Floor Pads, {} provides comprehensive training and support to cleaning professionals, equipping them with the knowledge and skills to utilize the pads effectively. By empowering cleaning teams with the right tools and techniques, {} aims to enhance the efficiency and quality of floor maintenance across various industries.As the demand for efficient and high-performance cleaning solutions continues to rise, Diamond Floor Pads have emerged as a game-changer in the industry, setting new standards for floor care. Their ability to deliver superior results while promoting sustainability and cost-effectiveness makes them a preferred choice for businesses and homeowners alike.Moving forward, {} remains committed to advancing the development of innovative cleaning solutions, with a focus on delivering products that elevate cleanliness standards, streamline cleaning processes, and contribute to a healthier and more sustainable environment. Through its ongoing commitment to excellence and innovation, {} is poised to remain a leader in the cleaning industry, driving positive change and redefining the way floors are cleaned and maintained.

Unveiling the Ultimate Collection of 8 Polishing Pads: A Must-Have for Precision Car Detailing

Title: Industry Leader Launches Innovative Polishing Pads for a Superior ShineIntroduction:In a bid to revolutionize the automotive detailing industry, one of the leading manufacturers of car care products has unveiled a cutting-edge line of Polishing Pads. These innovative pads promise to provide a superior shine while streamlining the polishing process. With a commitment to excellence and a focus on customer satisfaction, the company aims to set a new benchmark in automotive detailing.Brand's Pioneering Legacy:With a rich history spanning over two decades, this prominent manufacturer has earned a reputation for producing top-quality car care products. The brand's commitment to innovation and quality has consistently placed it at the forefront of the industry. Through extensive research and development, the company has continuously pushed boundaries to provide car enthusiasts and professionals with the most effective solutions.Unveiling the Revolutionary Polishing Pads:Committed to delivering exceptional results, the brand brings forth its groundbreaking line of Polishing Pads. Developed after years of research, these pads are engineered to address the most common challenges faced by automotive detailers. They guarantee a professional-grade finish and an unmatched shine, bringing out the true beauty of any vehicle.1. Advanced Material Technology:The introduction of these Polishing Pads showcases the brand's dedication to technological advancement. Featuring an innovative blend of abrasives and foams, these pads offer enhanced cutting power and improved performance. The unique composite material allows for efficient removal of imperfections, fine scratches, and swirl marks.2. Customized Solutions:Recognizing that no two polishing jobs are the same, the brand has introduced a range of eight specialized Polishing Pads to cater to various needs. Offering different levels of aggressiveness, these pads are designed to accommodate varying paint types, hardness, and surface conditions. This ensures that professionals and enthusiasts can achieve optimal results for any vehicle type.3. Ergonomic Design:The brand's commitment to user-friendly products is evident in the design of its Polishing Pads. The pads are crafted with precision and attention to detail, featuring a comfortable grip and strategic contours. This ergonomic design ensures ease of use and prevents hand fatigue during long polishing sessions, enabling detailers to work efficiently without compromising on quality.4. Longevity and Durability:The durability of these Polishing Pads is another area where the brand truly excels. Built to withstand the rigors of professional use, these pads are engineered to deliver consistent performance even under demanding conditions. Their long lifespan ensures that users can rely on them for multiple projects, making them a cost-effective choice for both professionals and hobbyists.5. Environmentally Conscious Approach:Amid growing concerns about environmental sustainability, the brand has demonstrated responsible manufacturing practices with these Polishing Pads. By adhering to stringent eco-friendly standards, the company minimizes its carbon footprint while delivering industry-leading products. This commitment to the environment showcases the brand's dedication to overall well-being and responsible business practices.Conclusion:With the launch of its state-of-the-art Polishing Pads, this industry-leading manufacturer continues to push boundaries and redefine automotive detailing standards. Combining cutting-edge technology, customizability, and ergonomic design, these pads are poised to become an essential tool for both professionals and enthusiasts. As the brand's commitment to excellence remains unwavering, automotive enthusiasts can now look forward to achieving a superior shine with ease and precision.

Discover the Benefits of Cutting Wheels and Grinding Wheels for Industrial Applications

article about the benefits of using cutting and grinding wheels in various industrial applications.Cutting Wheel And Grinding Wheel - Innovative Tools for Industrial ApplicationsCutting and grinding wheels have become popular tools in various industrial applications. These tools are often used in the metalworking industry, fabricated metals, construction, and other industries where cutting and grinding are required. Cutting and grinding wheels are made from abrasive materials that can cut through or grind away different types of materials such as metals, ceramics, glass, and more. Among the various brands available in the market, (BRAND NAME) brand cutting and grinding wheels are considered to be one of the most durable and effective tools. Let's discuss the benefits of using cutting and grinding wheels in different industrial applications.Metalworking Industry - Cutting and grinding wheels are often used in metalworking to shape and mold metals into specific shapes and sizes. These tools are beneficial for metal cutting and grinding operations, as they require less effort and human intervention. A good-quality cutting wheel can cut through various types of metals such as steel, aluminum, and iron. Similarly, grinding wheels are used for creating precise edges on metal surfaces and to remove rust and other impurities from metal surfaces. (BRAND NAME) brand cutting and grinding wheels are ideal for metalworking, as they are made of high-quality abrasive materials that can withstand high pressure and extreme temperatures.Fabricated Metals - Fabricated metals are often used in industry applications such as automobile manufacturing, aerospace, and construction. Cutting and grinding wheels are required to cut through such metals into desired shapes and sizes. (BRAND NAME) brand cutting and grinding wheels are an ideal choice for cutting and grinding various fabricated metals, as they are designed to withstand high pressure and heat.Construction Industry - Cutting and grinding wheels are widely used in the construction industry for cutting and grinding concrete, asphalt, and other materials. Diamond cutting wheels are often used in construction applications as they are strong and durable and can easily cut through hard materials. (BRAND NAME) brand diamond cutting wheels are made from high-quality diamond abrasive material and are ideal for cutting concrete and other hard materials.Automobile Industry - Cutting and grinding wheels are also used in the automobile industry. These tools are used in various operations such as cutting, grinding, and polishing automobile parts. (BRAND NAME) brand cutting and grinding wheels are ideal for the automobile industry, as they are designed to cut through materials used in automobile manufacturing such as aluminum, steel, and plastics.In conclusion, cutting and grinding wheels are essential tools in various industrial applications. These tools are designed to cut and grind through various materials efficiently and effectively. (BRAND NAME) brand cutting and grinding wheels are one of the most innovative tools available in the market, designed to withstand high pressure and extreme temperatures. Therefore, when choosing a cutting or grinding wheel, it is crucial to choose a brand that can provide you with durable and long-lasting tools.

Durable and Efficient 4.5 Inch Grinding Wheel for Industrial Use

4.5-Inch Grinding Wheel: The Latest Innovation from a Leading Manufacturing CompanyIn the world of manufacturing, precision and efficiency are paramount. Companies are constantly on the lookout for the latest innovations and technologies that can help them achieve their production goals with superior quality and cost-effectiveness. One such innovation that has recently hit the market is the 4.5-inch grinding wheel, developed and manufactured by [Company Name].[Company Name] has a long-standing reputation as a leader in the manufacturing industry, specializing in the production of high-quality abrasives, cutting tools, and precision equipment. With a commitment to innovation and excellence, the company has continuously pushed the boundaries of what is possible in the world of manufacturing.The 4.5-inch grinding wheel is the latest addition to [Company Name]'s extensive product lineup, and it is already making waves in the industry. With its advanced design and cutting-edge materials, this grinding wheel is designed to deliver unparalleled performance and efficiency, making it an essential tool for any manufacturing operation.One of the key features of the 4.5-inch grinding wheel is its superior durability and longevity. Made from high-quality abrasive materials, this grinding wheel is designed to withstand the rigors of heavy-duty use, ensuring that it maintains its sharpness and effectiveness over time. This not only helps to improve the quality of the finished product, but also reduces the need for frequent replacements, ultimately saving manufacturing companies time and money.In addition to its durability, the 4.5-inch grinding wheel also offers exceptional precision and accuracy. Its carefully engineered design ensures that it delivers uniform and consistent results, allowing manufacturers to achieve the exact specifications and tolerances required for their products. This level of precision is crucial in industries such as aerospace, automotive, and medical device manufacturing, where even the slightest deviation can have significant consequences.Furthermore, the 4.5-inch grinding wheel is designed for versatility, making it suitable for a wide range of applications. Whether it is used for shaping, sharpening, or smoothing, this grinding wheel is capable of handling various materials, including metal, stone, and concrete. This versatility makes it an invaluable tool for manufacturing companies that work with diverse materials and components.To complement the launch of the 4.5-inch grinding wheel, [Company Name] is offering comprehensive support and service to its customers. This includes technical assistance, training programs, and expert advice on best practices for using the grinding wheel. By providing this level of support, the company aims to ensure that its customers are able to maximize the benefits of this innovative product and achieve optimal results in their manufacturing processes.The release of the 4.5-inch grinding wheel underscores [Company Name]'s ongoing commitment to pushing the boundaries of innovation in the manufacturing industry. By developing products that are not only technologically advanced but also practical and cost-effective, the company is helping to drive the success and competitiveness of manufacturing companies around the world.As the industry continues to evolve, [Company Name] remains at the forefront, continuously developing new solutions that address the ever-changing needs of manufacturers. With the launch of the 4.5-inch grinding wheel, the company has once again demonstrated its dedication to providing cutting-edge products that empower manufacturers to achieve excellence in their production processes.In conclusion, the release of the 4.5-inch grinding wheel marks a significant milestone for [Company Name] and the manufacturing industry as a whole. With its advanced design, superior performance, and comprehensive support, this grinding wheel is poised to make a lasting impact on manufacturing operations, setting a new standard for precision and efficiency in the industry. As manufacturing companies continue to seek out the latest innovations, the 4.5-inch grinding wheel represents a compelling solution that is sure to be embraced by manufacturers looking to elevate their production capabilities.

High Quality Grinding Wheels for Diamond and CBN Materials

A leading manufacturer in the industry, we strive to continuously innovate and provide our customers with the highest quality products. In line with our commitment to excellence, we are thrilled to introduce our latest addition to our product line – the Diamond CBN Grinding Wheels.Our Diamond CBN Grinding Wheels are designed to meet the demands of today’s grinding applications. Whether you are working with ferrous metals, non-ferrous metals, or even hardened steel, our grinding wheels are engineered to deliver outstanding performance and exceptional results. With their superior cutting ability and longer lifespan, our Diamond CBN Grinding Wheels are the perfect choice for precision grinding operations.What sets our Diamond CBN Grinding Wheels apart from the competition is the use of high-quality materials and advanced manufacturing techniques. Each wheel is meticulously crafted with diamond and cubic boron nitride abrasives, allowing for efficient stock removal and exceptional surface finish. Additionally, our wheels are designed to minimize heat generation, reducing the risk of workpiece deformation and achieving greater accuracy in the grinding process.Furthermore, our Diamond CBN Grinding Wheels are engineered to enhance productivity and reduce downtime. Their excellent durability and resilience ensure prolonged use without compromising performance, ultimately resulting in cost savings for our customers. From tool and cutter grinding to the sharpening of high-speed steel and carbide tools, our wheels consistently deliver outstanding results, making them an indispensable asset in any machining environment.In addition to their exceptional performance, our Diamond CBN Grinding Wheels are also designed with user convenience in mind. The wheels are easily mountable and compatible with a wide range of grinding machines, ensuring seamless integration into your existing workflow. With our commitment to providing comprehensive solutions, we offer various wheel configurations to accommodate different grinding operations, allowing our customers to maximize their efficiency and achieve optimal results.To ensure the highest standard of quality, our Diamond CBN Grinding Wheels undergo rigorous testing and inspection processes. Each wheel is meticulously inspected for dimensional accuracy, balance, and overall quality to guarantee consistent performance and reliability. As a result, our customers can have full confidence in the durability and effectiveness of our grinding wheels, knowing that they are investing in a product that will consistently deliver exceptional results.Our dedication to customer satisfaction extends beyond the quality of our products. We understand that our customers may have diverse needs and specific requirements, which is why we offer customizable options for our Diamond CBN Grinding Wheels. Whether you require a specific wheel diameter, abrasive grit size, or special wheel profile, we can work with you to create a tailored solution that meets your unique needs.As a leading manufacturer in the industry, we are committed to providing innovative products that elevate our customers' success. Our Diamond CBN Grinding Wheels exemplify our dedication to excellence, setting a new standard for precision grinding solutions. With their unparalleled performance, durability, and versatility, our grinding wheels are the go-to choice for professionals who demand nothing but the best.In conclusion, our Diamond CBN Grinding Wheels are the result of extensive research, development, and optimization, making them an indispensable asset in any grinding operation. Backed by our unwavering commitment to quality and innovation, our grinding wheels are poised to revolutionize the way you approach precision grinding. Unlock the full potential of your grinding processes with our Diamond CBN Grinding Wheels, and experience the difference that superior quality and performance can make in your operations.

The Latest Development in Metal Halogen Bonds

Metal Halogen Bonds: The Next Frontier in Chemical InnovationIn recent years, the field of chemical research and development has seen remarkable advancements in the area of metal halogen bonds. These bonds, which involve the interaction between metal atoms and halogen atoms such as fluorine, chlorine, bromine, and iodine, have gained increasing attention for their potential applications in various industrial and scientific sectors.Leading the charge in harnessing the potential of metal halogen bonds is the innovative research and development (R&D) team at [company name]. Established in [year], [company name] has been at the forefront of pioneering new technologies and approaches to chemical synthesis and material science. With a dedicated team of scientists and experts, [company name] has solidified its position as a key player in the global chemical industry, consistently delivering cutting-edge solutions to meet the evolving needs of various sectors.Metal halogen bonds have emerged as a particularly promising area of research for [company name], with its potential to revolutionize the development of new materials, catalysts, pharmaceuticals, and more. By leveraging the unique properties of metal halogen bonds, [company name] aims to unlock new possibilities for enhancing the performance and functionality of a wide range of products and processes.One of the key strengths of metal halogen bonds lies in their versatility and tunability. Through precise control of the metal-halogen interactions, researchers can tailor the properties of resulting materials to meet specific requirements, such as enhanced stability, reactivity, or selectivity. This level of customization opens up a myriad of possibilities for innovative applications across multiple industries, from electronics and energy storage to pharmaceuticals and environmental remediation.In practical terms, the utilization of metal halogen bonds offers numerous potential benefits. For instance, in the realm of catalysis, the unique reactivity associated with these bonds can significantly improve the efficiency of chemical reactions, leading to streamlined production processes and reduced waste. Similarly, in material science, the ability to fine-tune the properties of materials through metal halogen bonds can lead to the development of advanced materials with enhanced strength, conductivity, or other desirable traits.The potential impact of metal halogen bonds extends beyond the laboratory, with implications for real-world challenges such as environmental sustainability and healthcare. Through the development of novel materials and processes based on metal halogen bonds, [company name] seeks to contribute to the global efforts in addressing pressing issues, such as pollution mitigation, resource conservation, and the development of new pharmaceuticals.Looking ahead, [company name] remains committed to furthering its exploration of metal halogen bonds, with a continued focus on innovation and collaboration. By staying at the forefront of this emerging field, [company name] seeks to not only unlock new opportunities for its own business but also contribute to the advancement of the chemical industry as a whole.As part of its commitment to advancing the frontiers of chemical science, [company name] is actively engaged in collaborations with leading academic and industrial partners, leveraging collective expertise to drive breakthrough discoveries in the realm of metal halogen bonds. Through these collaborative efforts, [company name] aims to foster knowledge exchange and accelerate the translation of scientific findings into practical applications that benefit society and the environment.In conclusion, the rise of metal halogen bonds as a pivotal area of chemical innovation presents an exciting opportunity for [company name] and the broader scientific community. With its longstanding expertise and dedication to pushing the boundaries of chemical research, [company name] is well-positioned to make significant contributions to the ongoing exploration and utilization of metal halogen bonds, paving the way for transformative advancements in a wide range of industries. As this field continues to evolve, [company name] is committed to remaining at the forefront of this exciting frontier, driving innovation and delivering solutions that have a lasting impact on the world.

High-Quality and Reliable Universal Diamond Cutting Disc 125x22.23mm - Professional Power Tools

article on the importance and benefits of using high-quality diamond cutting discs in various industries.As technology advances and new materials are developed, the need for precise and efficient cutting tools becomes increasingly important. In many industries, the use of cutting discs is crucial for producing high-quality products and completing tasks with precision and accuracy. With so many different types of cutting discs available on the market, it can be overwhelming to choose the right one for your specific needs.One type of cutting disc that has gained popularity in recent years is the diamond cutting disc. Diamond cutting discs are quickly becoming the standard for professionals in a wide variety of industries due to their exceptional strength, durability, and precision. These discs are made with industrial diamonds that are bonded to a metal or resin matrix, which provides a superior cutting edge that can handle tough materials like concrete, metal, glass, and ceramic tiles.One of the key features of diamond cutting discs is their versatility. Thanks to their durable composition, diamond cutting discs can cut through a wide range of materials, making them a go-to tool for professionals in a variety of industries. This versatility means that contractors and tradespeople can have a single cutting disc to handle various cutting needs, which can save them both time and money.Another benefit of diamond cutting discs is their long lifespan. With regular use and proper maintenance, diamond cutting discs can last significantly longer than traditional cutting discs. This is because the industrial diamonds used to make diamond cutting discs are incredibly hard and resilient, making them more resistant to wear and tear. Additionally, the bond that holds the diamonds in place is designed to withstand high temperatures and stress, further extending the lifespan of the disc.Aside from their durability, diamond cutting discs also offer exceptional cutting speed and precision. Because the industrial diamonds are much harder and sharper than traditional cutting materials like aluminum oxide or silicon carbide, they can cut through materials much faster, with less force required. This faster cutting speed not only increases efficiency on the job but also leads to a smoother finish with fewer burrs or jagged edges.When it comes to choosing a diamond cutting disc, it's crucial to consider factors like blade size, material composition, and intended use. For example, the Metabo diamond cutting disk 125x22.23mm, "UP", Universal "professional" (628559000) is designed to be a high-quality, reliable, and durable option for professionals in various industries. Its 125mm diameter makes it suitable for cutting a wide range of materials, while its universal "professional" design means that it can handle the toughest applications with ease. As a product known for its exceptional quality and performance in the industry, using it can ensure optimal results every time.In conclusion, there are significant benefits to using high-quality diamond cutting discs in various industries, including their versatility, long lifespan, and exceptional speed and precision. Although the initial cost of diamond cutting discs may be higher than traditional cutting discs, the superior performance and longevity make them a worthwhile investment in the long run. By choosing the right diamond cutting disc for your specific needs, you can ensure optimal results and save both time and money in the process.

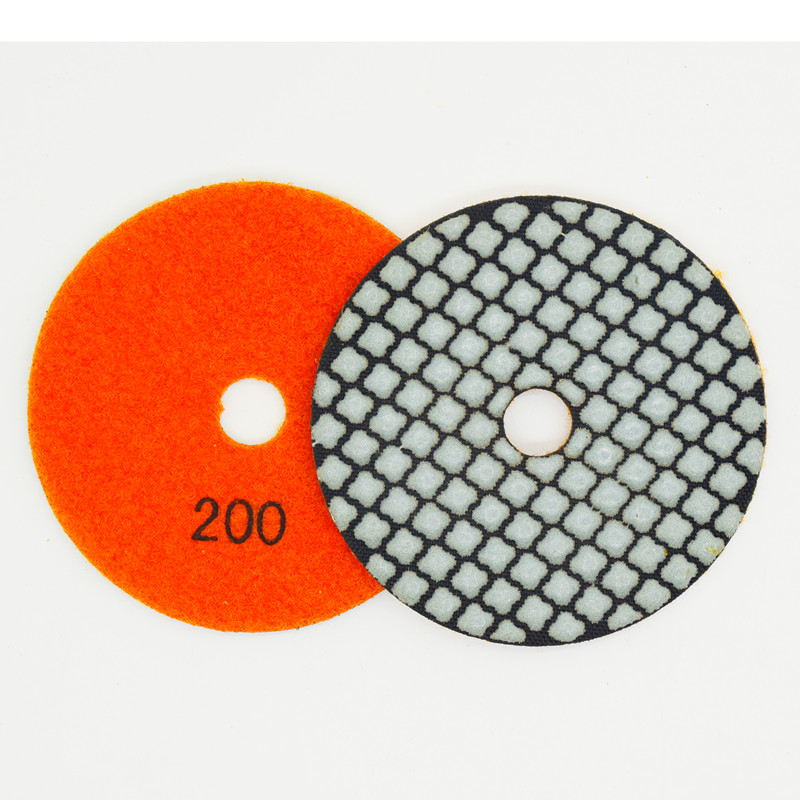

High-Quality Abrasive Polishing Pads for a Flawless Finish

Abrasive polishing pads are an essential tool for achieving a smooth and polished finish on a variety of surfaces. Whether you are working on wood, metal, or even concrete, abrasive polishing pads are designed to efficiently remove imperfections and create a high-quality finish. One of the leading producers of abrasive polishing pads is a company that has been a trusted name in the industry for over 30 years. Their commitment to providing high-quality products and exceptional customer service has made them a go-to choice for professionals and DIY enthusiasts alike.With a wide range of polishing pads available, this company offers options for every application. From heavy-duty concrete polishing pads to delicate wood polishing pads, their products are designed to meet the needs of any project. They also offer a variety of pad sizes and configurations to ensure that customers can find the perfect fit for their specific requirements.In addition to offering a comprehensive range of abrasive polishing pads, this company is also dedicated to innovation. They continuously invest in research and development to improve their products and stay ahead of the curve in the industry. This commitment to innovation has led to the creation of cutting-edge polishing pads that offer superior performance and durability.One of the key factors that sets this company apart from its competitors is its stringent quality control measures. Every abrasive polishing pad undergoes rigorous testing to ensure that it meets the company's high standards for performance and longevity. This dedication to quality has earned the company a reputation for reliability and consistency, making them a top choice for professionals who demand the best.As a customer-focused company, this company also prioritizes providing exceptional service. Their knowledgeable and experienced team is always on hand to offer advice and assistance, helping customers to find the right polishing pads for their specific needs. Whether you are a seasoned professional or a first-time user, you can trust that you will receive the support you need to achieve the best results.Furthermore, this company is committed to sustainability and environmental responsibility. They strive to minimize their environmental impact by using eco-friendly materials and manufacturing processes. This commitment to sustainability not only benefits the environment but also ensures that customers can feel good about choosing abrasive polishing pads from this company.In conclusion, abrasive polishing pads are an indispensable tool for achieving a flawless finish on a wide range of surfaces. With their dedication to quality, innovation, and customer service, this company has established itself as a leader in the industry. Their comprehensive range of high-quality polishing pads, combined with their commitment to sustainability and exceptional service, make them the top choice for professionals and DIY enthusiasts alike. Whether you are working on a small project at home or a large-scale industrial application, you can trust that abrasive polishing pads from this company will meet and exceed your expectations.

High-Quality Diamond Grinding Tools for Precise Surface Finishing

Diamond Grinding Tools are a game-changer in the construction and manufacturing industry, offering top-of-the-line precision and performance in various applications. With their advanced technology and superior quality, these tools are revolutionizing the way professionals approach cutting and grinding tasks.{Company Name} is a leading manufacturer and supplier of Diamond Grinding Tools, offering a wide range of products designed to meet the diverse needs of their customers. With a commitment to excellence and innovation, {Company Name} has established itself as a trusted name in the industry, providing cutting-edge solutions for cutting, grinding, and polishing applications.The company's Diamond Grinding Tools are engineered to deliver exceptional results in terms of performance, efficiency, and durability. Using advanced diamond technology, these tools are capable of providing high precision and superior finish in various materials, including concrete, stone, metal, and other hard surfaces. Whether it's for surface preparation, grinding, or polishing, {Company Name}'s Diamond Grinding Tools are designed to meet the demands of the most challenging projects.One of the key attributes of {Company Name}'s Diamond Grinding Tools is their versatility. These tools are available in a variety of sizes, shapes, and configurations, making them suitable for a wide range of applications. From small-scale residential projects to large-scale industrial operations, {Company Name} offers a comprehensive selection of Diamond Grinding Tools to meet the specific needs of their customers.Not only are these tools versatile, but they also offer high efficiency and productivity. The superior cutting and grinding capabilities of {Company Name}'s Diamond Grinding Tools allow for faster material removal and smoother surface finish, ultimately saving time and labor costs for their customers. Additionally, these tools are engineered for long-lasting performance, providing a reliable and cost-effective solution for the most demanding applications.In addition to their outstanding performance, {Company Name}'s Diamond Grinding Tools are also designed with user safety and convenience in mind. These tools are equipped with ergonomic features to ensure comfortable handling and reduced operator fatigue during prolonged use. Furthermore, they are engineered to produce minimal vibrations and noise, creating a safer and more comfortable working environment for the operators.{Company Name} takes pride in their commitment to quality and customer satisfaction. Each Diamond Grinding Tool undergoes rigorous testing and quality control measures to ensure that it meets the highest standards of performance and durability. By staying at the forefront of technological advancements, {Company Name} continues to develop innovative solutions that provide their customers with a competitive edge in their respective industries.The company's dedication to excellence extends beyond their product offerings. {Company Name} also provides exceptional customer service and technical support to assist their customers in finding the right Diamond Grinding Tool for their specific needs. Their team of knowledgeable professionals is readily available to offer guidance, recommendations, and troubleshooting assistance to ensure that their customers achieve optimal results with their Diamond Grinding Tools.As a responsible and environmentally conscious company, {Company Name} is committed to sustainable practices in their manufacturing processes. Their Diamond Grinding Tools are designed with energy-efficient and eco-friendly features, reducing their environmental footprint and contributing to a greener and more sustainable future.In conclusion, {Company Name}'s Diamond Grinding Tools are a testament to their relentless pursuit of innovation and excellence. With their advanced technology, outstanding performance, and unwavering commitment to customer satisfaction, these tools are setting a new standard in the industry. As the demand for high-quality cutting and grinding solutions continues to grow, {Company Name} stands ready to meet the evolving needs of their customers with their cutting-edge Diamond Grinding Tools.

Discover the Versatile Benefits of Lock Polishing Pads

article:Snail Lock Polishing Pad Revolutionizes Grinding and PolishingIn the world of grinding and polishing, efficiency and quality are two factors that cannot be compromised. Both are critical when it comes to achieving a perfect finish. One product that is quickly gaining traction in the industry is the Snail Lock Polishing Pad.Produced by a leading manufacturer of abrasives, the product is a game-changer in the world of grinding and polishing. It has been developed using the latest technology to ensure efficient and consistent grinding and polishing.The snail lock polishing pad is designed to work specifically with automatic edge polishing machines and bridge polishing machines equipped with the snail lock adapter. The pads are made from high-quality resin and diamond particles that make them durable and long-lasting. They are also easy to install and remove, making the grinding and polishing process quicker and more efficient.The unique design of the snail lock polishing pad consists of a double-layered resin and diamond grain structure that provides superior quality and consistent results. The single locking system ensures that the pad remains securely in place while in operation, reducing the risk of accidents and ensuring maximum safety for operators.According to the manufacturer, the snail lock polishing pad is suitable for use on a wide range of materials. These include natural stone, engineered stone, ceramics, and porcelain. This versatility makes it an indispensable tool for fabricators, contractors, and DIY enthusiasts.The snail lock polishing pad is also designed to reduce the need for multiple stages of grinding and polishing. Its superior quality means that it can deliver excellent results with minimal effort, time, and energy. This factor makes it a cost-effective solution for grinding and polishing professionals.The company behind the snail lock polishing pad has been in the business for over a decade and has built a strong reputation for producing high-quality abrasive products that meet the demands of the industry. Their team of experts includes experienced engineers, technicians, and customer service representatives who work tirelessly to ensure that their products are of superior quality and that they offer the best service to their clients.In addition to the snail lock polishing pad, the company produces a wide range of other abrasive products that cater to the needs of various industries. These products include diamond saw blades, diamond core bits, profiling wheels, and cup wheels, among others.The company believes that its success is driven by its commitment to quality and its willingness to go the extra mile to ensure customer satisfaction. This includes investing in research and development to improve its products' performance and quality continually.In conclusion, the snail lock polishing pad is a revolutionary product that is quickly gaining traction in the industry. Its unique design, efficiency, and durability make it a game-changer in the world of grinding and polishing. It is an indispensable tool for fabricators, contractors, and DIY enthusiasts looking for superior quality and consistent results. The manufacturer's commitment to quality and customer satisfaction make it a brand that customers can trust. With its continued investment in research and development, the company is poised to remain a leader in the abrasive products industry for years to come.