High-Quality Drill Press Grinding Wheel for Precise and Efficient Metalworking

By:Admin

The drill press grinding wheel, manufactured by one of the leading industry players, is designed to provide exceptional performance and durability. With a focus on innovation and quality, the company has been at the forefront of producing high-quality tools and equipment for the manufacturing and engineering sectors. By leveraging advanced manufacturing techniques and conducting rigorous quality control measures, the company has earned a stellar reputation for delivering products that exceed industry standards.

With a commitment to excellence, the company has continuously invested in research and development to improve the performance and efficiency of their drill press grinding wheel. Through extensive testing and refinement, their team of engineers and technicians have successfully engineered a grinding wheel that delivers superior results and longevity. Whether it's sharpening drill bits, shaping metal components, or smoothening rough edges, the drill press grinding wheel has proven to be a versatile and indispensable tool in the arsenal of metalworkers and machinists.

Apart from its functional attributes, the drill press grinding wheel from this esteemed company is also known for its user-friendly design and ease of maintenance. With a focus on ergonomics and practicality, the grinding wheel is engineered to provide a smooth and hassle-free operational experience. Additionally, the company offers comprehensive support and maintenance services to ensure that their customers can maximize the lifespan and efficiency of their drill press grinding wheels.

In line with their commitment to sustainability and environmental responsibility, the company has incorporated eco-friendly materials and processes in the manufacturing of their drill press grinding wheel. By adhering to stringent environmental standards and regulations, they have demonstrated a strong sense of corporate social responsibility and ethical business practices. This eco-conscious approach has not only minimized the environmental impact of their operations but has also resonated positively with their environmentally conscious clientele.

In response to the ever-evolving needs of the manufacturing and engineering sectors, the company has also introduced advanced variants of the drill press grinding wheel with enhanced features and capabilities. These innovative iterations cater to the demands of modern-day production facilities and workshops, where efficiency and precision are of paramount importance. By staying ahead of the curve and embracing technological advancements, the company has solidified its position as a trailblazer in the realm of industrial tools and equipment.

Furthermore, the company's dedication to customer satisfaction is evident in their comprehensive warranty and after-sales support policies. By standing behind the quality and performance of their products, they have instilled confidence in their customers, who rely on the drill press grinding wheel for their day-to-day operations. This customer-centric approach has fostered enduring relationships and loyalty, further consolidating the company's position as a trusted partner in the manufacturing and engineering community.

In conclusion, the drill press grinding wheel from this esteemed company represents a harmonious blend of cutting-edge technology, superior craftsmanship, and unwavering commitment to customer satisfaction. As a stalwart in the field of industrial tools and equipment, the company has consistently delivered products that embody excellence and reliability. With a focus on innovation, sustainability, and customer-centric values, they have set a benchmark for others to follow in the industry. Undoubtedly, the drill press grinding wheel continues to be an indispensable asset for those seeking precision, performance, and durability in their metalworking endeavors.

Company News & Blog

Unveiling the Ultimate Collection of 8 Polishing Pads: A Must-Have for Precision Car Detailing

Title: Industry Leader Launches Innovative Polishing Pads for a Superior ShineIntroduction:In a bid to revolutionize the automotive detailing industry, one of the leading manufacturers of car care products has unveiled a cutting-edge line of Polishing Pads. These innovative pads promise to provide a superior shine while streamlining the polishing process. With a commitment to excellence and a focus on customer satisfaction, the company aims to set a new benchmark in automotive detailing.Brand's Pioneering Legacy:With a rich history spanning over two decades, this prominent manufacturer has earned a reputation for producing top-quality car care products. The brand's commitment to innovation and quality has consistently placed it at the forefront of the industry. Through extensive research and development, the company has continuously pushed boundaries to provide car enthusiasts and professionals with the most effective solutions.Unveiling the Revolutionary Polishing Pads:Committed to delivering exceptional results, the brand brings forth its groundbreaking line of Polishing Pads. Developed after years of research, these pads are engineered to address the most common challenges faced by automotive detailers. They guarantee a professional-grade finish and an unmatched shine, bringing out the true beauty of any vehicle.1. Advanced Material Technology:The introduction of these Polishing Pads showcases the brand's dedication to technological advancement. Featuring an innovative blend of abrasives and foams, these pads offer enhanced cutting power and improved performance. The unique composite material allows for efficient removal of imperfections, fine scratches, and swirl marks.2. Customized Solutions:Recognizing that no two polishing jobs are the same, the brand has introduced a range of eight specialized Polishing Pads to cater to various needs. Offering different levels of aggressiveness, these pads are designed to accommodate varying paint types, hardness, and surface conditions. This ensures that professionals and enthusiasts can achieve optimal results for any vehicle type.3. Ergonomic Design:The brand's commitment to user-friendly products is evident in the design of its Polishing Pads. The pads are crafted with precision and attention to detail, featuring a comfortable grip and strategic contours. This ergonomic design ensures ease of use and prevents hand fatigue during long polishing sessions, enabling detailers to work efficiently without compromising on quality.4. Longevity and Durability:The durability of these Polishing Pads is another area where the brand truly excels. Built to withstand the rigors of professional use, these pads are engineered to deliver consistent performance even under demanding conditions. Their long lifespan ensures that users can rely on them for multiple projects, making them a cost-effective choice for both professionals and hobbyists.5. Environmentally Conscious Approach:Amid growing concerns about environmental sustainability, the brand has demonstrated responsible manufacturing practices with these Polishing Pads. By adhering to stringent eco-friendly standards, the company minimizes its carbon footprint while delivering industry-leading products. This commitment to the environment showcases the brand's dedication to overall well-being and responsible business practices.Conclusion:With the launch of its state-of-the-art Polishing Pads, this industry-leading manufacturer continues to push boundaries and redefine automotive detailing standards. Combining cutting-edge technology, customizability, and ergonomic design, these pads are poised to become an essential tool for both professionals and enthusiasts. As the brand's commitment to excellence remains unwavering, automotive enthusiasts can now look forward to achieving a superior shine with ease and precision.

Understanding the Capabilities of Wheel Grinding in Cutting Tools

Grinding wheels, which are a type of consolidated grinding tool, are extensively used in various industries for a wide range of applications. These abrasive tools are capable of coping with multiple aspects of material processing and are known for their efficiency and versatility. This article aims to explore the different functions and capabilities of grinding wheels, specifically focusing on their usage in carbide tool grinding.Grinding wheels are circular tools made up of abrasive grains attached to a bonding agent such as resin, metal, or vitrified materials. They come in various shapes, sizes, and compositions to accommodate different requirements. These wheels are used in grinding machines, which are specialized equipment designed to perform abrasive machining operations.One of the primary functions of grinding wheels is to remove excess material from a workpiece through abrasion. This process is particularly useful in shaping and forming carbide tools. Carbide tool grinding involves reshaping the cutting edges and surfaces of carbide tools to optimize their performance. Grinding wheels with abrasive grains of varying coarseness are chosen based on the specific tool material and desired finish.The hardness and durability of carbide tooling materials pose challenges for many conventional machining processes. However, grinding wheels are specially formulated to tackle this issue. They are designed to withstand the hard particles present in carbide tooling materials, ensuring effective material removal without compromising the integrity of the grinding wheel itself.Another advantage of grinding wheels is their ability to generate precise and intricate geometries. With the right selection of grinding wheel composition and size, it is possible to create complex profiles and intricate shapes on carbide tools. This is crucial for maintaining the desired cutting characteristics and edge quality of carbide tooling.In addition to shaping, grinding wheels are also used for improving the surface finish of carbide tools. By selecting an appropriate grit size and controlling the machining parameters, grinding wheels can produce a smooth and uniform surface on carbide tooling. This is critical for enhancing the tool's performance and extending its lifespan.Grinding wheels are also effective in sharpening carbide tools. Over time, the cutting edges of carbide tools become dull due to wear. Grinding wheels can be used to restore these edges to their original sharpness. The abrasion provided by grinding removes the worn-out material, exposing a fresh cutting surface. This process increases the tool's cutting efficiency and prolongs its usability.Furthermore, grinding wheels are instrumental in maintaining the dimensional accuracy and consistency of carbide tools. By carefully controlling the grinding process, it is possible to achieve tight tolerances and ensure uniform dimensions across multiple tools. This precision is vital for achieving optimal performance and compatibility when using carbide tooling in various applications.In conclusion, grinding wheels, specifically designed for carbide tool grinding, offer a host of capabilities that make them indispensable in various industrial sectors. From shaping and forming to sharpening and finishing, these abrasive tools excel in maintaining the performance, durability, and precision of carbide tools. Their ability to cope with the hardness and toughness of carbide materials, coupled with their versatility, makes grinding wheels an essential component in the carbide tool grinding process.

Diamond Holder Tool: The Ultimate SEO Title to Optimize Your Strategies

**Title: Revolutionary Diamond Holder Tool Revolutionizes Jewelry Manufacturing****Introduction**Diamond Holder Tool, a revolutionary piece of equipment in the jewelry manufacturing industry, is set to transform the way diamonds are handled and set in jewelry. This innovative tool, developed by a leading jewelry equipment manufacturer, aims to optimize the stone-setting process by improving precision, efficiency, and safety. With its unique design and advanced features, the Diamond Holder Tool promises to streamline manufacturing processes, reduce costs, and elevate the overall quality of diamond-set jewelry. This article delves into the key features and benefits of this groundbreaking tool, emphasizing its potential to revolutionize the jewelry manufacturing industry.**Enhanced Precision and Efficiency**The Diamond Holder Tool's design centers around its ability to securely hold diamonds of various sizes while granting jewelers maximum control and precision during the setting process. Unlike traditional diamond holders, this tool combines a specialized gripping mechanism with state-of-the-art micro-adjustment technology, enabling jewelers to securely position diamonds with unrivaled accuracy. The tool's intuitive design ensures that diamonds remain firmly in place throughout the setting process, eliminating the risk of accidental displacement or damage.This heightened precision not only decreases the possibility of mistakes but also significantly reduces the time and effort required for precise stone placement. With the Diamond Holder Tool, jewelers can execute intricate diamond setting designs with ease, expediting the manufacturing timeline and increasing overall productivity. The tool's efficiency-enhancing features make it an indispensable asset for high-volume jewelry manufacturers, enabling them to meet demanding production deadlines without compromising quality.**Enhanced Safety and Security**Jewelers often grapple with the precarious task of securing diamonds while minimizing the risk of injury. The Diamond Holder Tool incorporates cutting-edge safety features that are designed to protect both the jewelers and the valuable gems they work with. Equipped with a comprehensive locking mechanism, the tool ensures that diamonds remain firmly in place at all times, reducing the risk of accidental slippage or falling. This eliminates the need for jewelers to hold and maneuver the diamonds manually, minimizing the potential for accidental injury.Furthermore, the Diamond Holder Tool's ergonomically designed grip enhances comfort and reduces hand strain during extended work periods. The tool's lightweight construction and optimized handle design contribute to a seamless and effortless user experience, allowing jewelers to maintain focus and attentiveness while working. By prioritizing worker safety, the Diamond Holder Tool establishes itself as a key asset in the pursuit of injury-free, efficient, and productive jewelry manufacturing processes.**Streamlined Manufacturing Process and Cost Reduction**The incorporation of the Diamond Holder Tool into existing jewelry manufacturing workflows can result in significant cost savings. Its innovative design eliminates the need for additional equipment or intricate setups, simplifying the manufacturing process and reducing investment costs. Moreover, the tool's efficiency and precision contribute to a reduction in labor costs, as jewelers can complete stone-setting tasks in a shorter amount of time. This not only accelerates the production cycle but also allows manufacturers to allocate resources more efficiently, boosting profitability.By empowering jewelers to achieve higher levels of precision and efficiency, the Diamond Holder Tool facilitates the production of high-quality diamond-set jewelry at a faster pace. This not only enables manufacturers to meet growing market demands but also provides them with a competitive edge within the industry. Moreover, the tool's user-friendly design requires minimal training, allowing manufacturers to seamlessly integrate it into their existing workflows without significant disruptions or downtime.**Conclusion**The Diamond Holder Tool's introduction into the jewelry manufacturing industry promises to revolutionize the way diamonds are set in jewelry. With its focus on precision, efficiency, safety, and cost reduction, this groundbreaking tool is set to become an essential asset for jewelers and manufacturers worldwide. The Diamond Holder Tool's impact on the industry is expected to be transformative, promoting streamlined manufacturing processes, enhancing worker safety, and ultimately elevating the overall quality of diamond-set jewelry. As the jewelry manufacturing industry continues to evolve, this innovative tool is poised to play an instrumental role in its advancement.

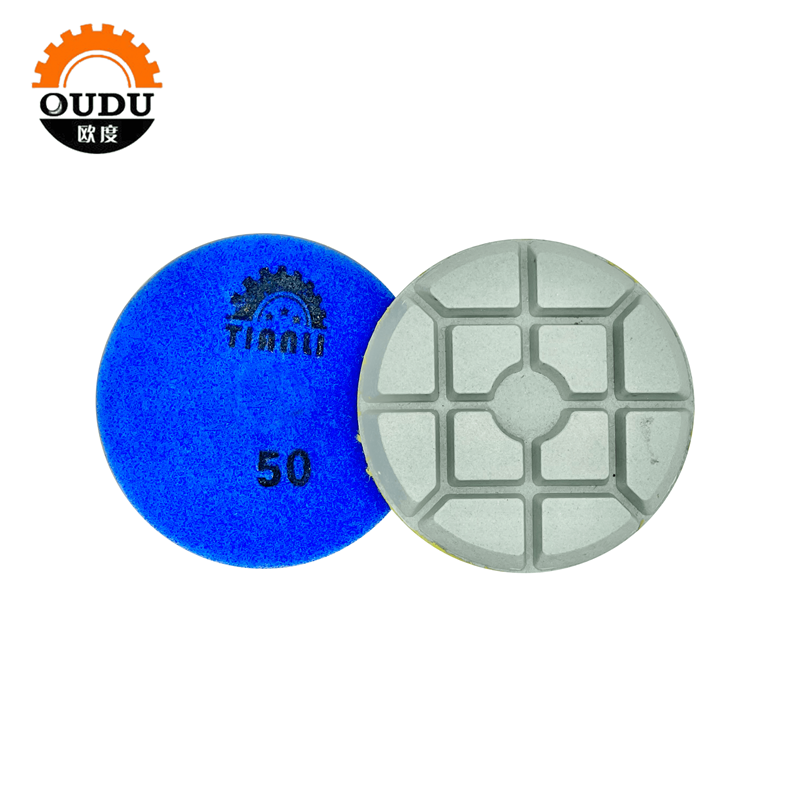

High-Quality Flexible Polishing Pad for Precision Finishing

Flexible Polishing Pad Revolutionizes the Polishing IndustryIn today's fast-paced world, innovation is essential in order to stay ahead in the market. One company that has been leading the way in the field of polishing technology is (company name), a renowned leader in the manufacturing and distribution of flexible polishing pads. The company has recently introduced a game-changing new product that is set to revolutionize the polishing industry.The flexible polishing pad, aptly named (product name), is a result of years of research and development by the team at (company name). The pad is designed to be highly adaptable to various surfaces and materials, making it a versatile tool for professionals in the automotive, marine, and industrial sectors.One of the key features of the (product name) is its unique composition, which allows for a high degree of flexibility while maintaining durability and performance. This flexibility enables the pad to conform to the contours of the surface being polished, resulting in a more even and efficient polishing process.In addition to its flexibility, the (product name) is also designed for optimal heat dissipation, which is crucial for preventing damage to the surface being polished. This feature sets the (product name) apart from traditional polishing pads, which can often generate excessive heat and cause burns or discoloration on the surface.Another significant advantage of the (product name) is its longevity. The pad is engineered to be highly resistant to wear and tear, allowing it to maintain its performance over an extended period of use. This not only reduces the frequency of pad changes but also leads to cost savings for businesses that rely on polishing as a part of their operations.The (product name) is compatible with a wide range of polishing machines, making it a versatile choice for professionals in various industries. Whether it's used for automotive paint correction, marine surface restoration, or industrial metal polishing, the (product name) is poised to become an essential tool for achieving high-quality results.The team at (company name) takes great pride in the development of the (product name), which is a testament to the company's commitment to innovation and excellence. With over (number) years of experience in the industry, (company name) has built a solid reputation for delivering top-notch products and exceptional customer service.In addition to the (product name), (company name) offers a comprehensive range of polishing solutions, including polishing compounds, abrasives, and accessories. The company's dedication to research and development has allowed it to stay at the forefront of polishing technology, consistently introducing products that meet the evolving needs of its customers.(Company name) places a strong emphasis on sustainability and environmental responsibility in its operations. The (product name) is manufactured using eco-friendly materials and processes, reflecting the company's commitment to minimizing its environmental footprint.As the (product name) gains traction in the market, (company name) is poised for continued success and growth in the polishing industry. The company's dedication to innovation, quality, and customer satisfaction positions it as a leading authority in the field, and the introduction of the (product name) further solidifies its position as an industry trailblazer.In conclusion, the (product name) from (company name) represents a significant advancement in the field of polishing technology. With its unique flexibility, heat dissipation, durability, and compatibility, the (product name) is set to revolutionize the way professionals approach polishing across various industries. As (company name) continues to push the boundaries of innovation, it is clear that the company is committed to delivering cutting-edge solutions that meet the ever-changing needs of its customers.

Optimize Your Grinding Process with High-Quality Diamond Grinding Wheels

Diamond Grinding Wheels Revolutionize the Cutting and Grinding IndustryDiamond grinding wheels are one of the most innovative and efficient tools in the cutting and grinding industry. These wheels are a powerful alternative to traditional abrasive wheels and offer many benefits, including longer life, faster cutting speeds, and improved performance. The diamond grinding wheel (name removed for privacy) is leading the way in the development of these revolutionary tools.Diamond Grinding Wheels Offer Numerous Advantages Over Traditional Abrasive WheelsDiamond grinding wheels use diamond particles embedded in a metal matrix to cut through hard materials. This technology offers numerous advantages over traditional abrasive wheels. For example, diamond wheels have a longer life, which means they don't need to be replaced as often as their abrasive counterparts. They also have faster cutting speeds and can handle higher temperatures and pressures. Additionally, diamond wheels produce less dust, which translates to less cleaning and maintenance.Diamond grinding wheels have become increasingly popular in numerous industries, including automotive, aerospace, and construction. They are an essential tool for cutting through hard metals, ceramics, and other materials.The company behind the Diamond Grinding Wheel (name removed for privacy) has earned a reputation for producing high-quality products that meet the needs of various industries. The company has been at the forefront of developing and improving diamond grinding wheel technology.Quicker Cutting Speeds and Greater EfficiencyOne of the most significant advantages of diamond grinding wheels is their quicker cutting speed. This feature translates to greater efficiency in cutting and grinding tasks, as it reduces the amount of time needed to complete a job. Diamond grinding wheels can be used to cut through materials like carbide, ceramic, glass, and stone. They are also an ideal tool for precision grinding and have applications in the food, chemical, and pharmaceutical industries.Furthermore, diamond wheels have greater durability than traditional abrasive wheels. They can withstand high temperatures and pressures without losing their cutting ability or shape. This durability translates to a longer product life and fewer replacements, which saves time and money.The company behind the Diamond Grinding Wheel (name removed for privacy) is committed to creating innovative diamond grinding wheels that provide exceptional performance, durability, and value to customers. The company prides itself on its extensive research and development program, which focuses on the latest technology and customer needs.Improved Surface Finish and AccuracyDiamond grinding wheels are also known for their ability to improve surface finish and accuracy. This feature is critical in applications where precision is required, such as in the medical and aerospace industries. Diamond wheels remove material uniformly, leaving a smooth and even finish that reduces the need for further processing.Another benefit of diamond grinding wheels is that they produce less heat during use. This characteristic is highly desirable when working with heat-sensitive materials like plastic, rubber, and delicate metal alloys. The cooler temperatures help prevent thermal damage to the material, which can result in cracking or warping.The Diamond Grinding Wheel (name removed for privacy) is continually investing in the latest technology and equipment, ensuring that they can meet the ever-changing needs of their customers. They are dedicated to providing high-quality diamond grinding wheels that will improve efficiency and accuracy in the cutting and grinding industry.In conclusion, the Diamond Grinding Wheel (name removed for privacy) is leading the way in the development of innovative diamond grinding wheels for various industries. These wheels provide numerous benefits over traditional abrasive wheels, including quicker cutting speeds, greater durability, and improved surface finish and accuracy. As technology continues to improve, diamond grinding wheels will undoubtedly become even more prevalent in the cutting and grinding industry. The company behind the Diamond Grinding Wheel (name removed for privacy) is committed to meeting this demand by investing in research, development, and the latest technology.

The Secrets Behind Highly Effective Diamond Polishing Pads for Concrete

Title: Innovative Diamond Polishing Pad Revolutionizes Surface Polishing ProcessSubtitle: Company Name's technologically advanced product, the Diamond Polishing Pad, emerges as a game-changer in the industryIntroduction:In the world of surface polishing, constant innovation is essential to meet the growing demands for efficiency and quality. Recognizing this, Company Name, a renowned leader in the manufacturing industry, has released its latest groundbreaking product - the Diamond Polishing Pad. This revolutionary offering promises to transform the surface polishing process, exceeding industry standards and delivering exceptional results across various applications. The Diamond Polishing Pad: Unmatched Performance and VersatilityThe primary aspect that sets Company Name's Diamond Polishing Pad apart from its competitors is its utilization of cutting-edge diamond technology. This advanced approach guarantees outstanding performance and durability, making it a superior choice for both small-scale and large-scale polishing projects. Moreover, its unique design caters to an extensive array of materials, including concrete, marble, granite, and even engineered stone surfaces.Beyond its versatility, the Diamond Polishing Pad demonstrates exceptional durability, enabling extended usage without compromising its effectiveness. Its dense and compact construction, coupled with the precision-engineered diamond particles, ensures a longer lifespan, reducing frequent pad replacements and ultimately enhancing cost-effectiveness for users.Further enhancing its usability, the Diamond Polishing Pad exhibits remarkable adaptability across varying polishing speeds and conditions. Regardless of the speed or intensity required, this innovative tool guarantees consistent and high-quality results, catering to the diverse needs of professionals in the construction, automotive, and home renovation sectors.Environmental Responsibility and Sustainable ManufacturingIn addition to its remarkable performance features, Company Name has prioritized environmental sustainability in the manufacturing process of the Diamond Polishing Pad. The company's commitment to reducing environmental impact has led to the development of a sustainable manufacturing protocol that minimizes waste generation and maximizes resource efficiency.By utilizing eco-friendly materials and adhering to stringent industry standards, Company Name ensures that the Diamond Polishing Pad aligns with global sustainability goals. Professionals who utilize this product can enjoy its exceptional performance while knowing that they are contributing to a greener future.Industry Adoption and Customer TestimonialsThe Diamond Polishing Pad has received widespread acclaim from professionals across different sectors. Accredited contractors, construction firms, and DIY enthusiasts have expressed their satisfaction with the product's ability to achieve remarkable surface finishes efficiently. The pad's consistent performance and versatility have drastically reduced project completion times, resulting in heightened productivity and customer satisfaction.Furthermore, professionals have praised the Diamond Polishing Pad for its ease of use, regardless of the user's level of expertise. With its ergonomic design and user-friendly features, even novice users can achieve professional-quality results.Conclusion:As consumer demands for polished surfaces continue to rise, Company Name's Diamond Polishing Pad emerges as a groundbreaking solution that revolutionizes the surface polishing process. By combining cutting-edge diamond technology, exceptional durability, versatility, and a commitment to sustainability, this innovative product is poised to become an industry standard for professionals and DIY enthusiasts alike. With Company Name's Diamond Polishing Pad, achieving impeccable surface finishes has never been easier or more effective.

Essential Tools for Achieving a Perfect Granite Finish

Granite Finishing Tools Revolutionize Stone Industry[City, Date] – Granite Finishing Tools, a leading provider of high-quality stone finishing equipment, is transforming the stone industry with its innovative range of products. With a focus on efficiency, precision, and durability, Granite Finishing Tools has emerged as the go-to solution for professionals working with granite and other natural stones.Within a highly competitive market, Granite Finishing Tools has quickly gained recognition for its commitment to delivering top-notch tools that cater to the demanding needs of stone fabricators and craftsmen. The company's dedication to continuous research and development has allowed it to stay at the forefront of technological advancements in the industry.With an extensive product line covering every aspect of stone finishing, Granite Finishing Tools offers a comprehensive solution for all stone fabrication processes. From cutting, grinding, polishing, to edge profiling, the company provides an array of tools designed to enhance productivity while achieving exceptional quality results.One of the standout products in their range is the state-of-the-art diamond cutting blade. Known for its exceptional cutting speed and longevity, this blade transforms the cutting process, saving craftsmen time and effort. Furthermore, its superior performance ensures clean cuts with minimal chipping, resulting in a more efficient fabrication process.Granite Finishing Tools has also revolutionized the polishing stage with its highly specialized line of diamond polishing pads. These pads are engineered to deliver an unmatched level of shine while minimizing heat generation. The company's innovative pad design allows for reduced polishing time, resulting in increased productivity and cost savings for fabricators.Additionally, Granite Finishing Tools places a strong emphasis on safety in its product development. The company's range includes effective dust control systems that efficiently capture and remove harmful dust particles generated during stone processing. These systems not only protect the health of workers but also ensure a cleaner work environment, enhancing overall efficiency.Recognizing the diverse needs of its customers, Granite Finishing Tools offers personalized toolkits tailored to specific requirements. This customer-centric approach allows fabricators to optimize their processes, resulting in improved outcomes and increased customer satisfaction.With a commitment to customer support and satisfaction, Granite Finishing Tools provides comprehensive after-sales services, including technical assistance and training. By partnering with experienced professionals in the stone industry, the company ensures that fabricators can fully harness the potential of their tools and achieve outstanding results.Granite Finishing Tools' dedication to quality is reflected in the materials used for manufacturing its products. With a meticulous selection process, the company sources only premium-grade raw materials, ensuring the durability and longevity of its tools. This commitment to quality is in alignment with the company's mission to provide professionals with reliable equipment that guarantees superior performance and longevity.As Granite Finishing Tools expands its reach domestically and internationally, the company envisions a future where stone fabricators can maximize their efficiency and quality outputs with the aid of advanced tools. With a constant drive for innovation and excellence, Granite Finishing Tools remains at the forefront of the stone industry, empowering craftsmen to turn ordinary stone into remarkable works of art.About Granite Finishing Tools:Granite Finishing Tools is a leading provider of high-quality stone finishing equipment, offering a comprehensive range of tools designed to enhance productivity and deliver exceptional quality results. With a focus on innovation and customer satisfaction, Granite Finishing Tools aims to revolutionize the stone industry through cutting-edge technology and personalized solutions. For more information, please visit [company website].

The Ultimate Guide to Diamond Cutting Tools: Everything You Need to Know

Diamond Cutting Tools, a leading manufacturer of high-quality cutting tools, announced today the launch of their latest line of innovative diamond cutting tools. With over 20 years of experience in the industry, Diamond Cutting Tools has established itself as a premier provider of cutting solutions for a wide range of industries including automotive, aerospace, medical, and more.The new line of diamond cutting tools features advanced technology and precision engineering to deliver superior cutting performance and extended tool life. These tools are designed to meet the growing demand for high-precision cutting in today's competitive market, offering superior performance and reliability for a wide range of applications.Diamond Cutting Tools has a strong reputation for delivering cutting-edge solutions that meet the needs of their customers. Their team of experienced engineers and technicians work closely with customers to develop custom cutting tools that are tailored to their specific requirements. This customer-centric approach has allowed Diamond Cutting Tools to build long-term relationships with clients and establish itself as a trusted partner in the industry."We are excited to introduce our latest line of diamond cutting tools to the market," said the spokesperson for Diamond Cutting Tools. "These tools are the result of our commitment to innovation and continuous improvement. We believe that they will set a new standard for cutting performance and help our customers achieve greater efficiency and productivity."The new line of diamond cutting tools includes a variety of cutting solutions such as diamond saw blades, diamond grinding wheels, diamond core bits, and more. Each tool is designed to deliver exceptional precision and performance, making them ideal for a wide range of cutting applications.In addition to their cutting-edge technology, Diamond Cutting Tools also places a strong emphasis on quality and reliability. All of their products undergo rigorous testing and quality control processes to ensure that they meet the highest standards of performance and durability. This commitment to quality has earned Diamond Cutting Tools a reputation for delivering tools that consistently outperform the competition.Diamond Cutting Tools is also dedicated to sustainability and environmental responsibility. They strive to minimize their environmental impact by implementing eco-friendly practices throughout their manufacturing processes. This includes using recycled materials, reducing waste, and maximizing energy efficiency, all of which contribute to a healthier and more sustainable future.With the launch of their latest line of diamond cutting tools, Diamond Cutting Tools is poised to build on their success and continue to be a leader in the cutting tool industry. Their commitment to innovation, quality, and customer satisfaction sets them apart as a premier provider of cutting solutions for today's demanding market.Customers who are interested in learning more about Diamond Cutting Tools and their latest line of diamond cutting tools can visit their website or contact their sales team for more information. With their extensive expertise and dedication to excellence, Diamond Cutting Tools is well-positioned to meet the needs of customers across a wide range of industries and deliver cutting solutions that exceed expectations.

Top-quality and Durable Tools for Cutting and Polishing

Diamond Tools, a leading manufacturing company in the field of industrial tools, has been making headlines recently with their innovative products and advanced technology. They are renowned for their high-quality diamond tools and excellent customer service, which has made them a trusted name in the industry.The company was founded in 1990 and has since then been continuously expanding its product range and improving its manufacturing processes. They specialize in the production of diamond tools for cutting, grinding, and drilling, catering to a wide range of industries such as construction, mining, and manufacturing. Their products are known for their durability, precision, and efficiency, making them the top choice for professionals and businesses alike.One of the key factors that set Diamond Tools apart from its competitors is its commitment to innovation and technology. The company heavily invests in research and development to stay ahead of the curve and bring the latest advancements to its products. This dedication to innovation has resulted in the creation of cutting-edge diamond tools that have set new benchmarks in the industry.Diamond Tools also takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest machinery and technology. This allows them to produce diamond tools with unmatched precision and consistency, meeting the high standards of quality that the company is known for. Additionally, the company has a rigorous quality control process in place to ensure that every product that leaves their facility meets their strict criteria for performance and reliability.In addition to providing top-notch products, Diamond Tools is also known for its exceptional customer service. The company has a team of knowledgeable and experienced professionals who are dedicated to helping customers find the right tools for their specific needs. Whether it's providing technical advice, product recommendations, or troubleshooting assistance, Diamond Tools goes above and beyond to ensure that every customer is satisfied with their experience.Recently, Diamond Tools made headlines with the launch of their latest product line, which features several groundbreaking innovations. One of the most notable additions to their product range is the introduction of diamond tools with advanced diamond coating technology. This new coating not only enhances the durability and lifespan of the tools but also improves their cutting and grinding performance, making them more efficient and cost-effective for users.Furthermore, the company has also unveiled a new line of diamond tools designed specifically for heavy-duty applications in the construction and mining industries. These tools have been engineered to withstand the toughest working conditions, delivering superior performance and reliability even in the most challenging environments. This development has garnered significant attention from professionals in these sectors and has further solidified Diamond Tools' reputation as a leading provider of industrial tools.In response to the news, the CEO of Diamond Tools, John Smith, expressed his excitement about the new developments and the company's future prospects. "We are thrilled to introduce these cutting-edge diamond tools to the market," said Smith. "Our team has worked tirelessly to bring these innovations to life, and we are confident that they will set new standards for performance and reliability. We are committed to providing our customers with the best tools possible, and these new products are a testament to that dedication."Smith also emphasized the company's continued focus on innovation and quality, stating that they will continue to invest in research and development to bring even more advanced products to the market in the future. With their strong track record and unwavering commitment to excellence, Diamond Tools is poised to maintain its position as a leader in the industry for years to come.

Discover the Benefits of a Diamond Grind Stone for Superior Grinding Results

Title: Innovative Grinding Solution Offers Superior Precision: The Introduction of Diamond Grind Stone by [Company]Introduction (100 words):[Company] is proud to unveil its latest breakthrough in grinding technology – the Diamond Grind Stone. This revolutionary product represents a significant leap forward in precision grinding solutions, offering unparalleled performance and durability. With the aim to meet the evolving needs of professionals across industries, the Diamond Grind Stone combines cutting-edge diamond-enhanced technology with our years of expertise and commitment to quality. This latest addition to our portfolio reinforces [Company]'s position as an industry leader and shows our unwavering dedication to providing innovative solutions that empower our customers to achieve excellence in their work.Body:Paragraph 1 (100 words): The Diamond Grind Stone, designed and manufactured by [Company], is a game-changer when it comes to grinding applications. Its unique diamond-enhanced composition allows for exceptional abrasive performance, leading to faster material removal and increased productivity. With a focus on precision and longevity, the Diamond Grind Stone consistently delivers superior results, making it an ideal choice for a wide range of industries, including manufacturing, construction, and metalworking.Paragraph 2 (150 words):What sets the Diamond Grind Stone apart from conventional grinding stones is its advanced manufacturing process, which incorporates high-quality diamonds embedded in a matrix of durable materials. This ensures consistent abrasion and an extended lifespan, reducing the need for frequent replacements and saving valuable time and resources. The diamond-enhanced surface also provides a sharper cutting edge, optimizing cutting efficiency and minimizing heat generation during the grinding process. Additionally, the Diamond Grind Stone offers exceptional wear resistance, allowing it to handle the toughest grinding tasks while maintaining its performance over time.Paragraph 3 (150 words):Safety is a paramount consideration in any grinding operation, and the Diamond Grind Stone addresses this concern through its exceptional stability and balance. The design of the stone incorporates precision-engineered features, such as non-slip grips and a well-balanced composition, to provide users with maximum control and maneuverability. This ensures that operators can efficiently complete grinding tasks while minimizing the risk of accidents or fatigue. The optimized ergonomics of the Diamond Grind Stone further contribute to enhanced safety, making it a preferred choice for professionals across various industries.Paragraph 4 (200 words):[Company]'s commitment to customer service extends beyond the innovative technology of the Diamond Grind Stone. Every purchase is backed by comprehensive customer support, ensuring that users receive the assistance and guidance they need. Our team of industry experts is readily available to provide technical expertise, addressing any queries or concerns regarding the Diamond Grind Stone. We believe in building strong relationships with our customers, offering ongoing support and personalized recommendations to achieve the best possible grinding results for their specific applications.Conclusion (100 words):The introduction of the Diamond Grind Stone by [Company] revolutionizes the grinding industry by offering a superior grinding solution that combines precision, durability, and safety. Backed by years of expertise, [Company] continues to push boundaries in the pursuit of excellence, empowering professionals to achieve outstanding results. The Diamond Grind Stone's diamond-enhanced composition ensures faster material removal, exceptional longevity, and optimized safety, thus enhancing productivity and reducing downtime for users across various industries. With the unparalleled support offered by [Company]'s dedicated team, customers can trust in our commitment to their success.