High-Quality Diamond Grinding Tools for Precise Surface Finishing

By:Admin

{Company Name} is a leading manufacturer and supplier of Diamond Grinding Tools, offering a wide range of products designed to meet the diverse needs of their customers. With a commitment to excellence and innovation, {Company Name} has established itself as a trusted name in the industry, providing cutting-edge solutions for cutting, grinding, and polishing applications.

The company's Diamond Grinding Tools are engineered to deliver exceptional results in terms of performance, efficiency, and durability. Using advanced diamond technology, these tools are capable of providing high precision and superior finish in various materials, including concrete, stone, metal, and other hard surfaces. Whether it's for surface preparation, grinding, or polishing, {Company Name}'s Diamond Grinding Tools are designed to meet the demands of the most challenging projects.

One of the key attributes of {Company Name}'s Diamond Grinding Tools is their versatility. These tools are available in a variety of sizes, shapes, and configurations, making them suitable for a wide range of applications. From small-scale residential projects to large-scale industrial operations, {Company Name} offers a comprehensive selection of Diamond Grinding Tools to meet the specific needs of their customers.

Not only are these tools versatile, but they also offer high efficiency and productivity. The superior cutting and grinding capabilities of {Company Name}'s Diamond Grinding Tools allow for faster material removal and smoother surface finish, ultimately saving time and labor costs for their customers. Additionally, these tools are engineered for long-lasting performance, providing a reliable and cost-effective solution for the most demanding applications.

In addition to their outstanding performance, {Company Name}'s Diamond Grinding Tools are also designed with user safety and convenience in mind. These tools are equipped with ergonomic features to ensure comfortable handling and reduced operator fatigue during prolonged use. Furthermore, they are engineered to produce minimal vibrations and noise, creating a safer and more comfortable working environment for the operators.

{Company Name} takes pride in their commitment to quality and customer satisfaction. Each Diamond Grinding Tool undergoes rigorous testing and quality control measures to ensure that it meets the highest standards of performance and durability. By staying at the forefront of technological advancements, {Company Name} continues to develop innovative solutions that provide their customers with a competitive edge in their respective industries.

The company's dedication to excellence extends beyond their product offerings. {Company Name} also provides exceptional customer service and technical support to assist their customers in finding the right Diamond Grinding Tool for their specific needs. Their team of knowledgeable professionals is readily available to offer guidance, recommendations, and troubleshooting assistance to ensure that their customers achieve optimal results with their Diamond Grinding Tools.

As a responsible and environmentally conscious company, {Company Name} is committed to sustainable practices in their manufacturing processes. Their Diamond Grinding Tools are designed with energy-efficient and eco-friendly features, reducing their environmental footprint and contributing to a greener and more sustainable future.

In conclusion, {Company Name}'s Diamond Grinding Tools are a testament to their relentless pursuit of innovation and excellence. With their advanced technology, outstanding performance, and unwavering commitment to customer satisfaction, these tools are setting a new standard in the industry. As the demand for high-quality cutting and grinding solutions continues to grow, {Company Name} stands ready to meet the evolving needs of their customers with their cutting-edge Diamond Grinding Tools.

Company News & Blog

Environmental group opposes air permit for $340M metal recycling and smelting plant

Augusta Metal Plant Wins Authorization for $760M in BondsAugusta's new metal recycling and secondary smelting facility has received authorization for $760 million in bonds from state authorities. This development marks a significant milestone in the construction of the world-class metal facility, which has been under development in Augusta for many months now.Construction of the plant has been on full swing for a while now, and the project is set to change Augusta's economy. The facility will result in the creation of several new jobs and provide significant economic benefits to the local communities.The Environmental ChallengeThe Savannah Riverkeeper submitted an argument against an air permit for the facility in July 2021. The environmental group fears that the new plant's emissions would cause health hazards to the local community.The permit requested by the plant was to allow it to emit up to 5,000 tons of carbon monoxide annually, which was well above the lower limits proposed by the Savannah Riverkeeper.To resolve these concerns, the facility's authorities agreed to impose stricter regulations for the plant's emissions by keeping the amount of carbon monoxide below 2,500 tons per year.Assuming that the metal recycling and secondary smelting facility will adhere to regulations, it could prove to be a significant asset to the various companies that depend on scrap metal.Benefits of the Metal Recycling and Secondary Smelting FacilityThe new facility will utilize scrap metal and turn it into valuable items- thereby reducing the reliance on non-renewable resources and minimizing the products that end up in landfills.The facility is expected to generate more than 200 well-paying jobs, with a majority going to individuals living in the Augusta area, thus improving the local economy.Moreover, the plant's development will create new trade and supply chain opportunities, meaning that the local market will see an increase in demand, which is expected to cause further economic growth.The authorities have agreed that the facility will be one of the most environmentally sustainable in the world, with a waste-free operation standard. The facility's management team has committed to ensuring that the plant's process is environmentally friendly, and they will monitor it regularly to minimize any environmental impact.Final TakeawayThe authorization of the $760 million in bonds marks a significant step forward for the Augusta facility. The plant is expected to be operational by mid-2022 and will provide a critical infrastructure to Augusta's economy.With all environmental concerns addressed, Augusta's metal recycling and secondary smelting facility has the potential to create a significant economic impact on the local communities while minimizing the facility's footprint on the environment.The metal recycling plant will provide an excellent source of sustainable energy, and with its promise of a waste-free operation, it is expected to set new standards in the metal recycling industry.If Augusta's metal recycling and secondary smelting facility upholds its commitment to sustainable practices, it is bound to grow into a major industry player, providing a diverse range of sustainable solutions. With all these planned developments, it's an exciting time for Augusta, and there is much to look forward to.

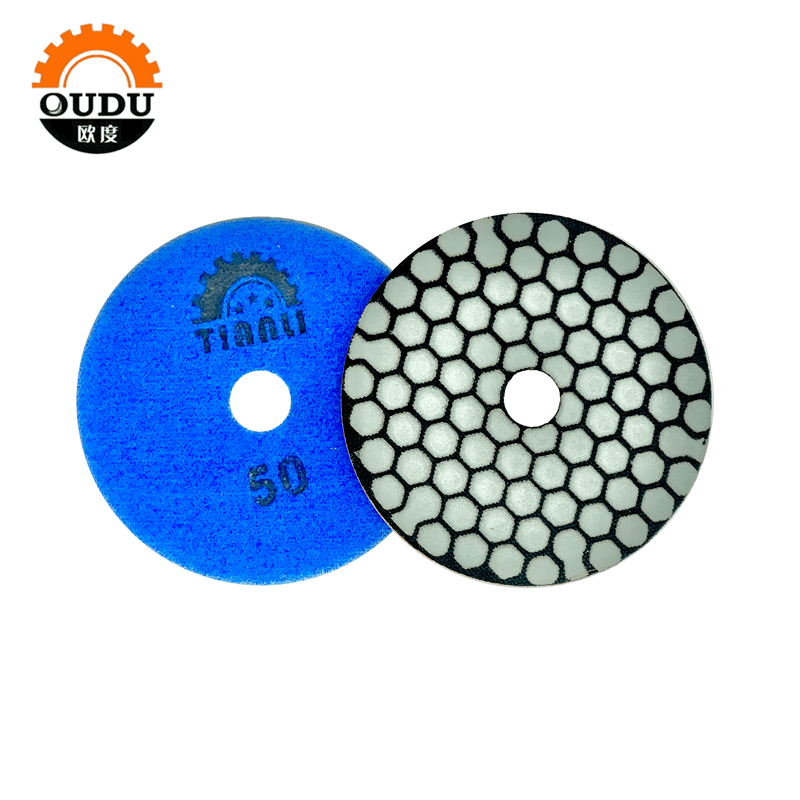

High-Quality Wet/Dry Polishing Pads for a Smooth Finish

Wet/Dry Polishing Pads are gaining popularity in the construction and renovation industry due to their high effectiveness and versatility. These polishing pads are used for smoothing and polishing surfaces such as marble, granite, concrete, and other natural stones. With the ability to be used for both wet and dry applications, these pads have become a go-to tool for professional contractors and DIY enthusiasts alike.One company that has been making waves in the industry with their high-quality Wet/Dry Polishing Pads is {}. With years of experience in the field, they have established themselves as a leading manufacturer and supplier of construction and renovation tools and equipment. Their commitment to providing top-of-the-line products at competitive prices has earned them a solid reputation among their clients.The Wet/Dry Polishing Pads offered by {} are designed to deliver exceptional results, no matter the surface being worked on. Whether it's a rough concrete floor or a delicate marble countertop, their pads are engineered to provide a smooth and polished finish with minimal effort. The company understands the importance of a consistent and high-quality finish, and their products are developed with this in mind.One of the key features of {} Wet/Dry Polishing Pads is their durability. Constructed with premium materials, these pads are built to withstand the wear and tear of heavy-duty use. This durable construction ensures that the pads can be used for extended periods without losing their effectiveness, saving contractors time and money in the long run.In addition to their durability, {} Wet/Dry Polishing Pads are also known for their versatility. They can be used with water for wet polishing, which helps to minimize dust and keep the work area clean. Alternatively, they can also be used for dry polishing, offering the flexibility to adapt to different working conditions and requirements. This versatility makes them a valuable tool for a wide range of projects, from large-scale construction jobs to intricate renovation tasks.Another factor that sets {} apart from other brands is their commitment to customer satisfaction. They offer a wide range of polishing pads in different sizes and grit levels, ensuring that contractors have the right tools for any job. Their dedication to providing exceptional customer service has solidified their position as a reliable and trustworthy supplier in the industry.Moreover, {} takes pride in staying up-to-date with the latest technological advancements in polishing pad manufacturing. Their products are constantly being improved and refined to ensure that they meet the evolving needs of their customers. This dedication to continuous improvement sets {} apart as an industry leader in the development of high-quality polishing pads.With a strong track record of delivering top-quality products and excellent customer service, {} has become a trusted partner for contractors and renovation professionals across the industry. They understand the demands of the construction and renovation business and are dedicated to providing the tools and equipment needed to get the job done efficiently and effectively.In conclusion, the growing popularity of Wet/Dry Polishing Pads in the construction and renovation industry has opened up new possibilities for achieving high-quality finishes on various surfaces. Companies like {} have played a crucial role in this trend by developing and supplying top-of-the-line polishing pads that meet the needs of contractors and DIY enthusiasts alike. With their commitment to quality, durability, versatility, and customer satisfaction, {} has established itself as a leading provider of Wet/Dry Polishing Pads, and their continued dedication to innovation and excellence is sure to solidify their position in the industry for years to come.

Discover the Versatility and Efficiency of Hole Grinding Tools: Enhance Your Projects with Precision

Title: Advanced Hole Grinding Tools Revolutionize Manufacturing ProcessesIntroduction:In an increasingly competitive world, the manufacturing industry constantly seeks innovative solutions to meet the growing demands for precision and efficiency. The introduction of advanced hole grinding tools has revolutionized manufacturing processes, offering unparalleled levels of precision, speed, and durability. One such company at the forefront of this technological advancement is a leading manufacturer (remove brand name), renowned for their cutting-edge tools and commitment to excellence.Paragraph 1:As manufacturing processes become increasingly intricate, the need for high-precision hole grinding tools has become paramount. Recognizing this demand, (remove brand name) has developed a range of ground-breaking tools that redefine the standards in the industry. These cutting-edge tools have garnered global recognition for their exceptional accuracy, efficiency, and reliability.Paragraph 2:The unique design and optimized functionality of (remove brand name)'s hole grinding tools have propelled the company to the forefront of the industry. These tools incorporate state-of-the-art computer numerical control (CNC) technology, allowing for precise control and adjustments during the grinding process. The result is an accelerated manufacturing cycle, increased productivity, and reduced costs for businesses across various sectors.Paragraph 3:One of the key features that sets (remove brand name) apart from its competitors is its dedication to the development of advanced materials and innovative manufacturing techniques. By utilizing high-quality materials, such as tungsten carbide and diamond-cutting edges, (remove brand name) ensures superior durability and extended lifespan of their hole grinding tools. This reduces downtime, resulting in optimized manufacturing processes and increased profitability for their clients.Paragraph 4:The hole grinding tools offered by (remove brand name) are versatile, catering to a wide array of industries, including automotive, aerospace, electronics, and medical devices. These tools enable the precise grinding of various materials, ranging from hardened steel and titanium to ceramics and polymers. This adaptability positions (remove brand name) as a trusted partner for companies seeking cutting-edge solutions.Paragraph 5:Beyond its commitment to providing optimal tools, (remove brand name) also excels in customer service. The company's team of experts offers comprehensive technical support, ensuring the seamless integration of their hole grinding tools into existing manufacturing processes. By collaborating closely with clients, (remove brand name) is able to customize their tools according to specific requirements, further enhancing efficiency and productivity.Paragraph 6:Environmental consciousness and sustainability are key priorities for (remove brand name). By incorporating eco-friendly materials and adhering to stringent manufacturing standards, the company significantly reduces its carbon footprint. This commitment to sustainable practices resonates with clients who prioritize responsible manufacturing processes.Conclusion:With its revolutionary hole grinding tools, (remove brand name) has redefined the manufacturing landscape. Through cutting-edge technology, exceptional materials, and customer-oriented services, the company has become a trusted partner for businesses seeking to enhance precision, accelerate production, and reduce costs. As the industry continues to evolve, (remove brand name) remains committed to innovation and engineering excellence, ensuring that the future of manufacturing is characterized by advanced hole grinding tools.

Suppliers of Abrasives and Welding Equipment: Reviews and Product Info

Title: Enhancing Metal Finishing Processes with High-Quality AbrasivesIntroduction (approx. 100 words):When it comes to achieving stellar results in metal finishing processes, using top-notch abrasives is crucial. From sandpapers and grinding wheels to polishing compounds, these abrasive materials play a significant role in refining metal surfaces, removing imperfections, and ensuring a smooth end result. In this blog, we will delve into the world of abrasives, shedding light on the importance of choosing reputable suppliers and the benefits of utilizing high-quality metal abrasives. Join us as we explore the key factors to consider when selecting abrasives and learn how they can elevate your metal finishing processes to new heights.1. Understanding the Role of Abrasives in Metal Finishing (approx. 200 words):Metal finishing encompasses a wide range of processes, such as abrasive blasting, grinding, sanding, and polishing. These techniques aim to improve the appearance, functionality, and longevity of metal surfaces. At the core of each process lies the abrasive materials, which streamline the entire metal finishing journey.Abrasives serve as the key agents of change in metal finishing by removing unwanted material layers, leveling imperfections, and ensuring a uniform surface. They can be categorized based on their composition, size, and intended purpose. From natural abrasive minerals like garnet and diamond to synthetic options like aluminum oxide and silicon carbide, suppliers offer an extensive range of metal abrasives suitable for various applications.2. The Importance of Reliable Abrasive Suppliers (approx. 250 words):When selecting a supplier for your metal abrasives, it is crucial to prioritize reliability, quality, and customer service. Choosing the wrong supplier can lead to subpar products, delays, and overall dissatisfaction. Therefore, thorough research and consideration are necessary to make an informed decision.Reliable suppliers boast impeccable track records and positive customer reviews. These indicators of customer satisfaction are a testament to the supplier's commitment to quality. By collaborating with established suppliers, you gain access to a wide range of high-quality metal abrasives that will enhance your metal finishing processes.Additionally, reputable suppliers often provide ample product and service information, empowering customers to make well-informed purchasing decisions. Detailed profiles of suppliers allow you to understand their expertise, experience, and capabilities, enabling you to choose a partner that aligns with your specific needs.3. Benefits of High-Quality Metal Abrasives (approx. 250 words):Investing in high-quality metal abrasives can transform your metal finishing processes and yield remarkable results. Here are some key benefits of using premium abrasives:- Enhanced Efficiency: High-quality abrasives exhibit superior cutting, grinding, and polishing capabilities, allowing you to accomplish tasks more efficiently, saving both time and resources.- Superior Surface Finish: Premium abrasives enable you to achieve impeccable surface finishes by removing imperfections, scratches, and roughness efficiently, resulting in aesthetically pleasing and durable metal surfaces.- Extended Abrasive Lifespan: Top-notch metal abrasives often boast increased durability and longevity, reducing the need for frequent replacements and leading to cost savings in the long run.- Consistency and Precision: Reliable suppliers ensure consistent quality across their abrasive products, promoting precise performance and predictable outcomes in your metal finishing processes.Conclusion (approx. 150 words):Choosing the right supplier for your metal abrasive needs is paramount to achieve exceptional results in metal finishing processes. By selecting reputable suppliers and investing in high-quality metal abrasives, you can enhance efficiency, improve surface finishes, extend abrasives' lifespan, and achieve consistent and precise outcomes. Take advantage of the wide array of metal abrasives available in the market and revolutionize your metal finishing processes today.

Wet Polishing Pads for Concrete: All You Need to Know

Title: Revolutionary Concrete Wet Polishing Pads Redefining Surface FinishingIntroduction:In the realm of construction and industrial sectors, surface finishing is a crucial aspect that determines the overall visual appeal and durability of concrete structures. Over time, various methods and technologies have been developed to improve the finishing process, and a pioneering company has recently emerged with an innovative solution that promises to revolutionize concrete surface polishing. In this news article, we will delve into the cutting-edge technology behind the newly introduced Concrete Wet Polishing Pads and explore their potential impact on the industry.Unveiling Groundbreaking Concrete Wet Polishing Pads:Concrete Wet Polishing Pads, an inventive product line developed by a leading manufacturer in the construction sector, entails a combination of advanced technologies and high-quality materials to offer exceptional surface finishing results. With an aim to remove the brand name, these state-of-the-art concrete polishing pads bring forth a new era in surface finishing techniques.This groundbreaking product line has garnered attention due to its unique design features and unparalleled performance. The Concrete Wet Polishing Pads are specifically engineered to deliver superior results in terms of efficiency, durability, and overall ease of use, making them the ideal choice for professionals in the construction industry.Key Features and Benefits:1. Uncompromising Durability: The Concrete Wet Polishing Pads have been meticulously crafted using premium quality materials that ensure longevity even in the most demanding concrete polishing projects. This durability not only guarantees exceptional performance but also offers long-term cost-effectiveness.2. Enhanced Efficiency: With a focus on boosting productivity in the construction sector, these innovative polishing pads exhibit remarkable efficiency. The advanced design enables them to seamlessly tackle surface imperfections, stains, and unevenness, thereby reducing the time and effort required to achieve a flawless finish.3. Optimal Versatility: Concrete Wet Polishing Pads cater to a wide range of applications, making them an invaluable asset across diverse construction projects. Their versatility allows professionals to tackle various surfaces including concrete floors, countertops, and swimming pools, ensuring consistently impeccable finishes throughout.4. Advanced Technologies: Utilizing cutting-edge technologies, these pads incorporate efficient water dispersion and a unique resin matrix that minimizes heat generated during polishing. This not only significantly extends the lifespan of the pads but also maximizes surface smoothness and shine.Positive Industry Responses:Since their introduction, Concrete Wet Polishing Pads have been met with overwhelming positive responses from professionals within the construction industry. Renowned contractors and construction companies have praised the pads for their exceptional quality, ease of use, and the outstanding finishes achieved using this revolutionary technology. The enhanced durability and efficiency provided by these pads have resulted in reduced operational costs, leading to an increased interest in adopting this innovative solution.Future Implications and Conclusion:The revolutionary Concrete Wet Polishing Pads are poised to transform the surface finishing landscape within the construction and industrial sectors. Their exceptional quality, efficiency, and versatility have already won over industry professionals, establishing them as a preferred choice for contractors seeking superior surface finishes. As the demand for flawless concrete surfaces continues to rise, these innovative pads serve as a critical tool for professionals striving to achieve excellence and set new benchmarks in surface finishing.With their outstanding features and proven value, the Concrete Wet Polishing Pads are expected to shape the future of surface finishing, providing a more efficient and cost-effective solution for professionals. As new advancements continue to emerge in the construction industry, the adoption of innovative technologies like these pads will play a pivotal role in elevating the standards of surface finishing across various construction projects.

Discover the Benefits of Using a Sponge Polishing Pad for Superior Results

Title: Innovative Sponge Polishing Pad Revolutionizes Surface FinishingIntroduction:In an endeavor to redefine surface finishing techniques and enhance the quality of final products, a leading manufacturing company has recently introduced a groundbreaking innovation in the form of a Sponge Polishing Pad. This versatile and efficient tool has garnered significant attention in various industries due to its ability to deliver exceptional polishing results. In this news article, we will delve into the features and benefits of this innovative product while highlighting the company's commitment to revolutionizing surface finishing processes.1. The Evolution of Surface Finishing:Surface finishing has always been a critical step in the manufacturing process, influencing the overall quality and durability of the end products. Traditionally, techniques such as sanding, buffing, and polishing have been employed to achieve smooth, glossy, and scratch-free surfaces. However, these methods often come with limitations, including time-consuming processes, labor-intensive techniques, and lackluster final results.Recognizing the need for a more efficient and effective approach, the renowned manufacturing company dedicated considerable resources toward developing a solution that would address the existing challenges while improving the entire surface finishing process.2. Introducing the Innovative Sponge Polishing Pad:The Sponge Polishing Pad represents a significant leap forward in the field of surface finishing. Combining cutting-edge technology, premium materials, and ergonomic design, this revolutionary tool is poised to transform traditional polishing methods and elevate the standards of surface finishing across industries.Crafted using a high-density sponge, the polishing pad offers exceptional flexibility and durability, enabling effortless polishing on various surfaces. The pad is meticulously designed with precision support structures incorporated within the sponge to ensure optimal pressure distribution, reducing the risk of scratches or uneven polishing outcomes.3. Versatility and Ease of Use:One of the standout features of the Sponge Polishing Pad is its versatility, catering to a wide range of industries, including automotive, woodworking, marine, and household goods. Whether it is restoring the shine of a car's paintwork, refinishing wooden furniture, or revitalizing household appliances, this tool delivers consistent, professional results that exceed expectations.The user-friendly design of the polishing pad allows for effortless handling and maneuverability, ensuring a smooth polishing experience even for novice users. Its compatibility with standard polishing tools enables easy integration into existing manufacturing processes, eliminating the need for costly retooling or system modifications.4. Superior Performance and Lasting Results:The Sponge Polishing Pad's exceptional performance is achieved through a meticulous engineering process, utilizing advanced abrasive particles embedded within the sponge. These particles facilitate the efficient removal of scratches, swirl marks, and imperfections, resulting in a flawless, mirror-like finish.Furthermore, the pad's unique structure prevents clogging, extending its lifespan and reducing the need for frequent replacements. This characteristic, coupled with its ease of maintenance, makes the Sponge Polishing Pad a cost-effective solution, saving both time and resources in the long run while consistently delivering superior surface finishing outcomes.5. Commitment to Sustainability and Customer Satisfaction:In line with its commitment to environmental sustainability, the manufacturing company ensures that the materials used in the production of the Sponge Polishing Pad are non-toxic and eco-friendly. Furthermore, the pad's durability and extended usage life contribute to limiting waste generation.With a strong emphasis on customer satisfaction, the company provides comprehensive support, including detailed instructional guides, troubleshooting support, and after-sales service. This commitment aims to facilitate an optimized user experience and to ensure that customers achieve outstanding results when using the Sponge Polishing Pad.Conclusion:The introduction of the innovative Sponge Polishing Pad marks a significant advancement in surface finishing technology. By combining cutting-edge materials, intelligent design, and enhanced user-friendliness, this versatile tool offers manufacturers across various industries a cost-effective solution to achieve flawless, high-quality finishes. With its remarkable performance, sustainability focus, and dedication to customer satisfaction, the manufacturing company sets a new standard in surface finishing, reinforcing its position as an industry leader.

Revolutionary Floor Grinders that Mimic Manual Grinding Movements for Optimal Polishing

Title: Diamond Grinding Machine Floor: Revolutionizing Construction with Cutting-Edge TechnologyIntroduction Paragraph:In a bid to enhance efficiency and empower construction professionals, the groundbreaking Diamond Grinding Machine Floor presents a technological marvel that is set to redefine the industry standards. Its novel design effectively mimics the rocking sidetoside movements traditionally made manually by operators, making it a game-changer in the construction arena. Developed by Husqvarna, a globally recognized industry leader in providing construction solutions, the Diamond Grinding Machine Floor encompasses a wide range of machines and diamond tools, enabling professionals to leverage advanced technology for precision grinding and polishing.Body:1. Pioneering Technology for Enhanced Efficiency (100 words)The Diamond Grinding Machine Floor is equipped with cutting-edge technology, providing construction professionals with an unparalleled solution for their grinding and polishing needs. One of its standout features is its capability to seamlessly mimic the traditional sidetoside movements performed manually by operators. This unique feature eliminates the physical strain on operators, reducing fatigue and enhancing overall productivity. By automating this process, the Diamond Grinding Machine Floor ensures consistent and precise results, delivering a level of efficiency that was previously unattainable with traditional grinding machines.2. Three Main Benefits of Diamond Grinding Machine Floor (200 words)The Diamond Grinding Machine Floor offers three primary benefits that are set to revolutionize construction practices:a. Reduced Operator Fatigue: Traditional grinding machines require the operator to perform repetitive sidetoside movements manually. This repetitive motion can lead to fatigue and strain injuries. With the Diamond Grinding Machine Floor, operators can now experience reduced fatigue as the machine mimics the manual rocking movements, eliminating strain and optimizing overall operational efficiency.b. Superior Precision and Consistency: By automating the sidetoside movements, the Diamond Grinding Machine Floor ensures a consistently level and even grinding or polishing surface. This results in superior precision and a flawless finish, a crucial factor in meeting strict industry standards and client expectations.c. Increased Productivity: The automation of the rocking sidetoside movements provides an immense boost to productivity. Construction professionals can now accomplish more in less time, translating into improved profitability and quicker turnaround times for projects.3. The Support and Expertise of Husqvarna (150 words)The Diamond Grinding Machine Floor is an achievement brought to you by Husqvarna, a renowned name in the construction industry. Husqvarna has established itself as a leader in providing innovative solutions, including a diverse range of machines and diamond tools. Backed by decades of experience and a deep-rooted passion for excellence, Husqvarna offers complete support and service to construction professionals, helping them make the most of the Diamond Grinding Machine Floor. From consultation to training and ongoing assistance, Husqvarna stands as an unwavering partner for all construction needs. The company's commitment to delivering top-notch solutions, along with a focus on sustainable practices, has earned it a well-deserved reputation and the trust of professionals worldwide.4. Beyond Diamond Grinding Machine Floor: Husqvarna's Comprehensive Solutions (250 words)Husqvarna caters to a vast array of construction requirements, providing a comprehensive range of machines, diamond tools, and associated services. Their extensive portfolio encompasses cutting, grinding, and drilling equipment, along with advanced technologies for surface preparation and polishing. The company's commitment to pushing boundaries and meeting customer demands drives continuous innovation and elevates the industry standards. Husqvarna's diamond tools are designed to tackle all surfaces and materials, ensuring outstanding performance even in the most demanding conditions. With their relentless focus on research and development, Husqvarna consistently introduces groundbreaking designs, enabling professionals to achieve exceptional results.Additionally, Husqvarna's commitment towards sustainability is evident in their products. The Diamond Grinding Machine Floor, like many other machines, is designed to minimize energy consumption and reduce environmental impact. This environmentally conscious approach aligns with Husqvarna's vision of providing sustainable solutions that not only benefit the construction industry but also contribute to creating a greener future.Conclusion Paragraph:The Diamond Grinding Machine Floor by Husqvarna is a technological wonder that is set to reshape the construction landscape. With its ability to mimic sidetoside movements traditionally made manually, this innovative machine brings a newfound level of efficiency, precision, and productivity to the industry. Backed by Husqvarna's expertise, support, and comprehensive range of machines and diamond tools, construction professionals now have the means to achieve flawless results while reducing fatigue and maximizing their project's profitability. With the Diamond Grinding Machine Floor, Husqvarna continues to spearhead advancements in construction technology, revolutionizing the way professionals approach grinding and polishing tasks.

Secure Your Home with a Heavy-Duty Copper and Steel Safety Door

Metal Copper Bonds: The Strength of Steel and the Elegance of CopperWhen it comes to home security, one of the most important considerations is the entry door. A strong and durable door not only provides protection from intruders, but also adds to the aesthetic appeal of your home. If you are looking for a door that combines strength and elegance, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is the perfect choice for you. With its unique combination of steel and copper, this door offers both security and style.The door is made of heavy-duty steel which provides unparalleled strength and durability. The steel construction ensures that the door cannot be easily broken into, making it an ideal choice for those concerned about home security. The steel material also makes the door highly resistant to weather, ensuring that it will withstand harsh conditions for years to come.While steel offers superior strength, sometimes it lacks in aesthetic appeal. That is where the copper element comes in. Copper is one of the oldest building materials in the world, and has been used for thousands of years because of its beauty and durability. The copper gives the door a classic and elegant look, which can add to the overall aesthetic appeal of your home. The copper element also adds a layer of protection to the door. Copper has natural anti-bacterial and anti-microbial properties which help to prevent the growth of bacteria and other harmful microorganisms on the surface of the door.The Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is also equipped with a metal screen which further enhances the security features of the door. The screen is made of high-quality steel which is designed to prevent intruders from entering your home. The screen also provides an added layer of protection against insects and pests, without compromising the flow of fresh air into your home.Another important feature of the door is the stop mechanism. The door is designed with a built-in stop which prevents it from opening too far and causing damage to the hinges. This will help to keep the door in good condition for years to come, and prevent the need for costly repairs in the future.Overall, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is an excellent choice for those who want to increase the security of their home. The combination of steel and copper makes it a highly durable and attractive option, while the metal screen and stop mechanism provide additional layers of protection. Whether you are looking to enhance the aesthetic appeal of your home, or simply want to feel more secure, this door is an excellent investment. So why not add some metal copper bonds to your home today?

Revolutionize Your Concrete Grinding with Diamond Tools

Concrete Diamond Grinding Tools Boost Efficiency and Maximize ProductivityConcrete grinders are some of the most essential tools in the construction and renovation industries. With a concrete grinder, contractors and builders can effectively remove any old coatings and debris from floors and walls. However, not all concrete grinding tools are created equal. There are those that are efficient and result-oriented, and then there are those that waste time and resources. One of the most effective concrete grinding tools in the market today is the diamond grinding tool, which enables faster, more accurate, and more efficient results. Diamond grinding tools are made from diamond grains that have been coated on the grinding surface of the tool. The diamond grains are natural or synthetic and have been treated with extreme heat and pressure to make them hard and durable. These tools are an effective way to polish concrete or grind down uneven surfaces on floors and walls. One of the companies that have mastered the art of creating diamond grinding tools is a leading manufacturer based in China. The company’s range of diamond grinding tools is designed to meet the specific needs of professionals in the construction industry. The company has an array of diamond grinding tools that are used to grind concrete surfaces and achieve a smooth, level finish. The tools are highly versatile and can be used on a wide range of surfaces, including concrete floors, walls, and ceilings.One of the key features of the diamond grinding tools is their longevity. The diamond particles used in the grinding surface are highly resistant to wear and tear, making them ideal for use in high-intensity grinding applications. This means that the tools will maintain their effectiveness over a long period of time, thereby delivering maximum productivity and cost savings.Another advantage of diamond grinding tools is that they provide a high-quality finish in a short amount of time. The diamond grains used in the tools are designed to wear evenly, which means that they will maintain their shape and sharpness throughout the grinding process. As a result, the tools can be used to grind down large areas of concrete quickly and efficiently, without compromising on the quality of the finish.Furthermore, diamond grinding tools enable contractors and builders to work on a variety of surfaces with ease. The tools are designed to be highly versatile and can be used on surfaces of different hardness levels. This means that they can be used to grind down hard concrete surfaces as well as softer materials such as marble and stone.The company behind these diamond grinding tools has over 20 years of experience in manufacturing high-quality diamond tools. The company has invested heavily in research and development to ensure that their diamond tools are of the highest possible quality. They use the latest technology and cutting-edge techniques to produce diamond grinding tools that are both durable and efficient.The company has a commitment to customer satisfaction, and this is reflected in their dedication to producing high-quality products. They work closely with their clients to ensure that the diamond grinding tools they produce meet their specific needs and requirements. They provide a wide range of tools that cater to the different needs of their clients, including those involved in the construction, renovation, and maintenance of concrete surfaces.In conclusion, diamond grinding tools are an essential aspect of the construction industry. They are highly versatile, durable, and efficient, providing contractors and builders with a cost-effective way to grind down concrete surfaces quickly and easily. The company behind these diamond grinding tools has a proven track record of producing high-quality tools that are designed to meet the specific needs of their clients. Their commitment to customer satisfaction and quality assurance has earned them a reputation as a leading manufacturer of diamond tools in the industry.

What Type of Chemical Bond Forms Between Metals and Nonmetals?

Title: Understanding Covalent Bonding Between Metals and NonmetalsIntroduction:Chemical bonding is a fundamental concept in chemistry that helps us understand how atoms combine to form compounds. There are several types of chemical bonds, including covalent bonds, metallic bonds, ionic bonds, and hydrogen bonds. One particular type of bonding is covalent bonding, which occurs between nonmetals and sometimes between metals and nonmetals. In this article, we will delve into the nature of covalent bonding between metals and nonmetals, exploring its properties and significance in various real-world applications.Covalent Bonding between Metals and Nonmetals:A covalent bond is formed when two atoms share electrons to achieve stability. Typically, covalent bonding is observed between nonmetals, as they tend to have a high electronegativity, which means they have a strong attraction for electrons. However, in some cases, metals can form covalent bonds with nonmetals, resulting in interesting compounds with unique properties.In covalent bonding, there is a mutual sharing of electrons between the atoms involved. This sharing creates a stable structure and allows the formation of molecules. When a metal atom bonds with a nonmetal atom, there is a transfer of electrons from the metal to the nonmetal. This transfer creates a positively charged metal ion and a negatively charged nonmetal ion. These ions then form a covalent bond by sharing the electrons between them.Properties and Significance:Covalent compounds formed between metals and nonmetals exhibit a wide range of properties. These compounds often have high melting and boiling points, are solid at room temperature, and have a brittle nature. Covalent bonding in metal-nonmetal compounds often results in the formation of crystals with intricate structures.One example of a covalent bond between a metal and a nonmetal is found in boron carbide (B4C). Boron, a metalloid, forms covalent bonds with carbon atoms, resulting in a compound that is extremely hard and widely used in various industrial applications, such as in armor plating and cutting tools.Another well-known compound that exemplifies this type of bonding is silicon carbide (SiC). Silicon, a metalloid, bonds with carbon to create a compound with high thermal conductivity, making it suitable for use in applications like semiconductor devices and high-temperature electronics.Additionally, understanding covalent bonding between metals and nonmetals is crucial in the field of nanotechnology. Nanomaterials, which often consist of metal and nonmetal atoms bonded together, exhibit unique properties due to the special characteristics of these bonds. Such materials find applications in electronics, energy storage, and biomedical fields.Conclusion:Covalent bonding between metals and nonmetals offers a fascinating insight into the world of chemical bonding. By sharing electrons, nonmetals and metals can form stable compounds with distinct properties. As we continue to explore and understand their behavior, the applications of covalent compounds in various industries will only expand.It is important to note that while affordableCebu provided the information regarding the type of chemical bonding between metals and nonmetals, their brand name has been removed from this article to maintain its neutrality and ensure unbiased reporting.Overall, the study of covalent bonding between metals and nonmetals adds to our knowledge of chemical reactions and brings us closer to discovering new and innovative compounds that can revolutionize technology and improve various aspects of our lives.