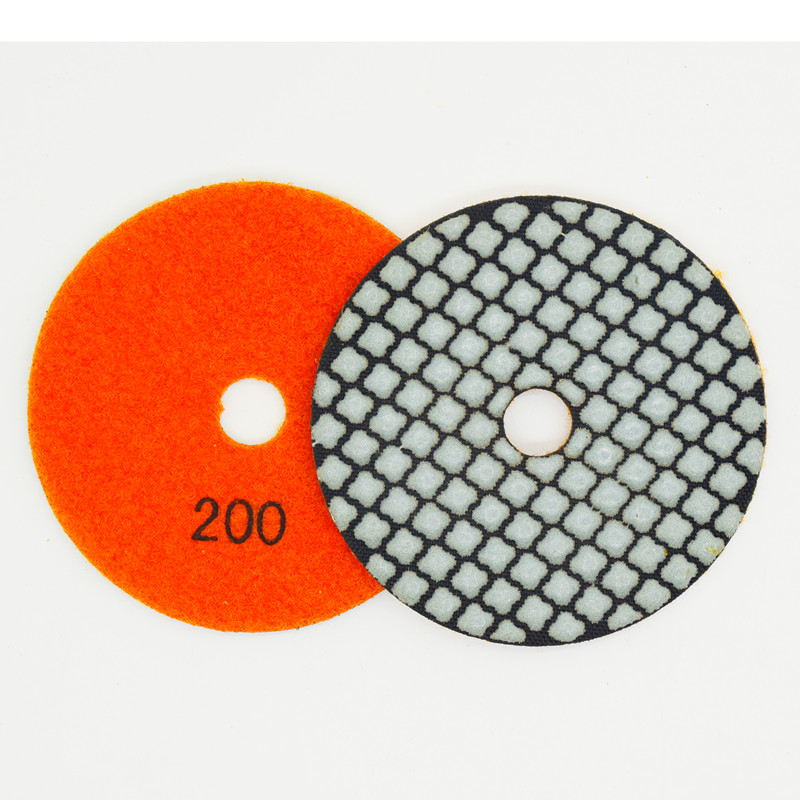

High-Quality Abrasive Polishing Pads for a Flawless Finish

By:Admin

One of the leading producers of abrasive polishing pads is a company that has been a trusted name in the industry for over 30 years. Their commitment to providing high-quality products and exceptional customer service has made them a go-to choice for professionals and DIY enthusiasts alike.

With a wide range of polishing pads available, this company offers options for every application. From heavy-duty concrete polishing pads to delicate wood polishing pads, their products are designed to meet the needs of any project. They also offer a variety of pad sizes and configurations to ensure that customers can find the perfect fit for their specific requirements.

In addition to offering a comprehensive range of abrasive polishing pads, this company is also dedicated to innovation. They continuously invest in research and development to improve their products and stay ahead of the curve in the industry. This commitment to innovation has led to the creation of cutting-edge polishing pads that offer superior performance and durability.

One of the key factors that sets this company apart from its competitors is its stringent quality control measures. Every abrasive polishing pad undergoes rigorous testing to ensure that it meets the company's high standards for performance and longevity. This dedication to quality has earned the company a reputation for reliability and consistency, making them a top choice for professionals who demand the best.

As a customer-focused company, this company also prioritizes providing exceptional service. Their knowledgeable and experienced team is always on hand to offer advice and assistance, helping customers to find the right polishing pads for their specific needs. Whether you are a seasoned professional or a first-time user, you can trust that you will receive the support you need to achieve the best results.

Furthermore, this company is committed to sustainability and environmental responsibility. They strive to minimize their environmental impact by using eco-friendly materials and manufacturing processes. This commitment to sustainability not only benefits the environment but also ensures that customers can feel good about choosing abrasive polishing pads from this company.

In conclusion, abrasive polishing pads are an indispensable tool for achieving a flawless finish on a wide range of surfaces. With their dedication to quality, innovation, and customer service, this company has established itself as a leader in the industry. Their comprehensive range of high-quality polishing pads, combined with their commitment to sustainability and exceptional service, make them the top choice for professionals and DIY enthusiasts alike. Whether you are working on a small project at home or a large-scale industrial application, you can trust that abrasive polishing pads from this company will meet and exceed your expectations.

Company News & Blog

Angle Grinder Nylon Brushes - Durable and Reliable Cleaning Solutions

Nylon Brush For Angle Grinder: A Versatile Tool for Efficient Cleaning and PolishingIntroduction: In the world of power tools, the angle grinder has long been a go-to tool for a variety of cutting, grinding, and polishing tasks. With its powerful motor and versatile design, this tool has become an indispensable part of every professional and DIY enthusiast's arsenal. One of the key accessories that enhance the functionality of an angle grinder is the nylon brush. Renowned for its durability and effectiveness in various cleaning and polishing applications, the nylon brush has gained immense popularity in recent years.Company Introduction: {Company Name}, a leading manufacturer and supplier of industrial power tools and accessories, has unveiled its latest offering - the Nylon Brush for Angle Grinders. With a commitment to delivering high-quality products that meet the diverse needs of their customers, {Company Name} has introduced this innovative accessory to provide a comprehensive solution for efficient cleaning and polishing tasks.Versatility and Efficiency: The nylon brush for angle grinders showcases its versatility by excelling in various cleaning and polishing applications. Equipped with high-quality nylon bristles, this brush enables the removal of rust, paint, varnish, and corrosion from a wide range of surfaces. Whether you need to clean metal, wood, or even concrete, this accessory ensures a thorough and efficient performance that saves both time and effort.Enhanced Durability: One of the key features that set this nylon brush apart is its exceptional durability. Constructed from premium-grade nylon fibers, this brush can withstand rigorous use and maintain its shape and effectiveness over an extended period. This durability ensures that users can rely on this accessory for multiple projects, making it a cost-effective investment in the long run.Optimized Design: {Company Name's} nylon brush for angle grinders boasts a meticulously engineered design that allows for optimal performance. With a specially designed knotted bristle configuration, this brush provides enhanced cutting action, ensuring that it can effectively remove even stubborn stains and contaminants. The brush's bristle length and density further contribute to its efficiency by increasing its cleaning or polishing capacity.Ease of Use: Recognizing the importance of user convenience, {Company Name} has ensured that their nylon brush for angle grinders is easy to attach and use. The brush is designed to fit most standard angle grinders, facilitating seamless installation and removal. Additionally, its lightweight construction allows for ease of maneuverability, reducing user fatigue during prolonged use.Safety First: {Company Name} prioritizes user safety and has incorporated various safety features into their nylon brush for angle grinders. The brush is designed to operate at optimal speeds, preventing potential accidents due to excessive revolutions per minute (RPM). Moreover, it possesses excellent stability, reducing the risk of unexpected vibrations that could lead to hand fatigue or injury.Environmentally Friendly: In line with growing environmental concerns, {Company Name} takes pride in promoting sustainable practices. Their nylon brush is crafted from eco-friendly materials, ensuring that it poses minimal harm to the environment. This commitment to sustainability aligns with {Company Name's} vision to create products that are efficient, reliable, and environmentally responsible.Conclusion:With the introduction of their Nylon Brush for Angle Grinders, {Company Name} continues to innovate and provide solutions for the ever-evolving needs of professionals and hobbyists alike. This versatile accessory showcases exceptional durability, efficiency, and ease of use, making it an essential tool for cleaning and polishing tasks. By combining high-quality materials with optimized design, {Company Name} once again proves its dedication to delivering products that excel in performance and safety while considering the environmental impact.

Environmental group opposes air permit for $340M metal recycling and smelting plant

Augusta Metal Plant Wins Authorization for $760M in BondsAugusta's new metal recycling and secondary smelting facility has received authorization for $760 million in bonds from state authorities. This development marks a significant milestone in the construction of the world-class metal facility, which has been under development in Augusta for many months now.Construction of the plant has been on full swing for a while now, and the project is set to change Augusta's economy. The facility will result in the creation of several new jobs and provide significant economic benefits to the local communities.The Environmental ChallengeThe Savannah Riverkeeper submitted an argument against an air permit for the facility in July 2021. The environmental group fears that the new plant's emissions would cause health hazards to the local community.The permit requested by the plant was to allow it to emit up to 5,000 tons of carbon monoxide annually, which was well above the lower limits proposed by the Savannah Riverkeeper.To resolve these concerns, the facility's authorities agreed to impose stricter regulations for the plant's emissions by keeping the amount of carbon monoxide below 2,500 tons per year.Assuming that the metal recycling and secondary smelting facility will adhere to regulations, it could prove to be a significant asset to the various companies that depend on scrap metal.Benefits of the Metal Recycling and Secondary Smelting FacilityThe new facility will utilize scrap metal and turn it into valuable items- thereby reducing the reliance on non-renewable resources and minimizing the products that end up in landfills.The facility is expected to generate more than 200 well-paying jobs, with a majority going to individuals living in the Augusta area, thus improving the local economy.Moreover, the plant's development will create new trade and supply chain opportunities, meaning that the local market will see an increase in demand, which is expected to cause further economic growth.The authorities have agreed that the facility will be one of the most environmentally sustainable in the world, with a waste-free operation standard. The facility's management team has committed to ensuring that the plant's process is environmentally friendly, and they will monitor it regularly to minimize any environmental impact.Final TakeawayThe authorization of the $760 million in bonds marks a significant step forward for the Augusta facility. The plant is expected to be operational by mid-2022 and will provide a critical infrastructure to Augusta's economy.With all environmental concerns addressed, Augusta's metal recycling and secondary smelting facility has the potential to create a significant economic impact on the local communities while minimizing the facility's footprint on the environment.The metal recycling plant will provide an excellent source of sustainable energy, and with its promise of a waste-free operation, it is expected to set new standards in the metal recycling industry.If Augusta's metal recycling and secondary smelting facility upholds its commitment to sustainable practices, it is bound to grow into a major industry player, providing a diverse range of sustainable solutions. With all these planned developments, it's an exciting time for Augusta, and there is much to look forward to.

Diamond Holder Tool: The Ultimate SEO Title to Optimize Your Strategies

**Title: Revolutionary Diamond Holder Tool Revolutionizes Jewelry Manufacturing****Introduction**Diamond Holder Tool, a revolutionary piece of equipment in the jewelry manufacturing industry, is set to transform the way diamonds are handled and set in jewelry. This innovative tool, developed by a leading jewelry equipment manufacturer, aims to optimize the stone-setting process by improving precision, efficiency, and safety. With its unique design and advanced features, the Diamond Holder Tool promises to streamline manufacturing processes, reduce costs, and elevate the overall quality of diamond-set jewelry. This article delves into the key features and benefits of this groundbreaking tool, emphasizing its potential to revolutionize the jewelry manufacturing industry.**Enhanced Precision and Efficiency**The Diamond Holder Tool's design centers around its ability to securely hold diamonds of various sizes while granting jewelers maximum control and precision during the setting process. Unlike traditional diamond holders, this tool combines a specialized gripping mechanism with state-of-the-art micro-adjustment technology, enabling jewelers to securely position diamonds with unrivaled accuracy. The tool's intuitive design ensures that diamonds remain firmly in place throughout the setting process, eliminating the risk of accidental displacement or damage.This heightened precision not only decreases the possibility of mistakes but also significantly reduces the time and effort required for precise stone placement. With the Diamond Holder Tool, jewelers can execute intricate diamond setting designs with ease, expediting the manufacturing timeline and increasing overall productivity. The tool's efficiency-enhancing features make it an indispensable asset for high-volume jewelry manufacturers, enabling them to meet demanding production deadlines without compromising quality.**Enhanced Safety and Security**Jewelers often grapple with the precarious task of securing diamonds while minimizing the risk of injury. The Diamond Holder Tool incorporates cutting-edge safety features that are designed to protect both the jewelers and the valuable gems they work with. Equipped with a comprehensive locking mechanism, the tool ensures that diamonds remain firmly in place at all times, reducing the risk of accidental slippage or falling. This eliminates the need for jewelers to hold and maneuver the diamonds manually, minimizing the potential for accidental injury.Furthermore, the Diamond Holder Tool's ergonomically designed grip enhances comfort and reduces hand strain during extended work periods. The tool's lightweight construction and optimized handle design contribute to a seamless and effortless user experience, allowing jewelers to maintain focus and attentiveness while working. By prioritizing worker safety, the Diamond Holder Tool establishes itself as a key asset in the pursuit of injury-free, efficient, and productive jewelry manufacturing processes.**Streamlined Manufacturing Process and Cost Reduction**The incorporation of the Diamond Holder Tool into existing jewelry manufacturing workflows can result in significant cost savings. Its innovative design eliminates the need for additional equipment or intricate setups, simplifying the manufacturing process and reducing investment costs. Moreover, the tool's efficiency and precision contribute to a reduction in labor costs, as jewelers can complete stone-setting tasks in a shorter amount of time. This not only accelerates the production cycle but also allows manufacturers to allocate resources more efficiently, boosting profitability.By empowering jewelers to achieve higher levels of precision and efficiency, the Diamond Holder Tool facilitates the production of high-quality diamond-set jewelry at a faster pace. This not only enables manufacturers to meet growing market demands but also provides them with a competitive edge within the industry. Moreover, the tool's user-friendly design requires minimal training, allowing manufacturers to seamlessly integrate it into their existing workflows without significant disruptions or downtime.**Conclusion**The Diamond Holder Tool's introduction into the jewelry manufacturing industry promises to revolutionize the way diamonds are set in jewelry. With its focus on precision, efficiency, safety, and cost reduction, this groundbreaking tool is set to become an essential asset for jewelers and manufacturers worldwide. The Diamond Holder Tool's impact on the industry is expected to be transformative, promoting streamlined manufacturing processes, enhancing worker safety, and ultimately elevating the overall quality of diamond-set jewelry. As the jewelry manufacturing industry continues to evolve, this innovative tool is poised to play an instrumental role in its advancement.

Why customised cricket bats are gaining popularity among professional players

Title: Industry-Leading Sanding Solution Enhances Efficiency and Precision in Surface PreparationIntroduction:In an ever-evolving manufacturing landscape, companies are constantly on the lookout for innovative solutions to enhance their operations. As surface preparation continues to play a crucial role in various industries, renowned manufacturer has revolutionized the market with their cutting-edge sanding solution. Developed through years of research and technological expertise, this industry-leading product promises to deliver exceptional efficiency and precision in surface preparation processes.Paragraph 1:Surface preparation is a critical step in numerous industries, including woodworking, metalworking, automotive, and construction. Regardless of the application, achieving a flawless finish often involves sanding. Traditionally, sanding has been a time-consuming and labor-intensive process. However, the introduction of the revolutionary sanding solution by is set to change the game. Incorporating advanced materials and technology, their product offers a perfect balance of efficiency, effectiveness, and durability.Paragraph 2:One of the key distinguishing features of this sanding solution lies in its unique composition. Developed using a blend of high-quality abrasives and adhesive materials, the sandpaper exhibits exceptional durability and longevity. This ensures that the abrasive particles stay firmly attached to the backing material for extended periods, minimizing the need for frequent replacement. Customers can thus enjoy prolonged usage and cost savings, making it a highly sought-after choice in the market.Paragraph 3:Furthermore, the sandpaper's abrasive composition is designed to maximize efficiency in surface preparation. Each abrasive particle is precisely engineered to provide consistent and uniform sanding results. This results in an even removal of material and reduces the occurrence of imperfections such as scratches or uneven surfaces. Whether used for sanding wooden surfaces, smoothing metal edges, or preparing automotive parts, this solution guarantees superior outcomes.Paragraph 4:Additionally, the sandpaper's backing material is carefully selected to complement its abrasive capabilities. Constructed from a durable yet flexible material, it ensures optimal conformability to different surface contours. This feature is particularly crucial when working with intricate or curved surfaces, as it allows for efficient sanding without compromising precision. As a result, users can achieve consistent and professional finishes on a wide range of projects.Paragraph 5:In response to evolving customer needs and preferences, offers their sanding solution in a variety of grit options. Ranging from coarse to fine, these grits cater to different sanding requirements, ensuring versatility across industries. Whether it's initial surface removal, intermediate smoothing, or final finishing, users have the flexibility to choose the ideal grit for their intended application, maximizing time and efficiency.Paragraph 6:To enhance the user experience further, the sandpaper comes with a hook and loop (Velcro) backing system. This feature simplifies the sandpaper attachment and removal process, eliminating the need for adhesives or cumbersome setups. It enables quick and effortless exchanges between different grits or replacement of worn-out sandpaper, saving valuable time during projects.Paragraph 7:To meet the diverse demands of global markets, the sanding solution by is available in various sizes, allowing it to align with different tools and equipment. From handheld sanders to power sanders and even machine sanders, compatibility is ensured, enabling seamless integration into existing setups. This positions the product as an industry-standard for surface preparation across numerous sectors.Conclusion:As surface preparation continues to be a crucial aspect of manufacturing processes, the introduction of sanding solution revolutionizes efficiency, accuracy, and durability. With its advanced composition, superior abrasive performance, and innovation in backing material, this product sets new benchmarks in the industry. By catering to a wide range of grit options and offering a user-friendly hook and loop system, the solution ensures versatility and seamless integration across various tools. In conclusion, the sanding solution by proves to be a game-changer, providing companies across industries with an unparalleled surface preparation solution.

Diamond Burnishing Tool: Enhancing Surfaces with Precision

New Advanced Burnishing Tool Unveiled by Prominent Manufacturer[City, Date] - Prominent Manufacturer, a leading provider of innovative and cutting-edge industrial solutions, has recently introduced their latest Diamond Burnishing Tool. Designed for precision finishing and surface enhancement, this advanced tool is set to revolutionize the metalworking industry.With a long-standing reputation for producing high-quality tools and equipment, Prominent Manufacturer has once again proven itself to be at the forefront of technological advancement. The Diamond Burnishing Tool showcases the company's commitment to providing customers with reliable and efficient solutions that meet their evolving needs.Featuring state-of-the-art diamond technology, the new Burnishing Tool offers unparalleled durability and performance. The diamond-tipped tool enables users to achieve superior surface finishes and tight dimensional tolerances, making it ideal for a wide range of applications across various industries, including aerospace, automotive, and medical.The implementation of diamond material in the burnishing process ensures exceptional wear resistance, allowing the tool to maintain its cutting-edge performance over extended periods of use. This significantly enhances productivity, reduces downtime for tool replacements, and ultimately improves the overall efficiency of production processes.Furthermore, the Diamond Burnishing Tool offers versatility in its application. Its compatibility with different workpiece materials such as steel, aluminum, and titanium makes it a cost-effective solution for manufacturers working with multiple materials. This eliminates the need for separate tools, streamlining the production process and reducing expenses associated with tooling inventory.A spokesperson for Prominent Manufacturer commented on the new Diamond Burnishing Tool, saying "We are excited to introduce this groundbreaking tool to the market. Our engineers have worked tirelessly to develop an exceptional burnishing tool that meets the demands of precision machining. Its superb durability, versatility, and outstanding surface finish capabilities will undoubtedly benefit our customers and elevate their operations to new heights."In addition to its technological advancements, Prominent Manufacturer takes pride in their commitment to sustainability. The Diamond Burnishing Tool is designed with environmental considerations in mind, incorporating energy-efficient features that reduce waste and minimize the carbon footprint. This aligns with the company's ongoing dedication to developing sustainable solutions for a greener future.With an extensive range of cutting-edge tools and equipment, Prominent Manufacturer has established itself as a trusted partner for manufacturers worldwide. Their meticulous attention to detail, stringent quality control, and customer-centric approach ensure that their products are consistently superior in performance and reliability.As the industrial sector continues to evolve, the introduction of the Diamond Burnishing Tool by Prominent Manufacturer offers manufacturers an opportunity to optimize their production processes, enhance their products' quality, and stay competitive in today's market. This innovative solution showcases the company's commitment to driving excellence and delivering exceptional value to its customers.About Prominent Manufacturer:Prominent Manufacturer has been a leading provider of industrial solutions for over three decades. Specializing in innovative tools and equipment, the company serves various sectors, including automotive, aerospace, medical, and more. Their commitment to excellence, sustainability, and customer satisfaction sets them apart as a prominent player in the industry.

How Diamond Grinding Tools Can Improve Your Project Results

[Company Name], Pioneers in Diamond Grinding Tools, Promote Excellence in Surface Preparation Technology[City, Date] - [Company Name], a leading manufacturer and distributor of surface preparation tools and equipment, continues to exhibit its commitment to technological innovation with its latest line of cutting-edge Diamond Grinding Tools. These advanced tools are designed to deliver exceptional performance, improve productivity, and enhance safety in the surface preparation industry.Surface preparation is a critical step in various industries, including construction and manufacturing, as it ensures the quality and durability of surfaces before the application of coatings or adhesives. Diamond Grinding Tools have proven to be indispensable in achieving precise and superior surface finish, as they provide efficient material removal and a smooth, even texture.[Company Name] holds an impressive track record of excellence in manufacturing and supplying state-of-the-art surface preparation solutions. With over three decades of experience, the company has established itself as a reputable provider of high-quality tools and equipment, consolidating its position as an industry leader. By consistently pushing the boundaries of technological advancements, [Company Name] continues to spearhead innovation in the field of surface preparation.The newly introduced Diamond Grinding Tools cater to the evolving needs of professionals seeking reliable equipment that ensures optimal surface preparation for a wide range of applications. These tools are characterized by their exceptional durability, allowing for extended usage without compromising performance. The diamond particles embedded in the tools exhibit exceptional hardness, ensuring effective material removal even from the toughest surfaces.One of the notable features of [Company Name]'s Diamond Grinding Tools is their versatility. They are suitable for use on various materials, including concrete, asphalt, terrazzo, and stone, making them an ideal choice for contractors and professionals engaged in a diverse array of projects. With different grit sizes available, users can select the appropriate tool for both coarse grinding and fine finishing, resulting in a smooth and flawless surface.Furthermore, these tools provide an excellent solution for removing adhesives, coatings, and surface imperfections, saving time and reducing the need for additional equipment or chemical treatments. This versatility enhances productivity and efficiency, allowing professionals to accomplish their tasks with precision and speed.In addition to their functional benefits, [Company Name]'s Diamond Grinding Tools place a strong emphasis on safety. The tools are designed with features that minimize operator fatigue and reduce the risk of accidents and injuries. Ergonomic handles provide a comfortable grip, preventing muscular strain during prolonged usage. Furthermore, the tools incorporate dust collection systems, effectively capturing and containing hazardous particles, promoting a safer working environment for professionals.To ensure customer satisfaction, [Company Name] maintains rigorous quality control measures throughout the manufacturing process. Each tool undergoes a comprehensive testing procedure to guarantee optimal performance and durability. In addition, the company provides comprehensive customer support, offering technical assistance and guidance to professionals seeking advice on tool selection and usage.The introduction of [Company Name]'s Diamond Grinding Tools marks another significant milestone in the company's commitment to excellence and technological advancement. By providing professionals with a powerful and versatile solution for surface preparation, [Company Name] strengthens its position as a trusted partner in the industry, offering tools that streamline operations, improve outcomes, and enhance overall efficiency.As industries continue to demand higher standards of surface preparation, [Company Name] remains at the forefront of innovation, constantly striving to exceed customer expectations. With its new line of Diamond Grinding Tools, the company affirms its ongoing dedication to developing cutting-edge solutions that elevate surface preparation technology to new heights.For more information about [Company Name]'s Diamond Grinding Tools and to explore their complete range of surface preparation solutions, please visit [Website] or contact [Phone number].About [Company Name]:[Company Name] is a renowned manufacturer and distributor of surface preparation tools and equipment, dedicated to providing innovative solutions that improve efficiency and productivity. With a commitment to quality and excellence, [Company Name] has firmly established itself as a leader in the industry, catering to the evolving needs of professionals across various sectors.

Secure Your Home with a Heavy-Duty Copper and Steel Safety Door

Metal Copper Bonds: The Strength of Steel and the Elegance of CopperWhen it comes to home security, one of the most important considerations is the entry door. A strong and durable door not only provides protection from intruders, but also adds to the aesthetic appeal of your home. If you are looking for a door that combines strength and elegance, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is the perfect choice for you. With its unique combination of steel and copper, this door offers both security and style.The door is made of heavy-duty steel which provides unparalleled strength and durability. The steel construction ensures that the door cannot be easily broken into, making it an ideal choice for those concerned about home security. The steel material also makes the door highly resistant to weather, ensuring that it will withstand harsh conditions for years to come.While steel offers superior strength, sometimes it lacks in aesthetic appeal. That is where the copper element comes in. Copper is one of the oldest building materials in the world, and has been used for thousands of years because of its beauty and durability. The copper gives the door a classic and elegant look, which can add to the overall aesthetic appeal of your home. The copper element also adds a layer of protection to the door. Copper has natural anti-bacterial and anti-microbial properties which help to prevent the growth of bacteria and other harmful microorganisms on the surface of the door.The Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is also equipped with a metal screen which further enhances the security features of the door. The screen is made of high-quality steel which is designed to prevent intruders from entering your home. The screen also provides an added layer of protection against insects and pests, without compromising the flow of fresh air into your home.Another important feature of the door is the stop mechanism. The door is designed with a built-in stop which prevents it from opening too far and causing damage to the hinges. This will help to keep the door in good condition for years to come, and prevent the need for costly repairs in the future.Overall, the Home Entry Heavy-Duty Steel Safety Metal Screen Stop Security Door is an excellent choice for those who want to increase the security of their home. The combination of steel and copper makes it a highly durable and attractive option, while the metal screen and stop mechanism provide additional layers of protection. Whether you are looking to enhance the aesthetic appeal of your home, or simply want to feel more secure, this door is an excellent investment. So why not add some metal copper bonds to your home today?

Ultimate Guide to Diamond Grinding Wheels: Everything You Need to Know

Title: Advanced Diamond Grinding Wheel Technology Revolutionizes Grinding ProcessesIntroductionLeading-edge technology is transforming industries worldwide, and the realm of grinding and material removal is no exception. One significant development in this field is the revolutionary diamond grinding wheel, designed to enhance grinding efficiencies and optimize output quality. In this article, we explore the exceptional features and benefits of this cutting-edge technology, sans any brand name, along with a brief introduction to the company behind this groundbreaking innovation.I. The Evolution of Grinding WheelsGrinding wheels have long been a crucial tool for numerous industries, enabling precision shaping, finishing, and removing material from a range of surfaces. Over time, advancements in manufacturing techniques and material science have led to the creation of various grinding wheel types. Among them, diamond grinding wheels have emerged as the pinnacle in terms of performance, durability, and versatility.II. Characteristics and Features of Diamond Grinding Wheels1. Exceptional Material Hardness:Diamond grinding wheels are renowned for their exceptional hardness, ensuring extended lifespan and enhanced longevity. Composed of industrial-grade diamond particles, these wheels effectively resist wear, maintaining their sharpness and consistency over prolonged periods.2. Superior Abrasion Resistance:High abrasion resistance is a defining attribute of diamond grinding wheels. This resistance enables them to endure the harsh conditions of various grinding operations, even when subjected to demanding applications that involve the removal of tough materials such as ceramics, composites, and hardened steel.3. Heat Dissipation Capability:One of the key challenges in grinding processes is effectively managing heat generation, as excessive heat can compromise material integrity. Diamond grinding wheels excel in dissipating heat effectively due to the material's exceptional thermal conductivity, minimizing the risk of material distortion or damage during grinding.4. Precision Profiling and Shaping:Diamond grinding wheels offer unparalleled precision for profiling and shaping tasks. The extreme hardness of the diamond abrasive particles allows for precise grinding, enabling exceptional control over the desired surface finish and intricate detailing.5. Minimal Wheel Dressing Requirement:Thanks to the durability and superior abrasive properties, diamond grinding wheels require less frequent dressing to maintain optimal performance. This reduction in downtime for wheel dressing translates into enhanced productivity and cost savings for businesses relying on grinding operations.III. The Company Behind the InnovationThe company leading the charge in revolutionizing grinding processes with diamond grinding wheels is a trailblazer in the field of abrasive tools. With decades of research and development, this company has established itself as a global leader in manufacturing high-quality, cutting-edge grinding wheel systems.Their commitment to innovation, combined with a strong focus on customer needs, has propelled them to the forefront of the industry. They invest substantial resources in continuous product improvement, ensuring their diamond grinding wheels meet and exceed the evolving demands of various industries, including automotive, aerospace, machinery, and more.Furthermore, this visionary company operates under a strict quality control framework, employing rigorous testing procedures to ensure that each grinding wheel leaving their facilities meets the highest standards of performance and reliability. Through collaborations with industry partners and a customer-centric approach, they continue to set new benchmarks for grinding wheel technologies.ConclusionThe advent of diamond grinding wheels has revolutionized grinding processes across industries. The extraordinary characteristics of these wheels, including their hardness, superior abrasion resistance, heat dissipation capabilities, precision profiling and shaping abilities, and reduced dressing requirements, have made them the tool of choice for the most challenging grinding applications.Thanks to the pioneering efforts of the company spearheading this innovation, they have paved the way for enhanced productivity, improved finished product quality, and cost savings for businesses across the globe. As grinding technology continues to evolve, diamond grinding wheels will undoubtedly remain at the forefront, offering efficient and reliable solutions for the material removal needs of countless industries.

Top Hardware Tools: Must-Have Equipment for All Your DIY Projects

[News]Title: Prominent Hardware Tools Company Announces Launch of Cutting-Edge Product LineIntroduction:[City, Date] - In a bid to revolutionize the hardware tools industry, renowned company [Brand Name] is proud to unveil its latest range of state-of-the-art tools, designed to simplify tasks, enhance productivity, and provide unbeatable performance to professionals and DIY enthusiasts alike. With their commitment to innovation and precision engineering, [Brand Name] has firmly established itself as a trusted provider of high-quality tools over the years. The introduction of this new product line is set to further solidify their position as an industry leader.Body:1. A Legacy of Excellence:For several decades, [Brand Name] has played an intrinsic role in providing reliable solutions to hardware-related challenges. The company's journey began with a visionary entrepreneur who recognized the need for durable and dependable tools that would withstand even the toughest conditions. Maintaining a relentless focus on innovation and customer satisfaction, [Brand Name] continues to deliver products that set new benchmarks in performance.2. Unveiling the cutting-edge product line:The new range of hardware tools from [Brand Name] features an array of groundbreaking advancements, combining the latest technology with precision engineering. This collection includes power tools, hand tools, measuring equipment, and accessories, catering to the diverse needs of professionals across various industries.a) Power Tools:[Brand Name]'s power tools feature enhanced motors, offering greater torque and increased RPMs for more efficient performance. With improved ergonomics, these tools ensure an optimum balance between power and user comfort, reducing fatigue during prolonged operations. From drills and saws to routers and impact drivers, the power tool range is designed to deliver exceptional results.b) Hand Tools:The hand tool selection boasts innovative designs and superior craftsmanship, making tasks easier and more precise. Built with durable materials, these versatile tools offer reliability and longevity. The ergonomic handles provide a comfortable grip, contributing to overall ease of use. From wrenches and pliers to screwdrivers and hammers, the hand tool range offers a comprehensive solution for every project.c) Measuring Equipment:Accuracy and precision form the foundation of [Brand Name]'s range of measuring equipment. With advanced sensors and cutting-edge technology, these tools provide accurate measurements for professionals in construction, woodworking, and electrical industries. The measuring equipment boasts user-friendly interfaces, allowing for quick and efficient readings, further increasing productivity on the job site.d) Accessories:[Brand Name] also provides an extensive selection of accessories that complement their hardware tools. These accessories include high-quality blades, bits, drill attachments, sanding discs, and more. Specially designed to match the performance and longevity of [Brand Name]'s tools, these accessories ensure an enhanced user experience and increased tool lifespan.3. Commitment to Innovation and Quality:Underpinning its success, [Brand Name] has established a culture of continuous innovation and quality control. Every tool goes through rigorous testing procedures to ensure durability, reliability, and compliance with the highest safety standards. By combining cutting-edge technology, meticulous engineering, and customer-centric design, [Brand Name] continually strives to surpass industry expectations.4. Future Endeavors:Looking ahead, [Brand Name] plans to expand its product line further, addressing emerging needs within the hardware tools market. The company aims to collaborate with industry experts and engage in comprehensive research and development to stay at the forefront of innovation. By consistently surpassing customer expectations, [Brand Name] remains committed to empowering professionals and DIY enthusiasts with reliable, efficient, and durable tools for years to come.Conclusion:With the launch of their revolutionary range of hardware tools, [Brand Name] reinforces its commitment to excellence and innovation. Through their unmatched craftsmanship, precision engineering, and customer-first approach, [Brand Name] continues to set new standards in the industry. This latest product line will undoubtedly empower professionals and hobbyists, making their work easier, more efficient, and more enjoyable. As [Brand Name] continues to evolve and expand its offerings, it remains positioned as a leading provider of high-quality tools for both current and future generations.

Discover the Versatile Benefits of Lock Polishing Pads

article:Snail Lock Polishing Pad Revolutionizes Grinding and PolishingIn the world of grinding and polishing, efficiency and quality are two factors that cannot be compromised. Both are critical when it comes to achieving a perfect finish. One product that is quickly gaining traction in the industry is the Snail Lock Polishing Pad.Produced by a leading manufacturer of abrasives, the product is a game-changer in the world of grinding and polishing. It has been developed using the latest technology to ensure efficient and consistent grinding and polishing.The snail lock polishing pad is designed to work specifically with automatic edge polishing machines and bridge polishing machines equipped with the snail lock adapter. The pads are made from high-quality resin and diamond particles that make them durable and long-lasting. They are also easy to install and remove, making the grinding and polishing process quicker and more efficient.The unique design of the snail lock polishing pad consists of a double-layered resin and diamond grain structure that provides superior quality and consistent results. The single locking system ensures that the pad remains securely in place while in operation, reducing the risk of accidents and ensuring maximum safety for operators.According to the manufacturer, the snail lock polishing pad is suitable for use on a wide range of materials. These include natural stone, engineered stone, ceramics, and porcelain. This versatility makes it an indispensable tool for fabricators, contractors, and DIY enthusiasts.The snail lock polishing pad is also designed to reduce the need for multiple stages of grinding and polishing. Its superior quality means that it can deliver excellent results with minimal effort, time, and energy. This factor makes it a cost-effective solution for grinding and polishing professionals.The company behind the snail lock polishing pad has been in the business for over a decade and has built a strong reputation for producing high-quality abrasive products that meet the demands of the industry. Their team of experts includes experienced engineers, technicians, and customer service representatives who work tirelessly to ensure that their products are of superior quality and that they offer the best service to their clients.In addition to the snail lock polishing pad, the company produces a wide range of other abrasive products that cater to the needs of various industries. These products include diamond saw blades, diamond core bits, profiling wheels, and cup wheels, among others.The company believes that its success is driven by its commitment to quality and its willingness to go the extra mile to ensure customer satisfaction. This includes investing in research and development to improve its products' performance and quality continually.In conclusion, the snail lock polishing pad is a revolutionary product that is quickly gaining traction in the industry. Its unique design, efficiency, and durability make it a game-changer in the world of grinding and polishing. It is an indispensable tool for fabricators, contractors, and DIY enthusiasts looking for superior quality and consistent results. The manufacturer's commitment to quality and customer satisfaction make it a brand that customers can trust. With its continued investment in research and development, the company is poised to remain a leader in the abrasive products industry for years to come.